Adjustable sealing rotary valve

A sealed rotary valve and adjustable technology, applied in the field of rotary valves, can solve the problems of heavy maintenance and management workload, short service life, poor air tightness, etc., and achieve the effect of reducing product cost, reducing processing technology, and ensuring reasonable clearance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Below in conjunction with embodiment the present invention is further described as follows:

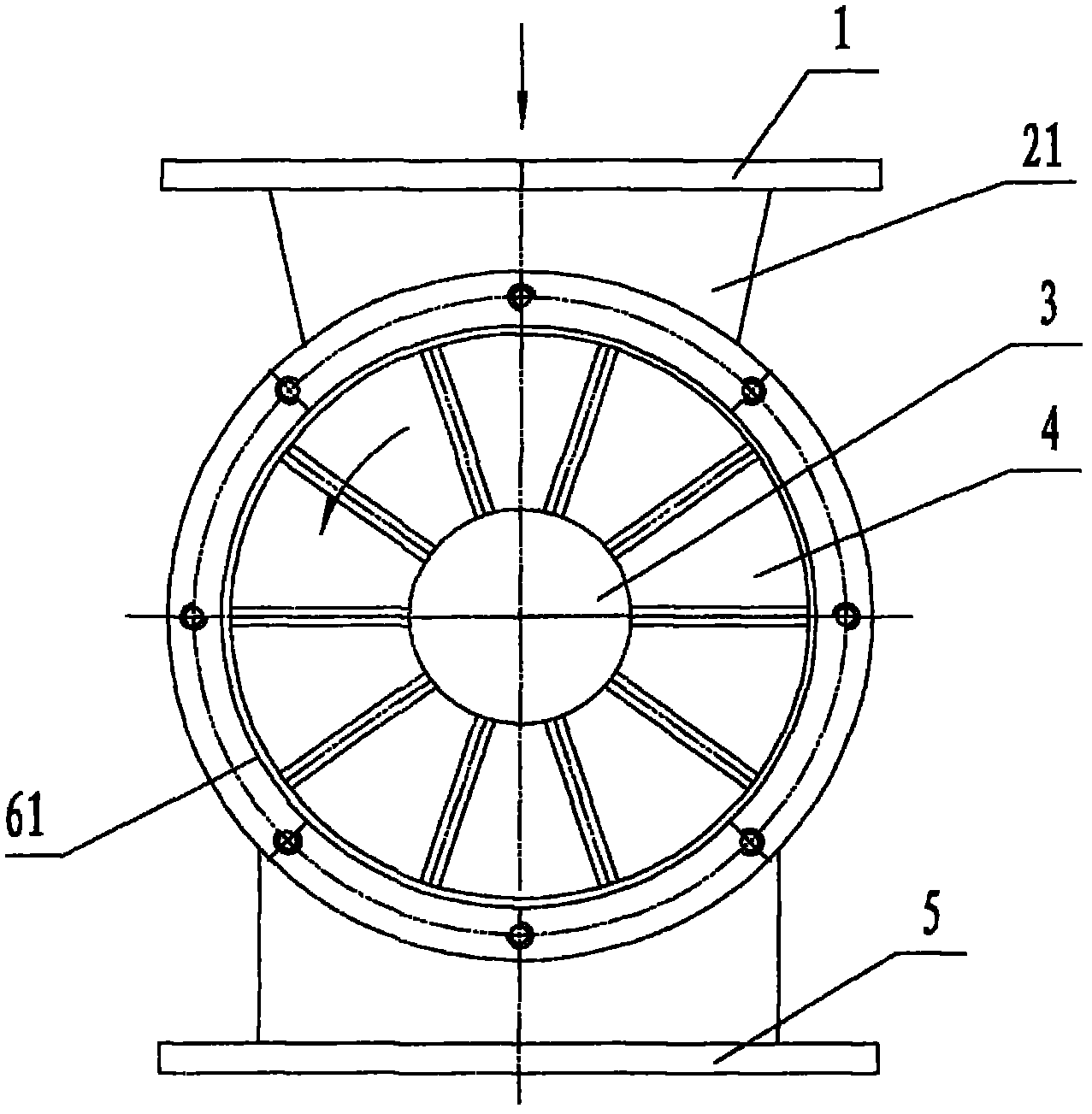

