Horizontal lifting transfer truck

A technology of horizontal lifting and transfer vehicles, applied in the direction of lifting devices, etc., can solve the problems of inconvenient use and high cost, and achieve the effect of overcoming high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

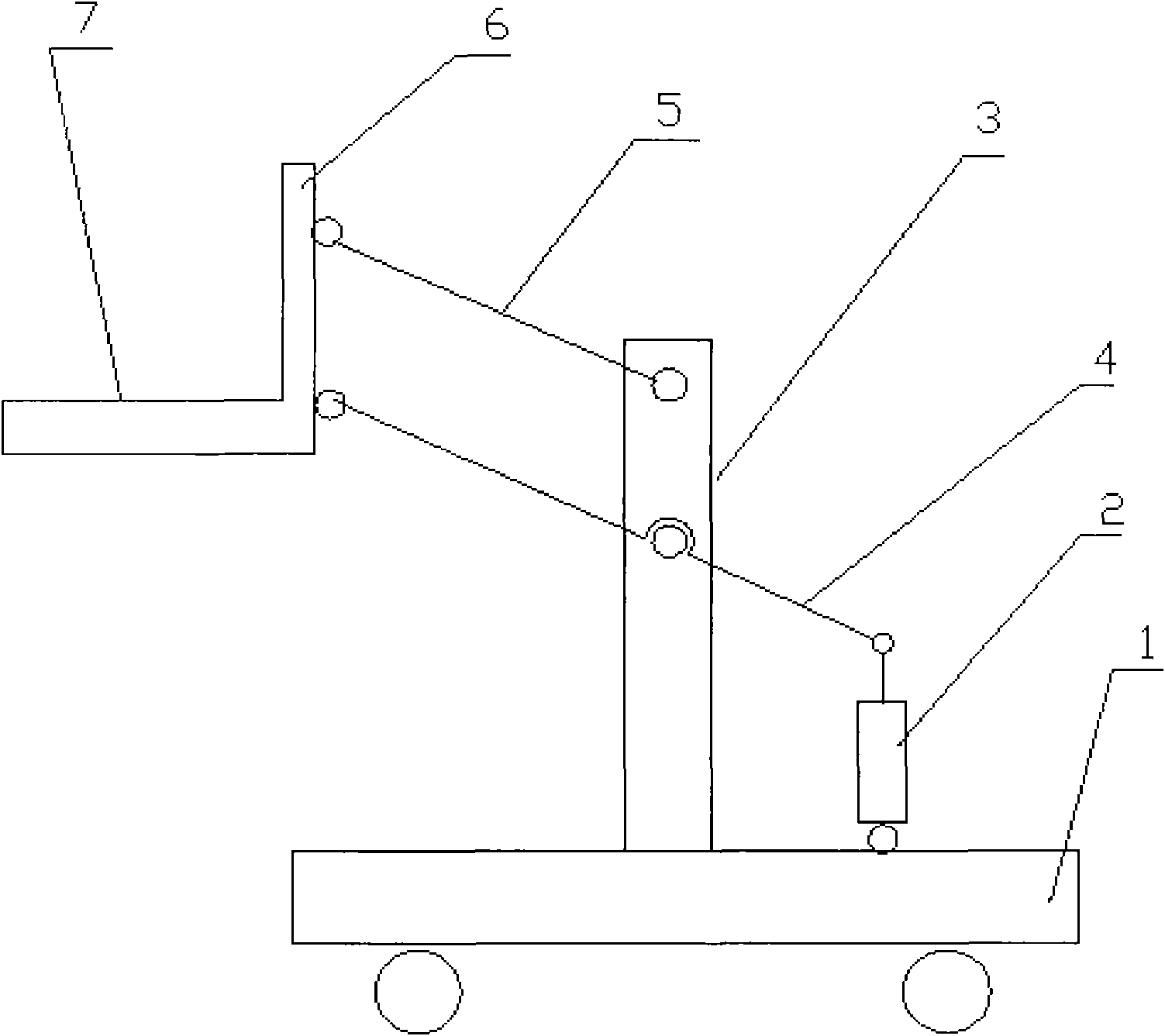

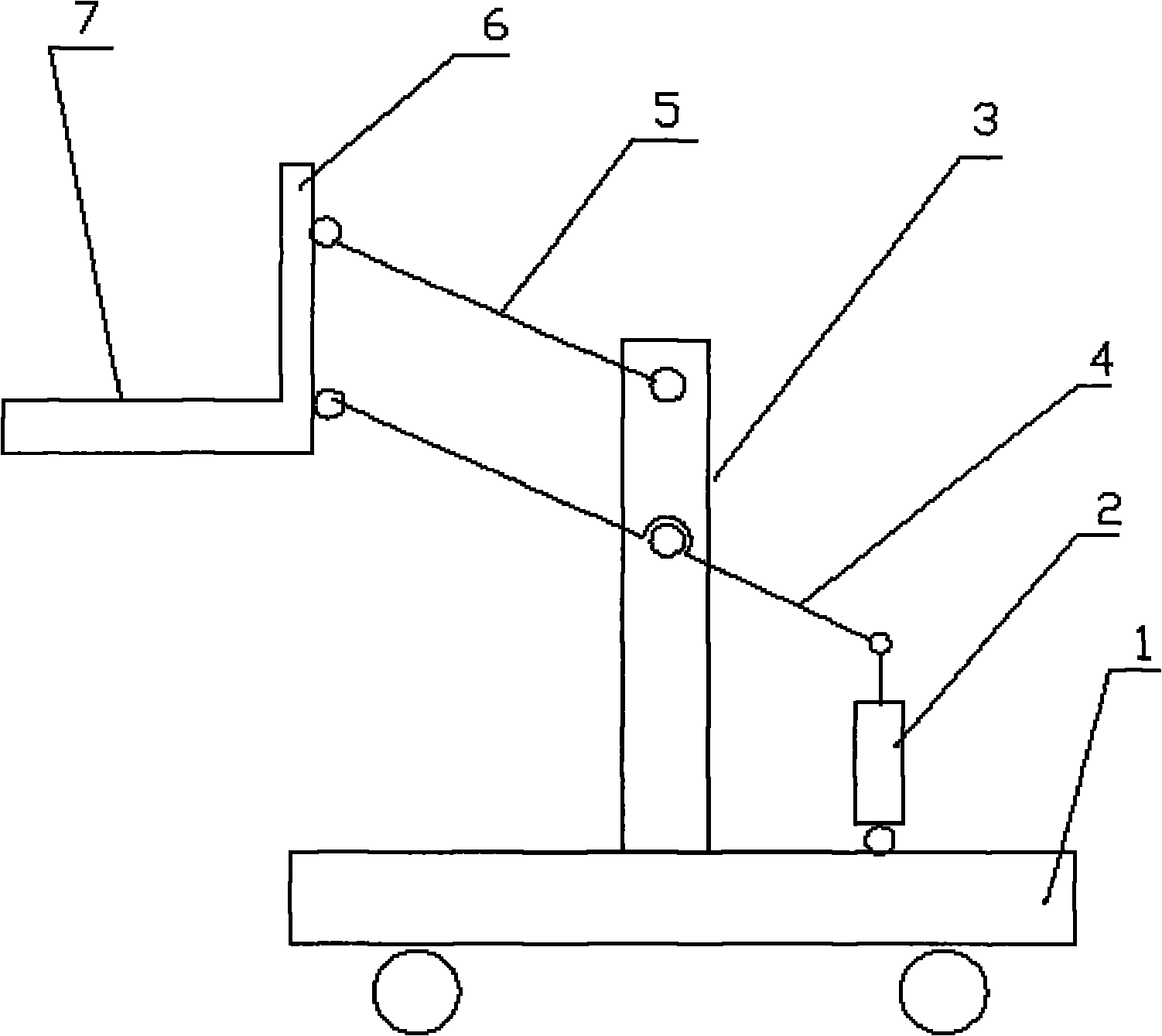

[0009] The upright (3) is vertically installed on the walking trolley (1), and the upright (3), the long lever (4), the short lever (5), and the vertical plane (6) plates are hinged together in an appropriate manner, That is, one end of the short lever (5) is hinged on the top position of the column (3), and the long lever (4) is hinged on the column (3) at the bottom of the short lever (5) at an appropriate position in the middle, which is on the left side of the column (3) The length of the part long lever (4) and the short connecting rod (5) is equal, and the vertical panel (6) is respectively hinged with the left end of the short connecting rod (5) and the left end of the long connecting rod (4) in the up-down direction, Wherein, the linear distance between the two hinge points on the vertical panel (6) is equal to the distance between the two hinge points on the column (3), and the cylinder part and the piston rod of the hydraulic cylinder (2) are respectively hinged on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com