Patents

Literature

137results about "Variable capacitor structural combinations" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

System and method of fabricating micro cavities

InactiveUS20080308920A1Decorative surface effectsSemiconductor/solid-state device detailsEpoxyMicroelectromechanical systems

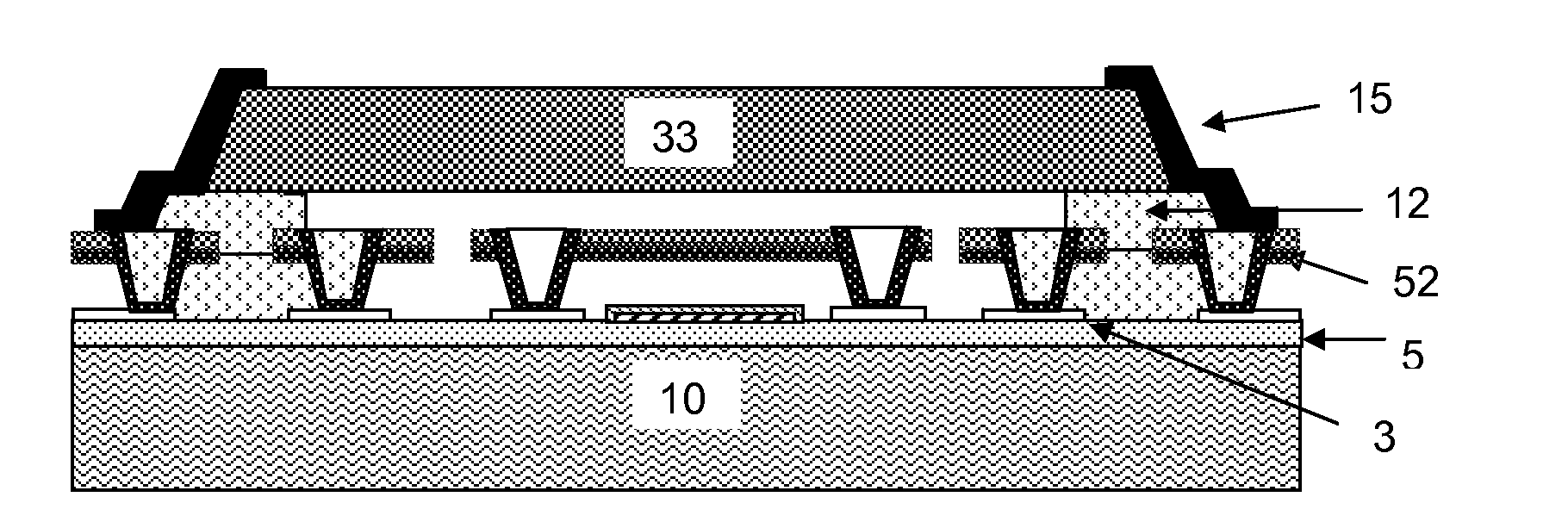

A system and method for manufacturing micro cavity packaging enclosure at the wafer level using MEMS (MicroElectroMechanical Systems) process, wherein micro cavities are formed from epoxy-bonded single-crystalline silicon wafer as its cap, epoxy and deposited metal or insulator as at least part of its sidewall, on substrate wafers.

Owner:WAN CHANG FENG

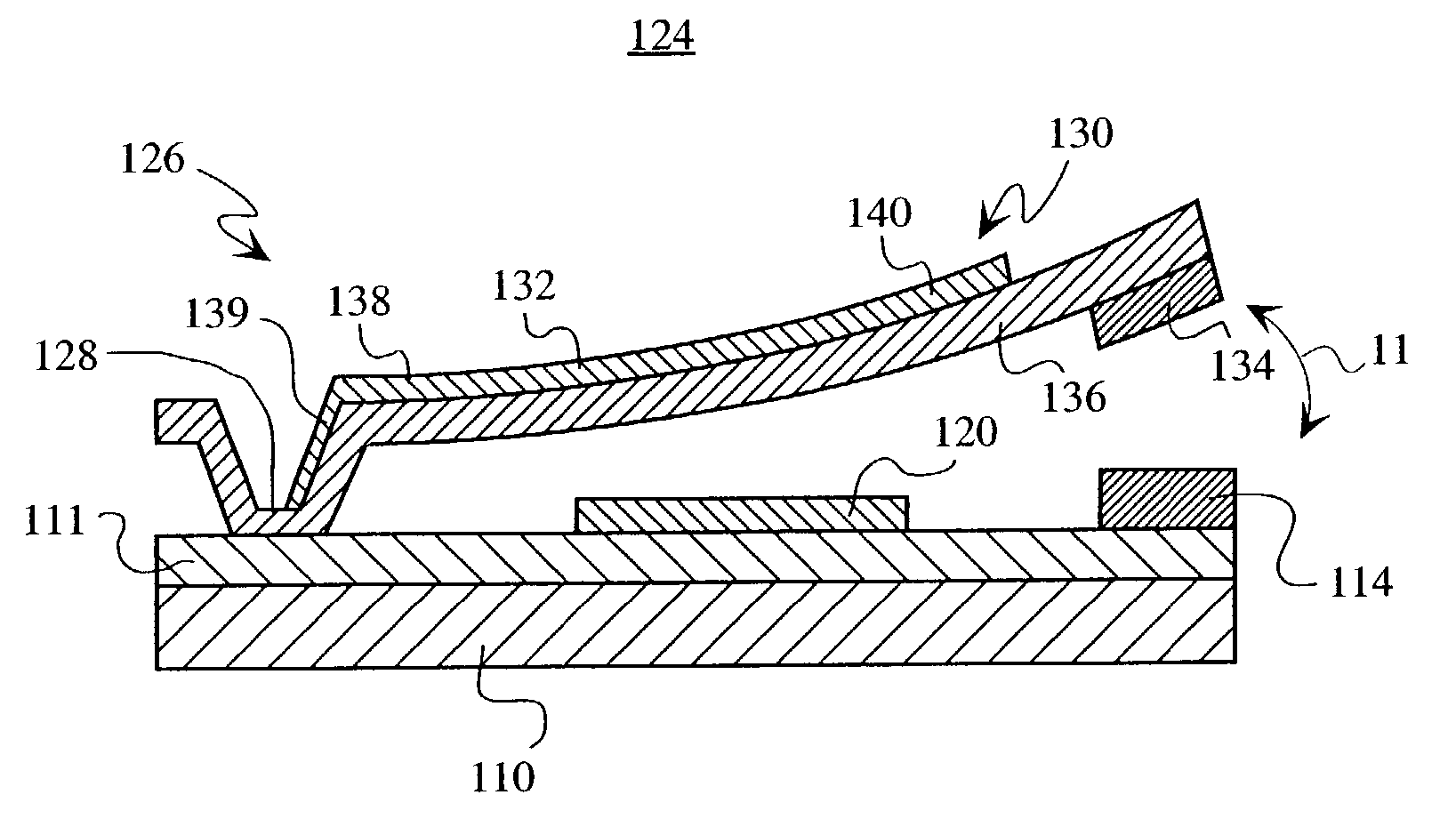

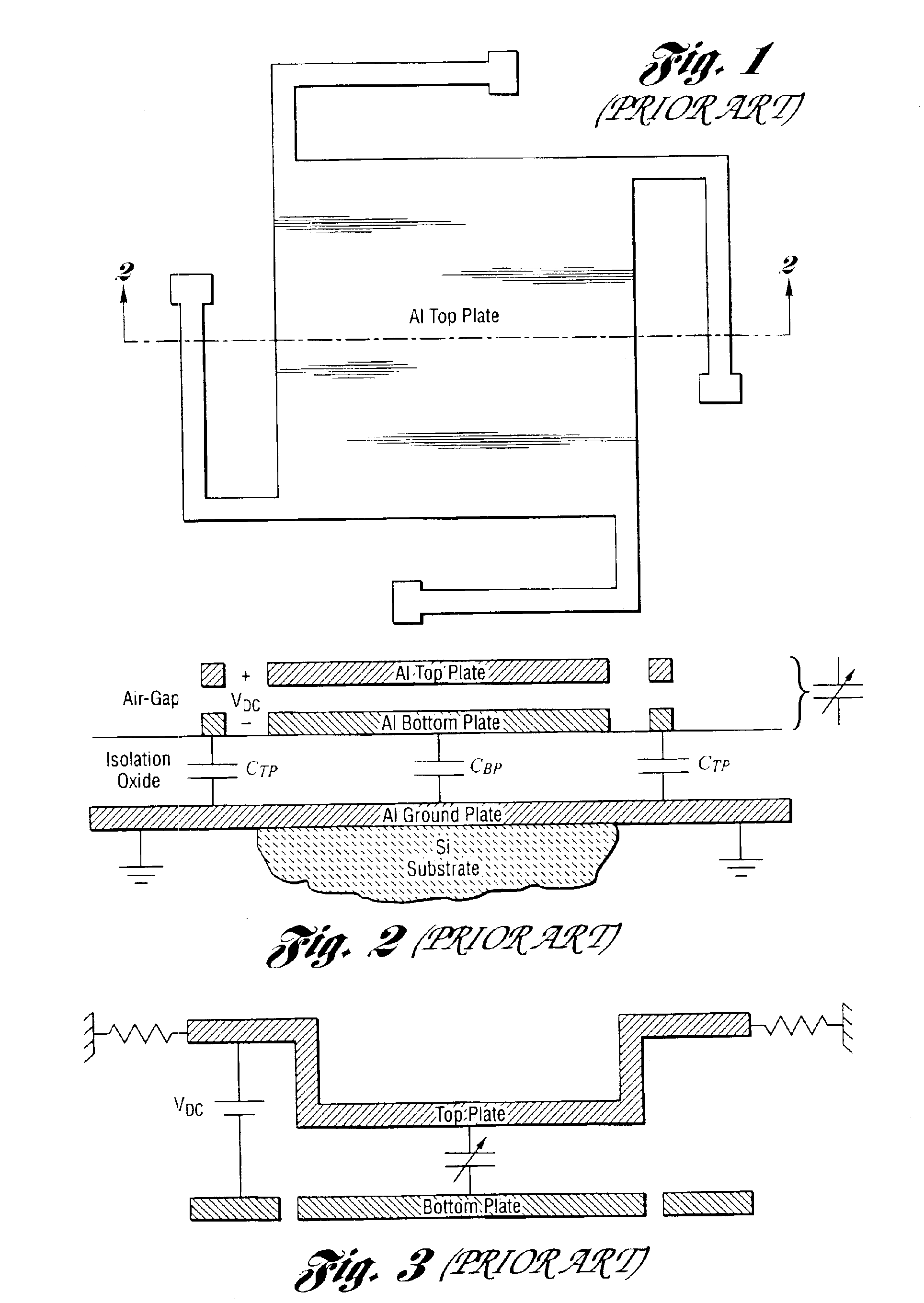

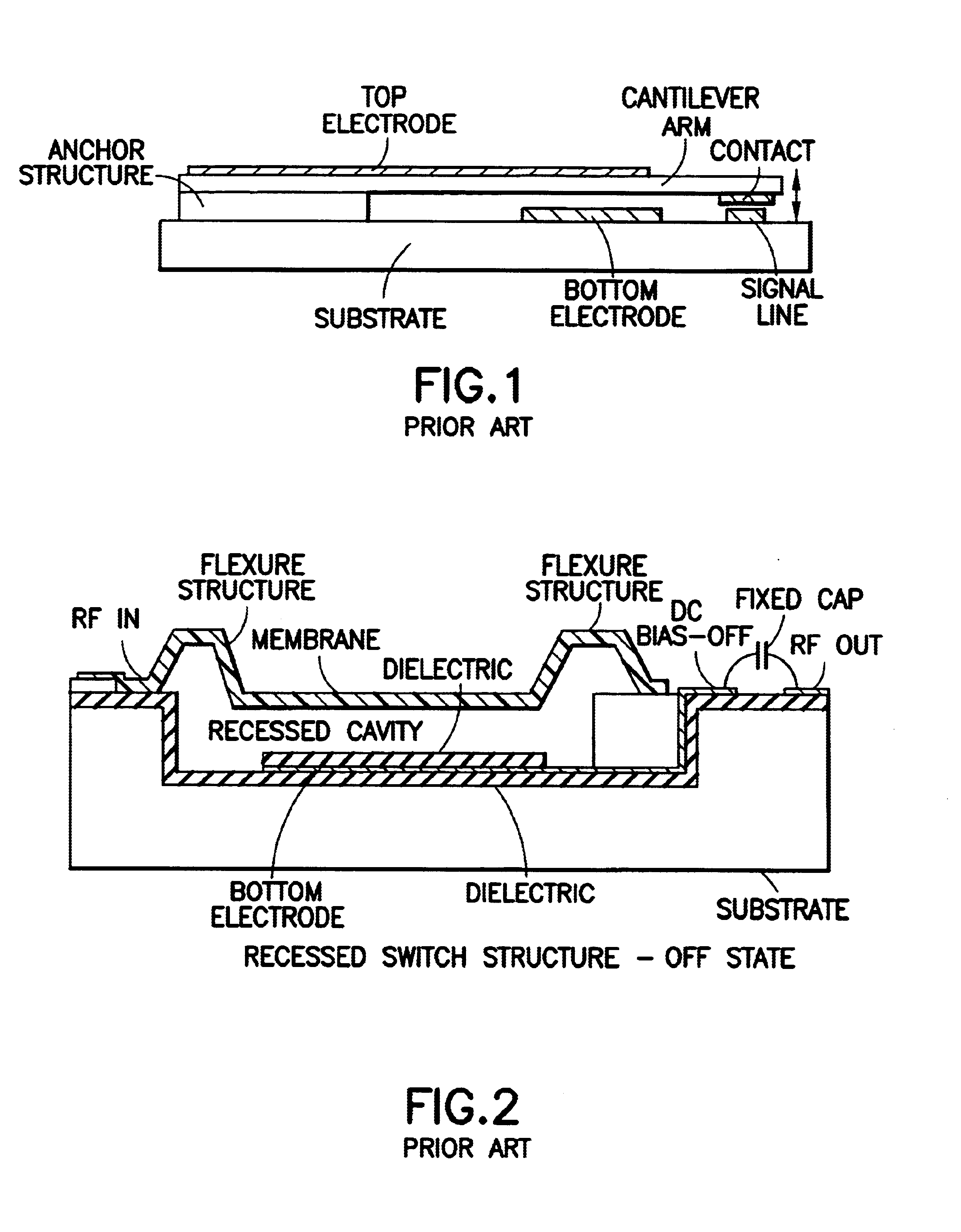

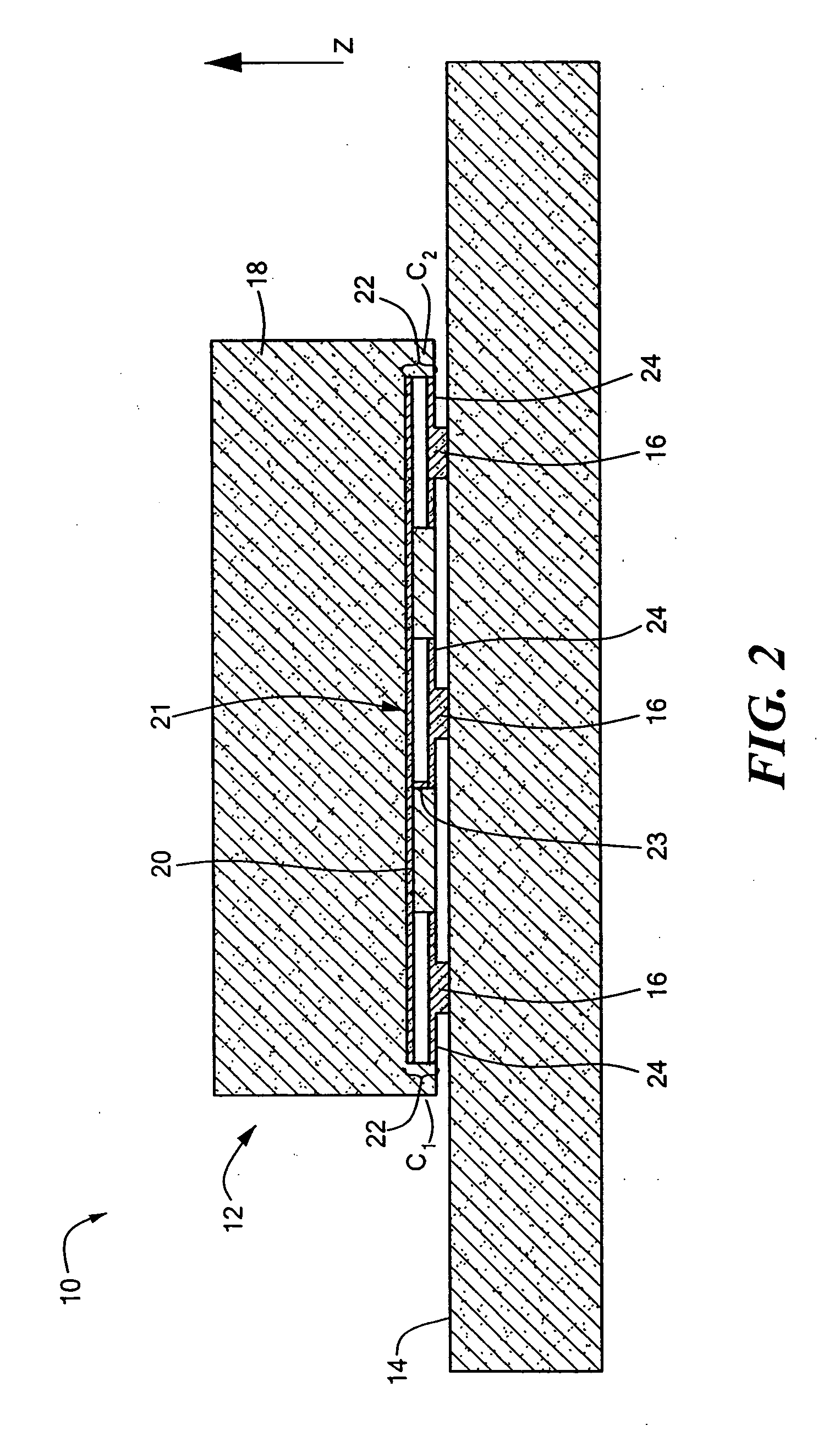

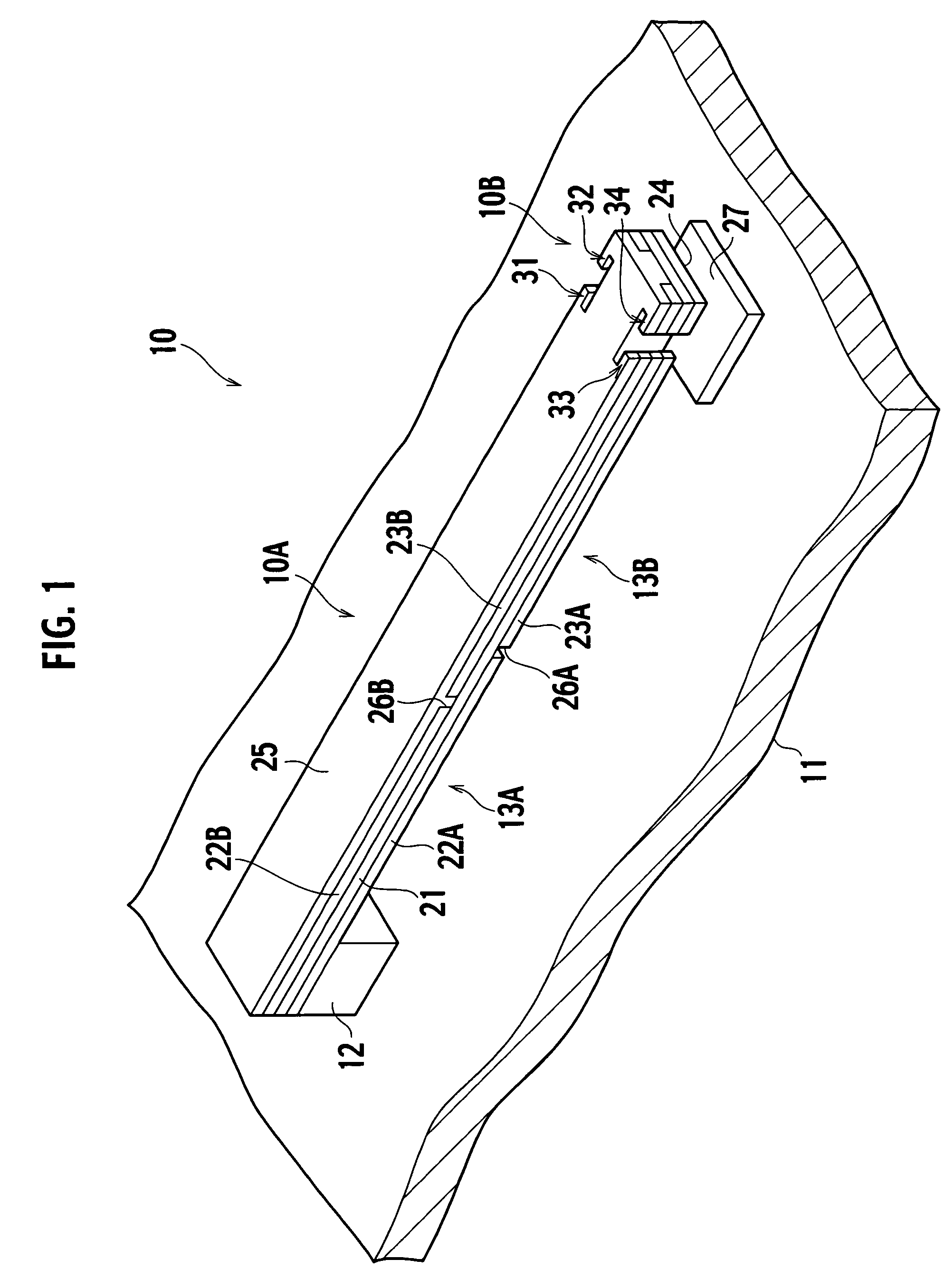

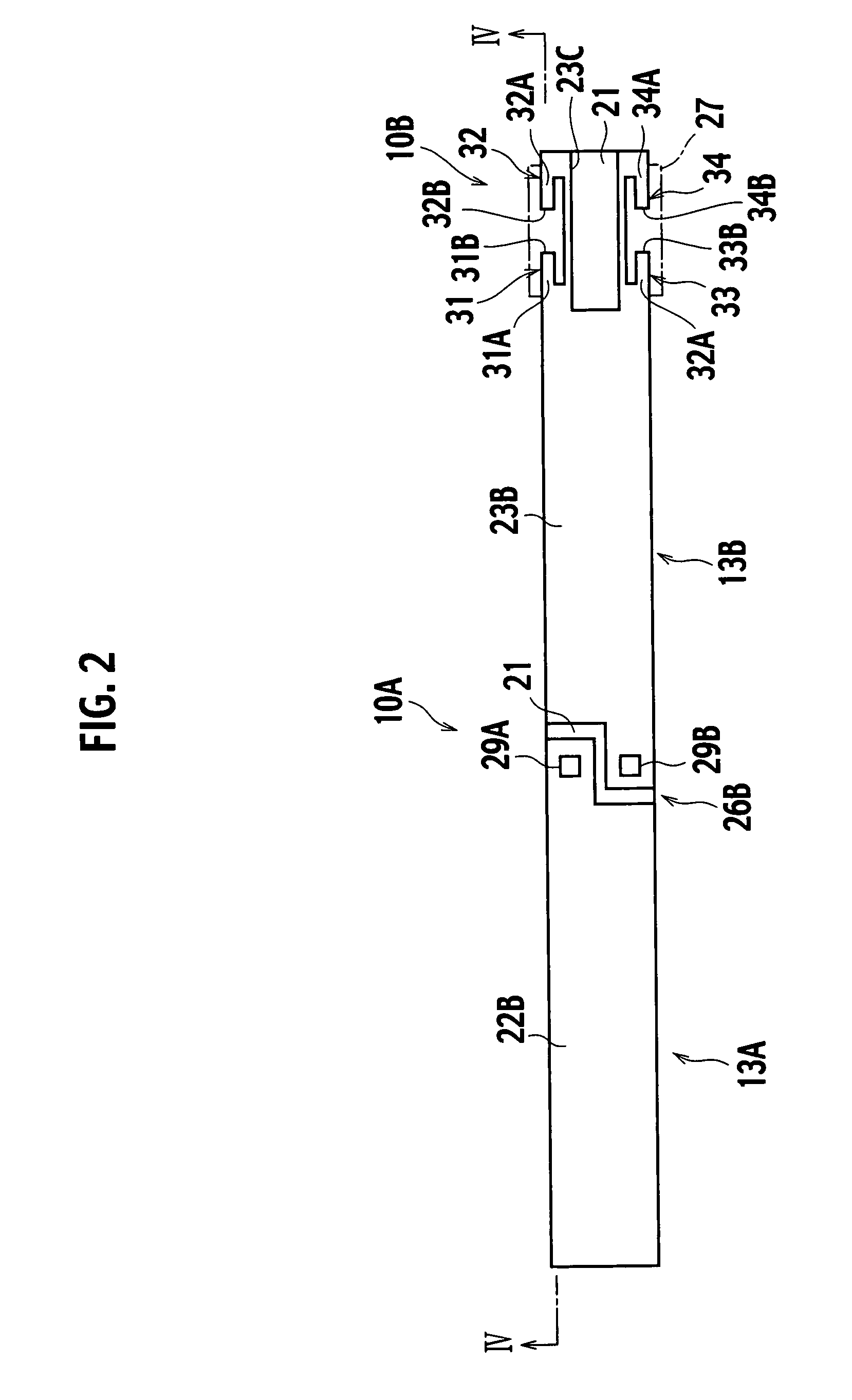

Stress bimorph MEMS switches and methods of making same

InactiveUS7053737B2Reduce capacitanceMinimize OFF-state capacitanceElectrostatic/electro-adhesion relaysCapacitor with electrode distance variationEngineeringCantilever

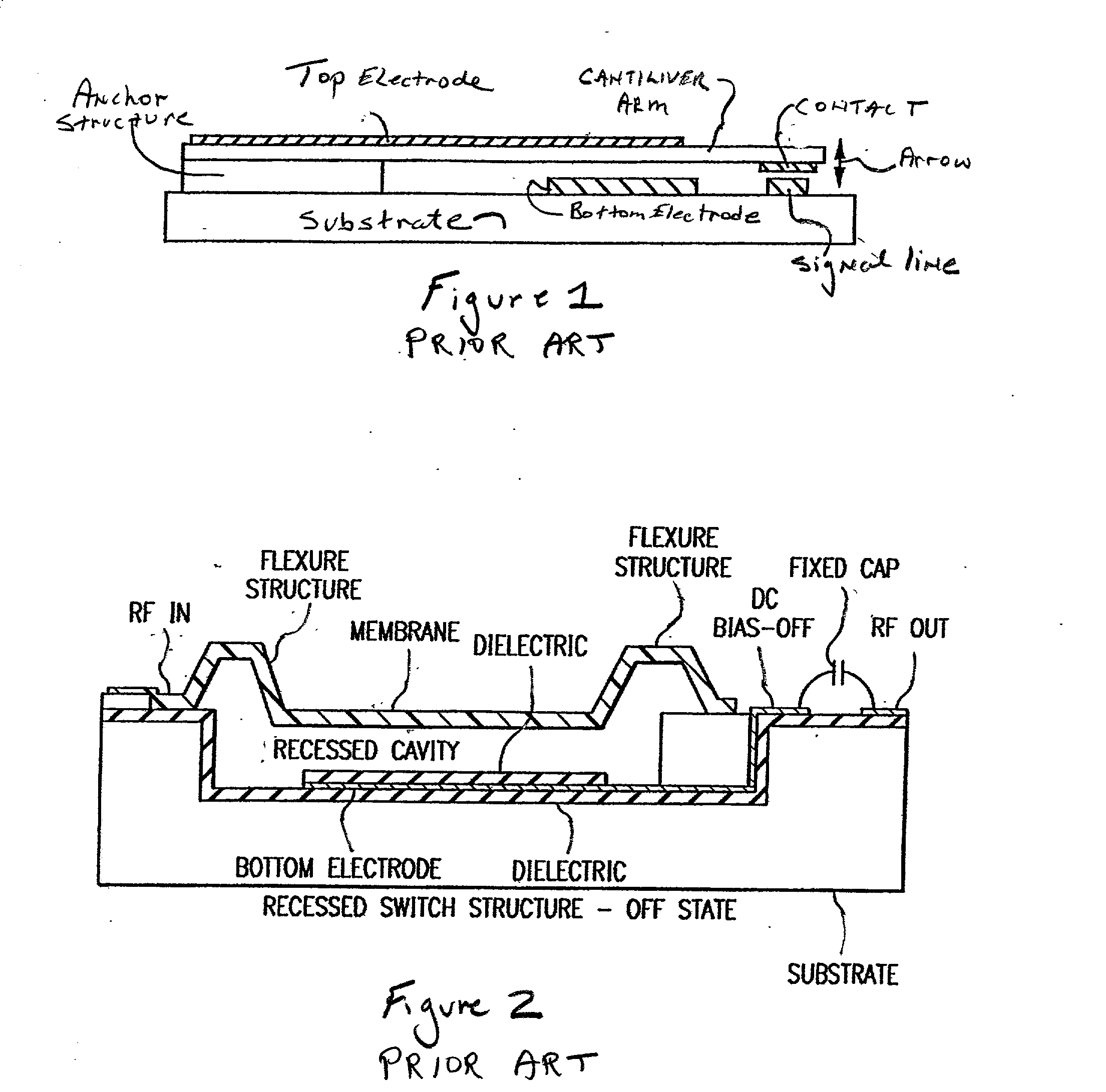

A micro-electromechanical system (MEMS) switch formed on a substrate, the switch comprising a transmission line formed on the substrate, a substrate electrostatic plate formed on the substrate, and an actuating portion. The actuating portion comprises a cantilever anchor formed on the substrate and a cantilevered actuator arm extending from the cantilever anchor. Attraction of the actuator arm toward the substrate brings an electrical contact into engagement with the portions of the transmission line separated by a gap, thus bridging the transmission line gap and closing the circuit. In order to maximize electrical isolation between the transmission line and the electrical contact in an OFF-state while maintaining a low actuation voltage, the actuator arm is bent such that the minimum separation distance between the transmission line and the electrical contact is equal to or greater than the maximum separation distance between the substrate electrostatic plate and arm electrostatic plate.

Owner:HRL LAB +1

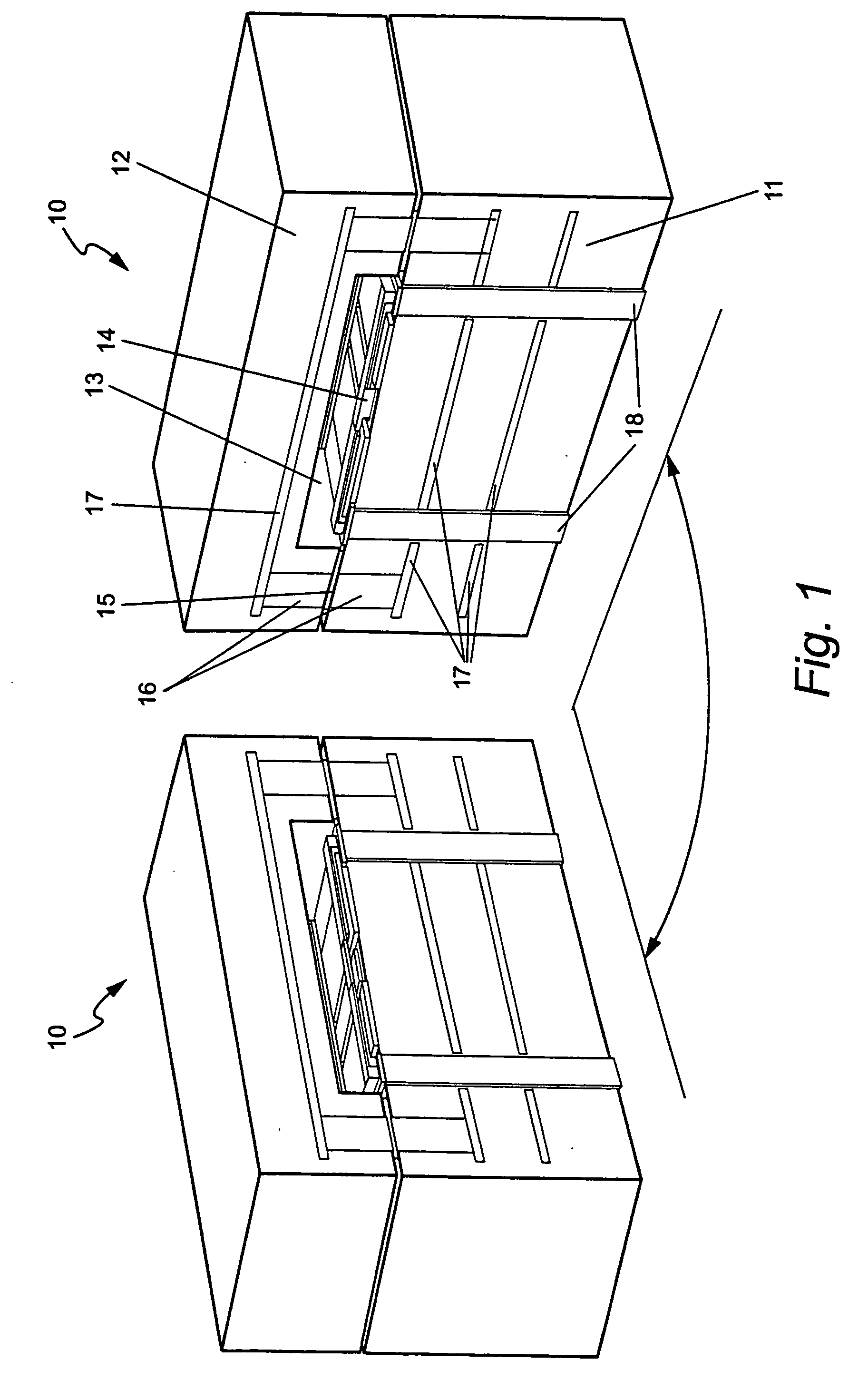

Method and apparatus for an improved micro-electrical mechanical switch

InactiveUS6127744ABatteries circuit arrangementsBoards/switchyards circuit arrangementsElectricityFriction effect

A method, device and circuit which applies an electrostatic repulsion pushing force to a MEM switch armature during an opening process. The repulsive force adds to the spring restoration force on the armature, increasing the opening speed of the switch and aids in overcoming stiction effects. The inventive switch includes a contact electrically connected to a first terminal of the switch. A throw is electrically connected to a second terminal of the switch. Finally, a mechanism is provided for opening the switch by electrostatically causing the throw to disengage the contact. In the illustrative implementation, the mechanism for opening the switch includes a first charge storage structure mounted on the throw and a second charge storage structure mounted in proximity to the first charge storage structure. When charges are applied between the first and the second charge storage structures, a force of repulsion is created or a force of attraction is created depending on the polarity of the potential.