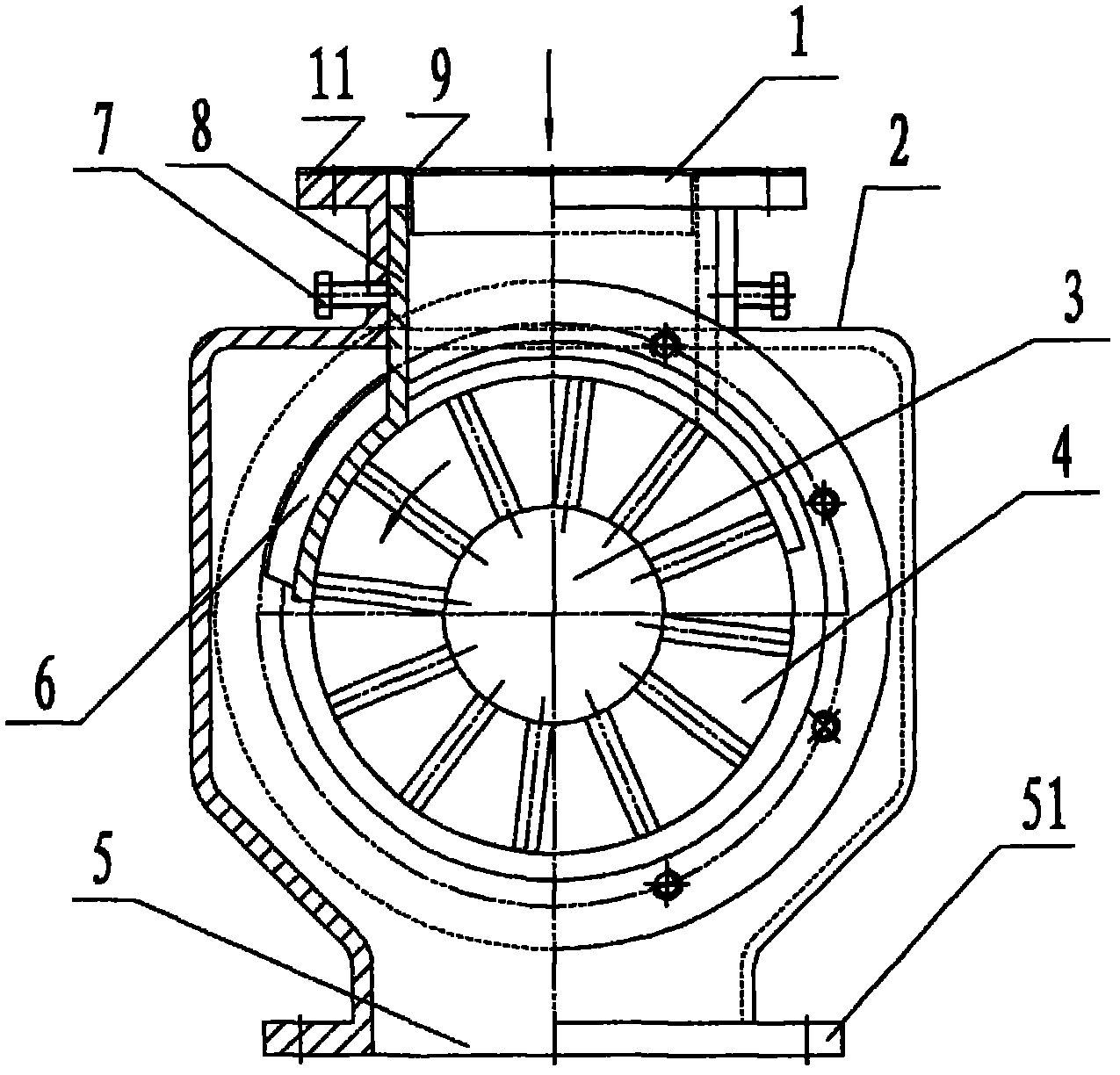

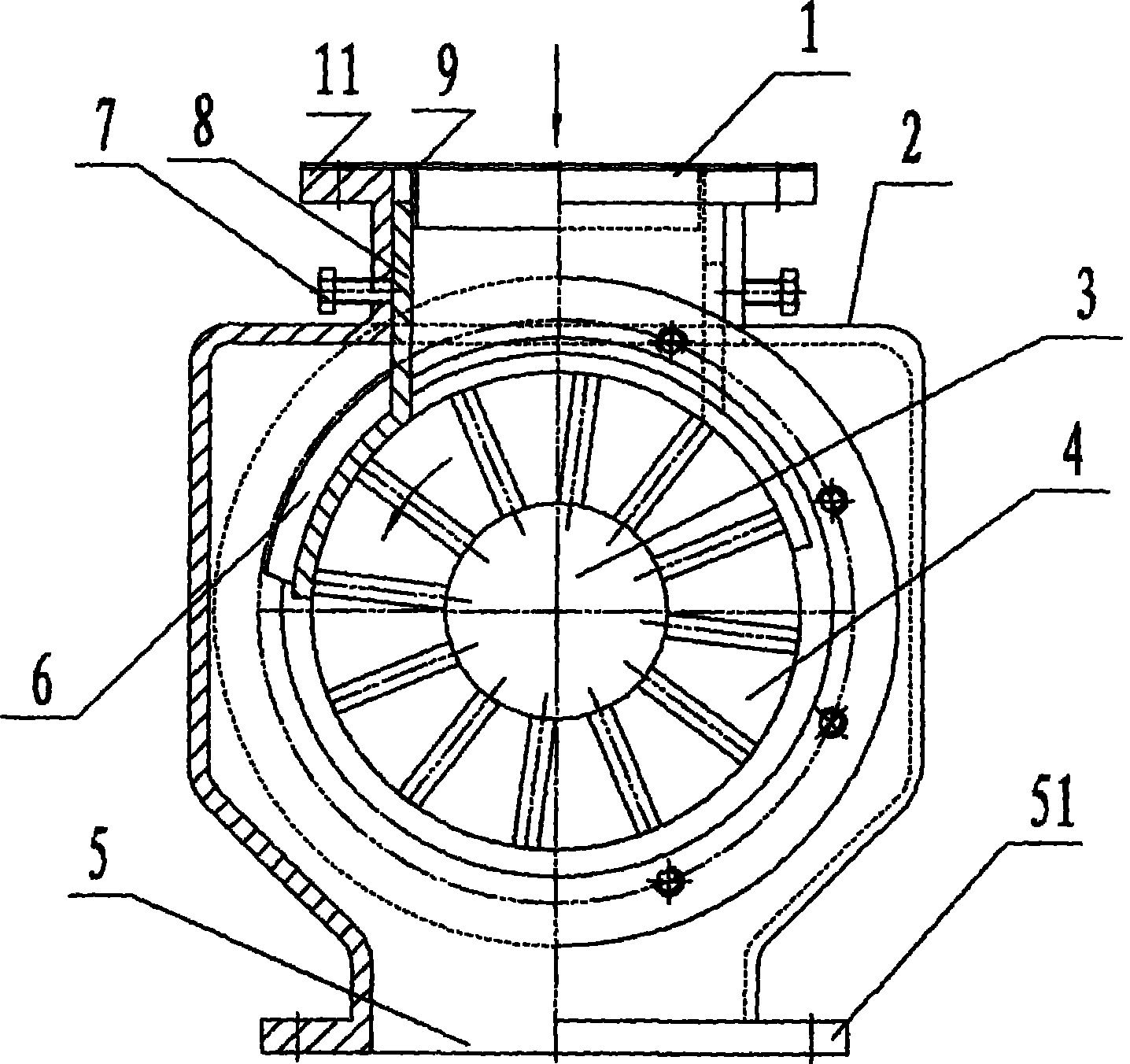

[0017] As shown in the structure of the present invention figure 2 As shown, it is composed of a rotary valve housing 2, a sealing sleeve 6 and a rotor 3, and a rotor groove 4 is provided on the rotor 3, and a feed port 1 and a discharge port are provided on the valve rotary valve housing. 5. The feed port connector 11 and the discharge port connector 51 are provided on the feed port 1 and the discharge port 5, and the sealing sleeve 6 is set in the rotary valve housing 2, and the sealing sleeve 6 is in the shape of a circle Structure, in the feed port 1 on the top of the rotary valve housing 2, there is a sliding sleeve 8 that is movably matched, and the lower part of the sliding sleeve 8 is arc-shaped and fitted between the sealing sleeve 6 and the rotor 3. An adjusting bolt 7 matched with the sliding sleeve 8 may also be provided on the wall of the rotary valve housing 2 o...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap