Automatic battery quick replacement system and method for electric vehicles

A technology of electric vehicles and batteries, applied in the direction of electric power devices, power devices, vehicle components, etc., can solve problems such as unrealistic, unsafe, and complex systems, and achieve the effects of weight reduction, simple structure, and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be further described in detail below in combination with specific embodiments.

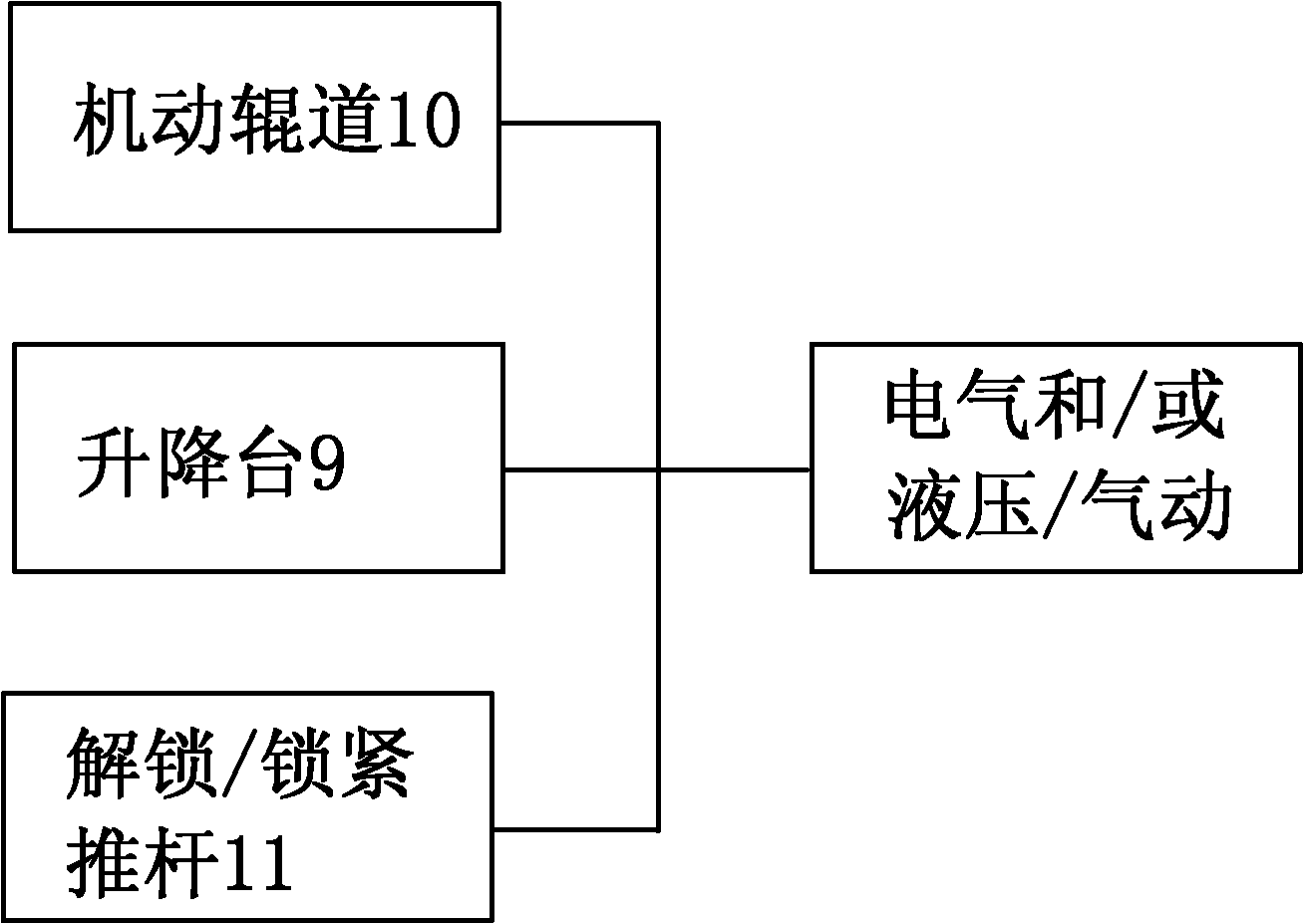

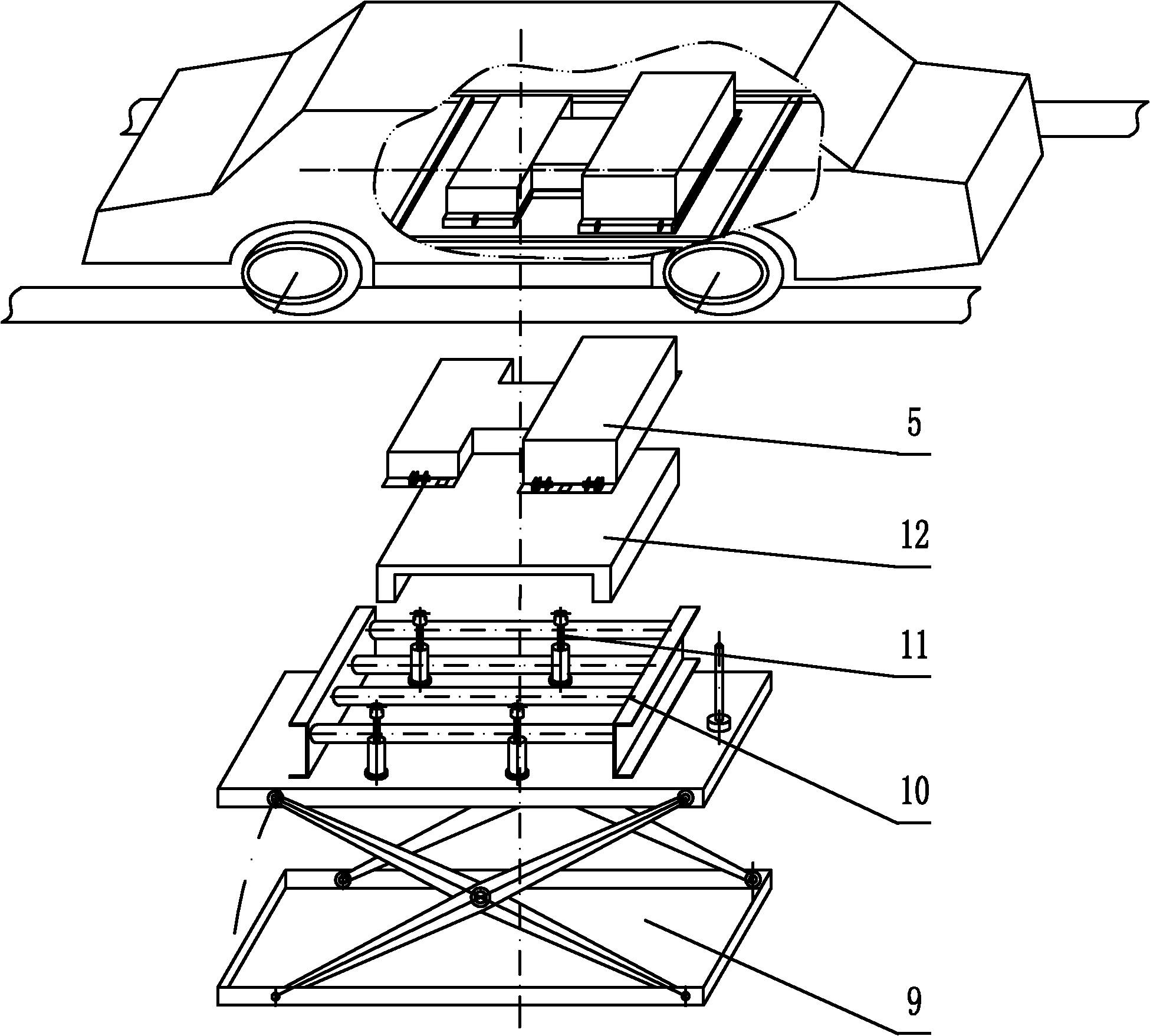

[0043] Such as image 3 As shown, the present invention is an automatic quick-change system for an electric vehicle battery. The system includes a battery compartment 2, a battery box 5 and a bracket 12 arranged at the lower part of the vehicle body of the electric vehicle, and an elevating platform 9 positioned below a workbench.

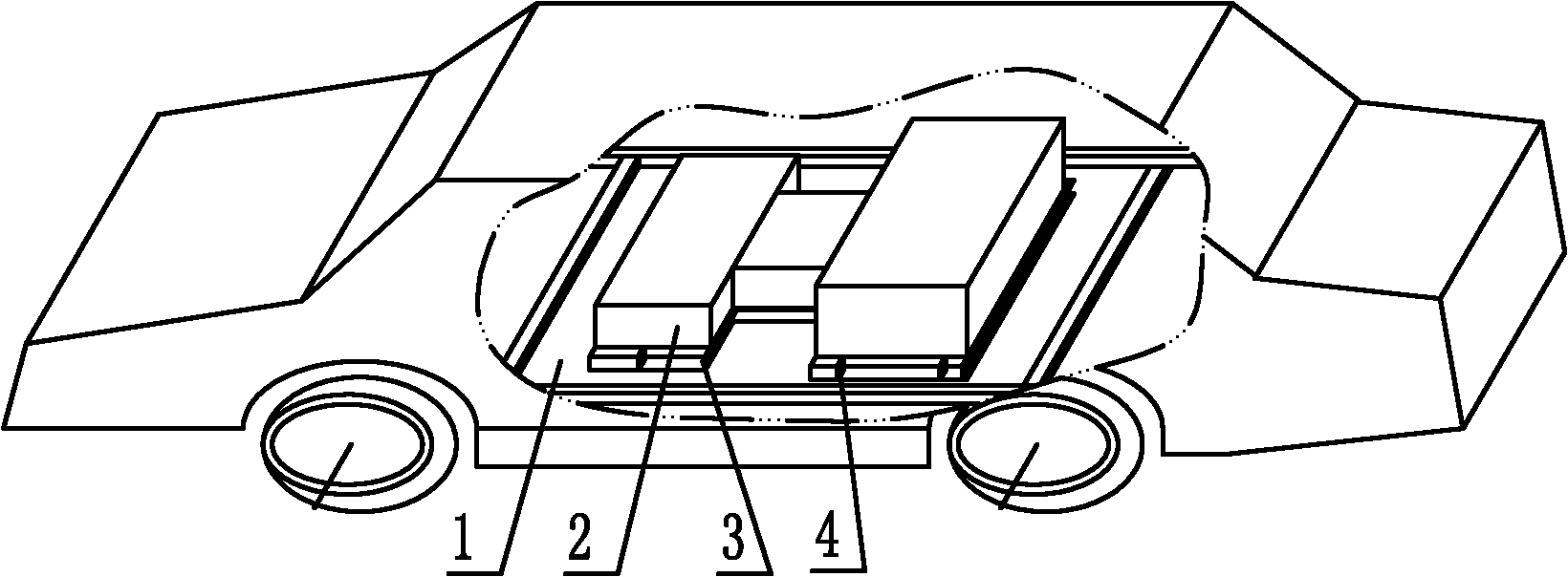

[0044] Such as figure 1As shown, the battery compartment 2 is set in the shape of "I" or "T", fully utilizes the space of the front row, the lower part of the rear seat and the middle channel of the car, meets the requirements of the battery capacity of the electric car, and increases the driving range. ; The left and right sides of the battery compartment 2 are provided with a plurality of lifting lugs 4 for connection with the battery box 5; the battery compartment 2 is provided with an electrical plug; the battery compartment 2 can...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com