Comb tooth capacitor of micromachine

A capacitor and micro-mechanical technology, applied in the field of micro-mechanical comb capacitors, achieves the effects of simple structure, elimination of mechanical coupling and low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] In order to make the above objects, features and advantages of the present invention more comprehensible, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

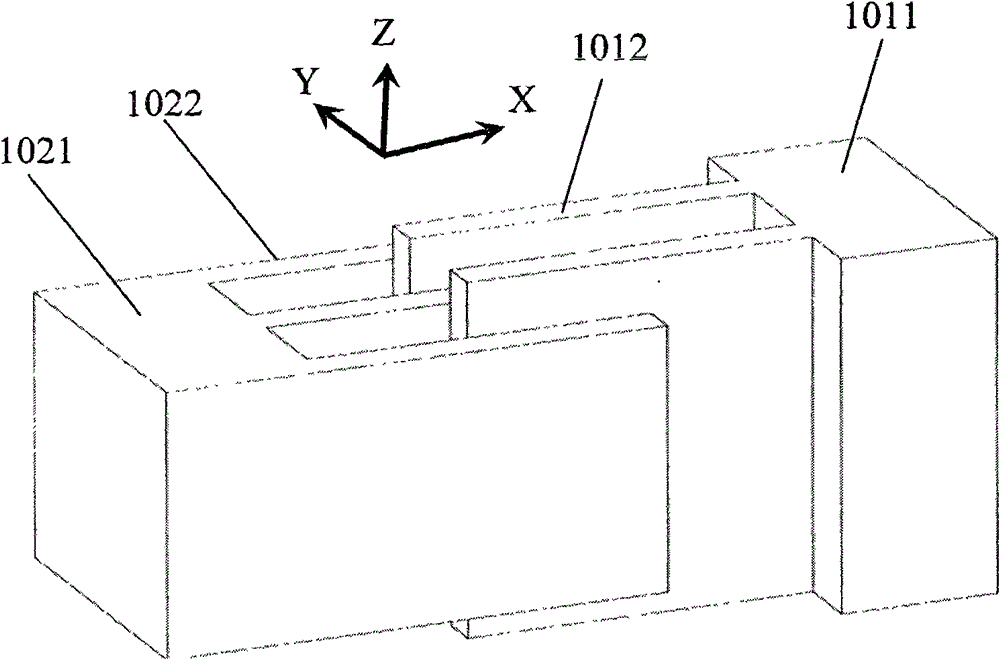

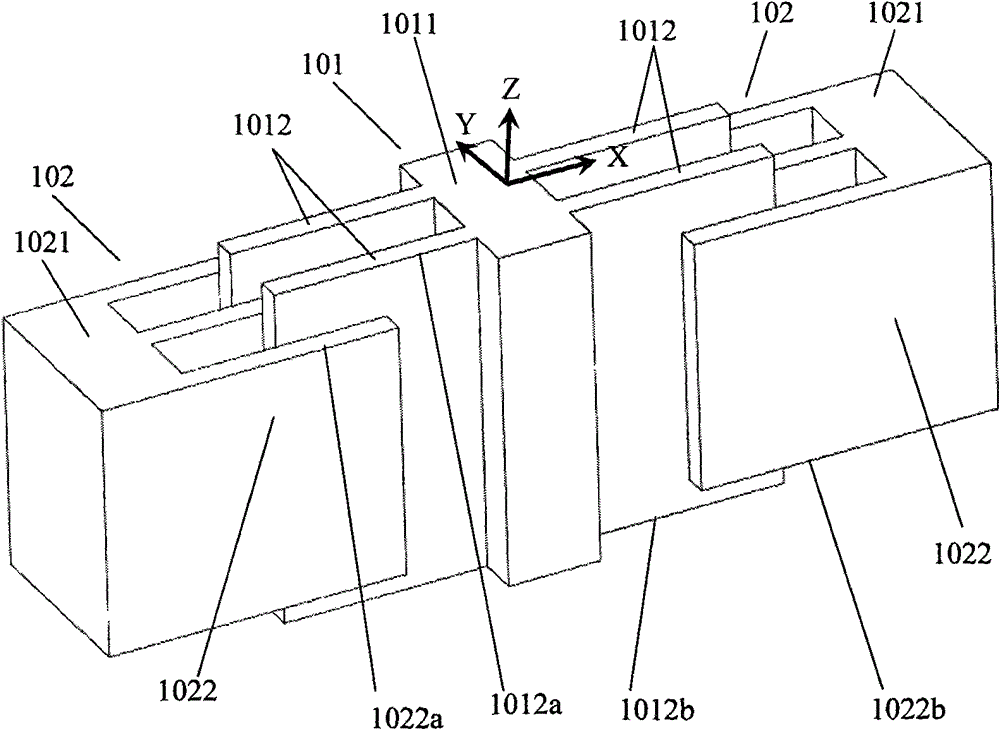

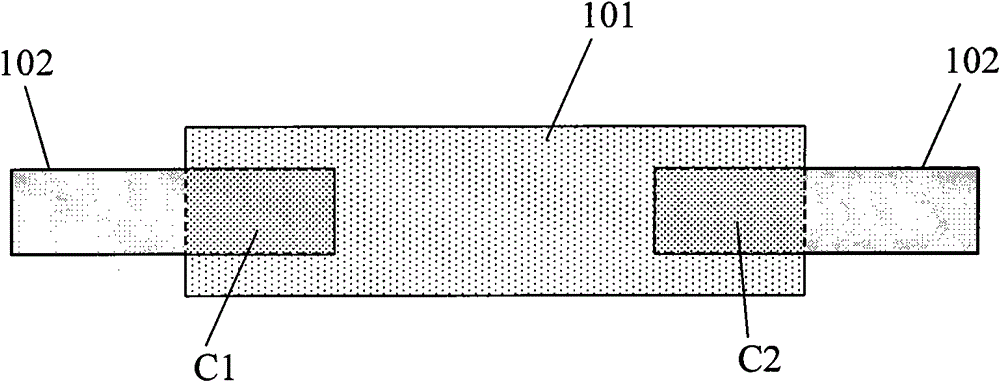

[0037] The micromechanical comb tooth capacitor of the present invention is mainly used for the comb tooth driver of the micromechanical gyroscope measuring the X-axis and Y-axis angular velocity in the horizontal plane direction, or the detection capacitor of the Z-axis gyroscope and the horizontal axis accelerometer, and can also be used for other similar Capacitive sensor or driver for functional requirements. refer to figure 1 , shows a schematic perspective view of the three-dimensional structure of Embodiment 1 of a micromechanical comb-teeth capacitor of the present invention, including: a movable comb-teeth electrode 101 and a fixed comb-teeth electrode 102 . Wherein, the movable comb electrode 101 includes a movable com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com