Owner:RAYTHEON CO

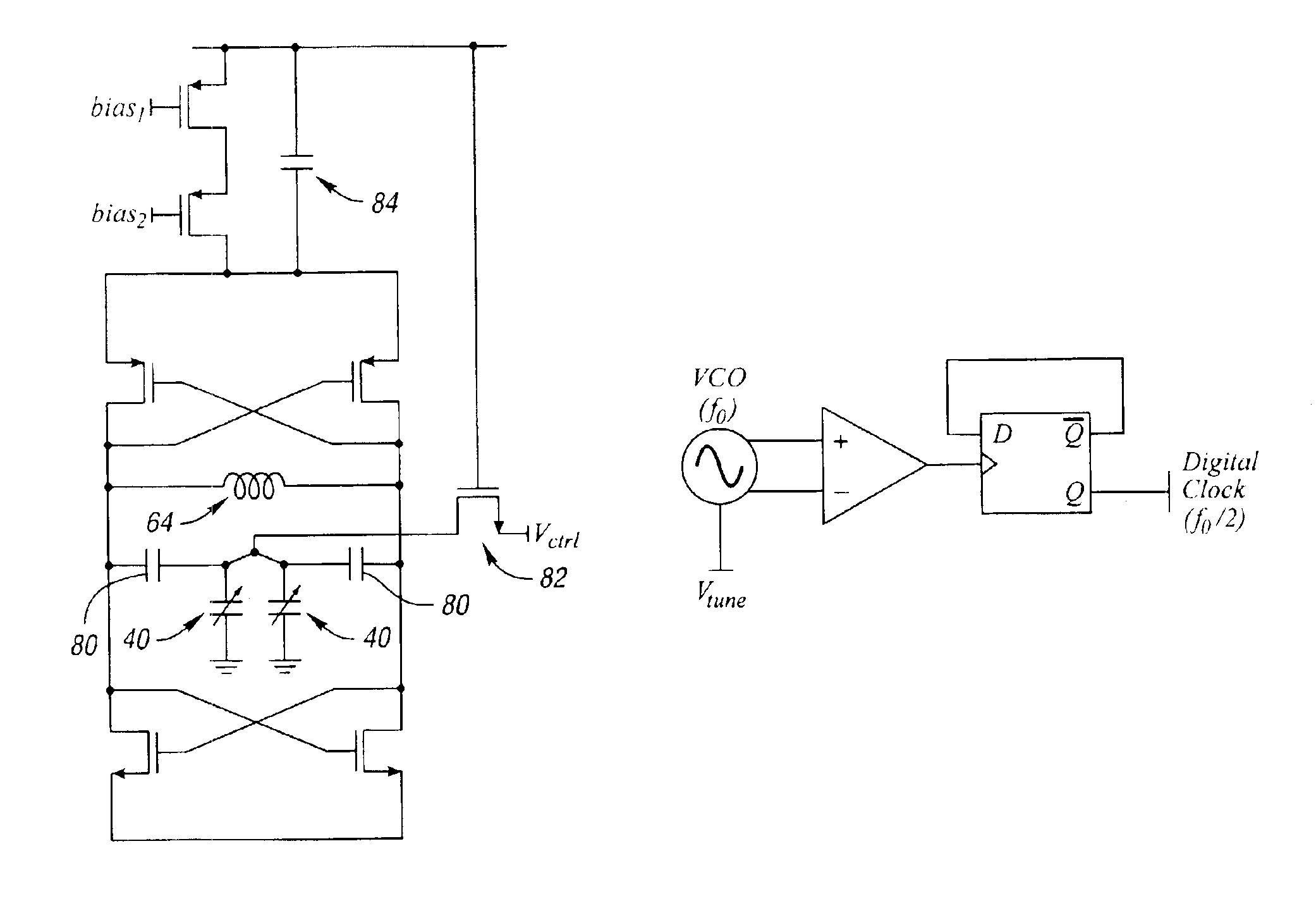

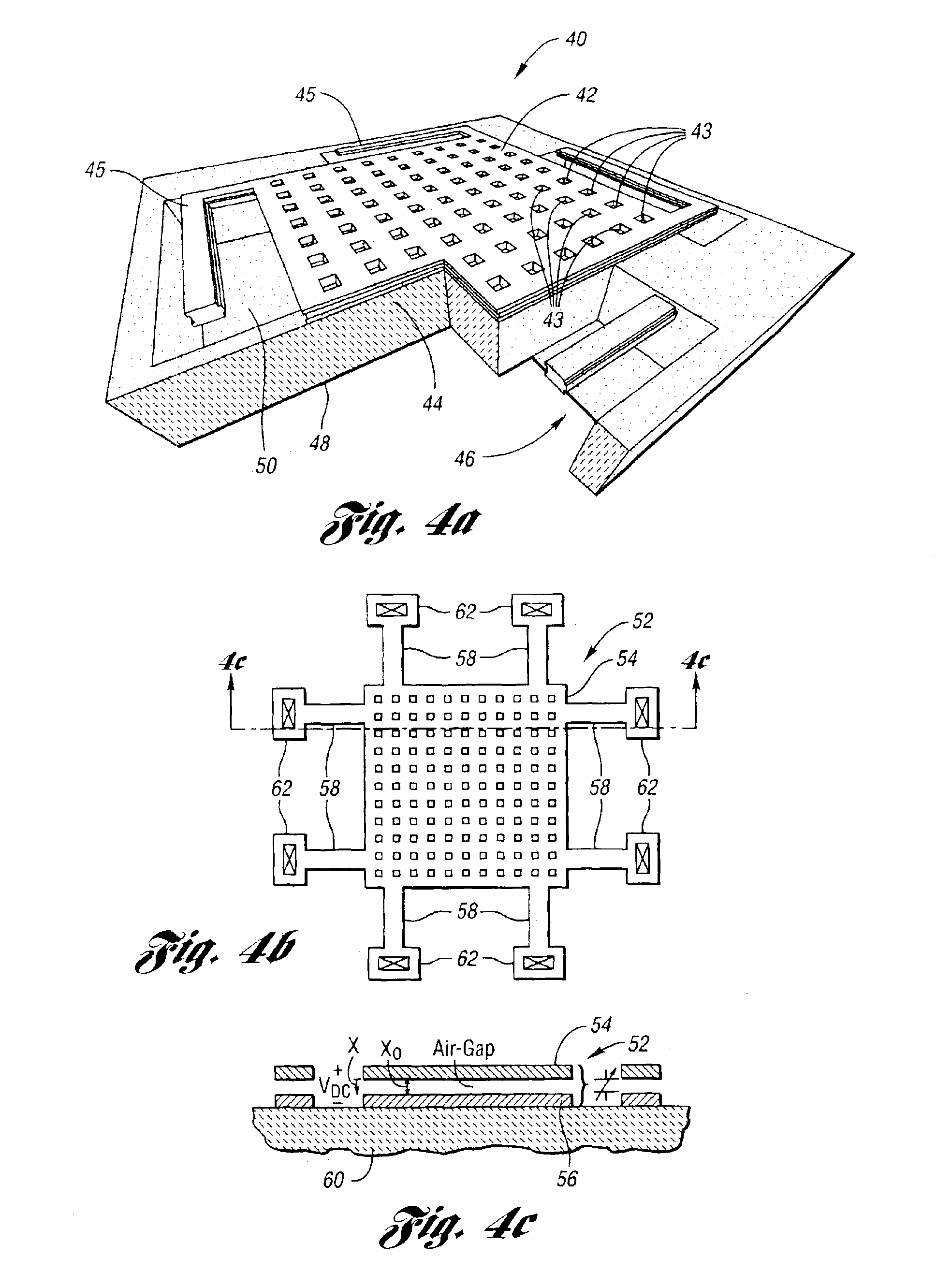

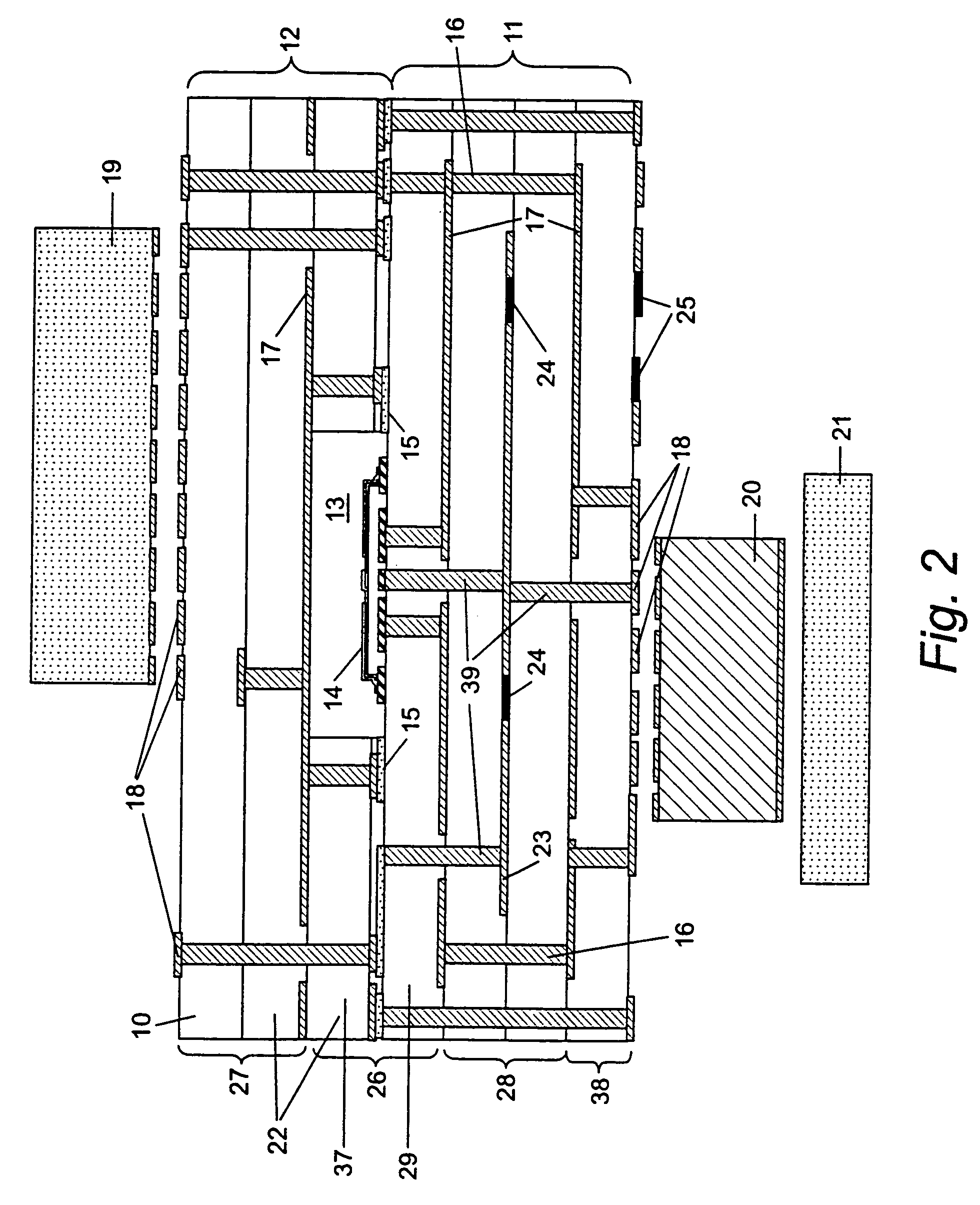

MEMS-based, computer systems, clock generation and oscillator circuits and LC-tank apparatus for use therein

InactiveUS6972635B2Reduce flicker noiseReduce phase noiseAngle modulation by variable impedenceMultiple-port networksEngineeringVaricap

MEMS-based, computer system, clock generation and oscillator circuits and LC-tank apparatus for use therein are provided and which are fabricated using a CMOS-compatible process. A micromachined inductor (L) and a pair of varactors (C) are developed in metal layers on a silicon substrate to realize the high quality factor LC-tank apparatus. This micromachined LC-tank apparatus is incorporated with CMOS transistor circuitry in order to realize a digital, tunable, low phase jitter, and low power clock, or time base, for synchronous integrated circuits. The synthesized clock signal can be divided down with digital circuitry from several GHz to tens of MHz—a systemic approach that substantially improves stability as compared to the state of the art. Advanced circuit design techniques have been utilized to minimize power consumption and mitigate transistor flicker noise upconversion, thus enhancing clock stability.

Owner:RGT UNIV OF MICHIGAN

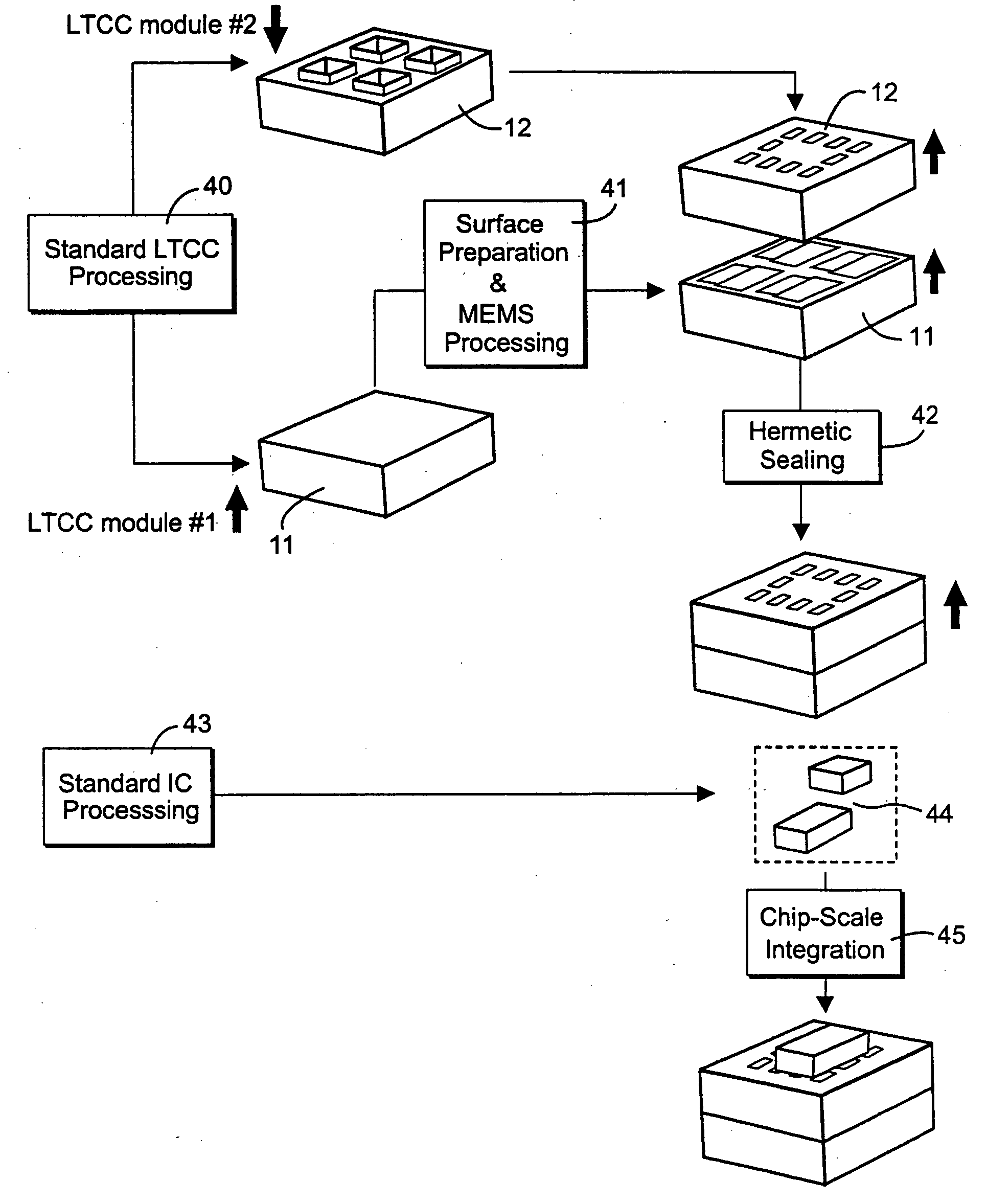

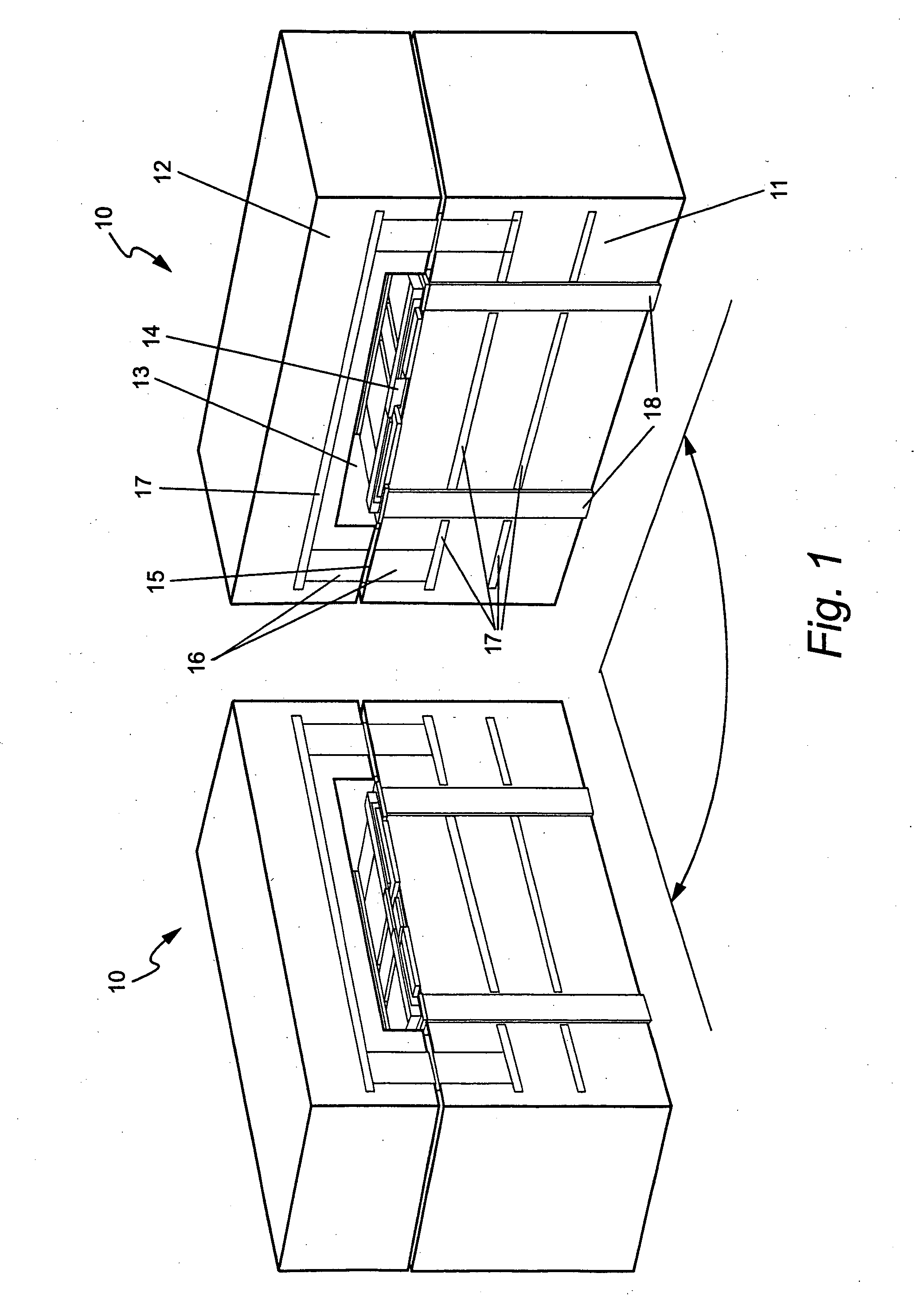

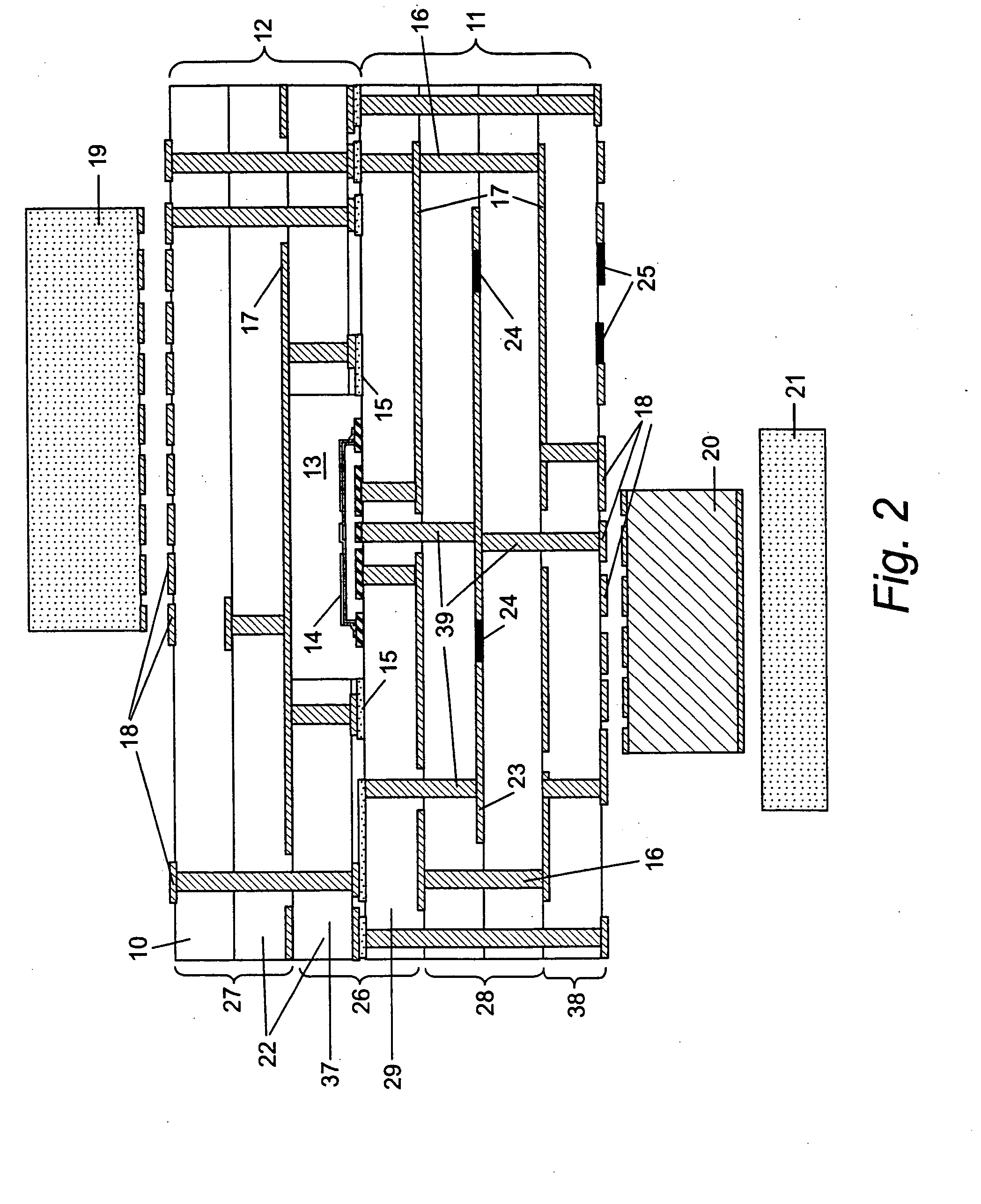

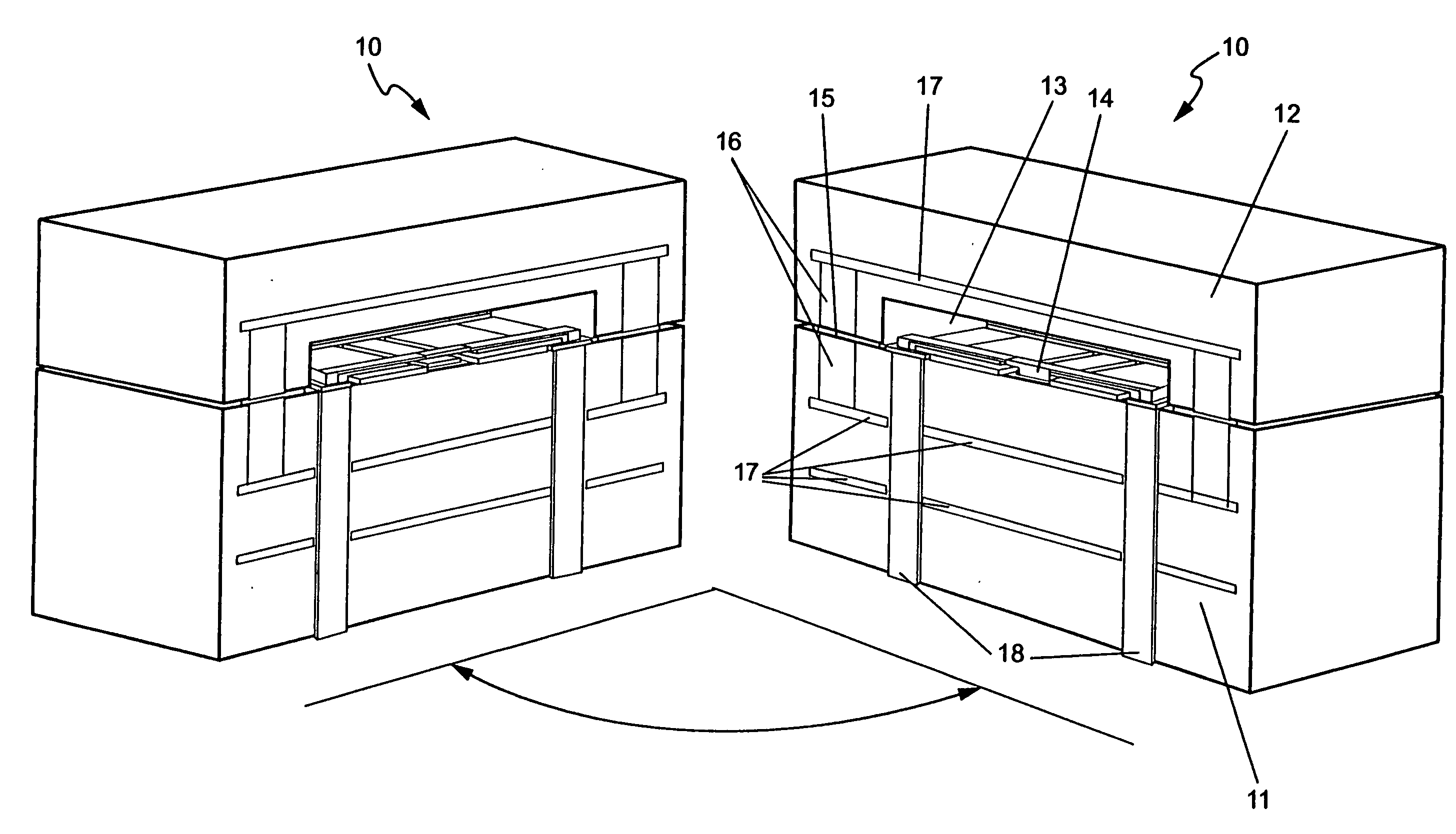

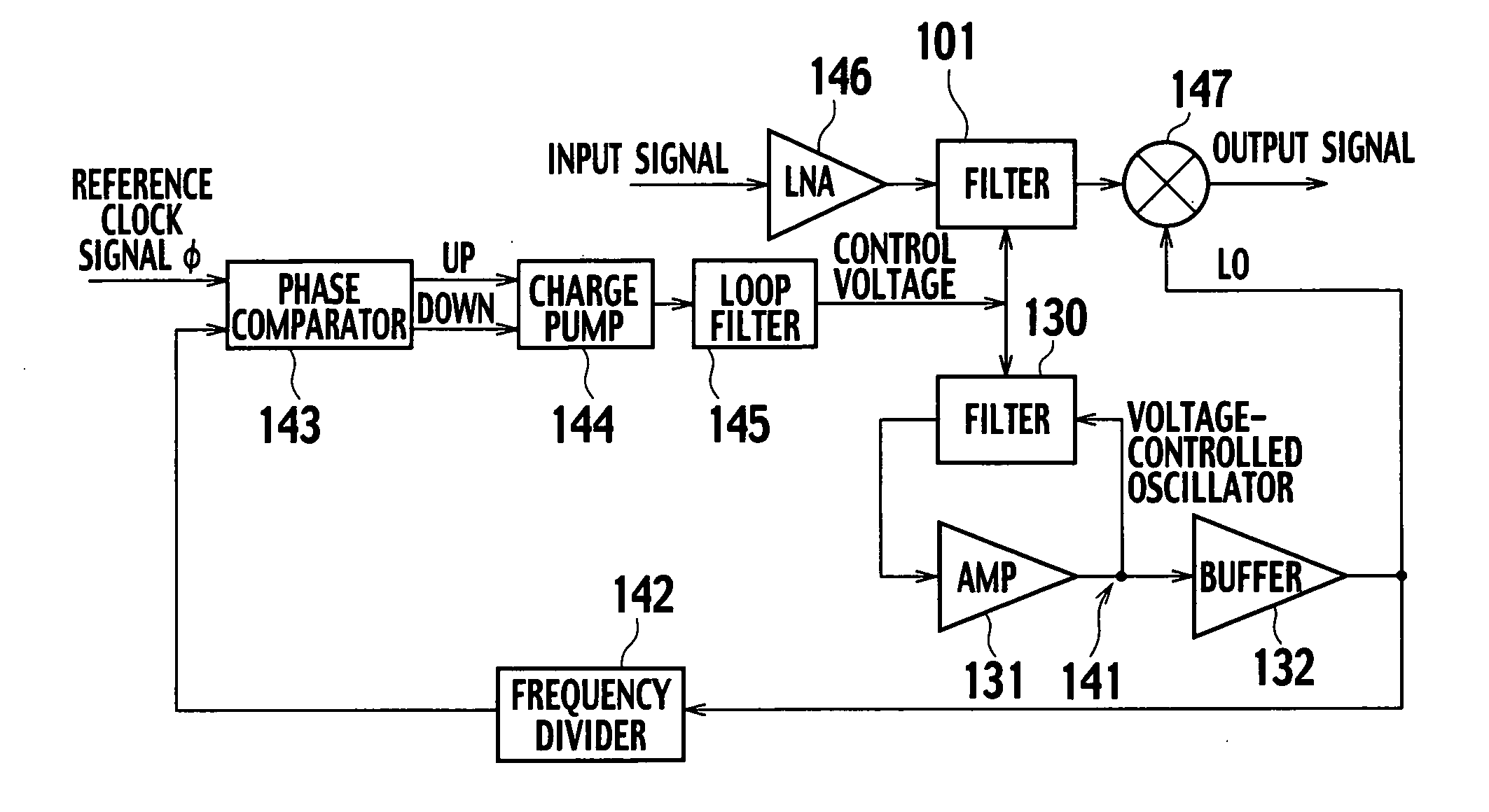

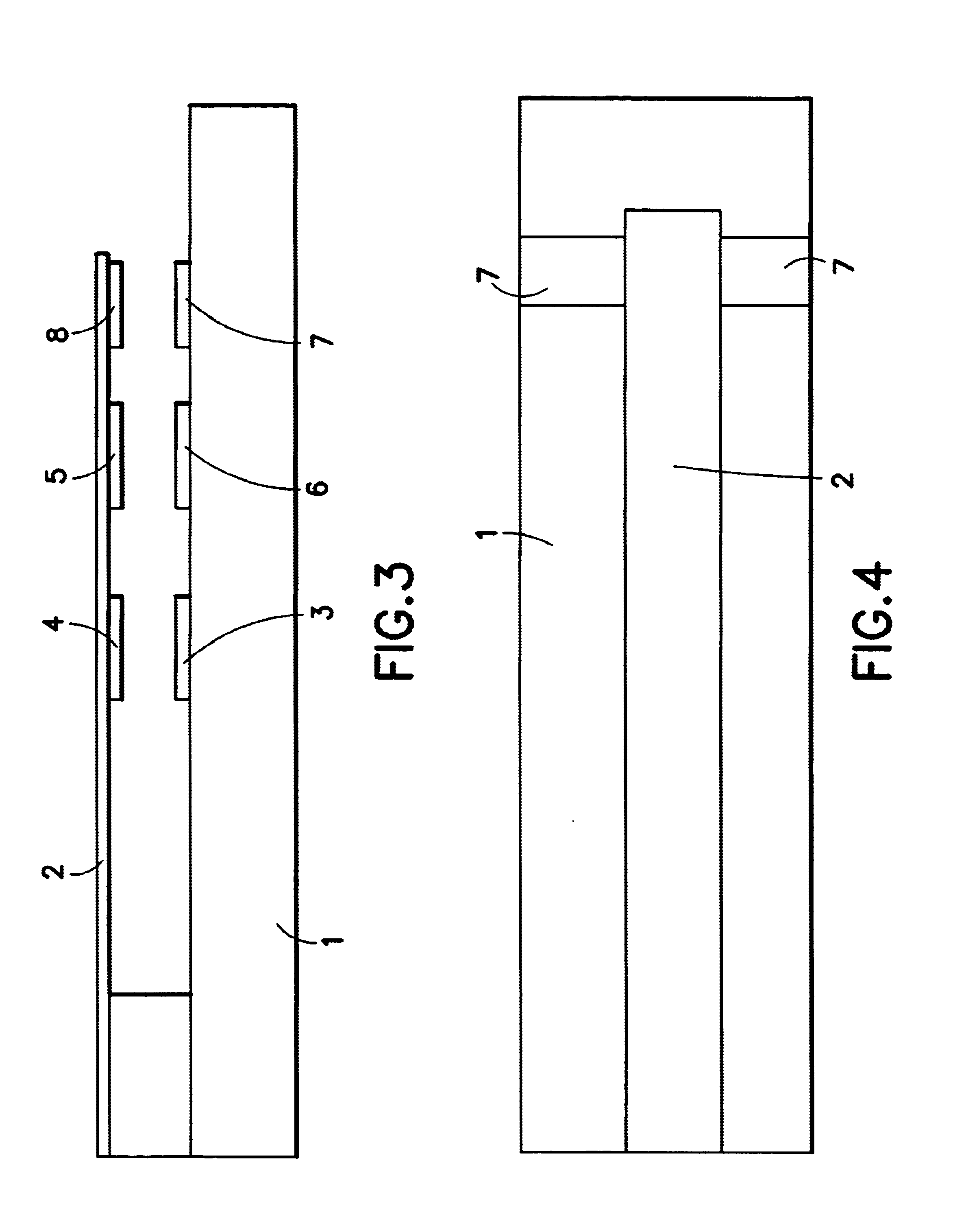

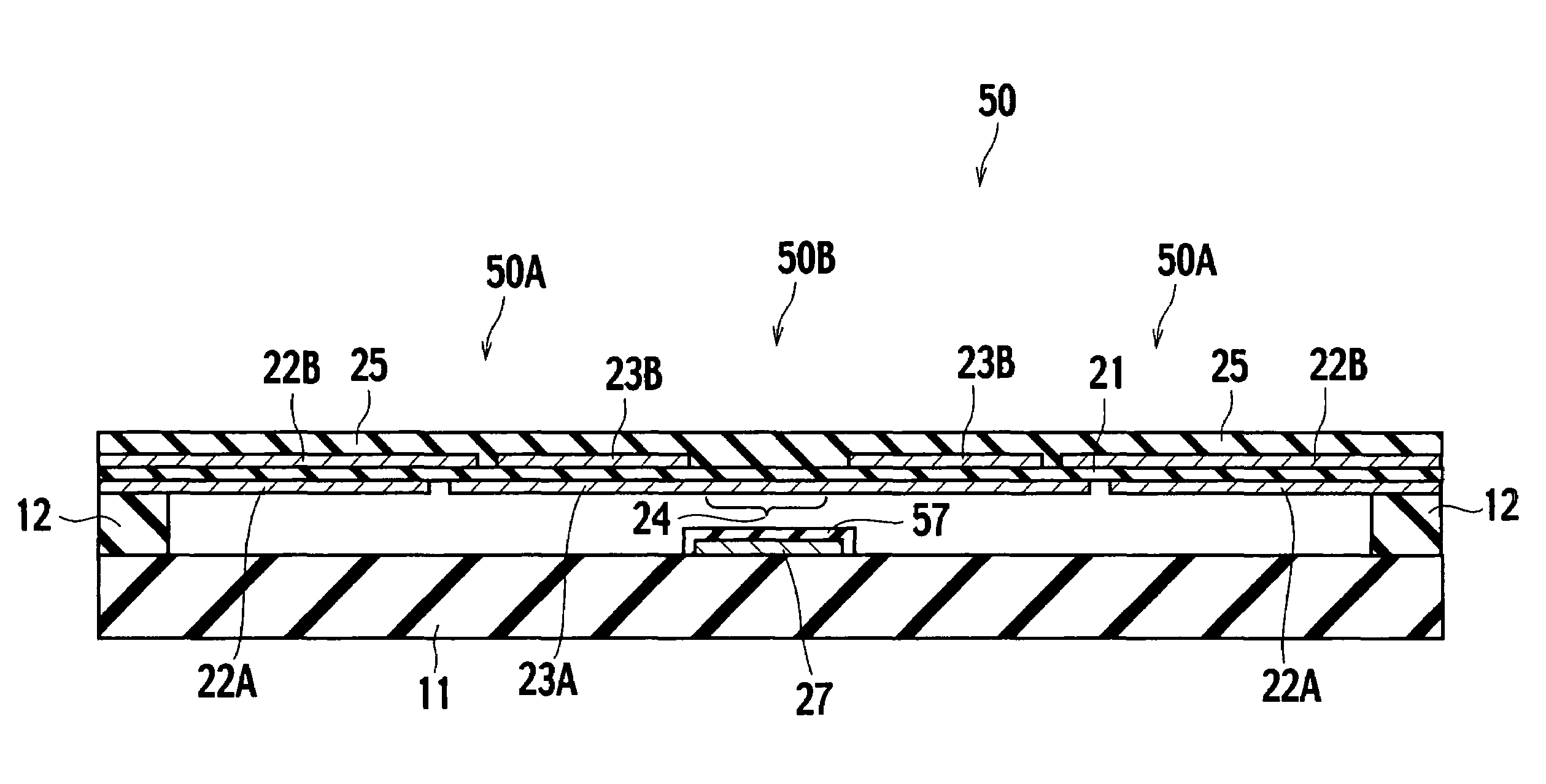

Method of fabricating radio frequency microelectromechanical systems (MEMS) devices on low-temperature co-fired ceramic (LTCC) substrates

InactiveUS20050161753A1Material nanotechnologySemiconductor/solid-state device detailsDielectricRadio frequency microelectromechanical system

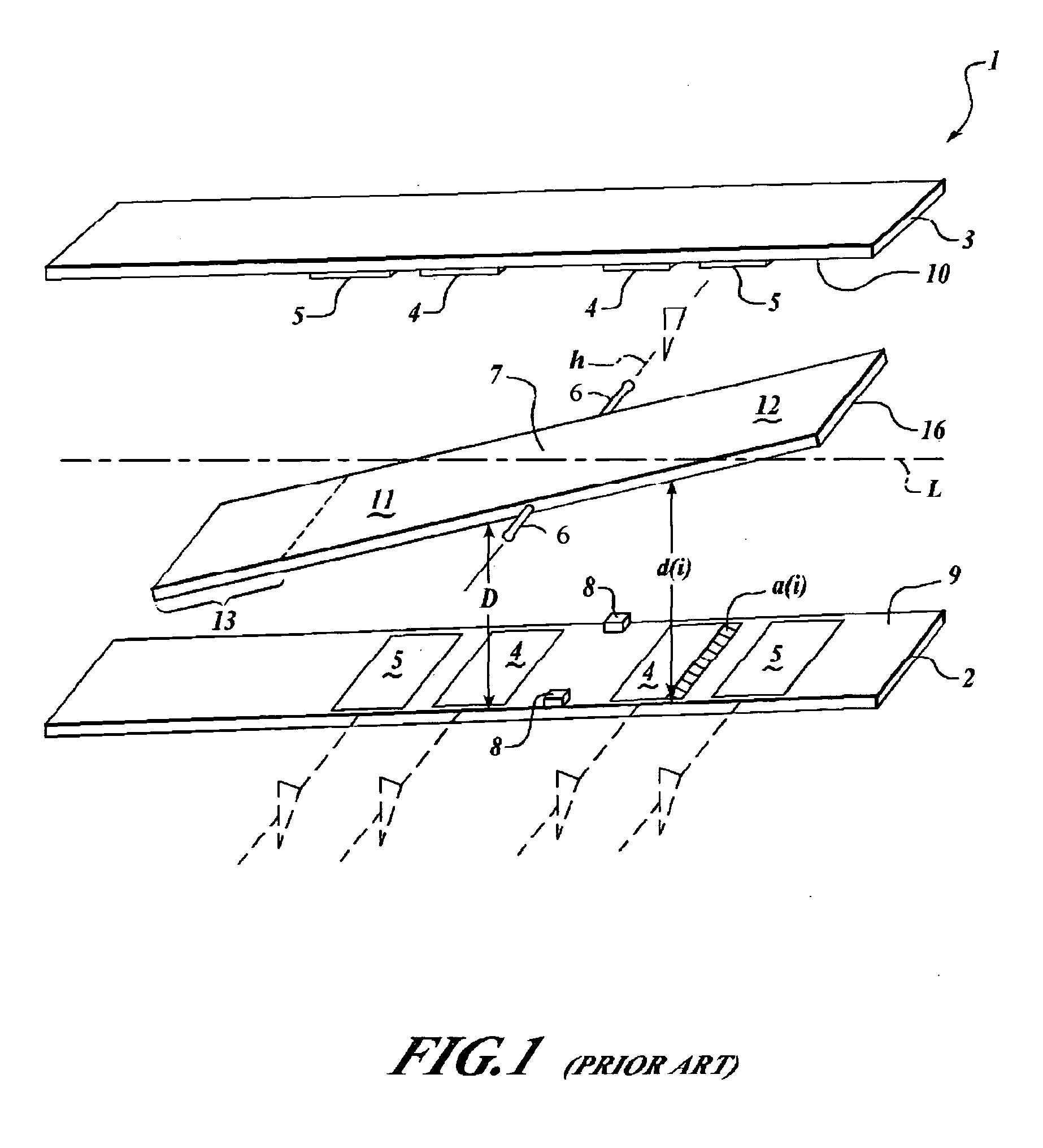

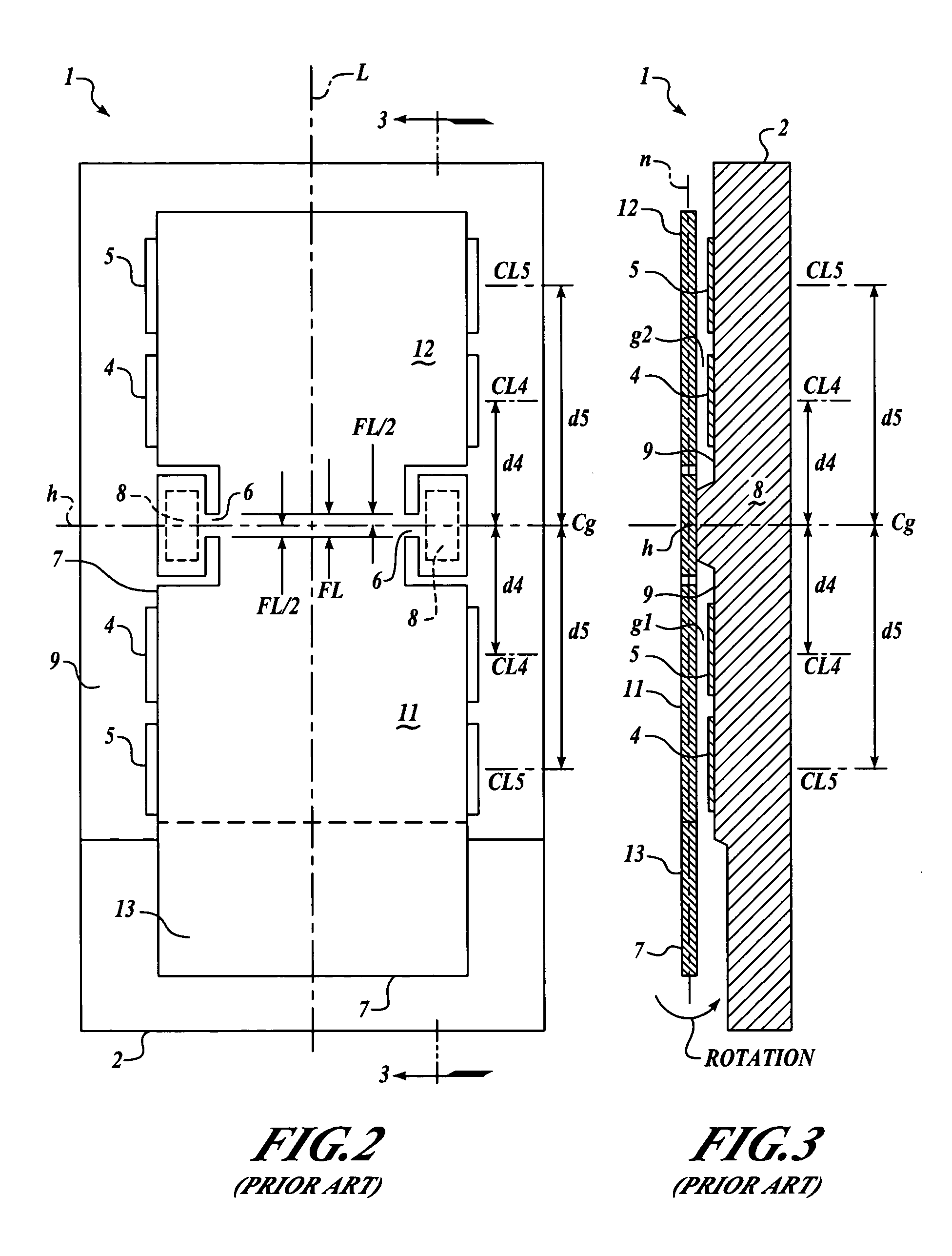

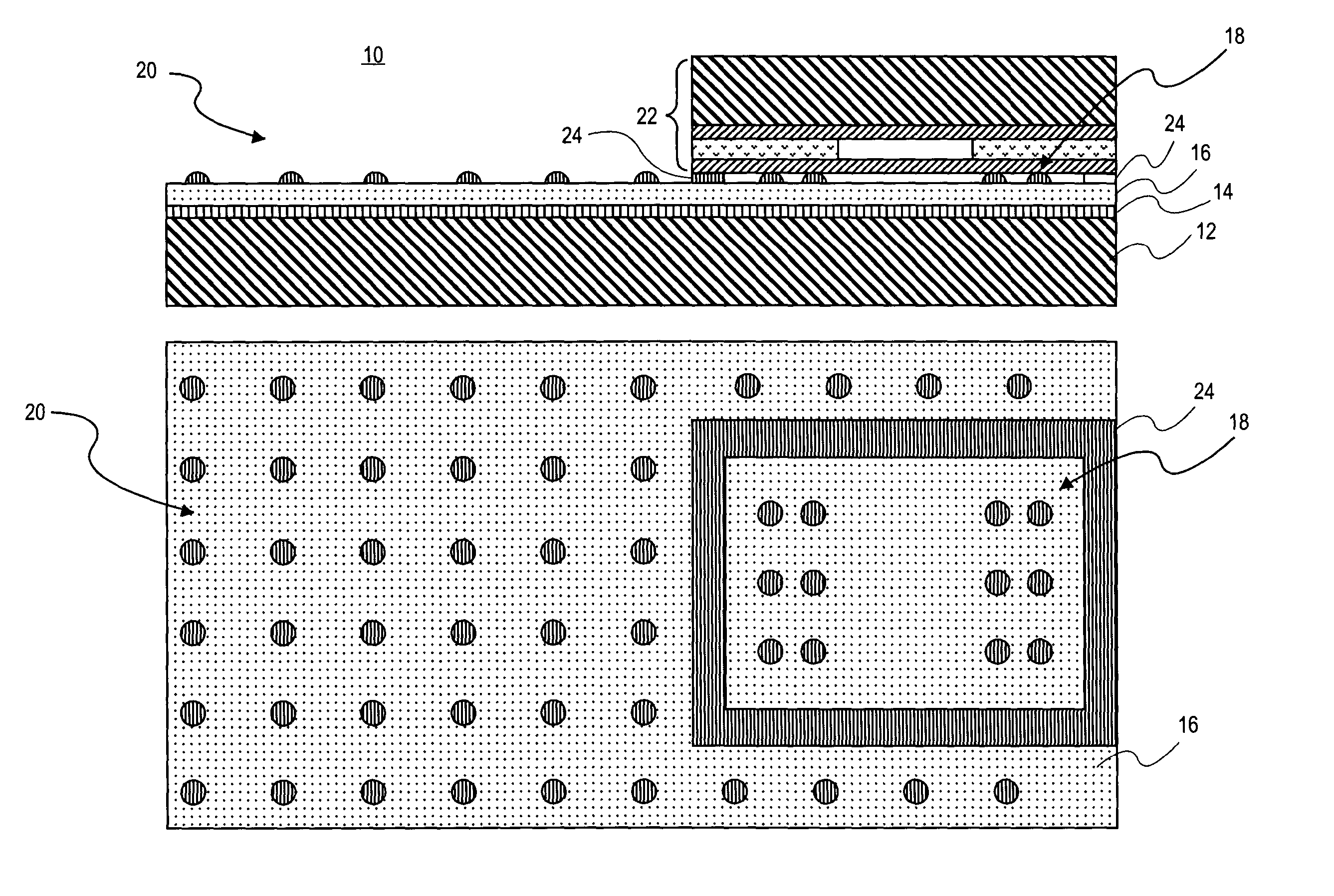

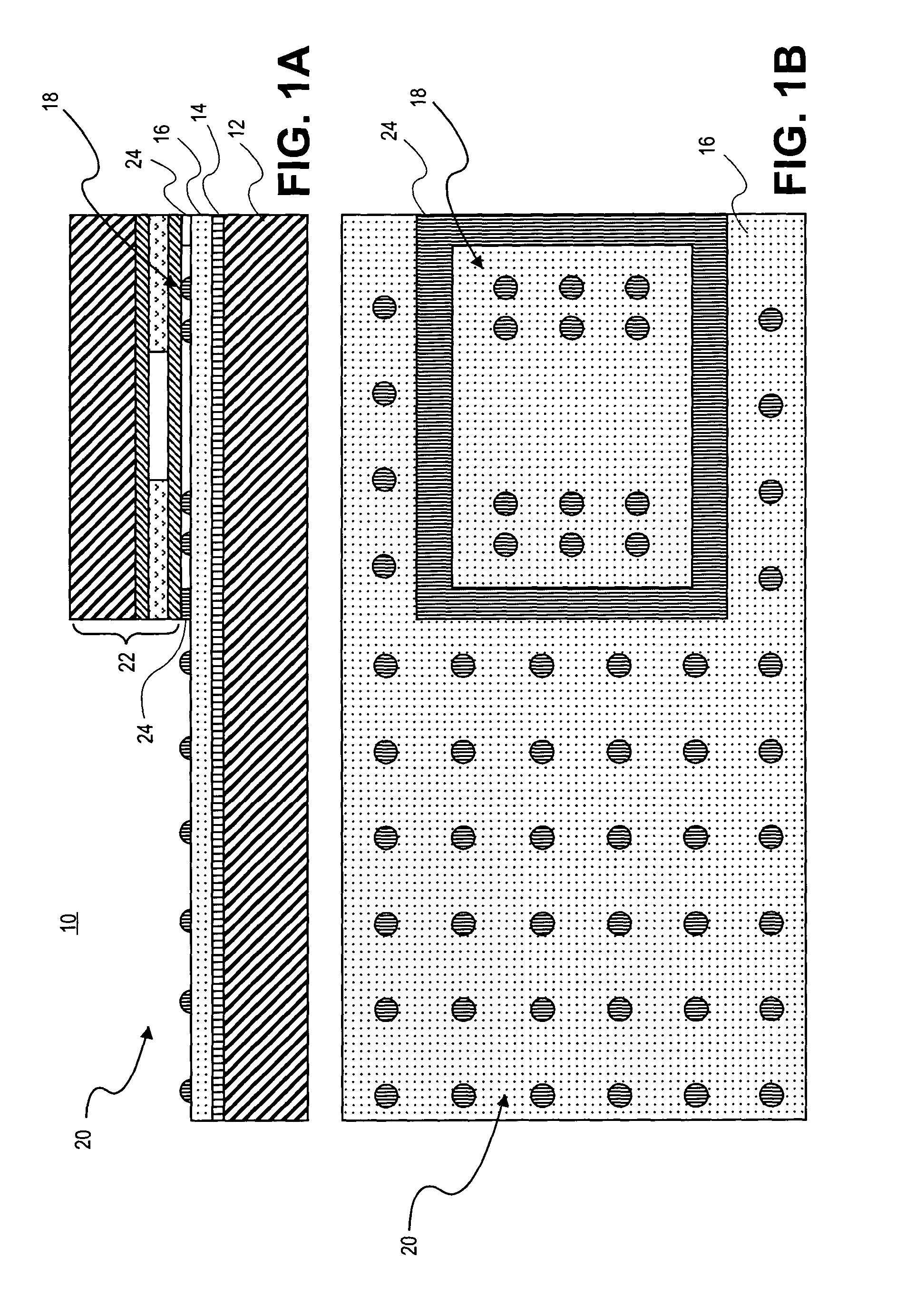

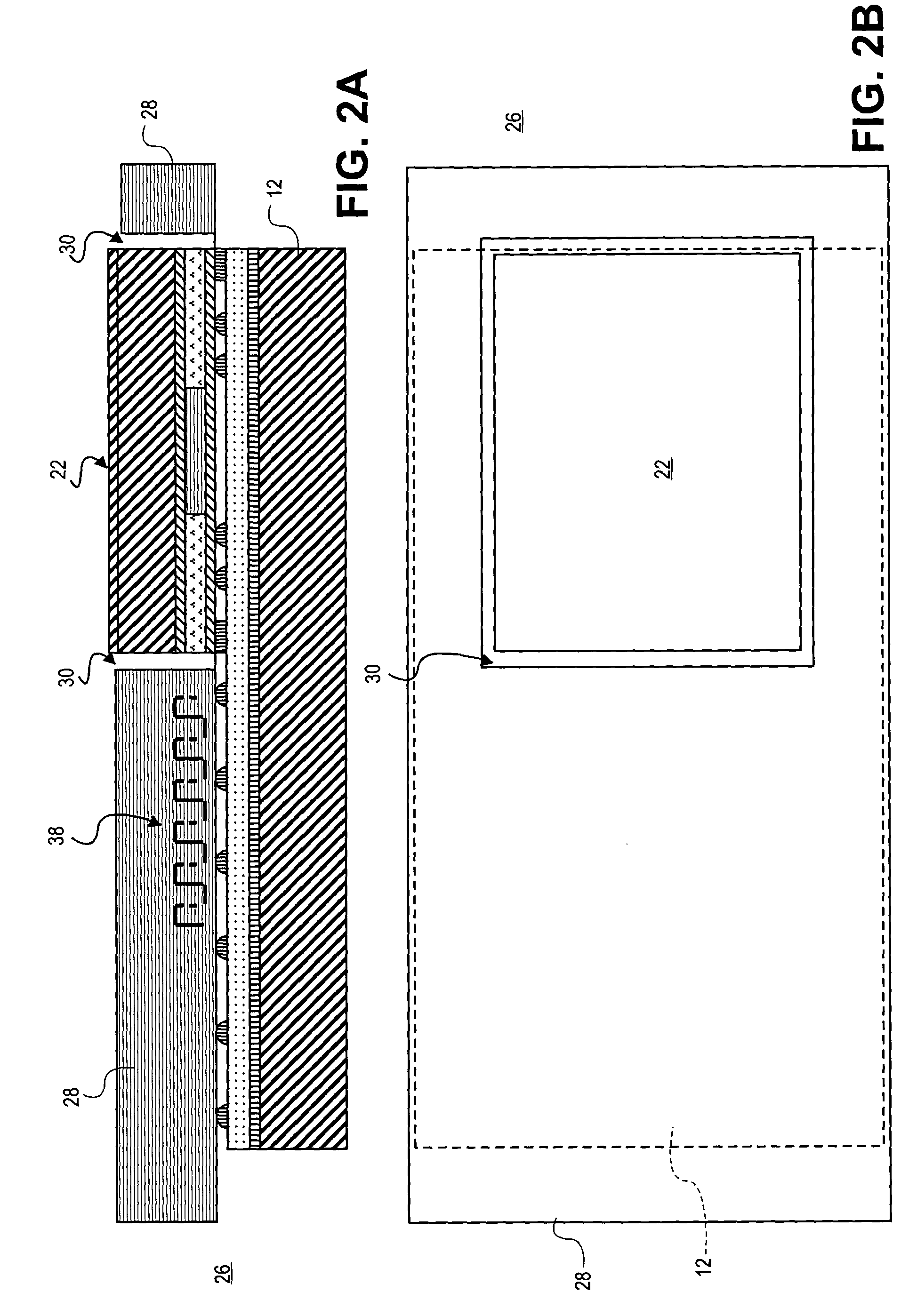

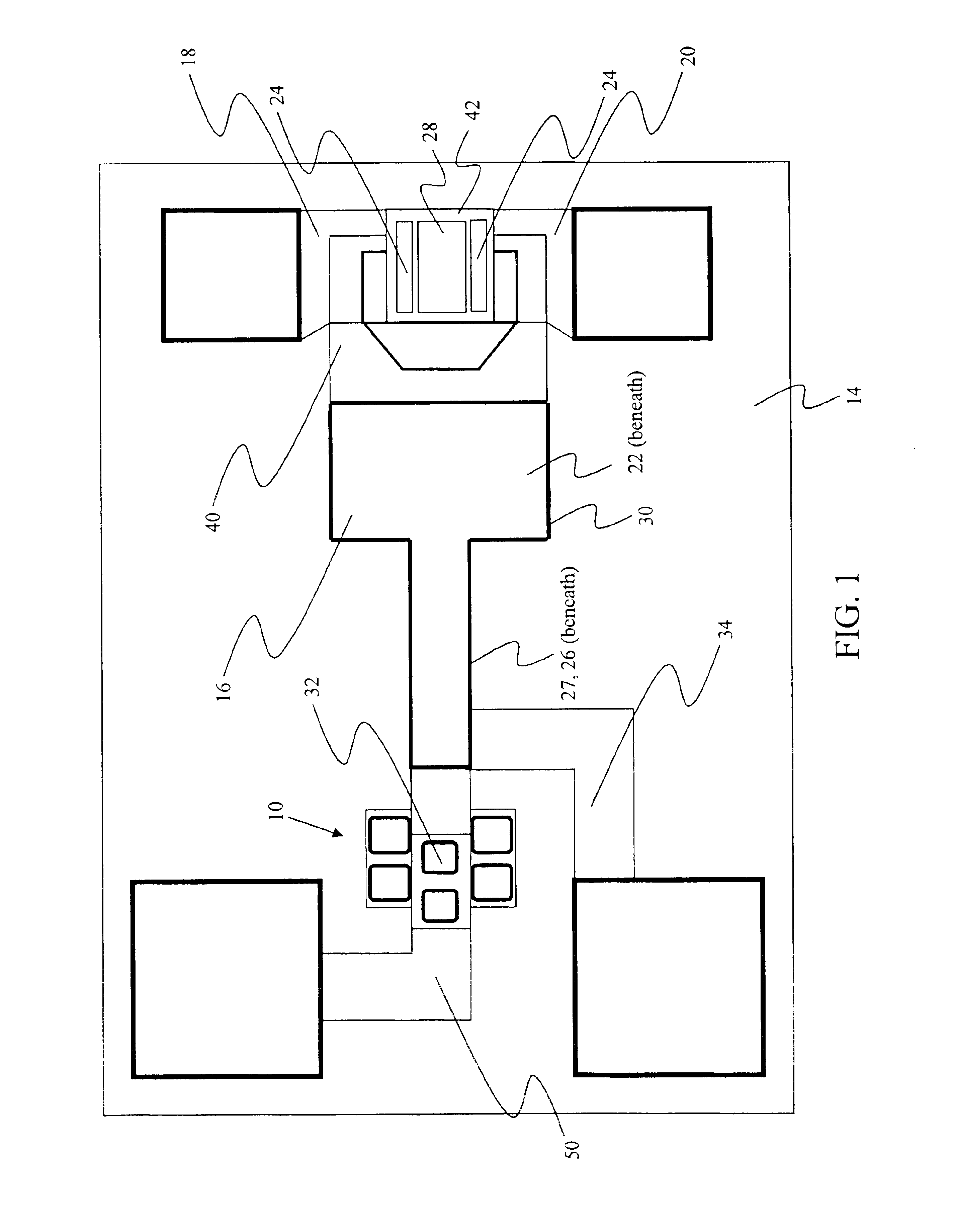

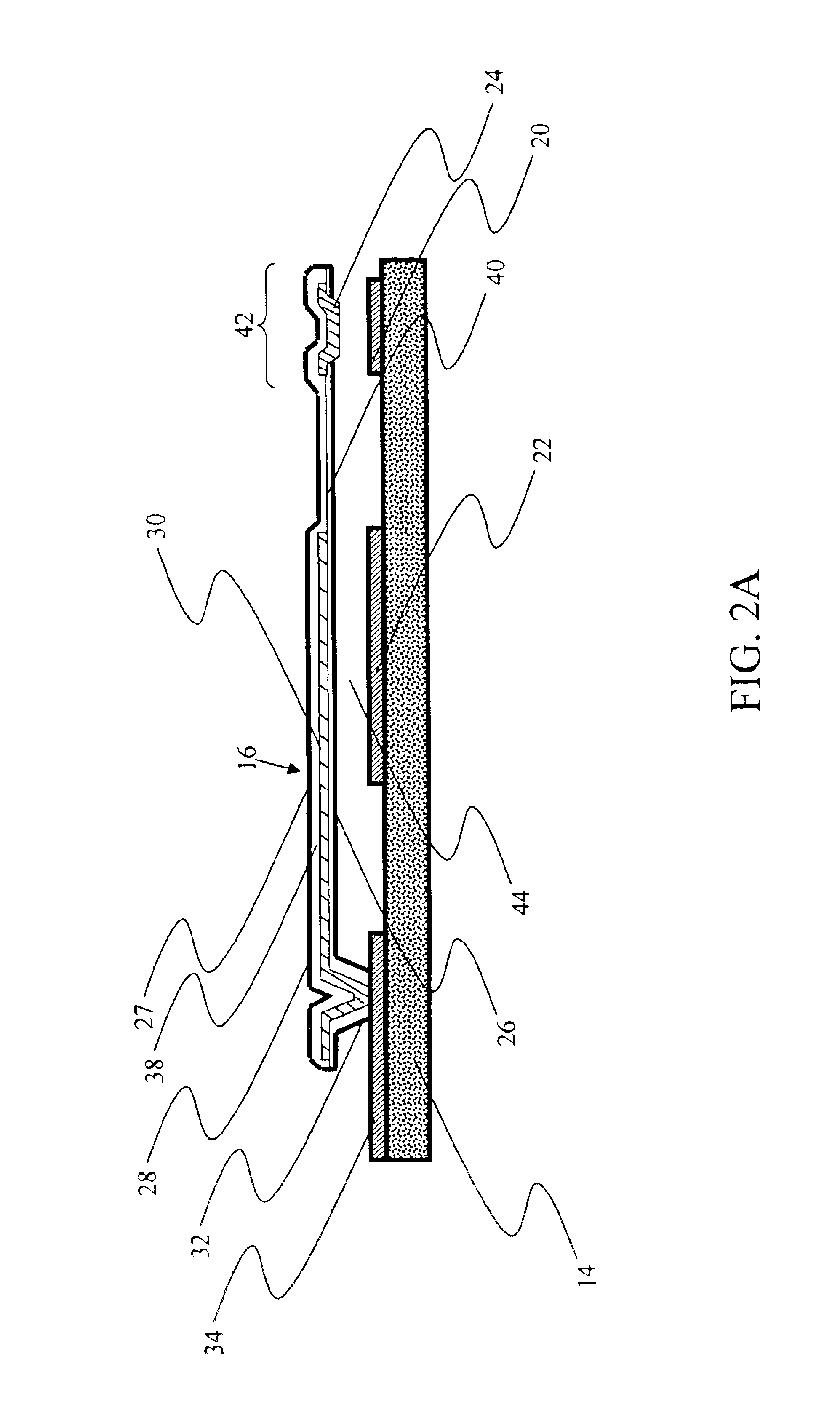

A phased-array antenna system and other types of radio frequency (RF) devices and systems using microelectromechanical switches (“MEMS”) and low-temperature co-fired ceramic (“LTCC”) technology and a method of fabricating such phased-array antenna system and other types of radio frequency (RF) devices are disclosed. Each antenna or other type of device includes at least two multilayer ceramic modules and a MEMS device fabricated on one of the modules. Once fabrication of the MEMS device is completed, the two ceramic modules are bonded together, hermetically sealing the MEMS device, as well as allowing electrical connections between all device layers. The bottom ceramic module has also cavities at the backside for mounting integrated circuits. The internal layers are formed using conducting, resistive and high-k dielectric pastes available in standard LTCC fabrication and low-loss dielectric LTCC tape materials.

Owner:FOR NAT RES INITIATIVES

Method of fabricating radio frequency microelectromechanical systems (MEMS) devices on low-temperature co-fired ceramic (LTCC) substrates

InactiveUS20050167047A1Material nanotechnologySemiconductor/solid-state device detailsDielectricRadio frequency microelectromechanical system

A phased-array antenna system and other types of radio frequency (RF) devices and systems using microelectromechanical switches (“MEMS”) and low-temperature co-fired ceramic (“LTCC”) technology and a method of fabricating such phased-array antenna system and other types of radio frequency (RF) devices are disclosed. Each antenna or other type of device includes at least two multilayer ceramic modules and a MEMS device fabricated on one of the modules. Once fabrication of the MEMS device is completed, the two ceramic modules are bonded together, hermetically sealing the MEMS device, as well as allowing electrical connections between all device layers. The bottom ceramic module has also cavities at the backside for mounting integrated circuits. The internal layers are formed using conducting, resistive and high-k dielectric pastes available in standard LTCC fabrication and low-loss dielectric LTCC tape materials.

Owner:FOR NAT RES INITIATIVES

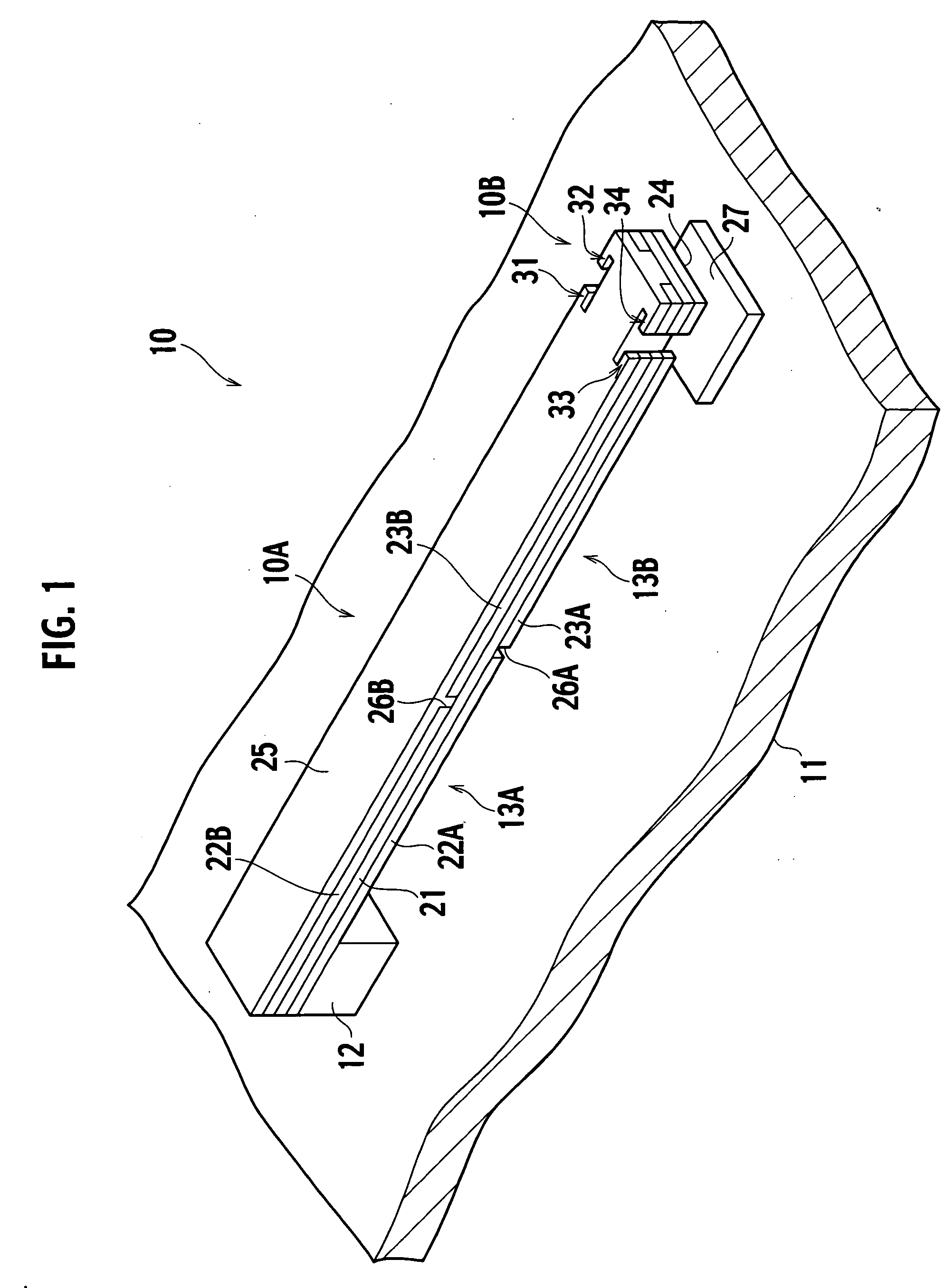

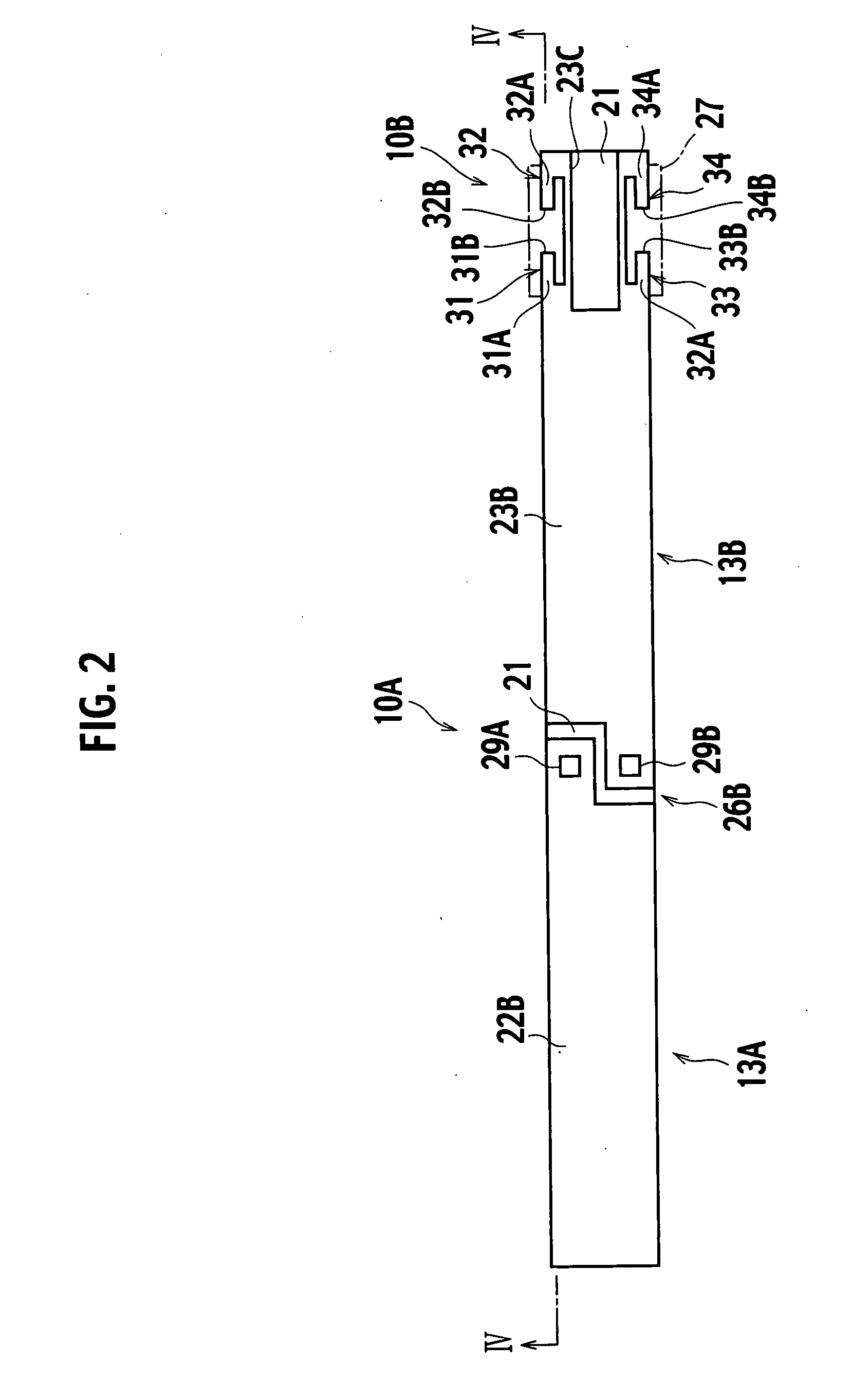

Micro-mechanical device, micro-switch, variable capacitor high frequency circuit and optical switch

InactiveUS20060285255A1Disposition/mounting of recording headsPiezoelectric/electrostriction/magnetostriction machinesElectricityPiezoelectric actuators

A micro-mechanical device includes a first piezoelectric actuator including a piezoelectric film, and lower and upper electrodes interleaving the piezoelectric film, and extending from a first fixing part on a substrate to a first operating end, and a second piezoelectric actuator connected to the first piezoelectric actuator via a connecting part at the first operating end of the first piezoelectric actuator, and extending from the connecting part to a second operating end, the second piezoelectric actuator being shorter than the first piezoelectric actuator.

Owner:KK TOSHIBA

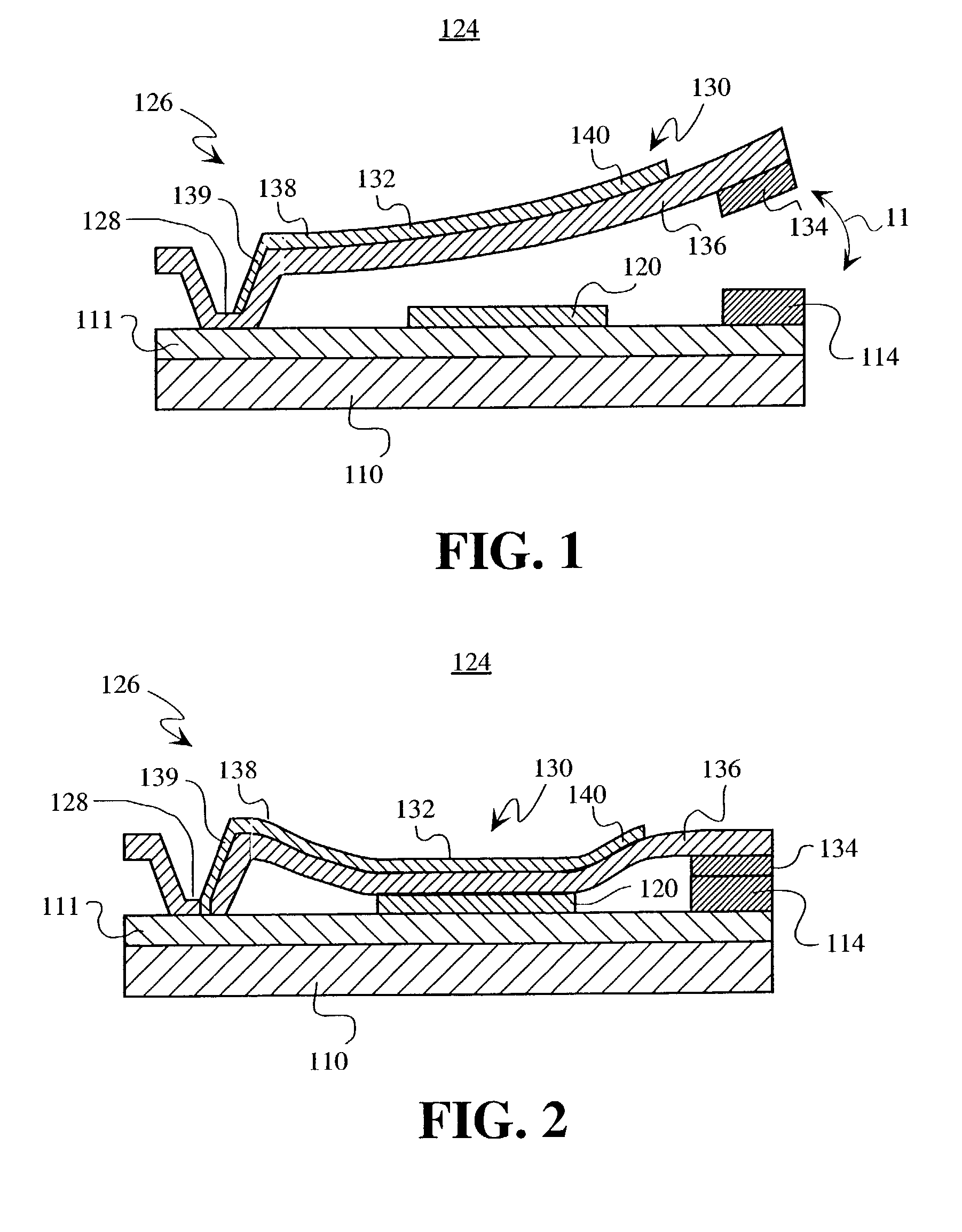

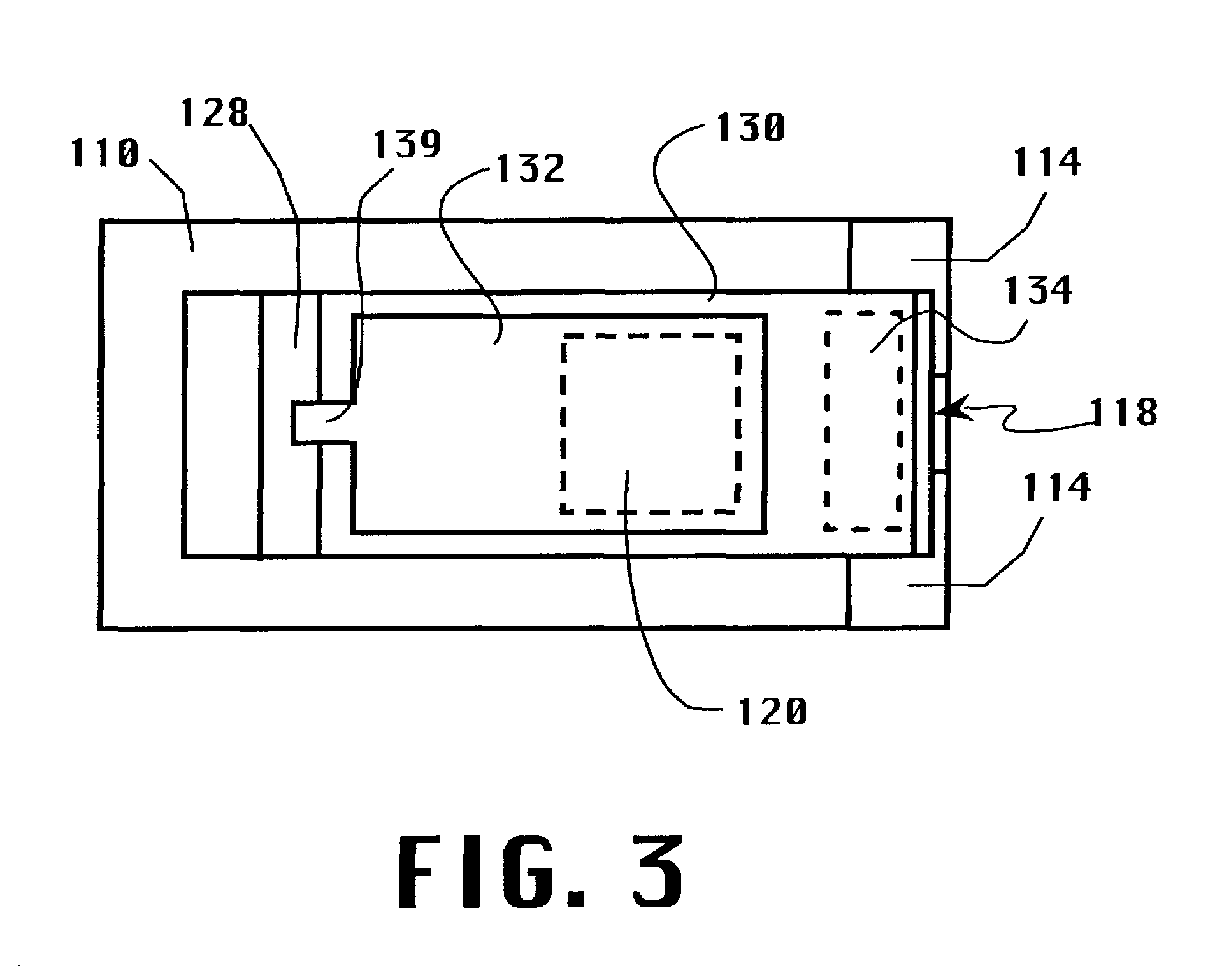

Stress bimorph MEMS switches and methods of making same

InactiveUS20060181379A1Reduce capacitanceMinimize OFF-state capacitanceElectrostatic/electro-adhesion relaysCapacitor with electrode distance variationEngineeringCantilever

A micro-electromechanical system (MEMS) switch formed on a substrate, the switch comprising a transmission line formed on the substrate, a substrate electrostatic plate formed on the substrate, and an actuating portion. The actuating portion comprises a cantilever anchor formed on the substrate and a cantilevered actuator arm extending from the cantilever anchor. Attraction of the actuator arm toward the substrate brings an electrical contact into engagement with the portions of the transmission line separated by a gap, thus bridging the transmission line gap and closing the circuit. In order to maximize electrical isolation between the transmission line and the electrical contact in an OFF-state while maintaining a low actuation voltage, the actuator arm is bent such that the minimum separation distance between the transmission line and the electrical contact is equal to or greater than the maximum separation distance between the substrate electrostatic plate and arm electrostatic plate.

Owner:HRL LAB +1

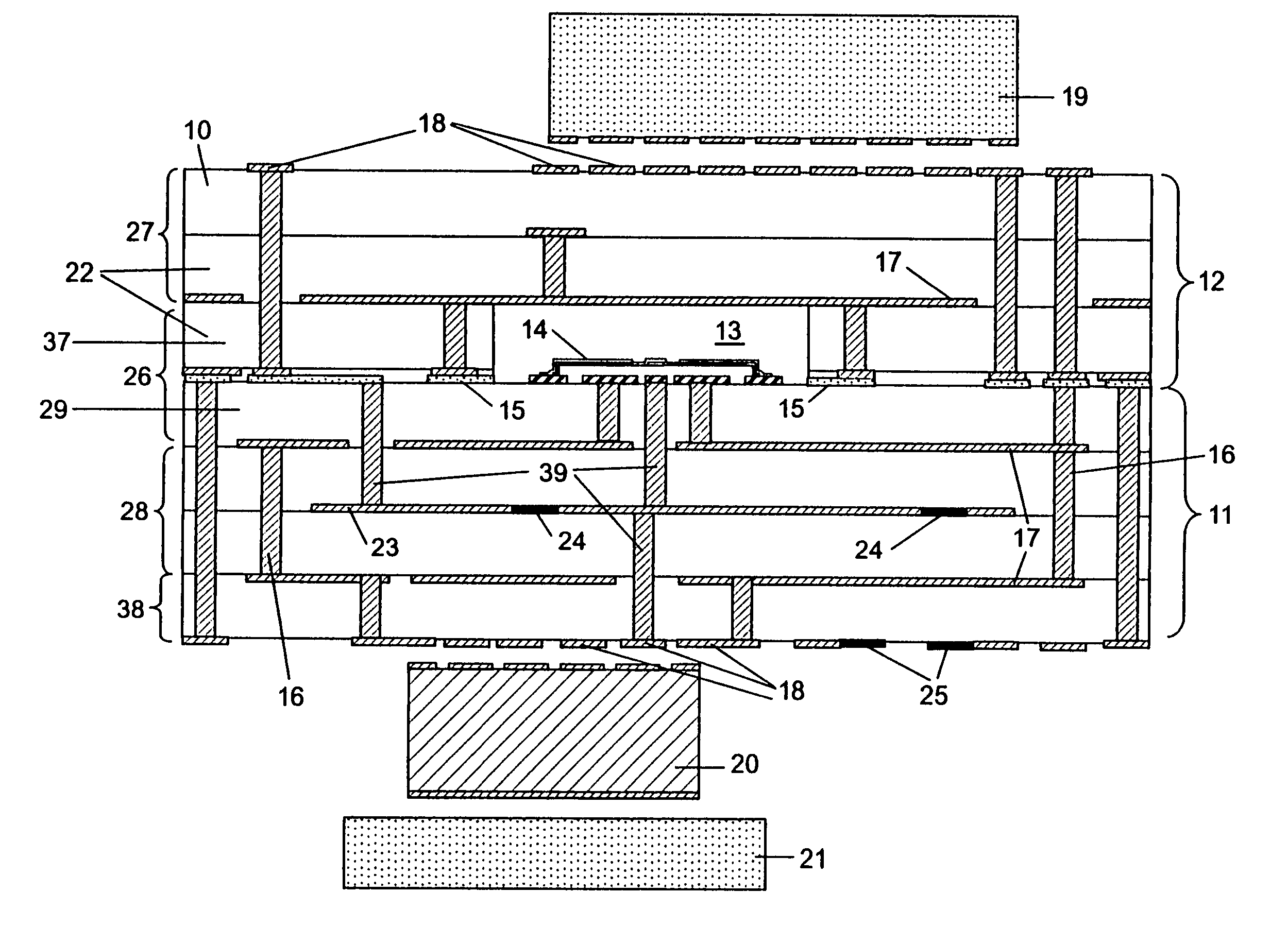

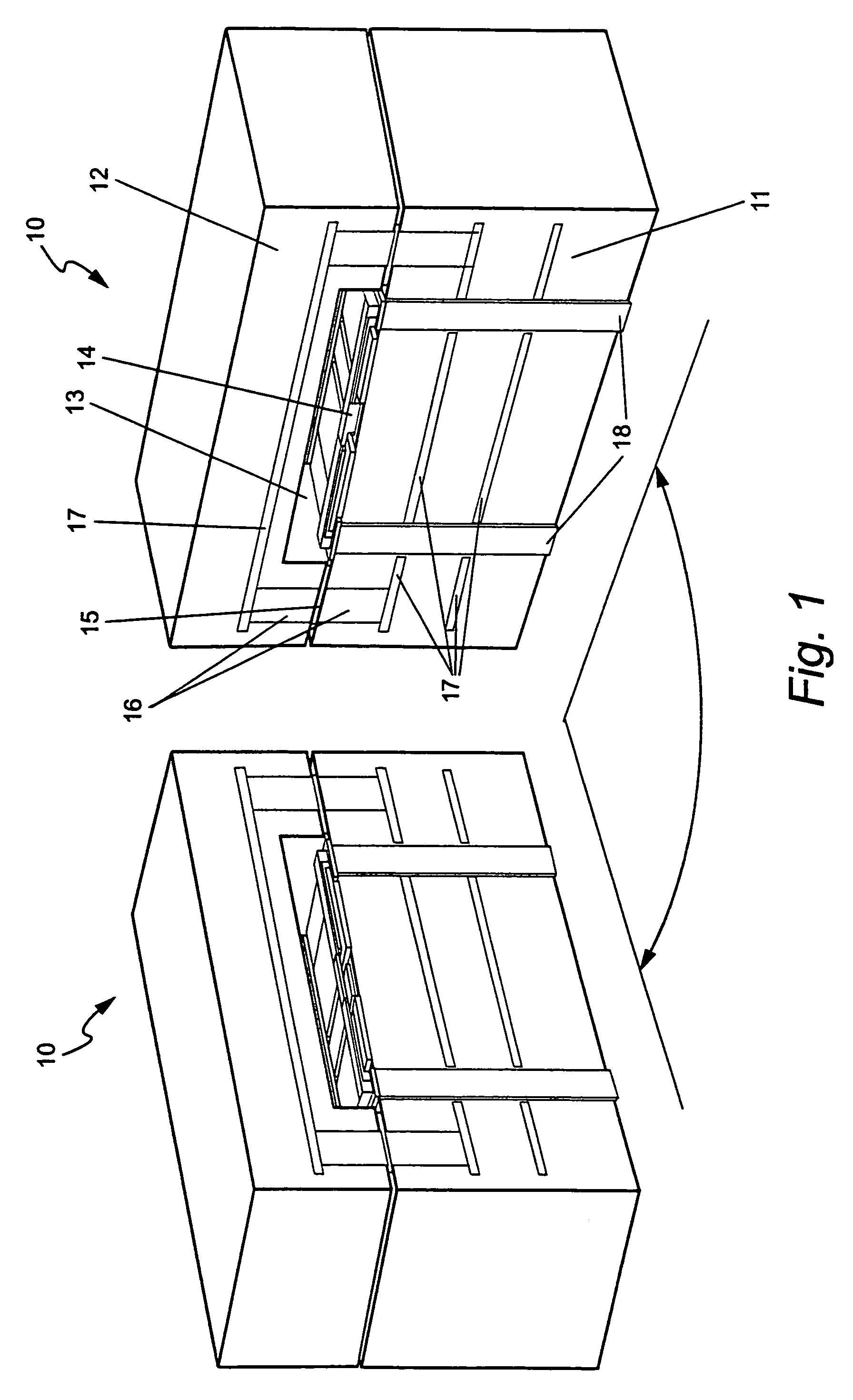

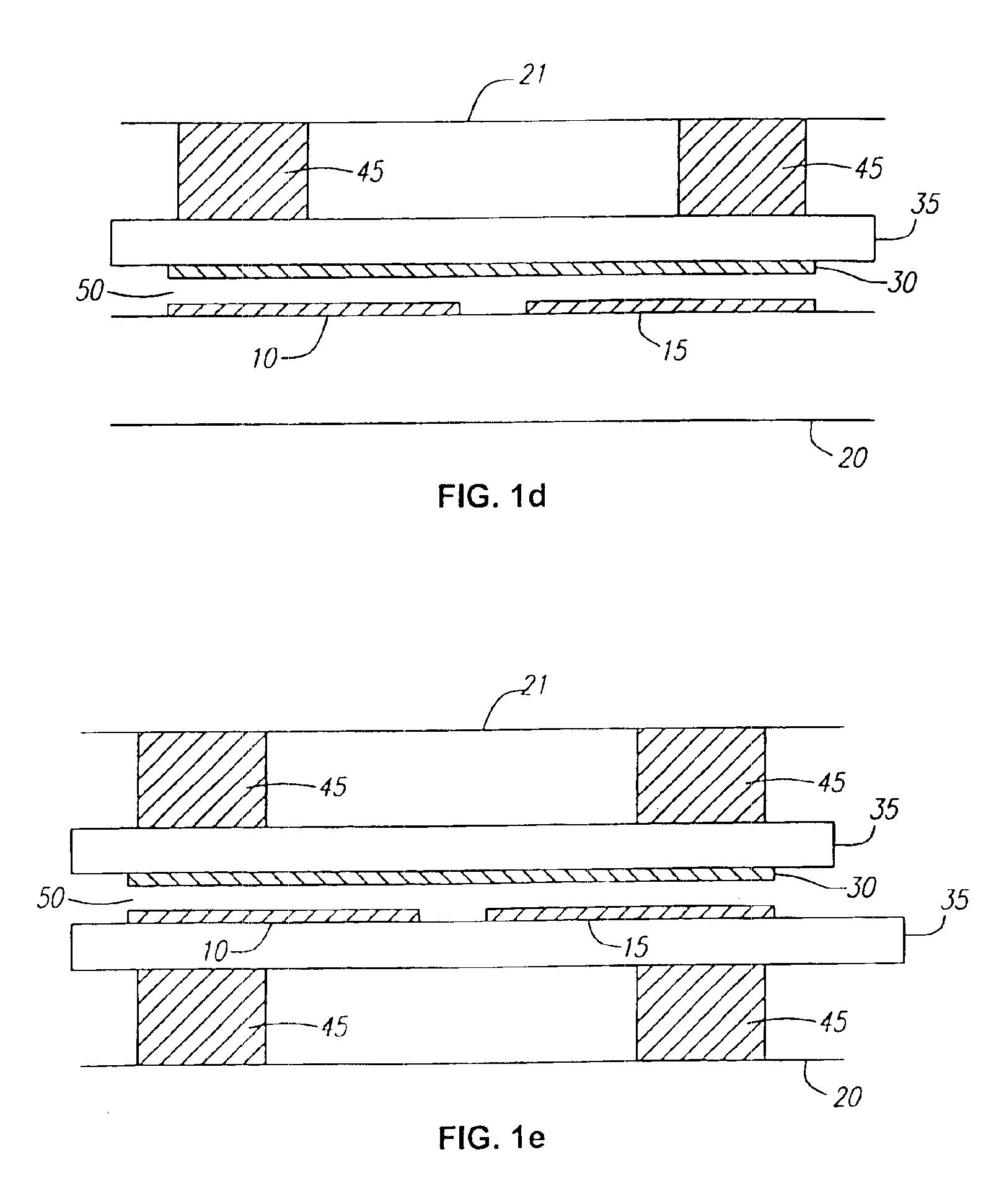

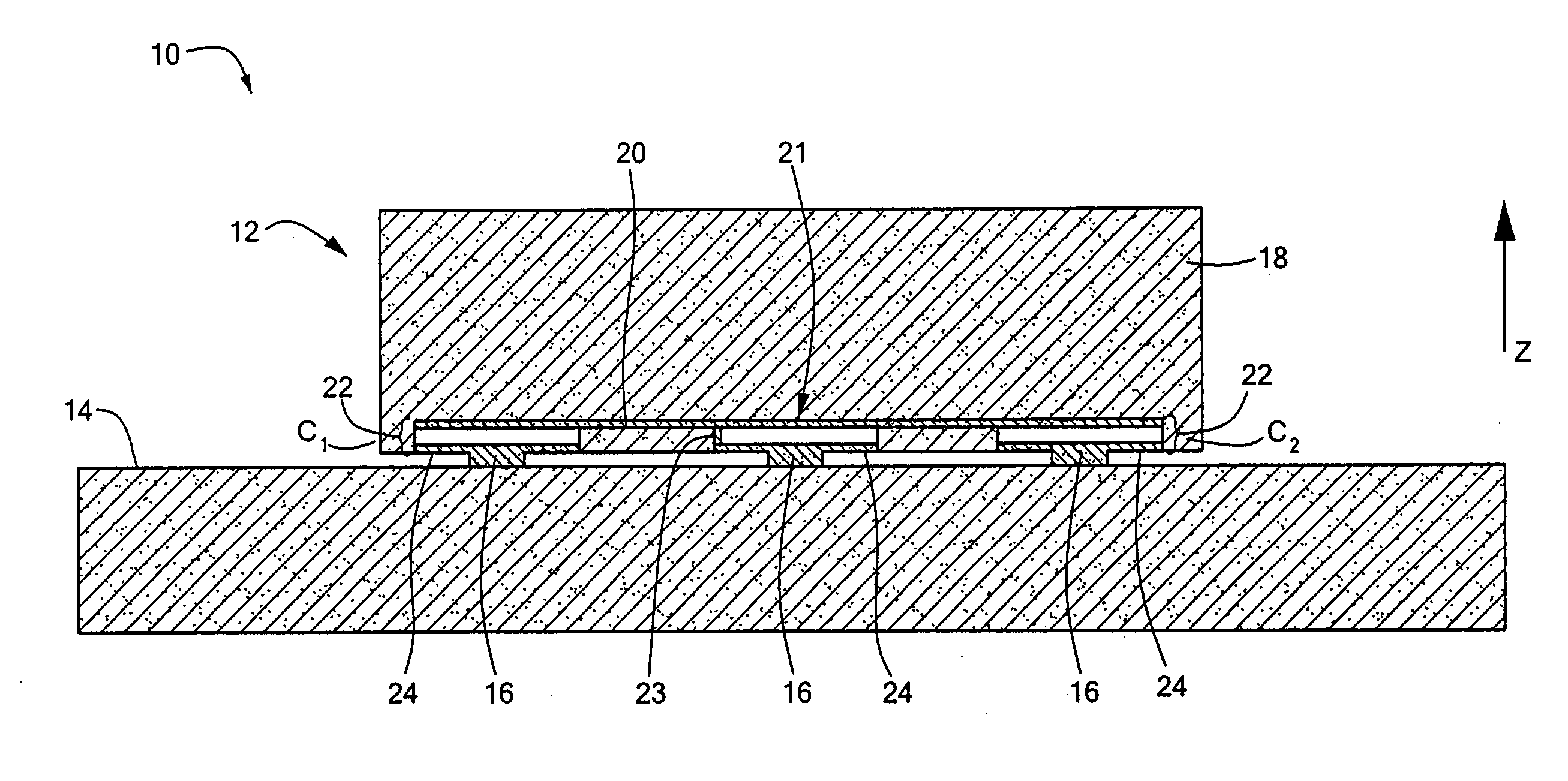

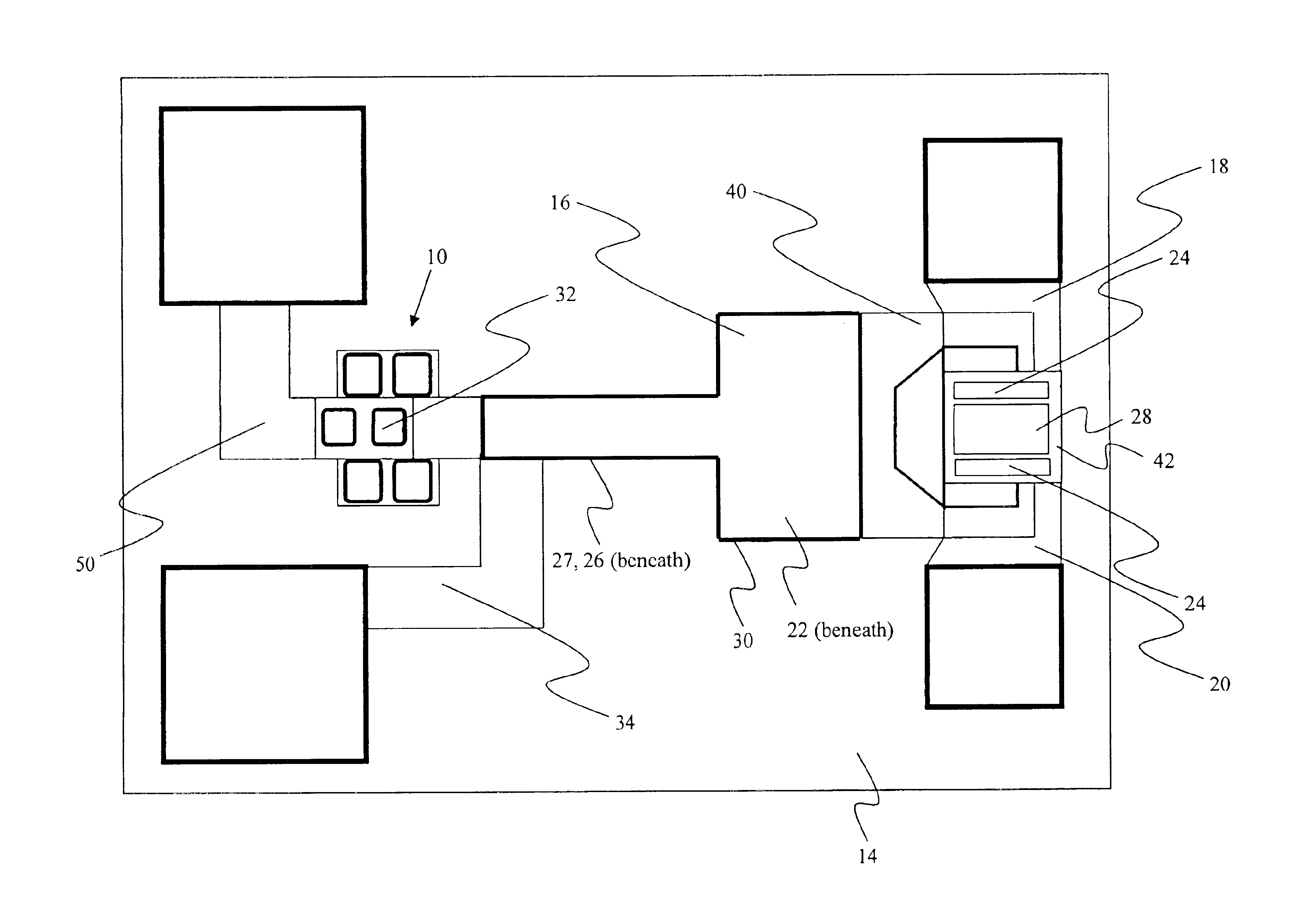

Modules integrating MEMS devices with pre-processed electronic circuitry, and methods for fabricating such modules

A MEMS module is provided comprising at least one MEMS device adhesively bonded to a substrate or wafer, such as a CMOS die, carrying pre-processed electronic circuitry. The at least one MEMS device, which may comprise a sensor or an actuator, may thus be integrated with related control, readout / signal conditioning, and / or signal processing circuitry.An example of a method pursuant to the invention comprises the adhesive bonding of a pre-processed electronics substrate or wafer to a layered structure preferably in the form of a silicon-on-insulator (SOI) substrate. The SOI is then bulk micromachined to selectively remove portions thereof to define the MEMS device. Prior to release of the MEMS device, the device and the associated electronic circuitry are electrically interconnected, for example, by wire bonds or metallized vias.

Owner:TELEDYNE SCI & IMAGING

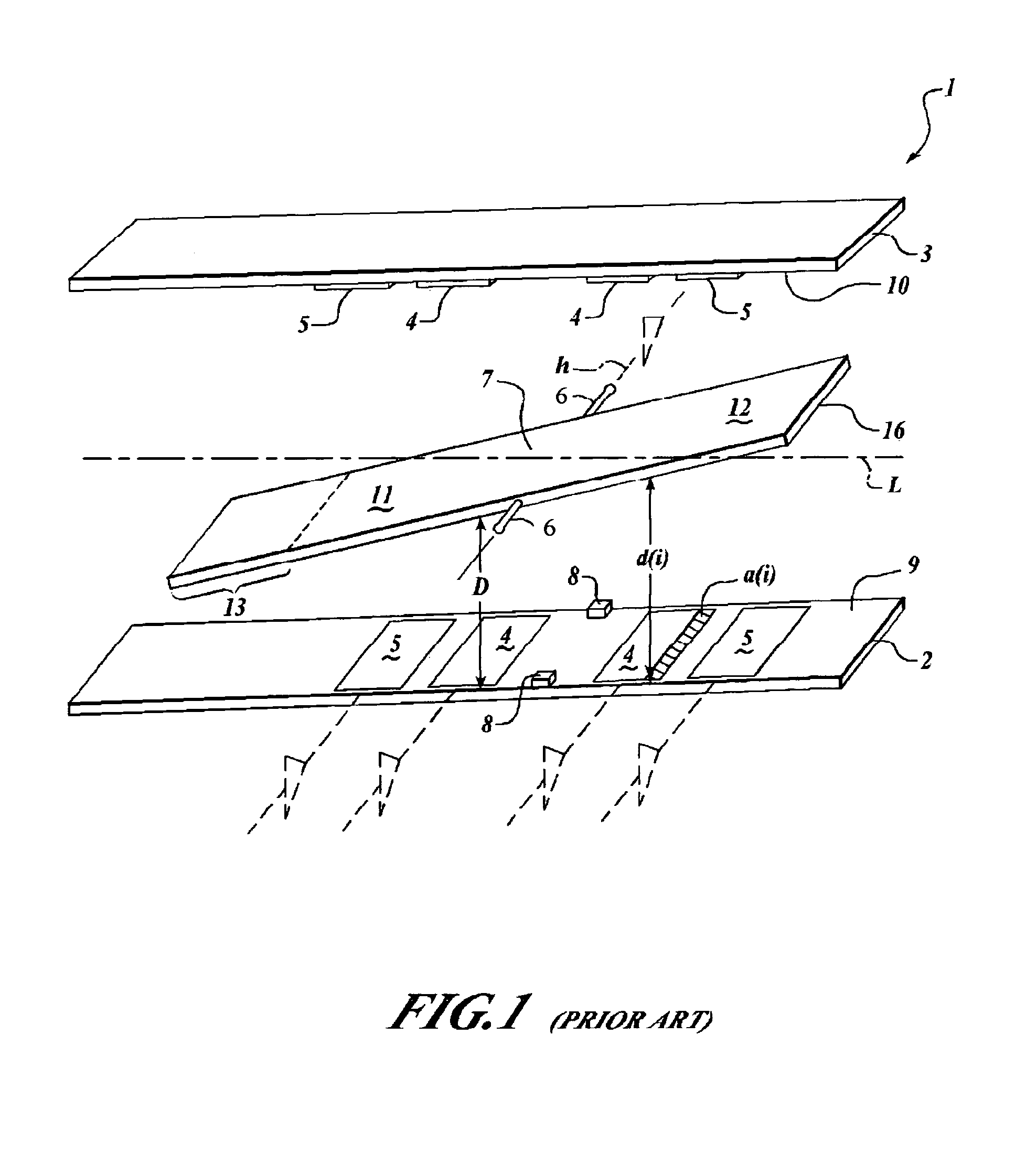

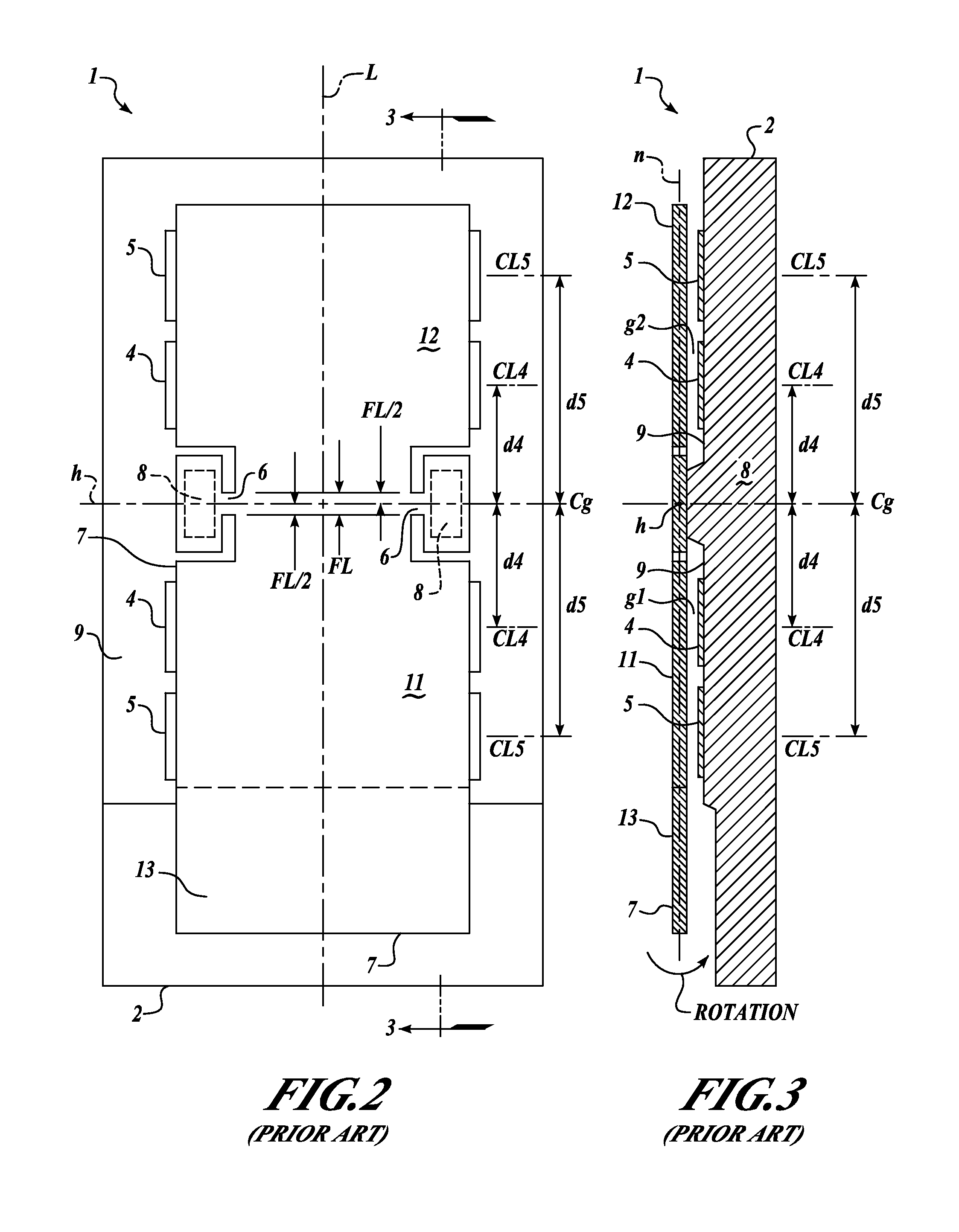

Dynamically balanced capacitive pick-off accelerometer

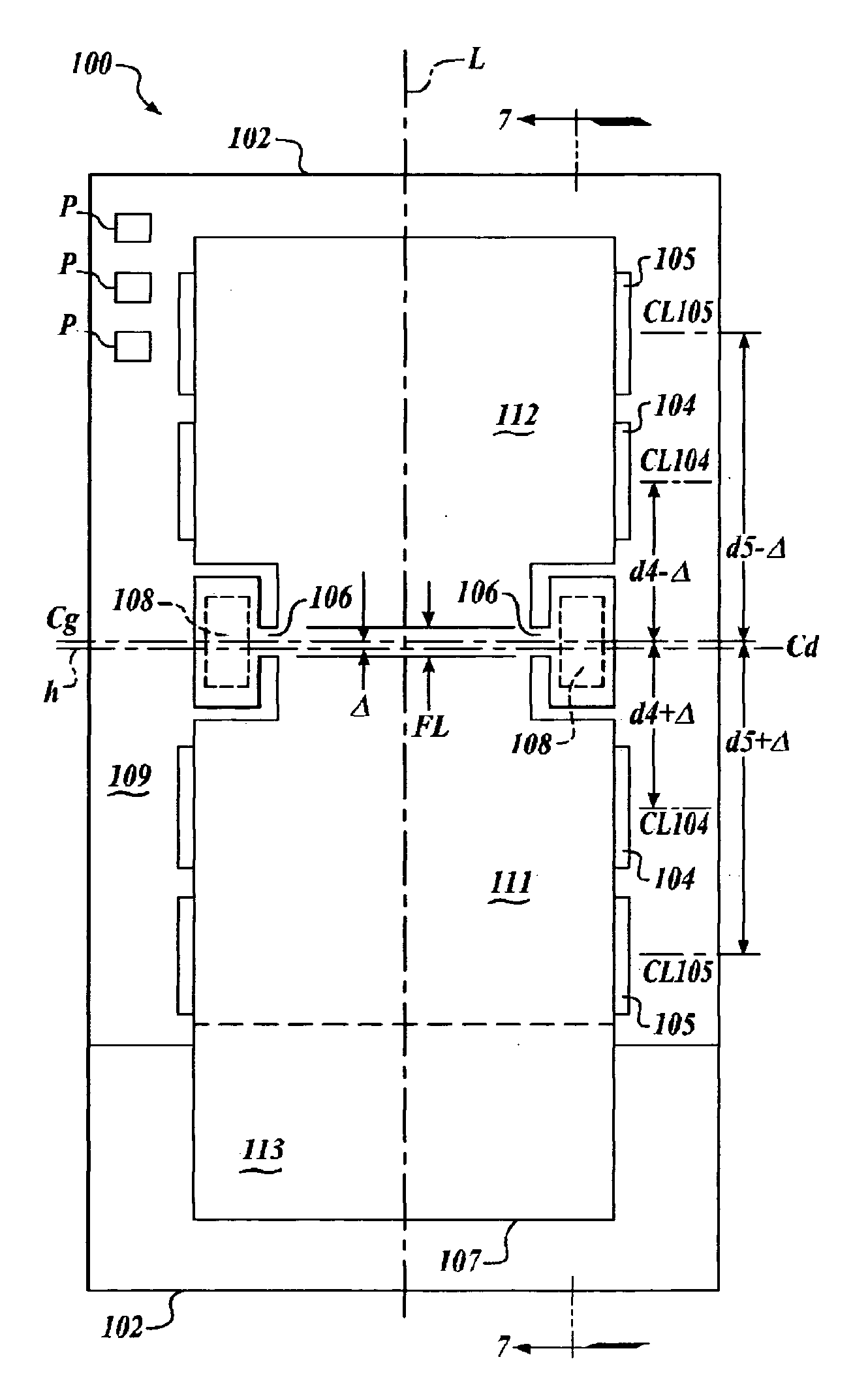

ActiveUS7146856B2Improve the level ofReduce impactAcceleration measurement using interia forcesCapacitor with electrode distance variationAccelerometerDevice form

A Micro Electro-Mechanical System (MEMS) acceleration sensing device formed of a silicon substrate having a substantially planar surface; a pendulous sensing element having a substantially planar surface suspended in close proximity to the substrate planar surface; a flexure suspending the sensing element for motion relative to the substrate planar surface, the flexure having a both static geometric centerline and a dynamic centerline that is offset from the static geometric centerline; and a metal electrode positioned on the substrate surface for forming a capacitor with the pendulous sensing element, the metal electrode being positioned as a function of the dynamic centerline of the flexure.

Owner:HONEYWELL INT INC

Phased array antenna using (MEMS) devices on low-temperature co-fired ceramic (LTCC) substrates

InactiveUS7012327B2Material nanotechnologySemiconductor/solid-state device detailsDielectricElectrical connection

Owner:FOR NAT RES INITIATIVES

Dynamically balanced capacitive pick-off accelerometer

ActiveUS20050268719A1Reducing nonlinearity effect causeImprove the level ofAcceleration measurement using interia forcesCapacitor with electrode distance variationAccelerometerDevice form

A Micro Electro-Mechanical System (MEMS) acceleration sensing device formed of a silicon substrate having a substantially planar surface; a pendulous sensing element having a substantially planar surface suspended in close proximity to the substrate planar surface; a flexure suspending the sensing element for motion relative to the substrate planar surface, the flexure having a both static geometric centerline and a dynamic centerline that is offset from the static geometric centerline; and a metal electrode positioned on the substrate surface for forming a capacitor with the pendulous sensing element, the metal electrode being positioned as a function of the dynamic centerline of the flexure.

Owner:HONEYWELL INT INC

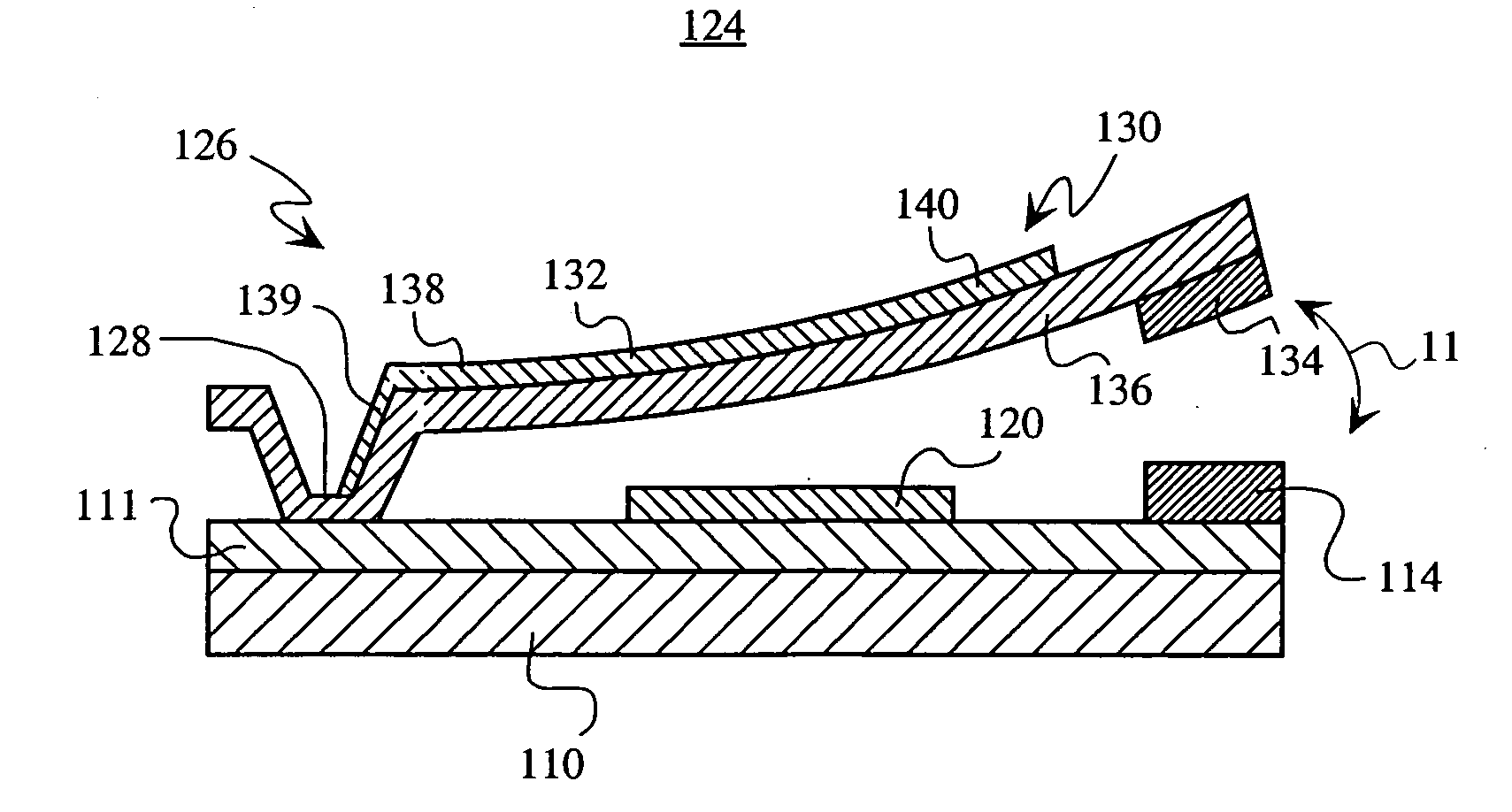

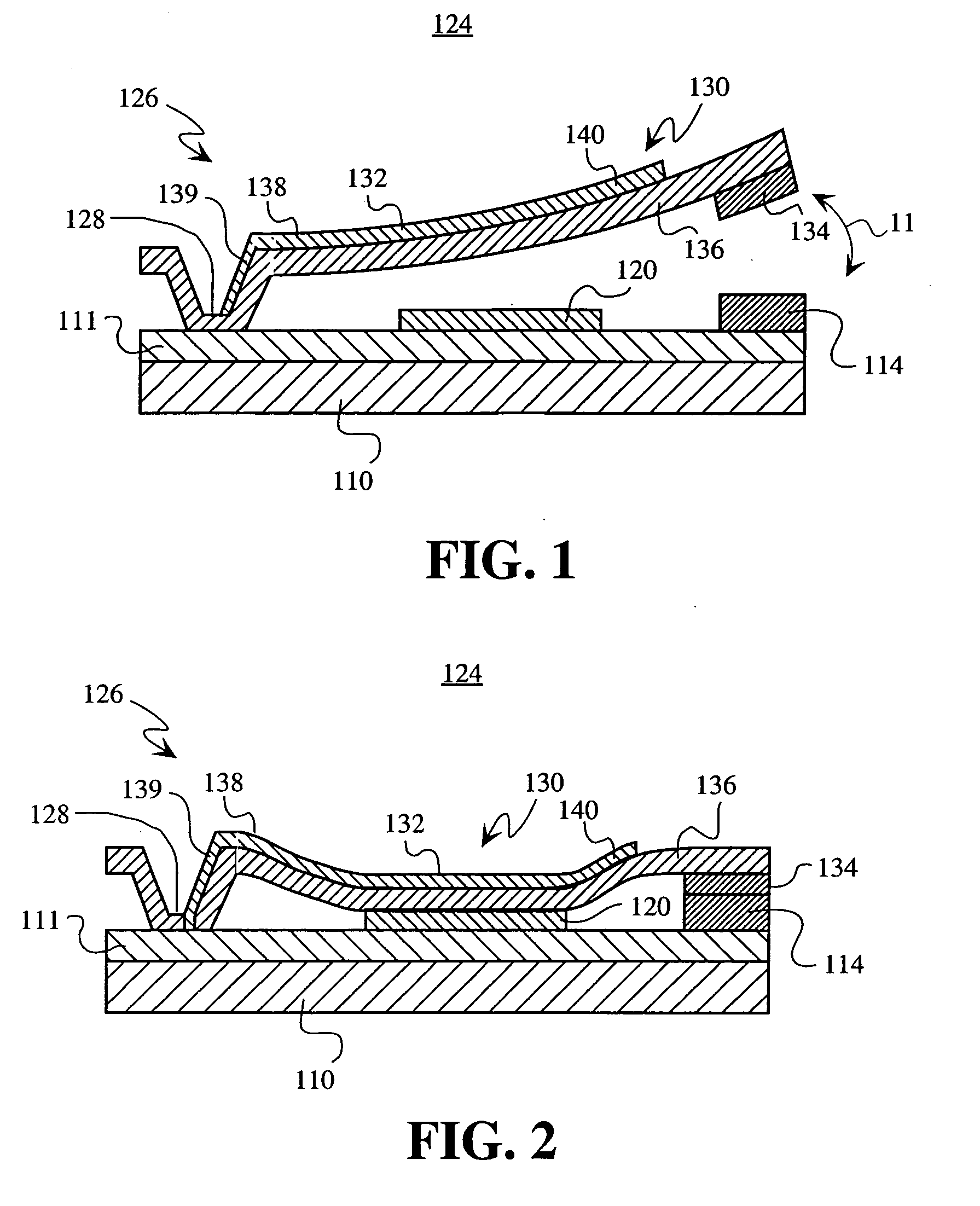

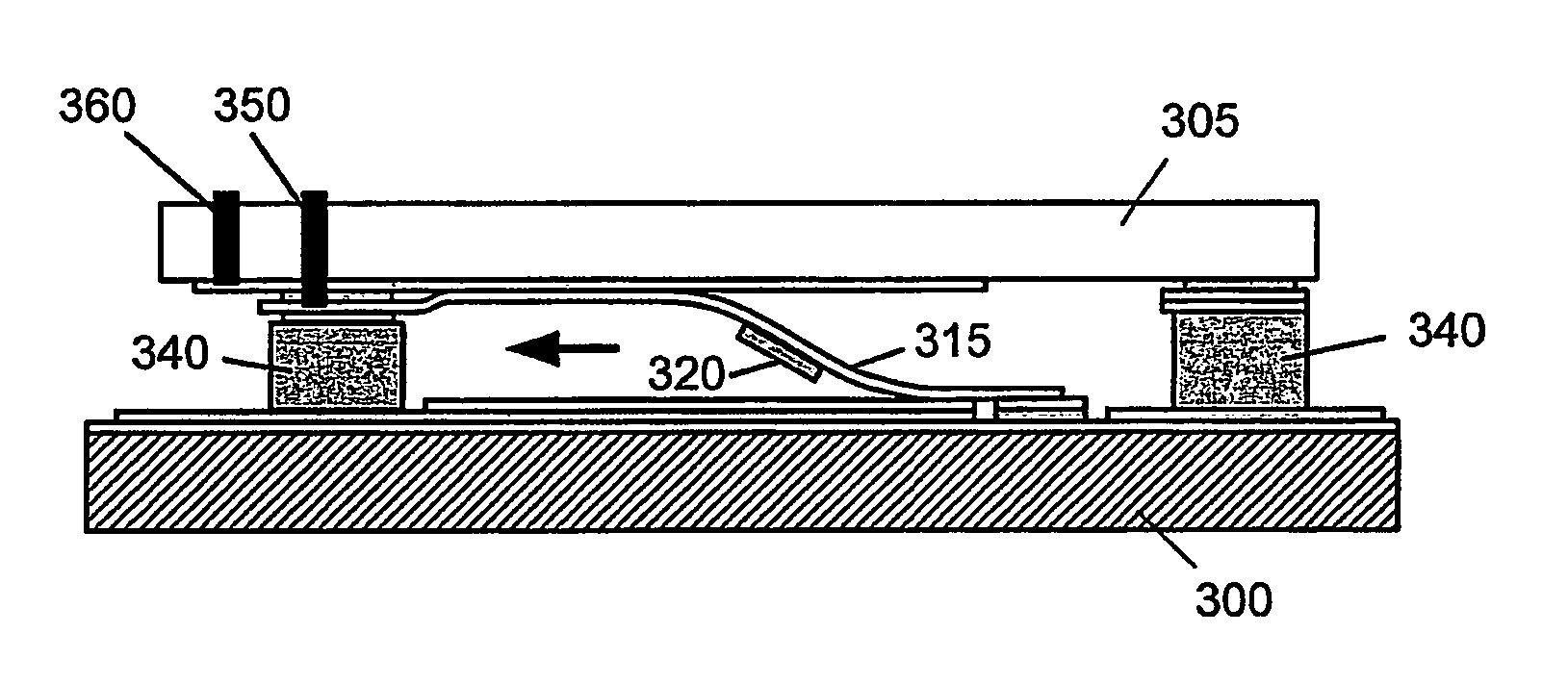

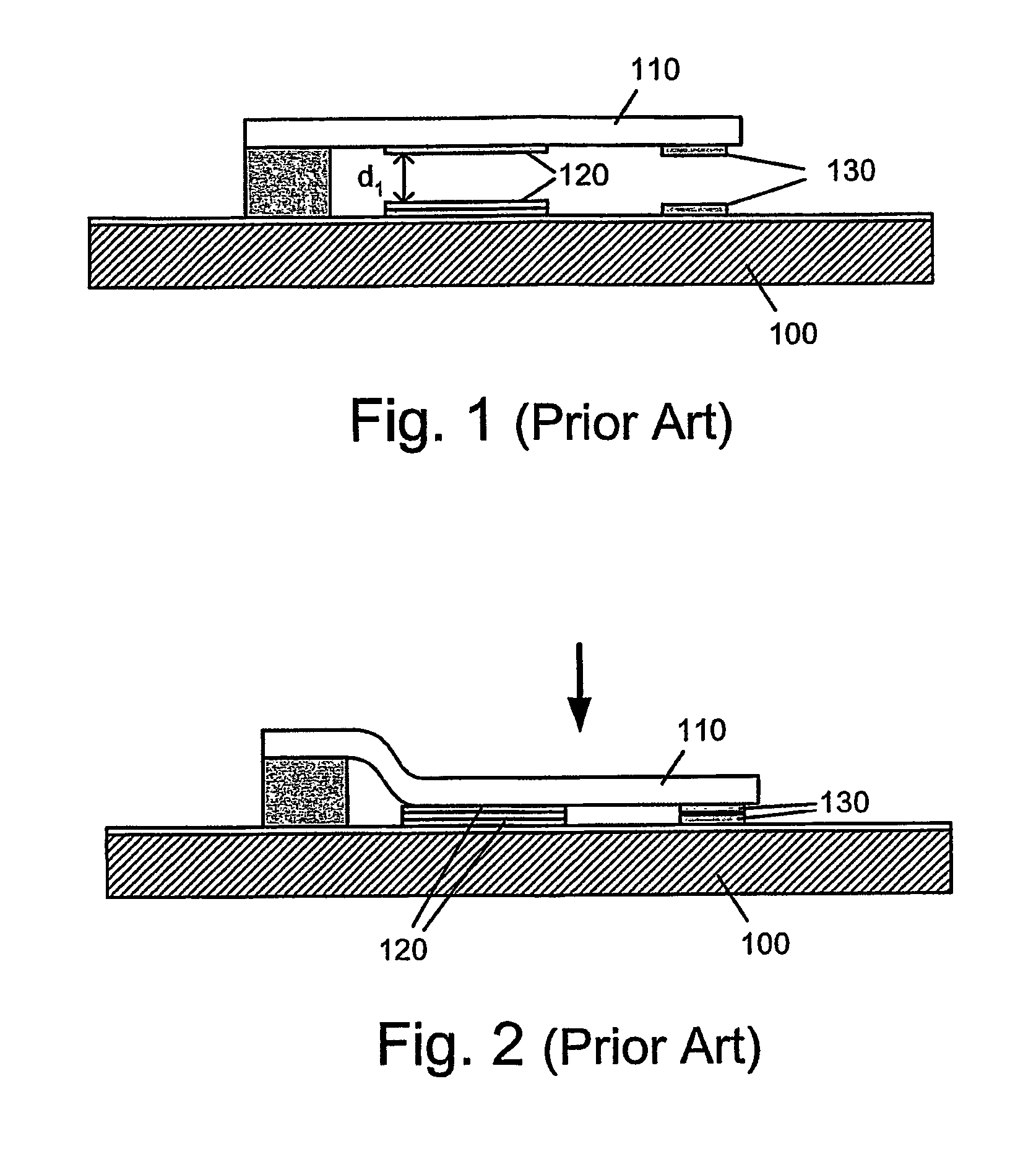

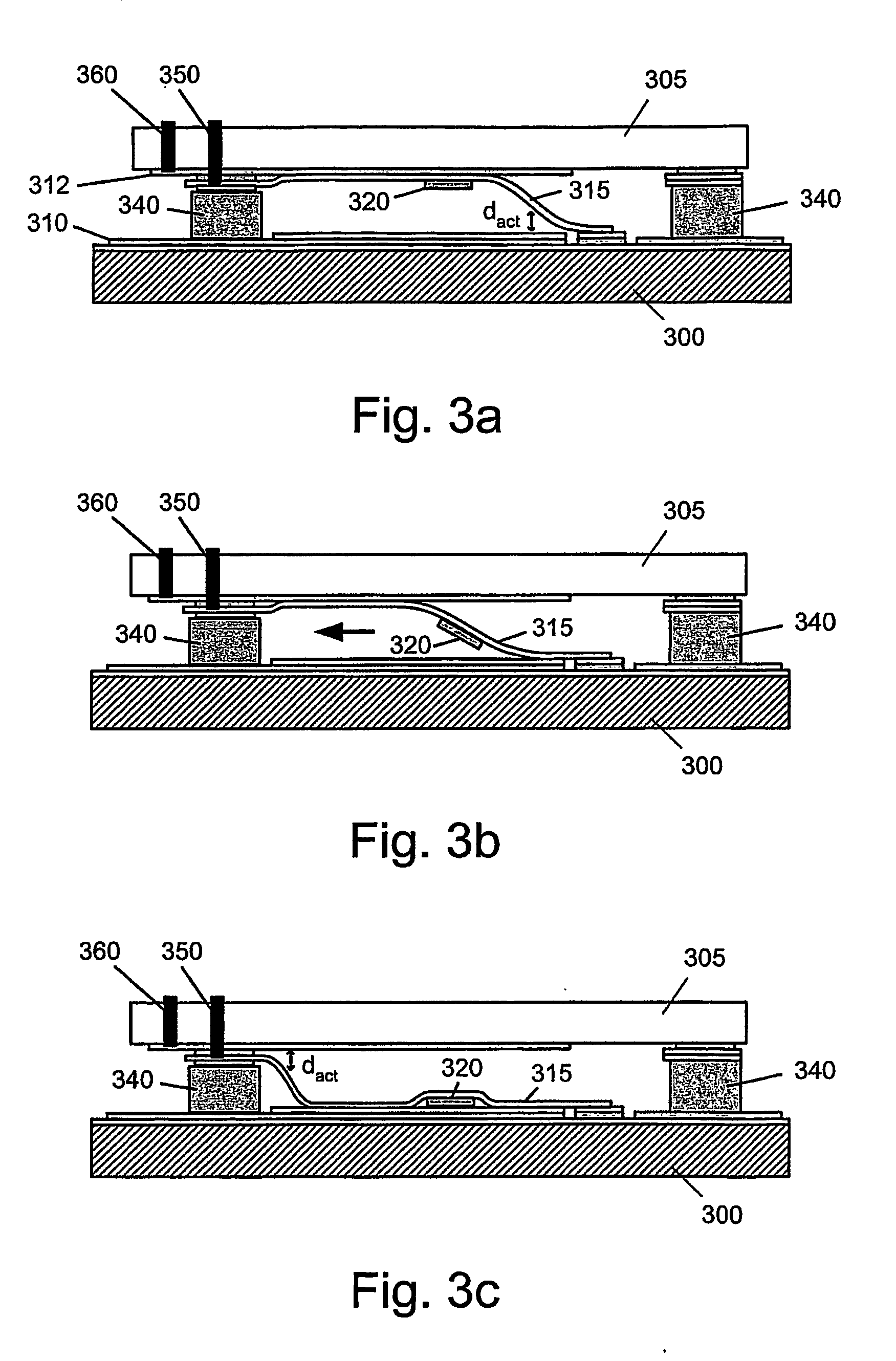

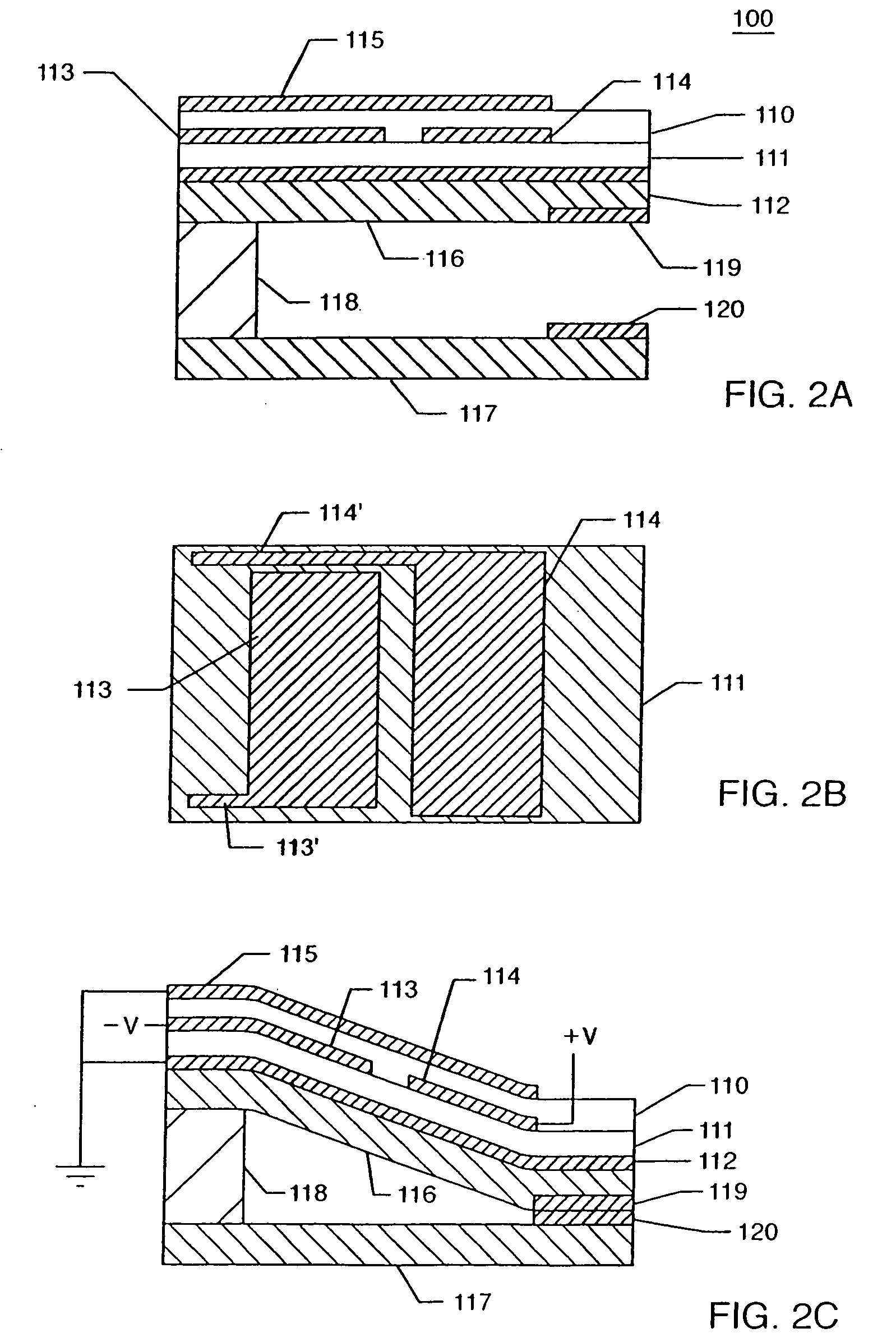

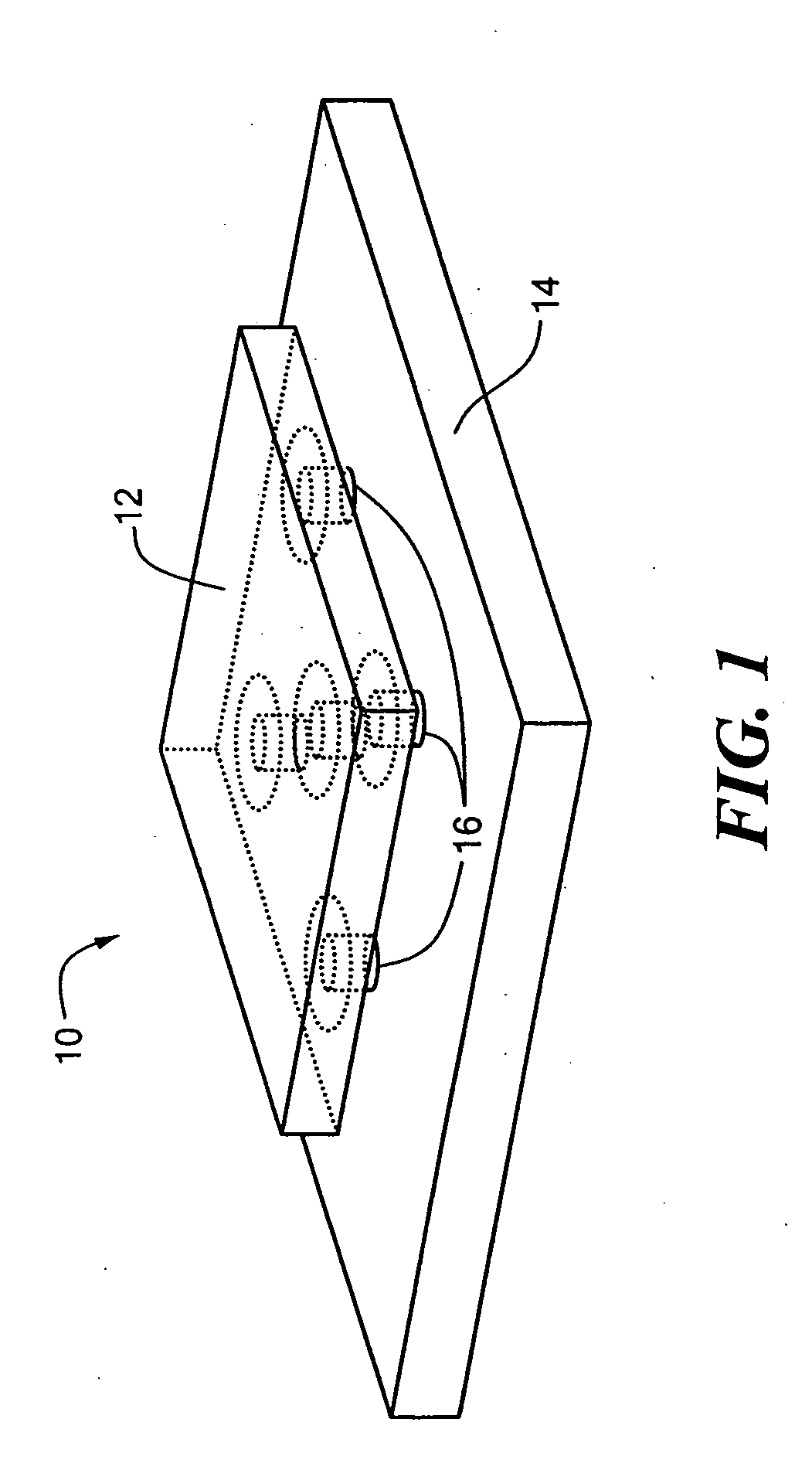

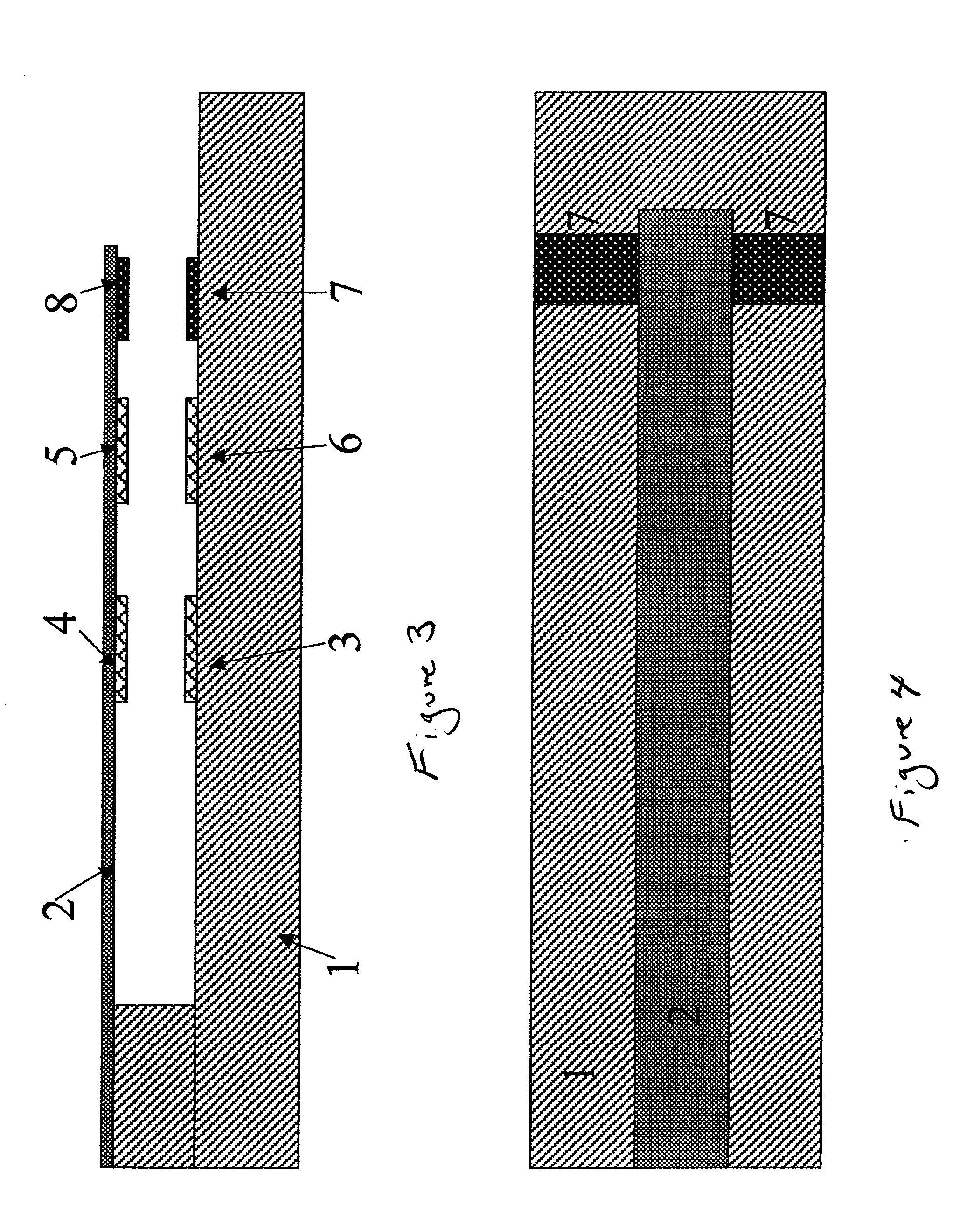

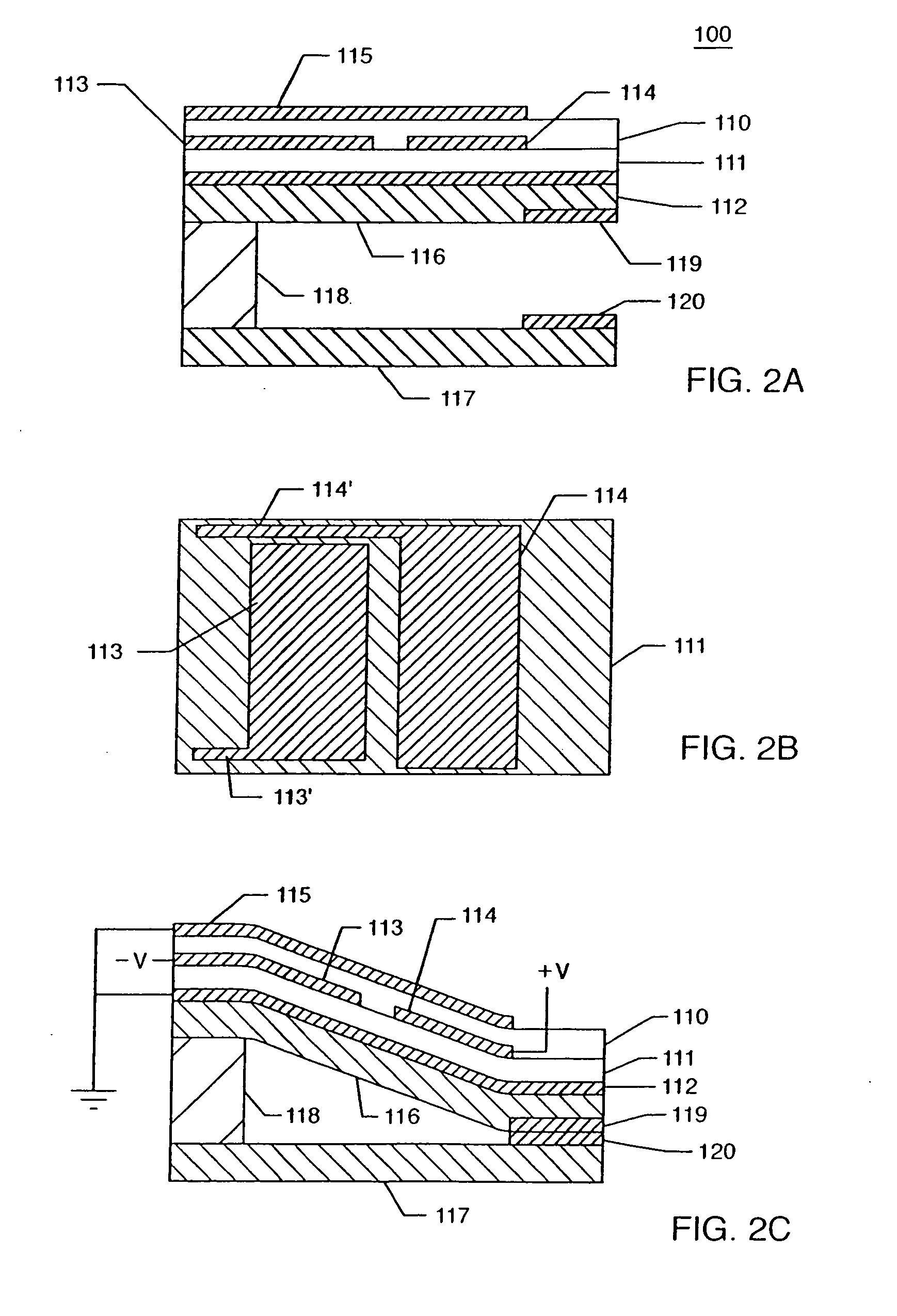

Film Actuator Based Mems Device and Method

InactiveUS20070256917A1Improve electrical isolationReduce the starting voltageElectrostatic/electro-adhesion relaysCapacitor with electrode distance variationEngineeringActuator

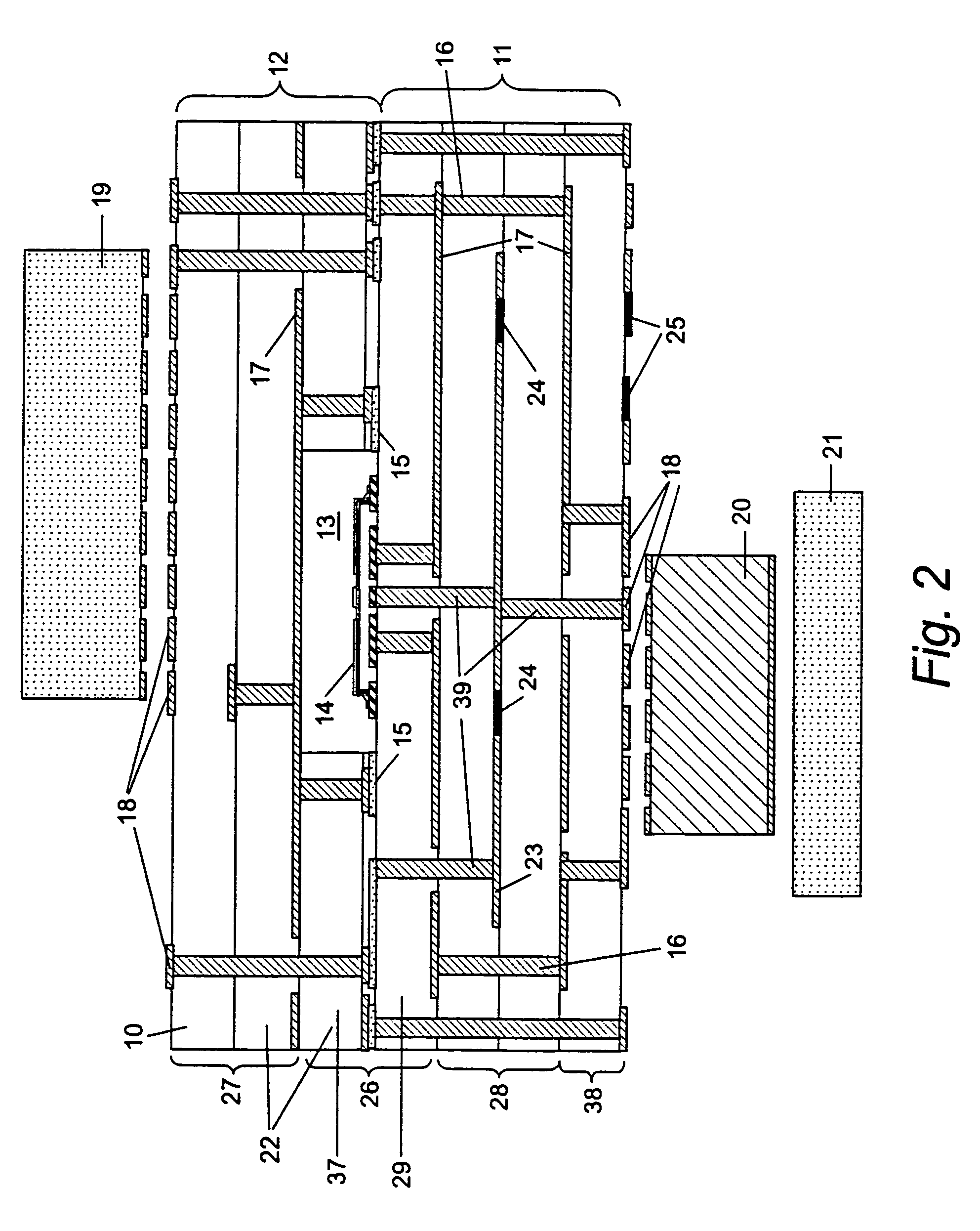

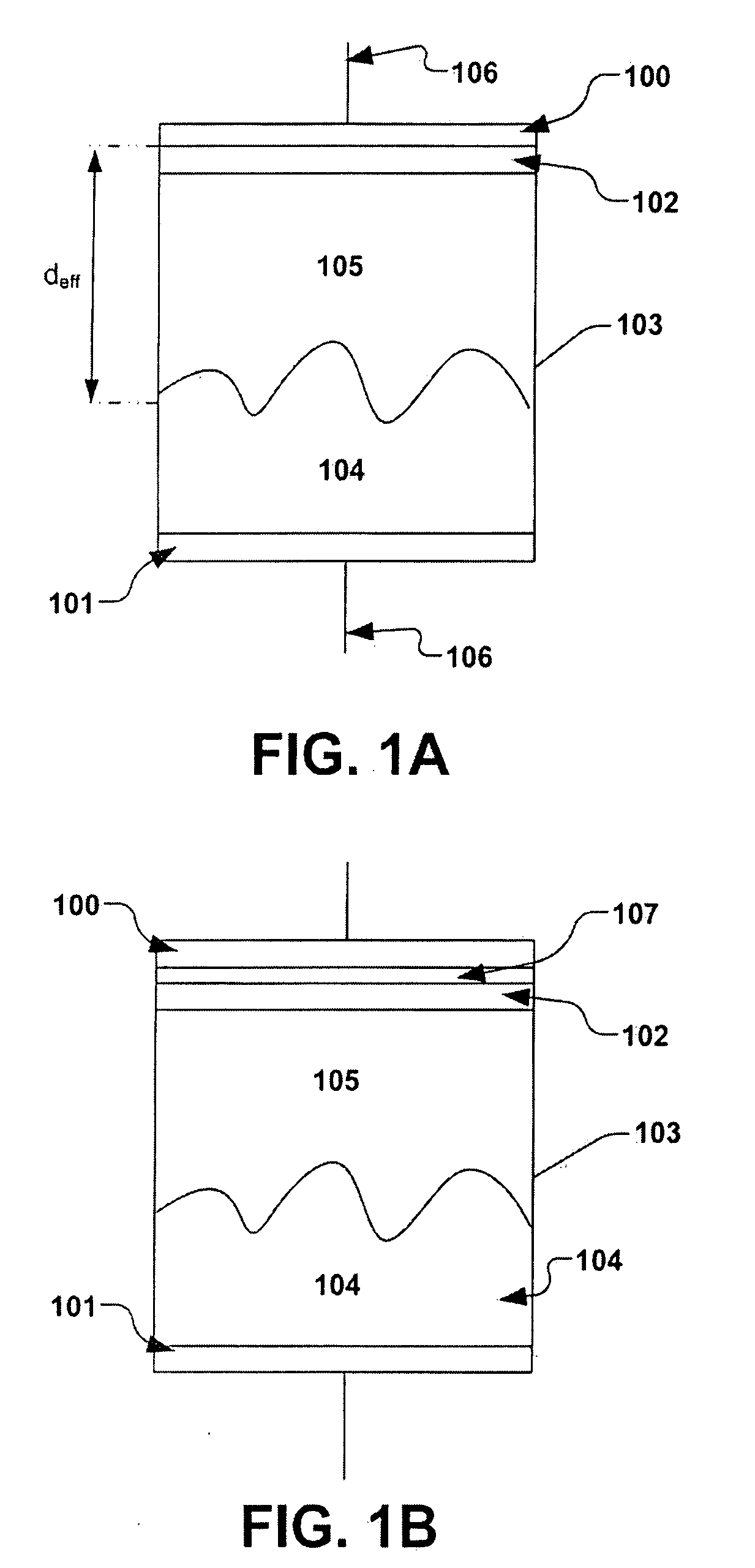

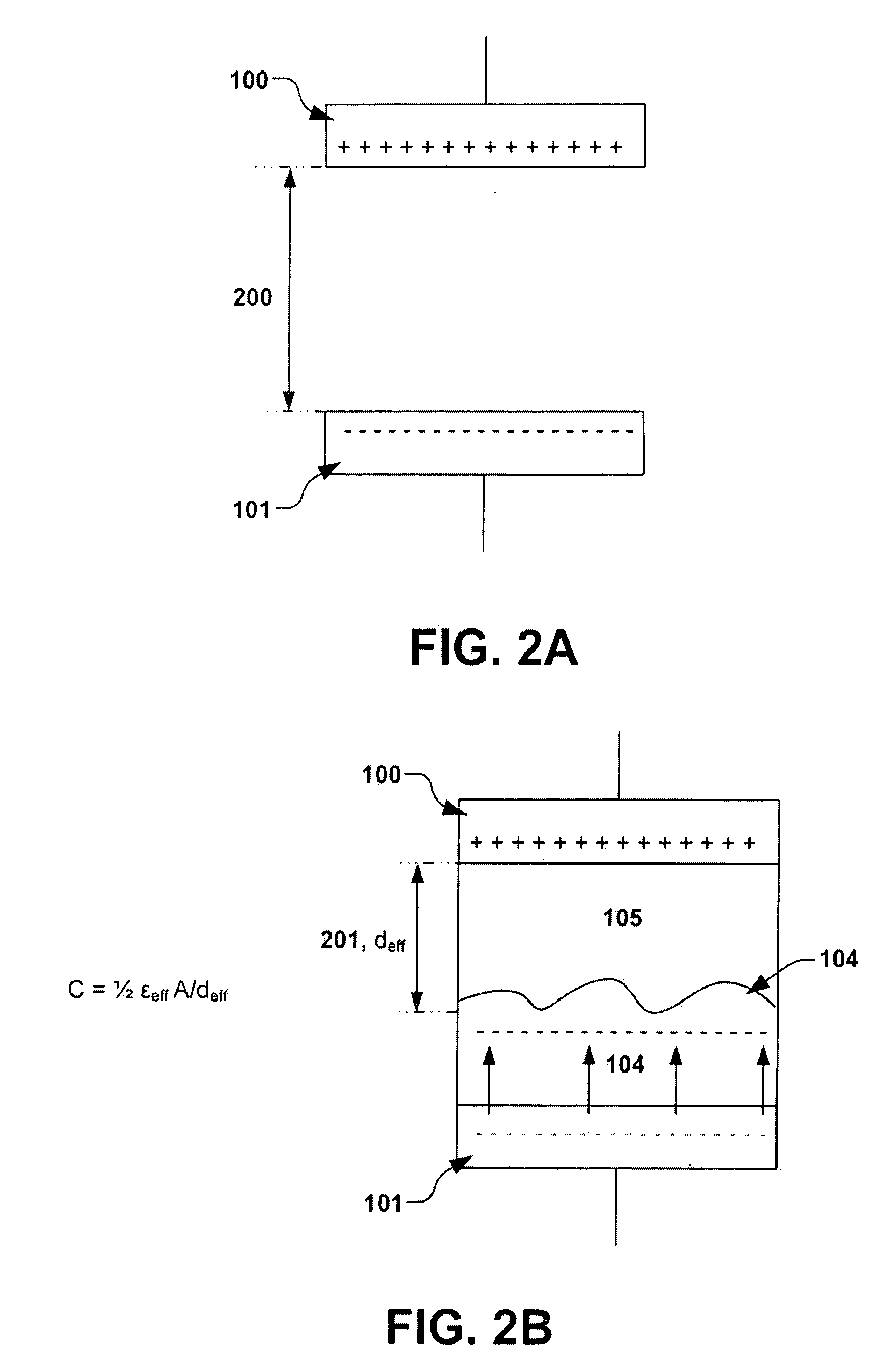

The present invention discloses a Micro-Electro-Mechanical systems (MEMS) device suitable for use in a range of applications from DC, such as switching electrical signal lines, to RF applications such as tunable capacitors and switches. In an embodiment of the invention, the device comprises a bottom substrate and a top substrate separated at a fixed distance from each other. Disposed between the substrates is a flexible S-shaped membrane having an electrode or an electrically conducting electrode layer with one end attached to the top substrate and the other end in contact with the bottom substrate. An electrically conducting contact block is attached to the underside of the membrane actuator for short circuiting a signal line when the switch is in the closed position. When a voltage is applied between the membrane and an electrode layer on the bottom substrate, the membrane is induced by electrostatic force to deflect in a rolling wave-like motion such that the contact block is displaced into contact with the signal line. The device can be actively opened when a voltage is applied between the membrane actuator and a electrode layer on the top substrate causing the contact block to displace upward breaking contact with the signal line. The MEMS switching device is applicable for use in a switch matrix board for automatically switching telephone lines or in RF applications in the form of a tunable capacitor.

Owner:OBERHAMMER JOACHIM +1

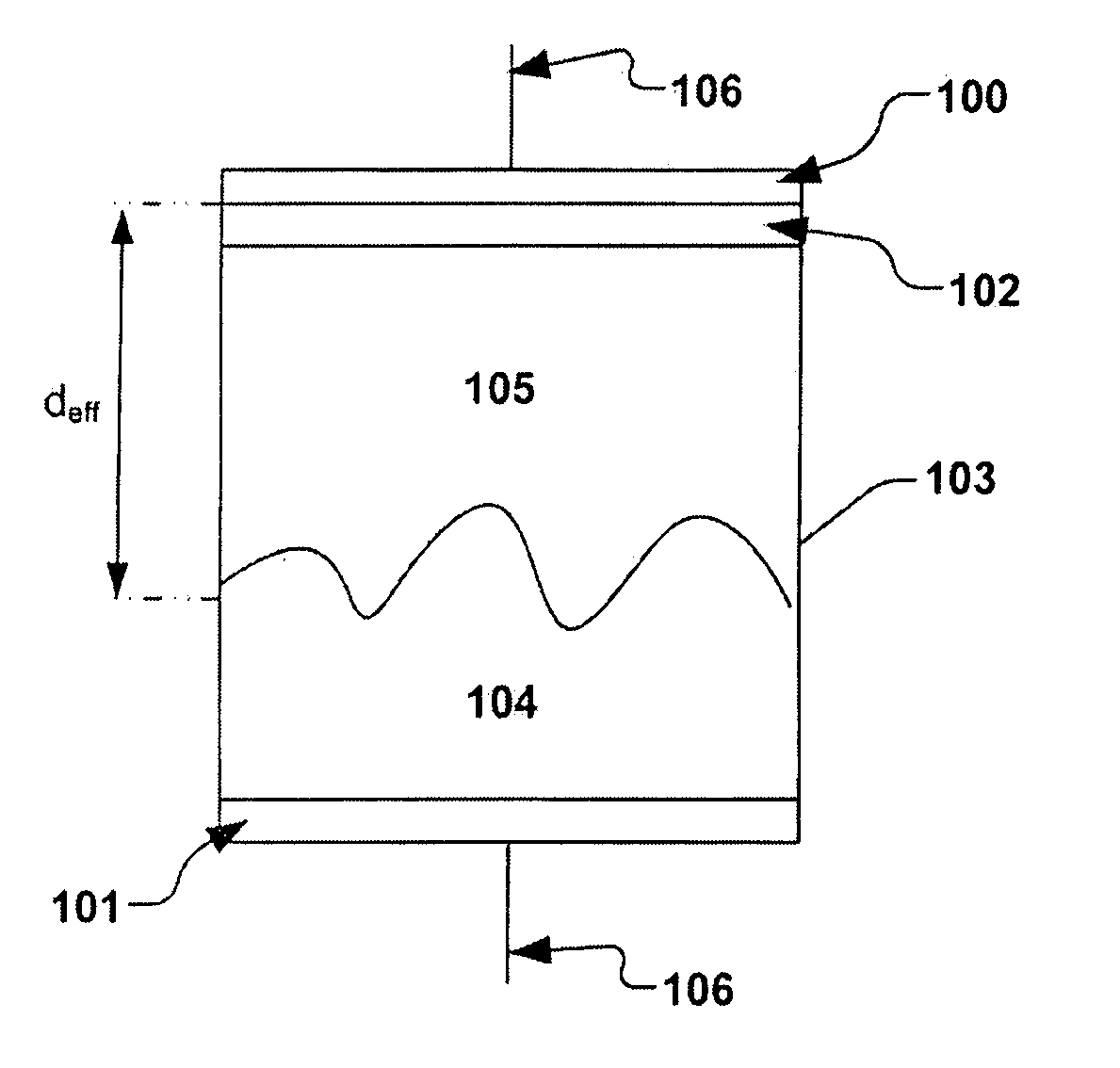

Fluidic electrostatic energy harvester

InactiveUS20090080138A1Mechanically variable capacitor detailsCapacitor with electrode area variationCapacitanceEnergy harvester

One embodiment of the present invention relates to a variable capacitor that operates without moving mechanical parts. In this capacitor electrically conductive electrodes are separated by an enclosed chamber filled with an electrically conductive material. The electrically conductive material can freely vary its position within the chamber. The capacitance of the device will vary as position of the conductive material changes due to external mechanical motion (ex: rotation vibration, etc.) of the device. Other embodiments of this device are also disclosed.

Owner:INFINEON TECH AG

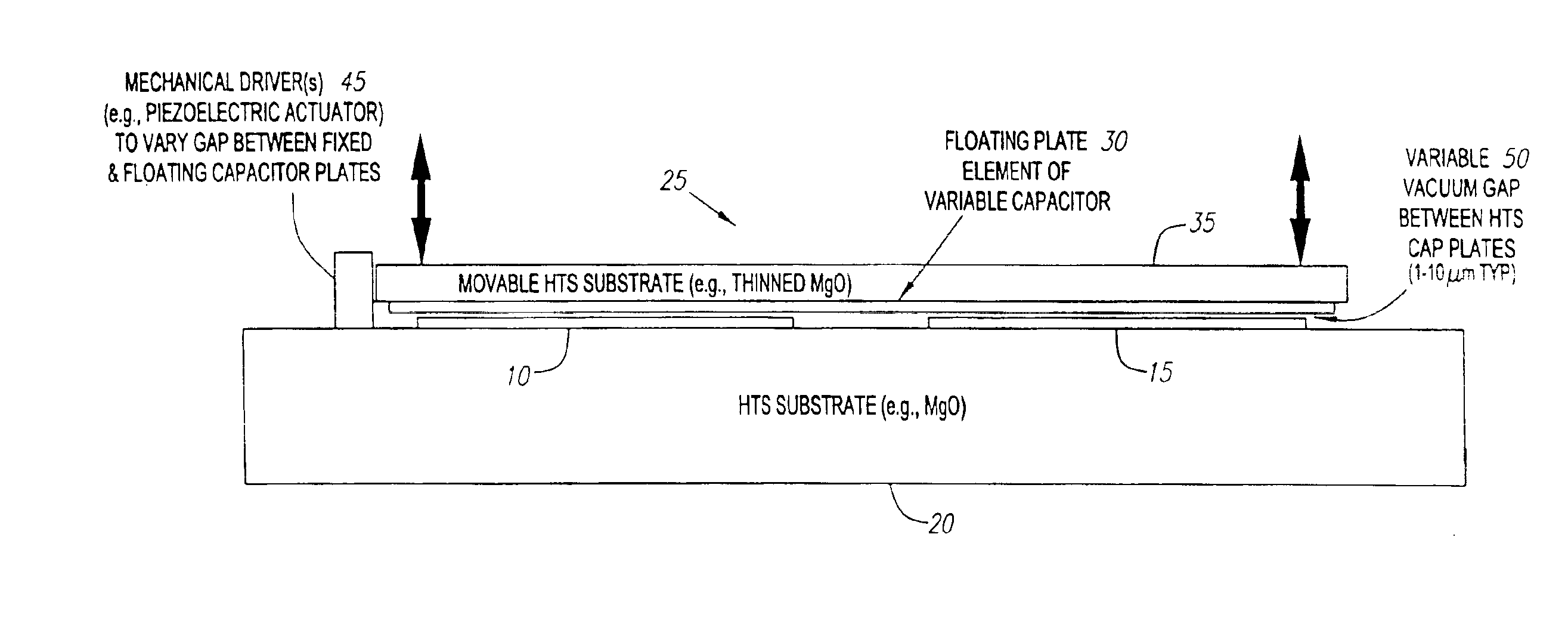

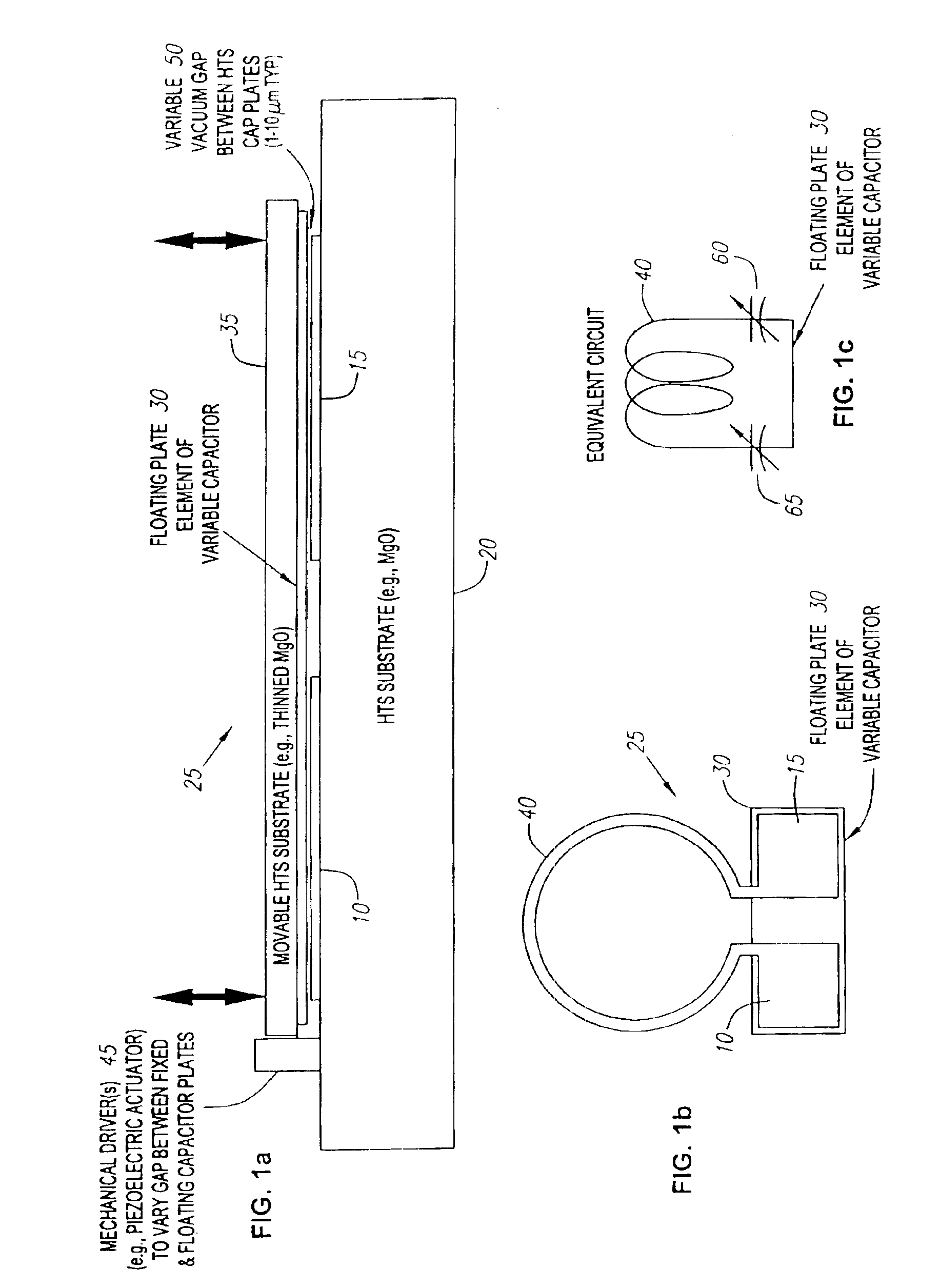

High temperature superconducting tunable filter with an adjustable capacitance gap

InactiveUS6898450B2Increase speedLow microphonicsMultiple-port networksSuperconductors/hyperconductorsCapacitanceHigh temperature superconducting

Owner:SUPERCONDUCTOR TECHNOLOGIES INC

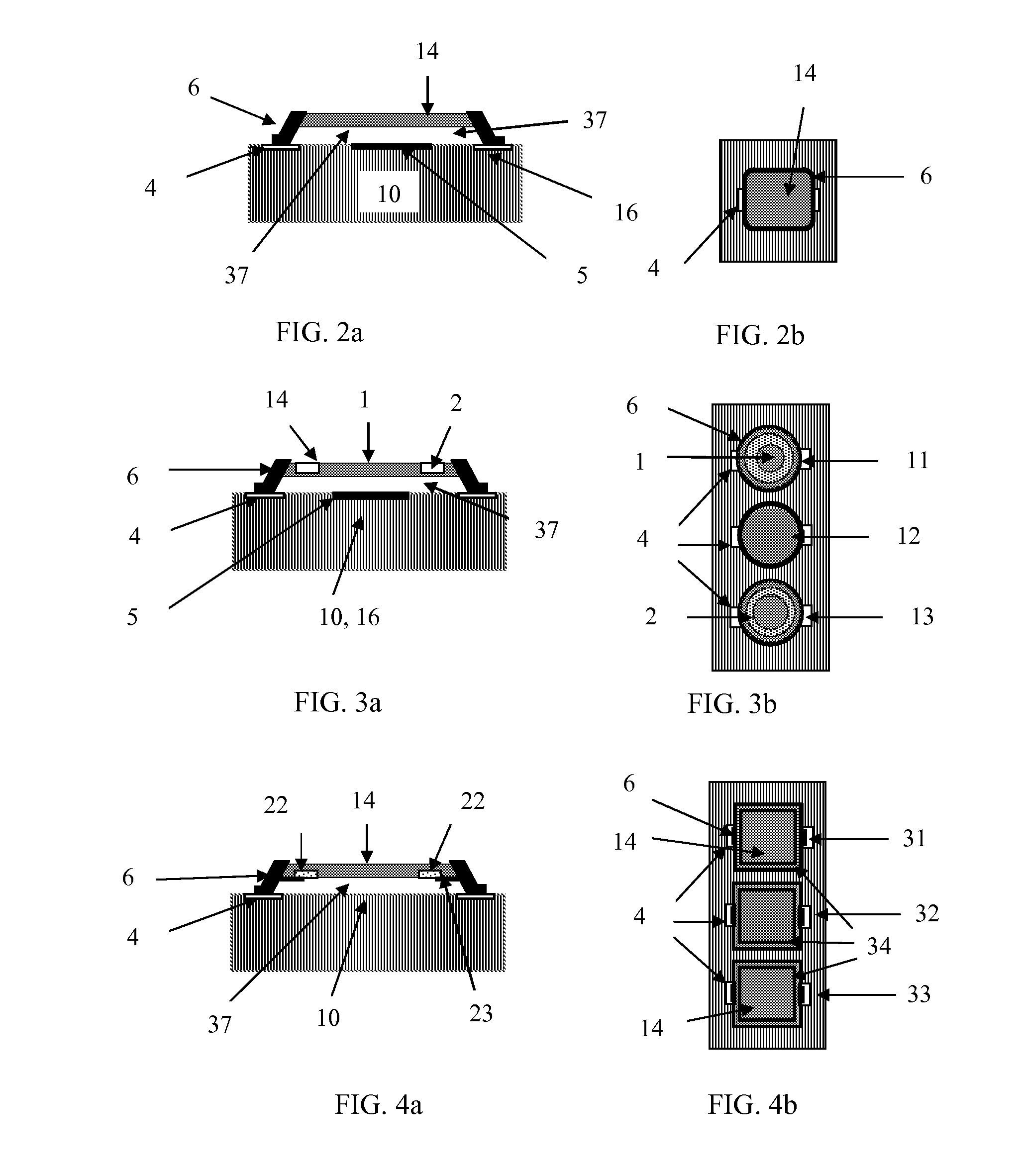

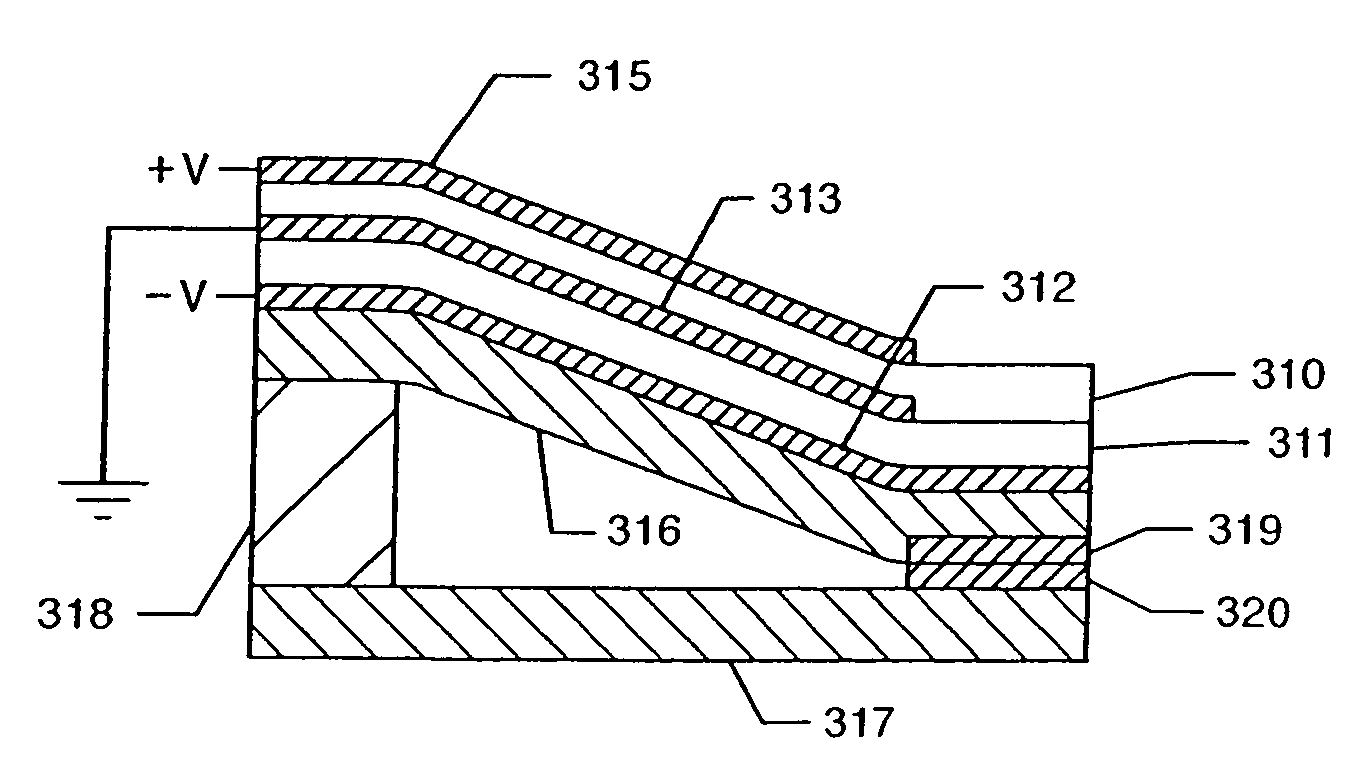

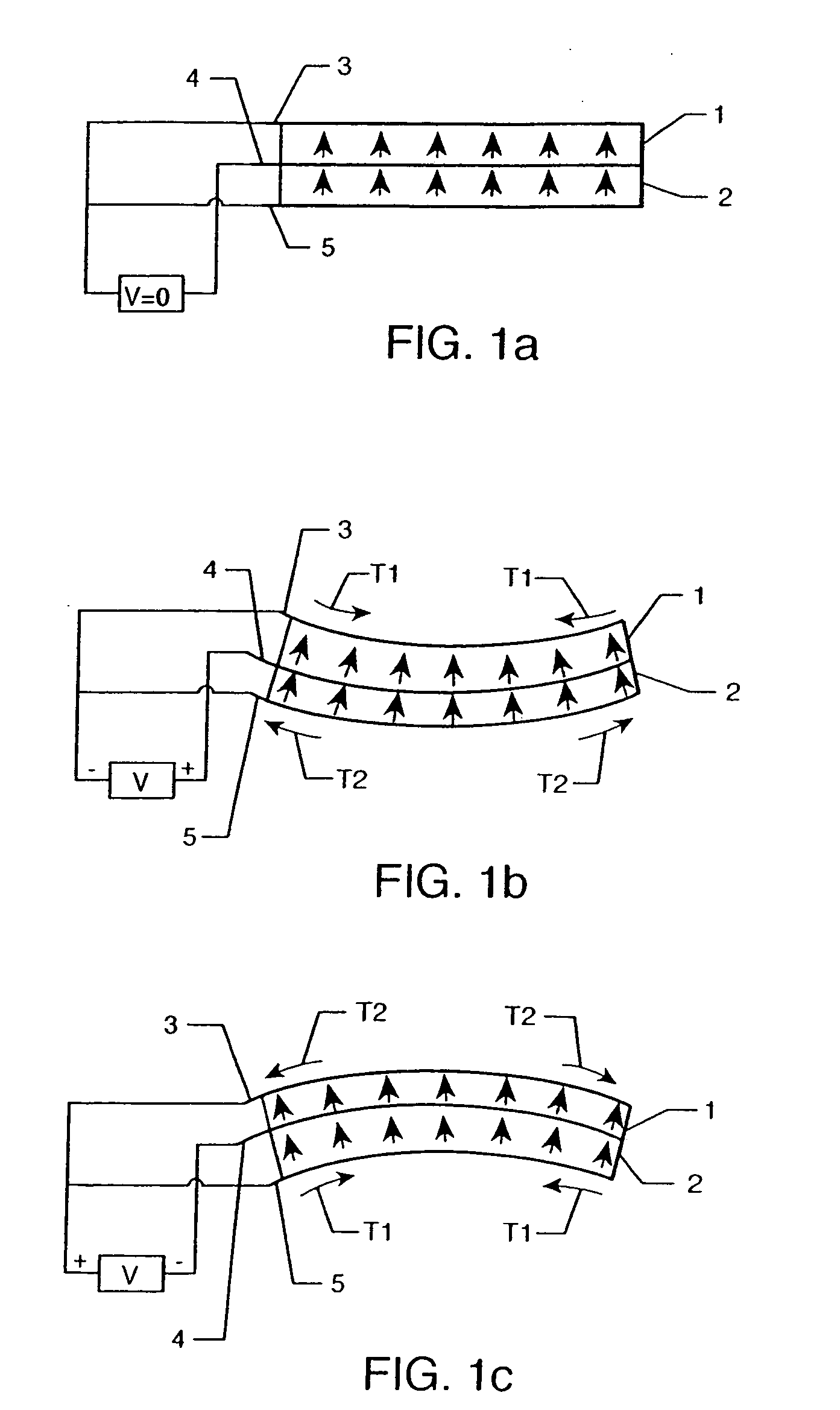

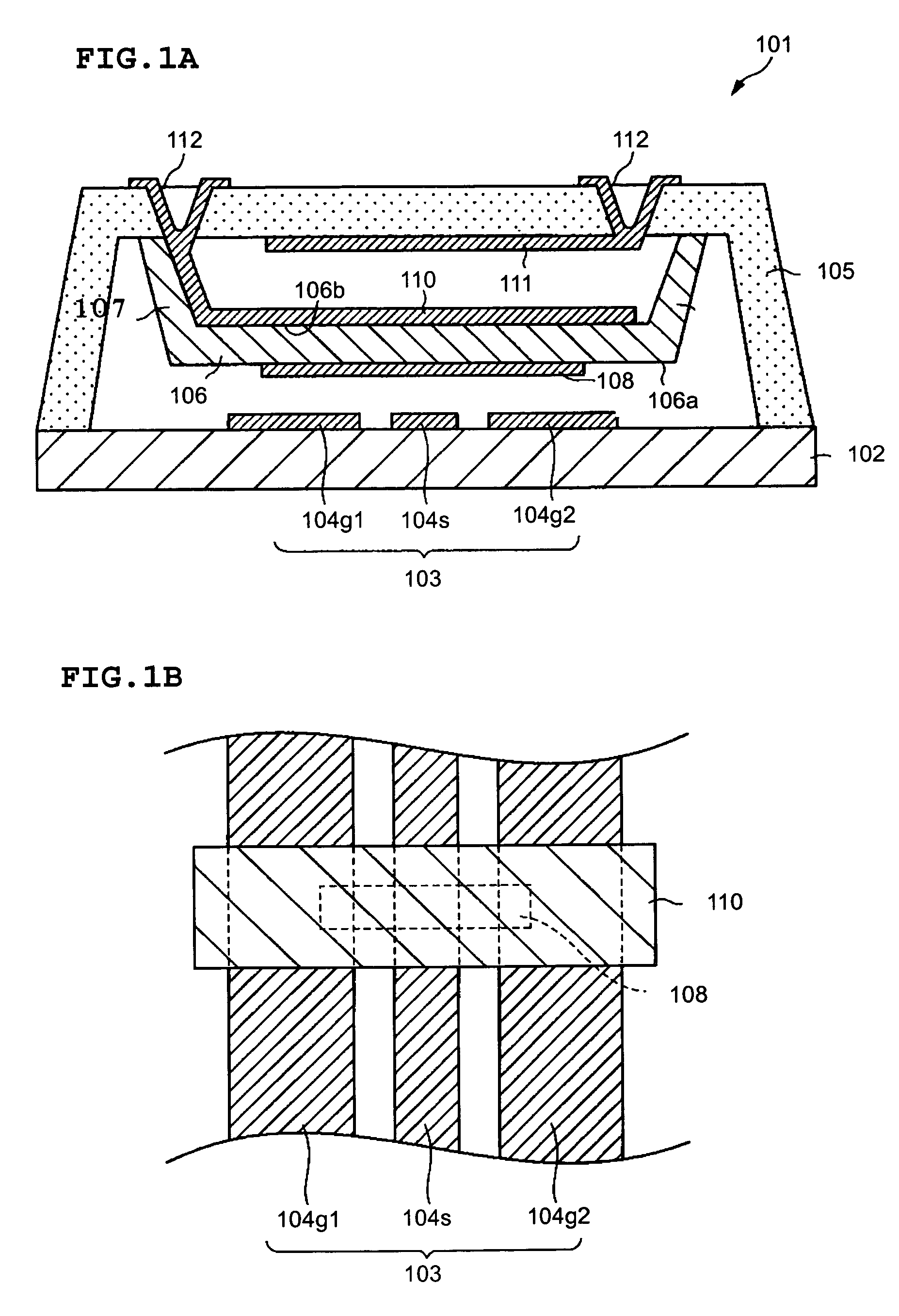

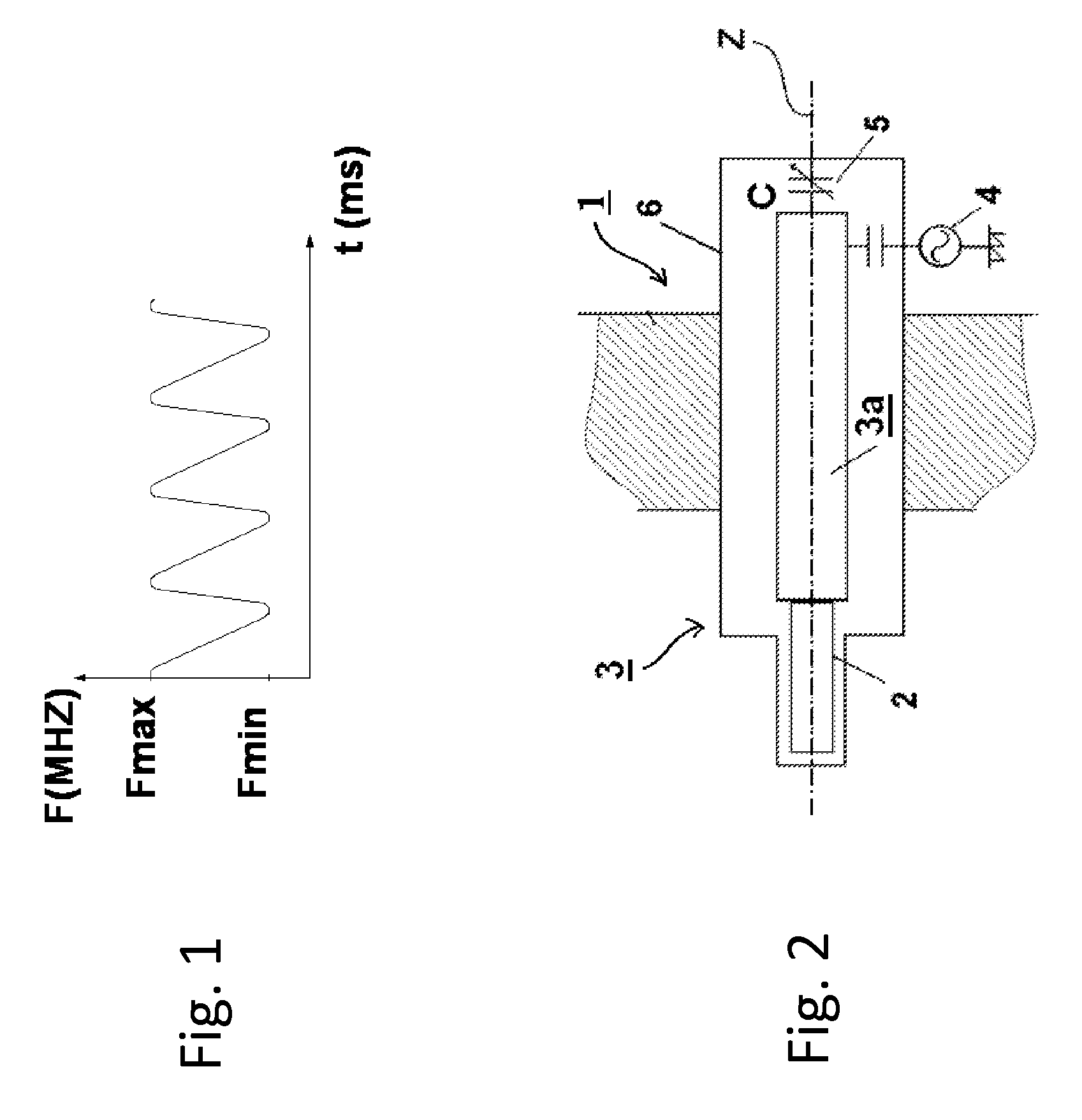

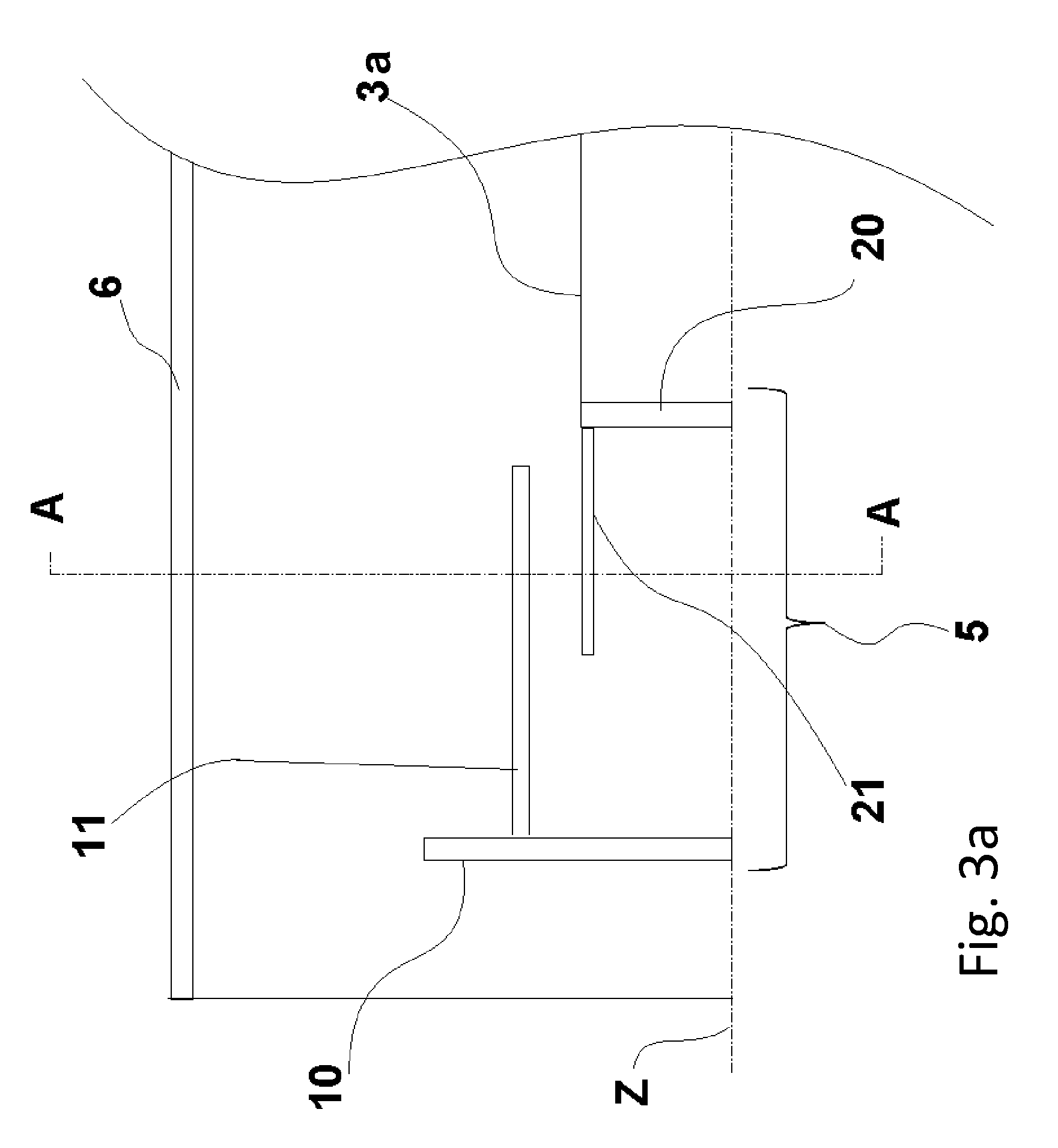

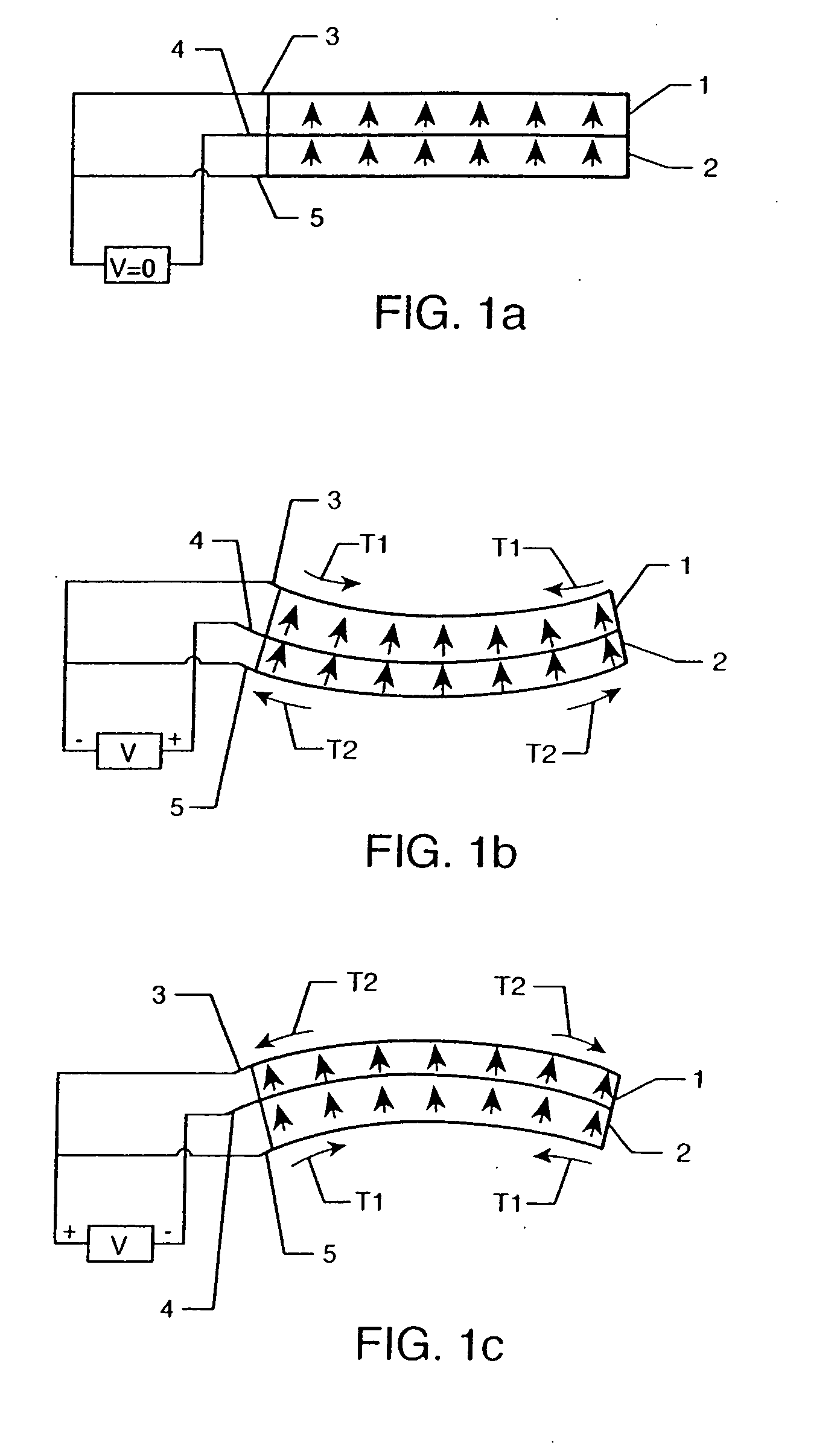

Piezoelectric switch for tunable electronic components

InactiveUS20050127792A1Reduce the starting voltageReduce horizontal sizePiezoelectric/electrostriction/magnetostriction machinesElectrostatic/electro-adhesion relaysElectricityContact pad

A piezoelectric switch for tunable electronic components comprises piezoelectric layers, metal electrodes alternated with the layers and contact pads. Cross voltages are applied to the electrodes, in order to obtain an S-shaped deformation of the switch and allow contact between the contact pads. Additionally, a further electrode can be provided on a substrate where the switch is fabricated, to allow an additional electrostatic effect during movement of the piezoelectric layers to obtain contact between the contact pads. The overall dimensions of the switch are very small and the required actuation voltage is very low, when compared to existing switches.

Owner:HRL LAB

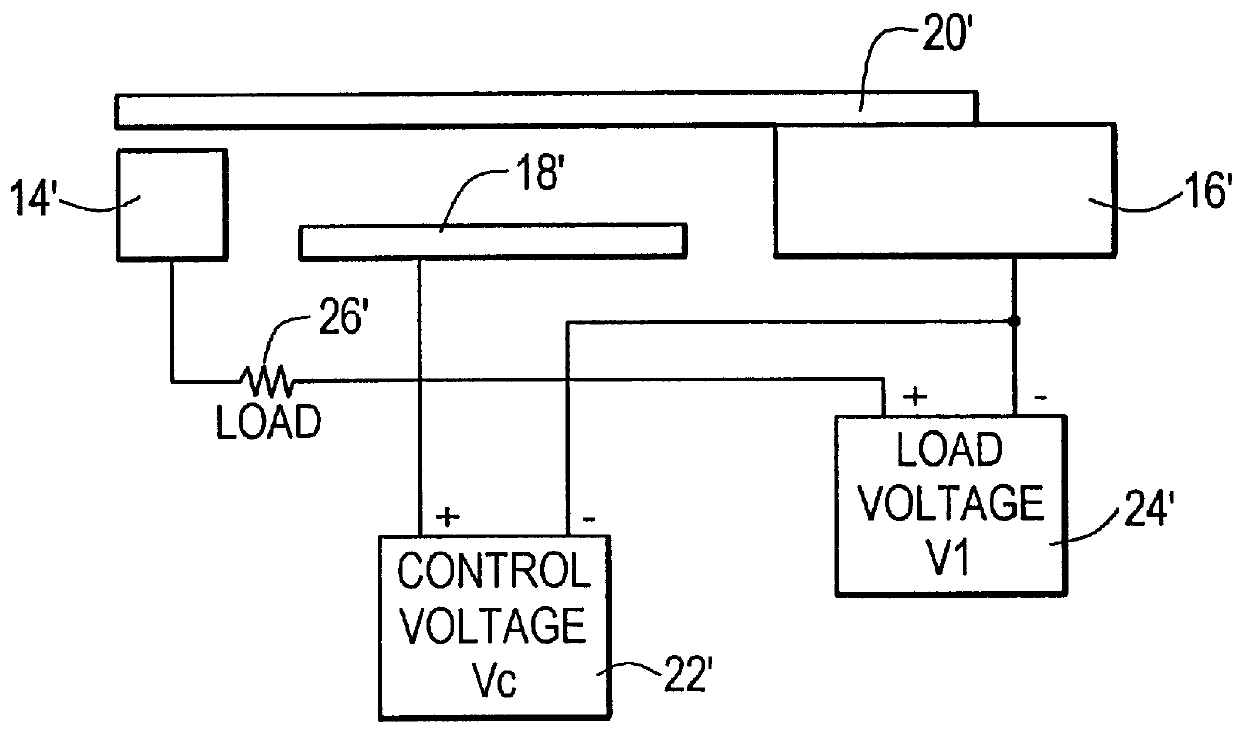

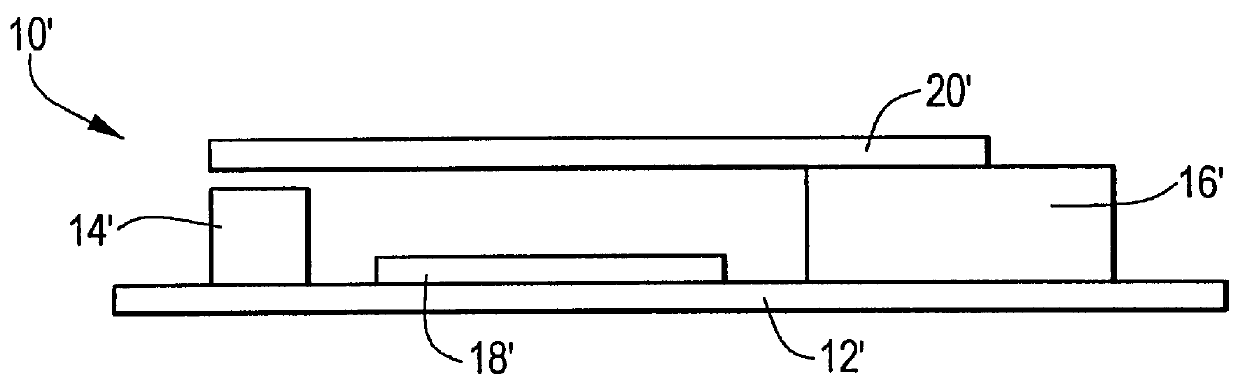

Resonant operation of MEMS switch

InactiveUS6744338B2Reduce problemsReduces stictionBatteries circuit arrangementsBoards/switchyards circuit arrangementsEngineeringVoltage

A switch arrangement includes a MEMS switch connected to a voltage supply system. The MEMS switch has a mechanical resonant frequency. The voltage supply system has a capability for supplying a voltage with a frequency corresponding to the mechanical resonant frequency of the switch. A method includes providing a MEMS switch including a movable part which has a mechanical resonant frequency, and then supplying an AC voltage to the movable part. The AC voltage has a frequency corresponding to the mechanical resonant frequency of the movable part.

Owner:GLOBALFOUNDRIES U S INC

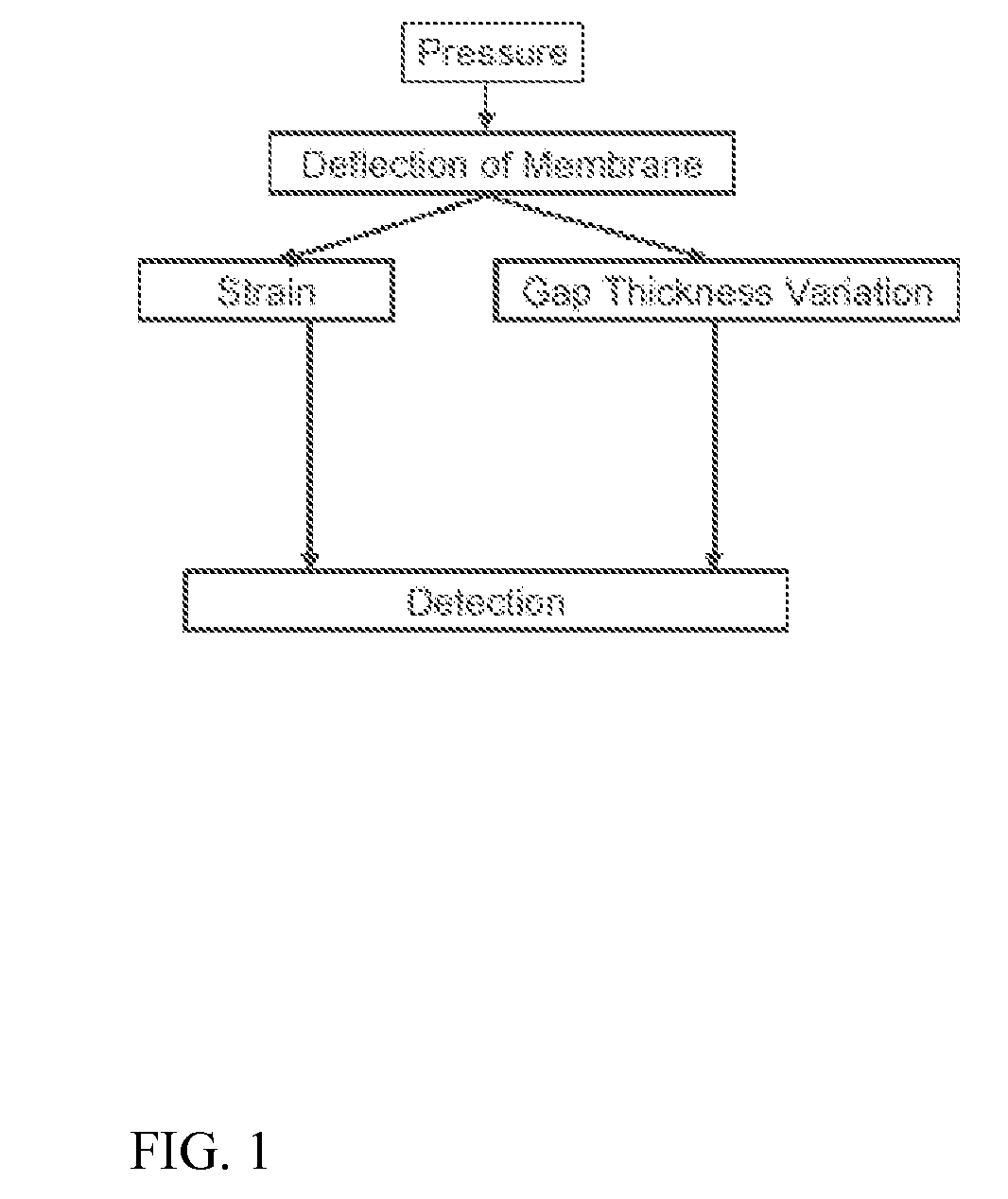

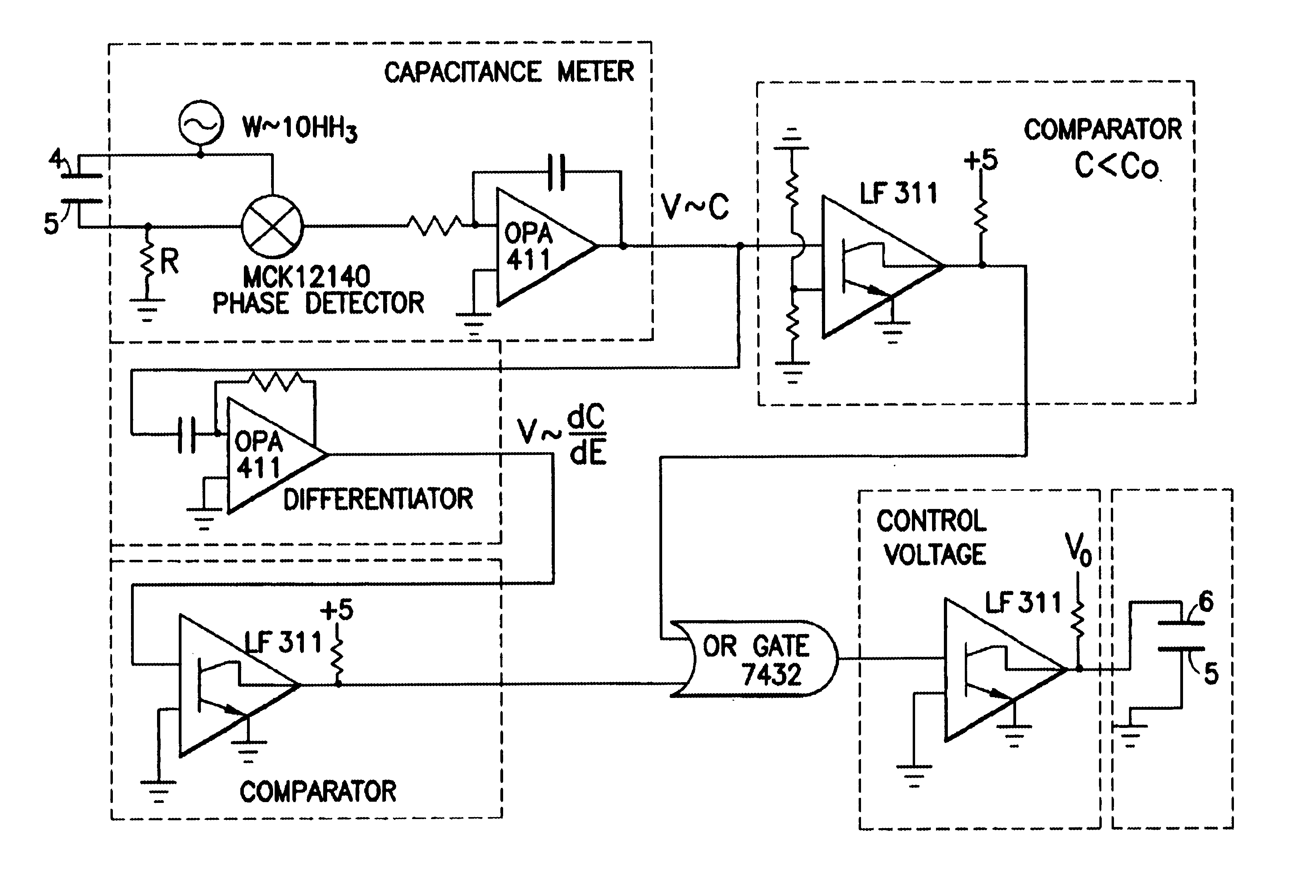

Sensor system

ActiveUS20060180896A1Quality improvementCapacitor with electrode distance variationFluid pressure measurement by electric/magnetic elementsEngineeringSensor system

Rather than increasing the mass of the structure, the structure in a sensor system suspends its substrate from some mechanical ground. Motion of the substrate relative to the mechanical ground thus provides the movement information. To those ends, the sensor system includes a base, a substrate, and a flexible member suspended from at least a portion of the substrate. At least a portion of the flexible member is capable of moving relative to at least a portion of the substrate. In addition, the flexible member is secured to the base, thus causing the substrate to be movable relative to the base. Moreover, the mass of the substrate is greater than the mass of the flexible member. The substrate and flexible member are configured to interact to produce a motion signal identifying movement of the base.

Owner:ANALOG DEVICES INC

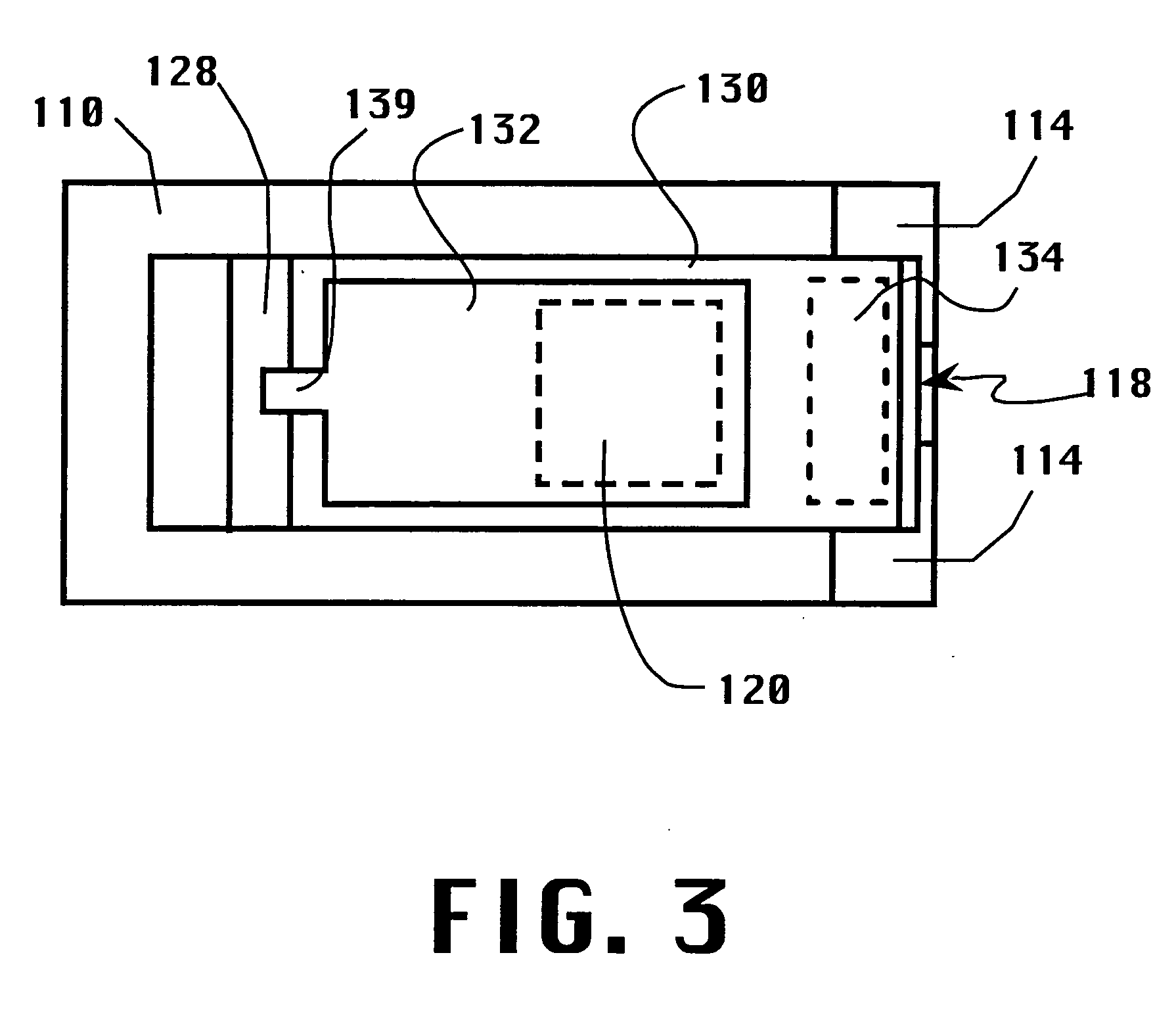

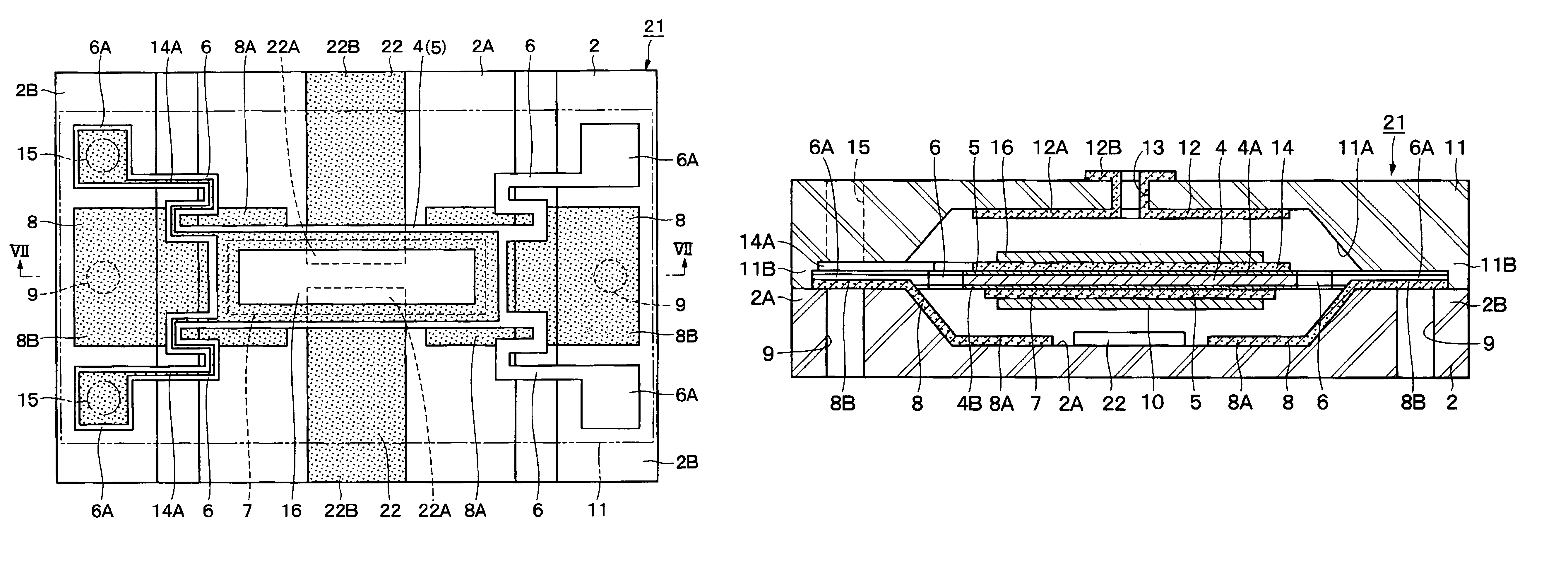

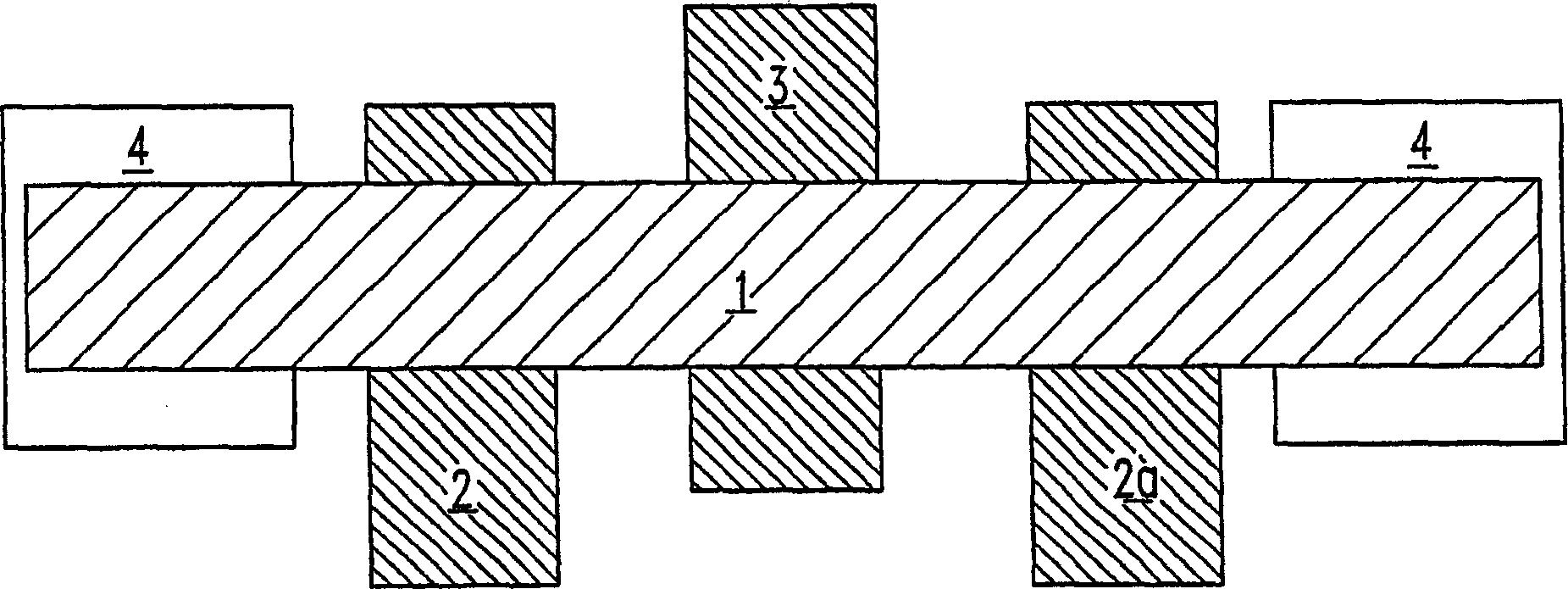

Variable capacitance element

InactiveUS7027284B2Guaranteed uptimeImprove reliabilityMechanically variable capacitor detailsElectrostatic/electro-adhesion relaysCapacitanceEngineering

A variable capacitance element includes a coplanar line or signal conduction and a movable body, which are vertically displaced through a supporting bar and which are provided on a substrate. A movable electrode is provided between a first driving electrode and second and third driving electrodes which are movable electrodes. Voltage is applied between the movable electrodes, such that one of the movable electrodes is pressed against the coplanar line through a dielectric film. Thus, high frequency signals conducting through the coplanar line are shut off. When voltage is applied between the other electrodes, the movable electrode and the dielectric film are moved apart from the coplanar line. Thus, high frequency signals are conducted through the coplanar line.

Owner:MURATA MFG CO LTD

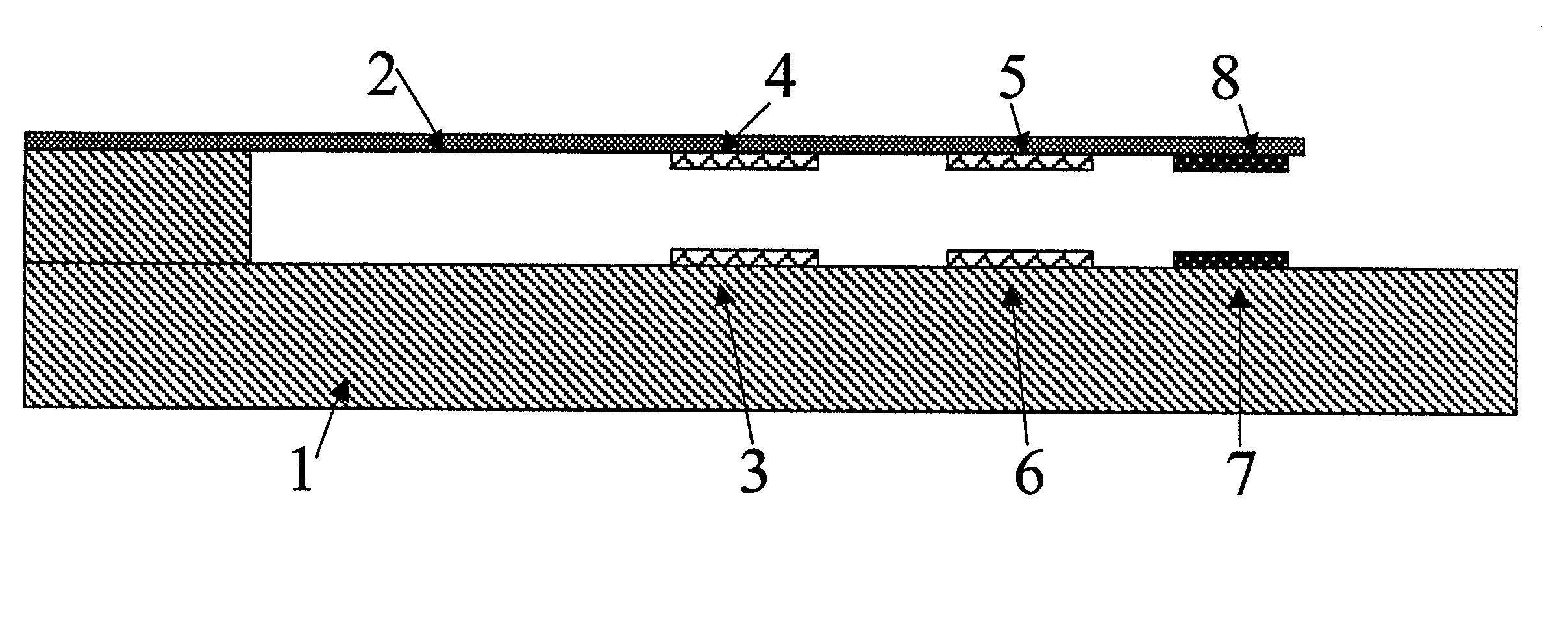

Method of fabricating micro-electromechanical switches on cmos compatible substrates

InactiveCN1575506AElectrostatic/electro-adhesion relaysDecorative surface effectsElectrical conductorEngineering

A method of fabricating micro-electromechanical switches (MEMS) integrated with conventional semiconductor interconnect levels, using compatible processes and materials is described. The method is based upon fabricating a capacitive switch that is easily modified to produce various configurations for contact switching and any number of metal-dielectric-metal switches. The process starts with a copper damascene interconnect layer, made of metal conductors inlaid in a dielectric. All or portions of the copper interconnects are recessed to a degree sufficient to provide a capacitive air gap when the switch is in the closed state, as well as provide space for a protective layer of, e.g., Ta / TaN. The metal structures defined within the area specified for the switch act as actuator electrodes to pull down the movable beam and provide one or more paths for the switched signal to traverse. The advantage of an air gap is that air is not subject to charge storage or trapping that can cause reliability and voltage drift problems. Instead of recessing the electrodes to provide a gap, one may just add dielectric on or around the electrode. The next layer is another dielectric layer which is deposited to the desired thickness of the gap formed between the lower electrodes and the moveable beam that forms the switching device. Vias are fabricated through this dielectric to provide connections between the metal interconnect layer and the next metal layer which will also contain the switchable beam. The via layer is then patterned and etched to provide a cavity area which contains the lower activation electrodes as well as the signal paths. The cavity is then back-filled with a sacrificial release material. This release material is then planarized with the top of the dielectric, thereby providing a planar surface upon which the beam layer is constructed.

Owner:格芯公司

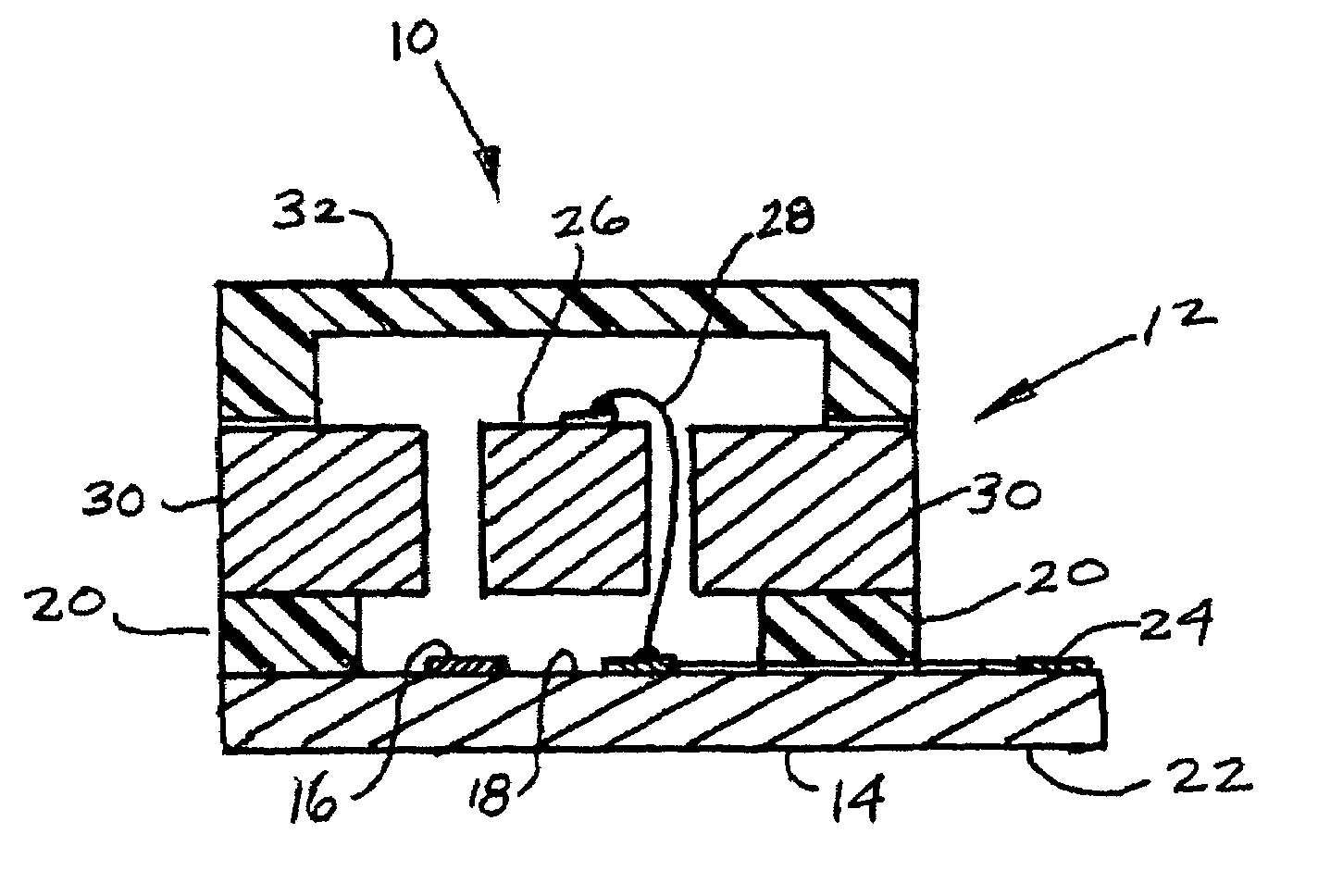

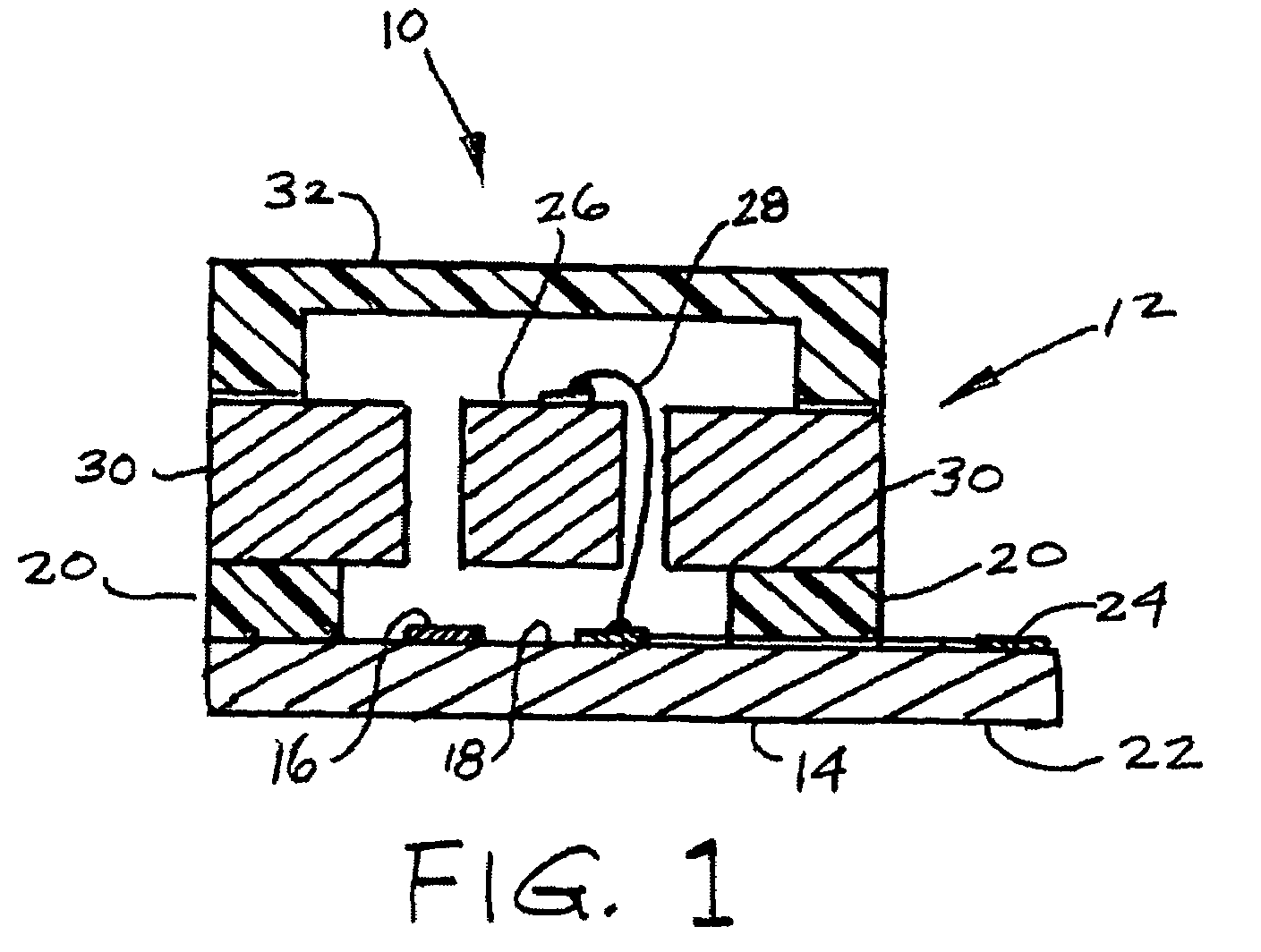

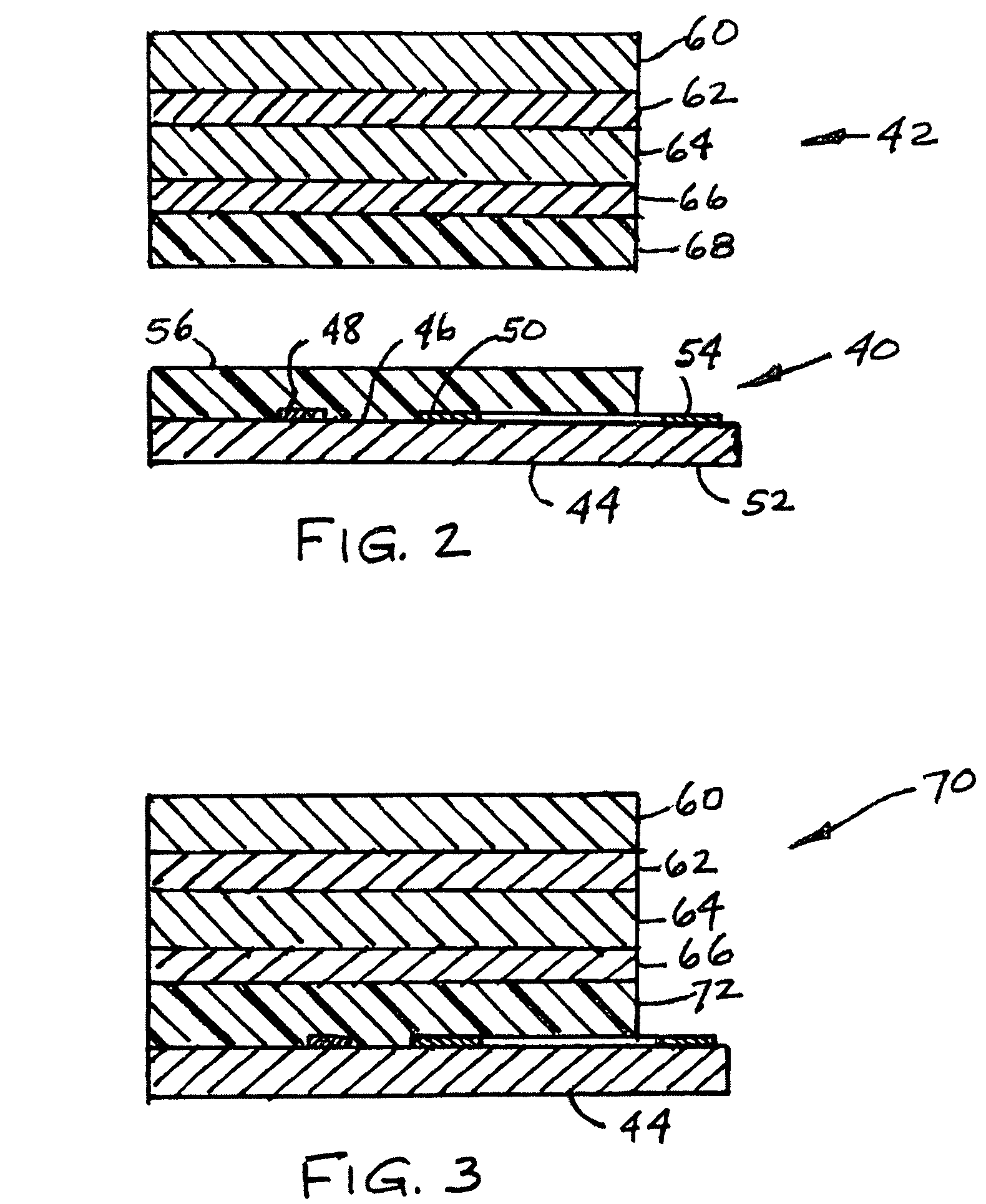

MEMS device integrated chip package, and method of making same

The present invention relates to a chip package that includes a semiconductor device and at least one micro electromechanical structure (MEMS) such that the semiconductor device and the MEMS form an integrated package. One embodiment of the present invention includes a semiconductor device, a first MEMS device disposed in a conveyance such as a film, and a second MEMS device disposed upon the semiconductor device through a via in the conveyance.The present invention also relates to a process of forming a chip package that includes providing a conveyance such as a tape automated bonding (TAB) structure, that may hold at least one MEMS device. The method is further carried out by disposing the conveyance over the active surface of the device in a manner that causes the at least one MEMS to communicate electrically to the active surface. Where appropriate, a sealing structure such as a solder ring may be used to protect the MEMS.

Owner:INTEL CORP

Torsion spring for electro-mechanical switches and a cantilever-type RF micro-electromechanical switch incorporating the torsion spring

InactiveUS6842097B2Increased durabilityGood electrical contactContact surface shape/structureElectrostatic/electro-adhesion relaysConformal connectionEngineering

A torsion spring for an electro-mechanical switch is presented. The torsion spring comprises a set of tines including at least one tine extending from the free end of the armature of a switch. A terminus portion is rotatably suspended between the tines, and includes a conducting transmission line, at least a portion of which is exposed for electrical contact. The conducting transmission line has a length selected such that the exposed portion of the transmission line forms a circuit between the input and output of the micro-electro-mechanical switch when the micro-electro-mechanical switch is urged into a closed position, with the terminus portion rotating via the tines to form a conformal connection between the exposed portion of the conducting transmission line and the input and output of the switch, thus optimizing the electrical flow therebetween. The switch is also applied to MEMS devices.

Owner:HRL LAB

Resonant operation of MEMS switch

InactiveUS20030090346A1Reduce problemsReduces stictionBatteries circuit arrangementsBoards/switchyards circuit arrangementsEngineeringVoltage

A switch arrangement includes a MEMS switch connected to a voltage supply system. The MEMS switch has a mechanical resonant frequency. The voltage supply system has a capability for supplying a voltage with a frequency corresponding to the mechanical resonant frequency of the switch. A method includes providing a MEMS switch including a movable part which has a mechanical resonant frequency, and then supplying an AC voltage to the movable part. The AC voltage has a frequency corresponding to the mechanical resonant frequency of the movable part.

Owner:GLOBALFOUNDRIES US INC

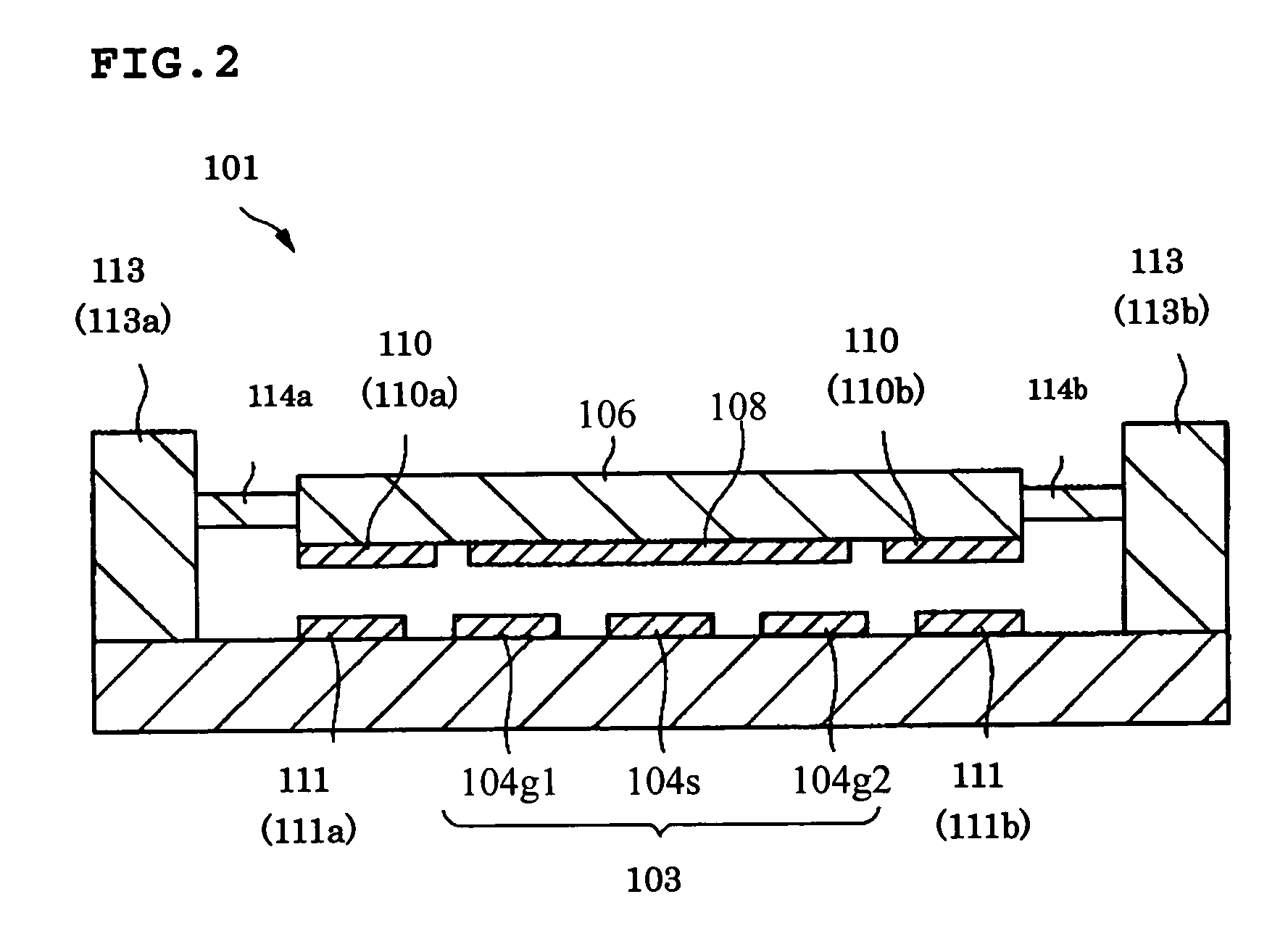

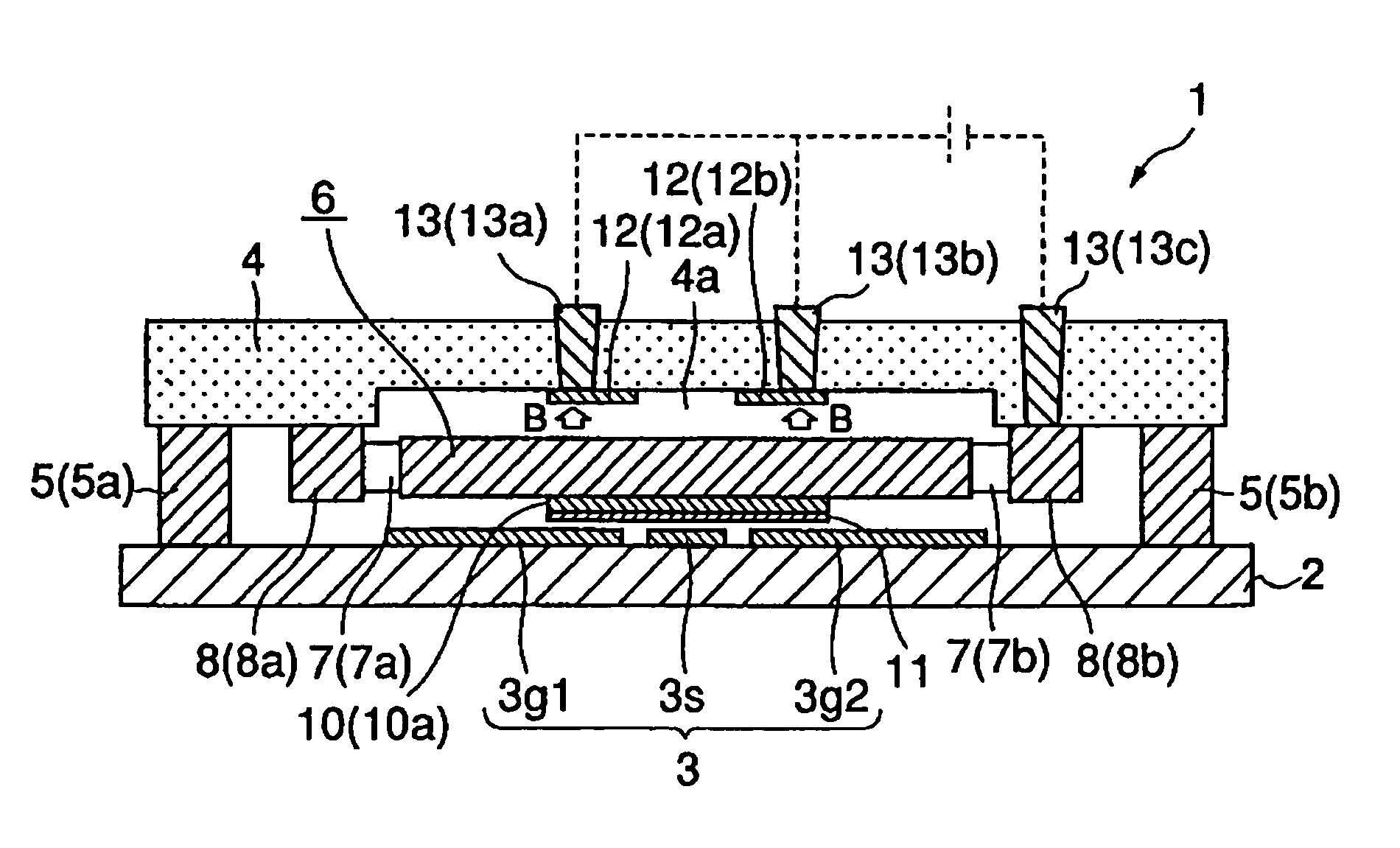

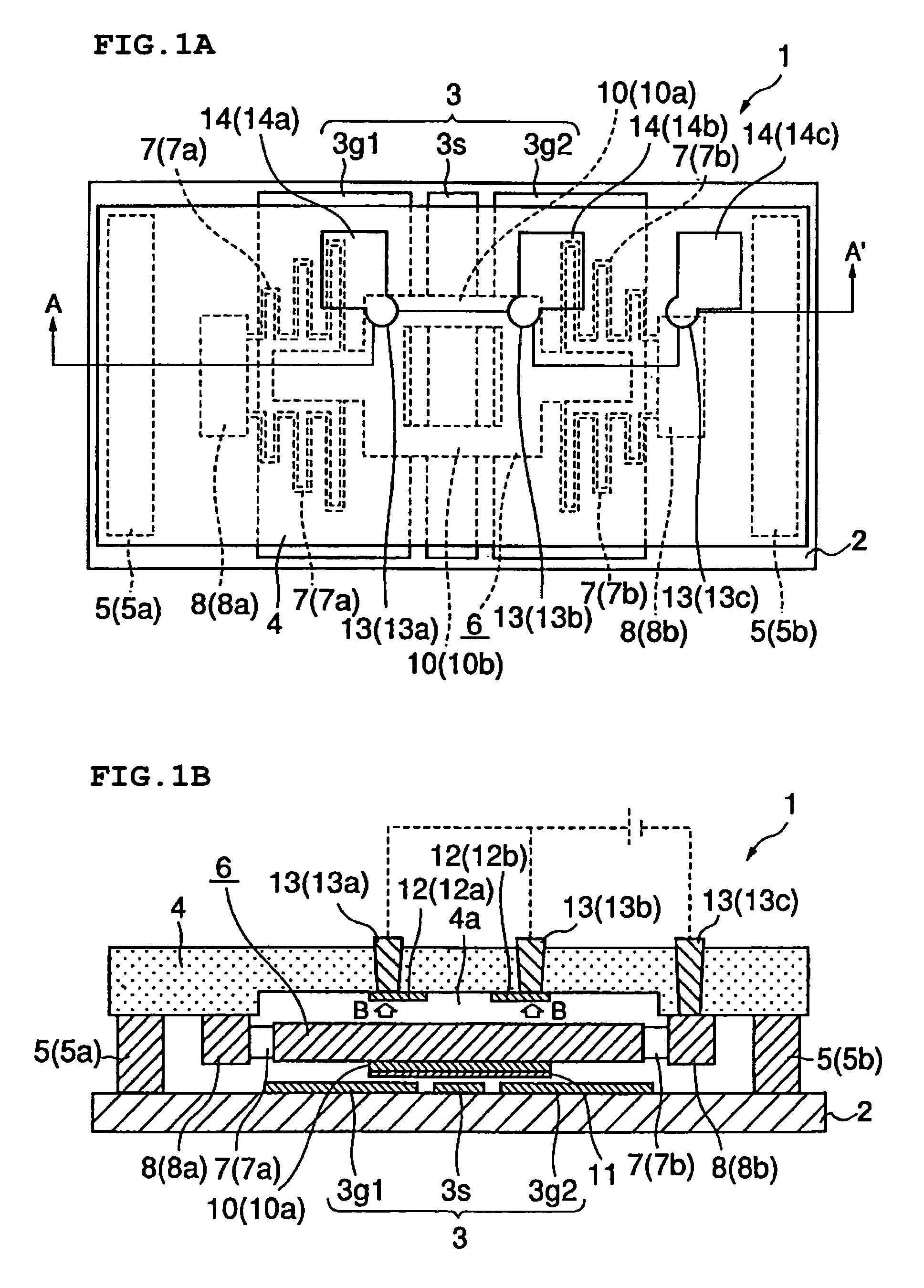

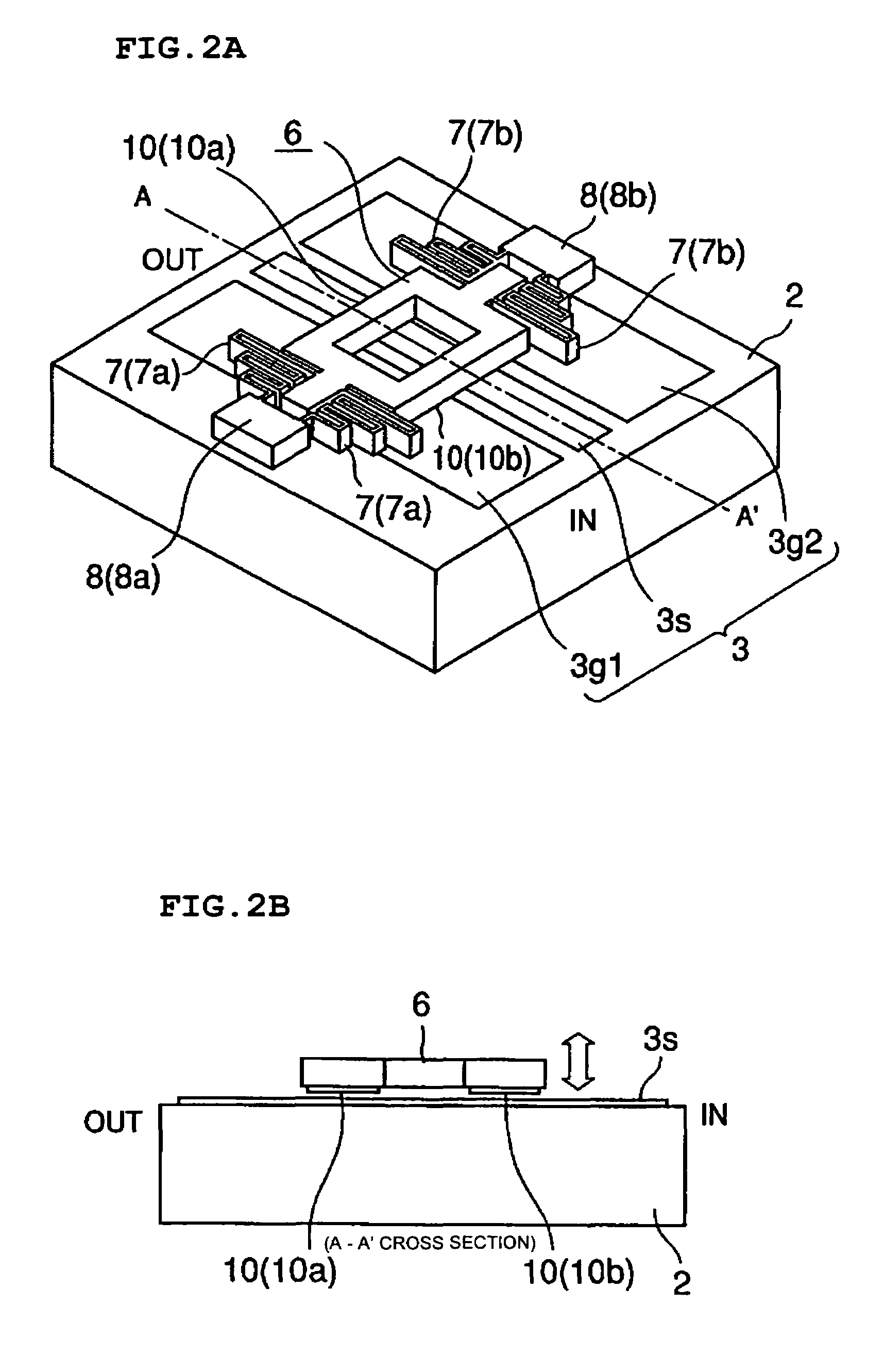

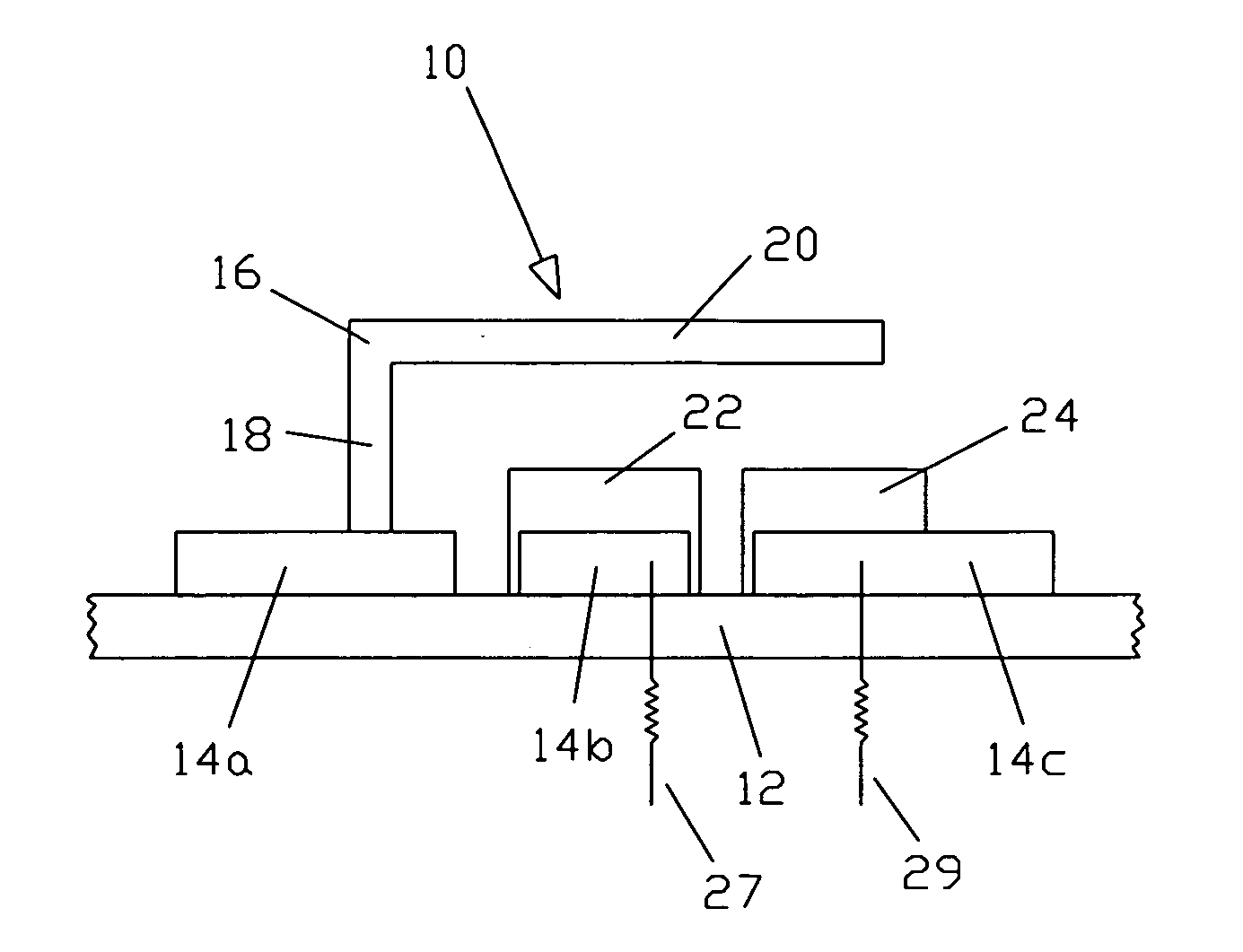

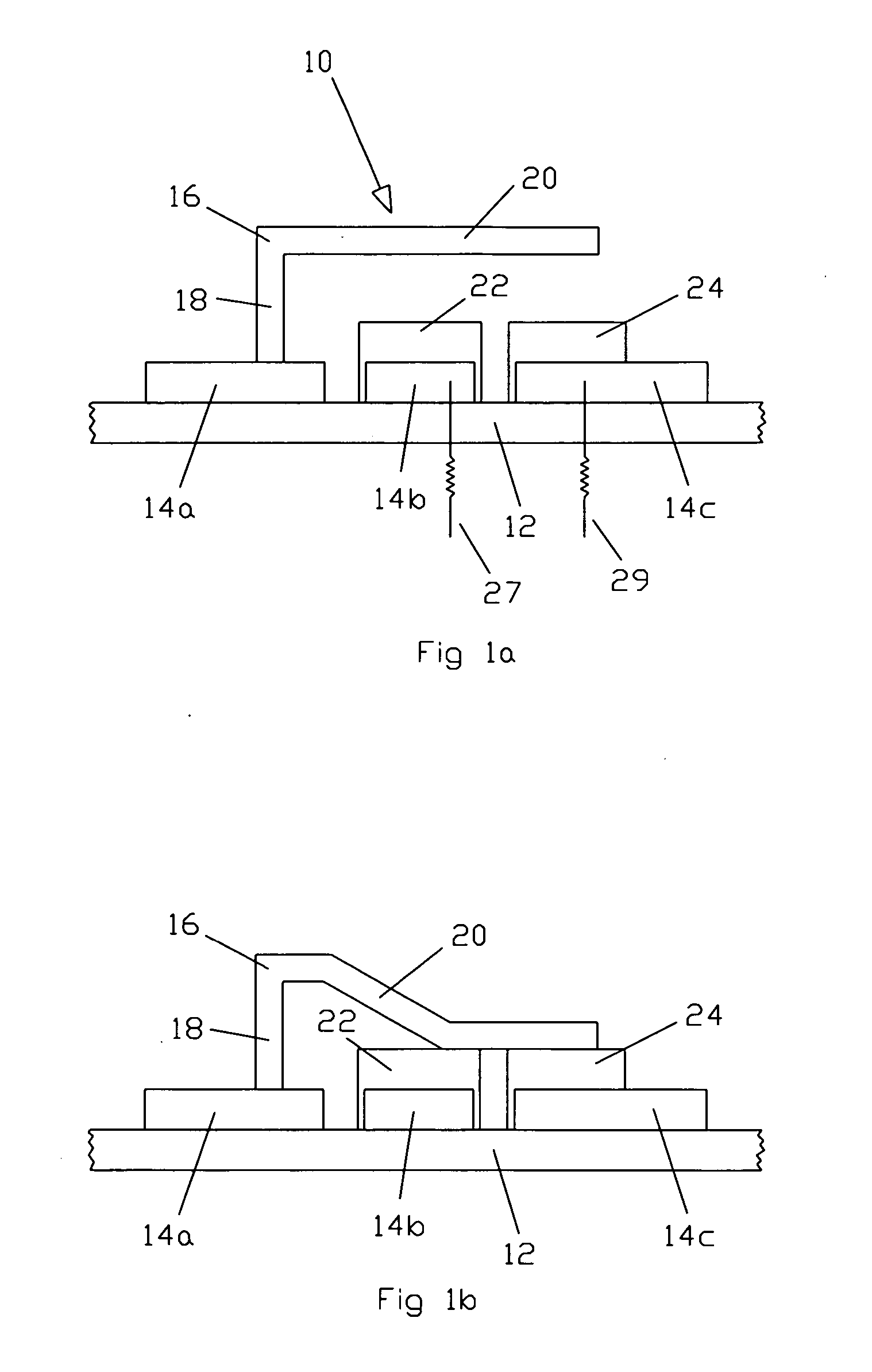

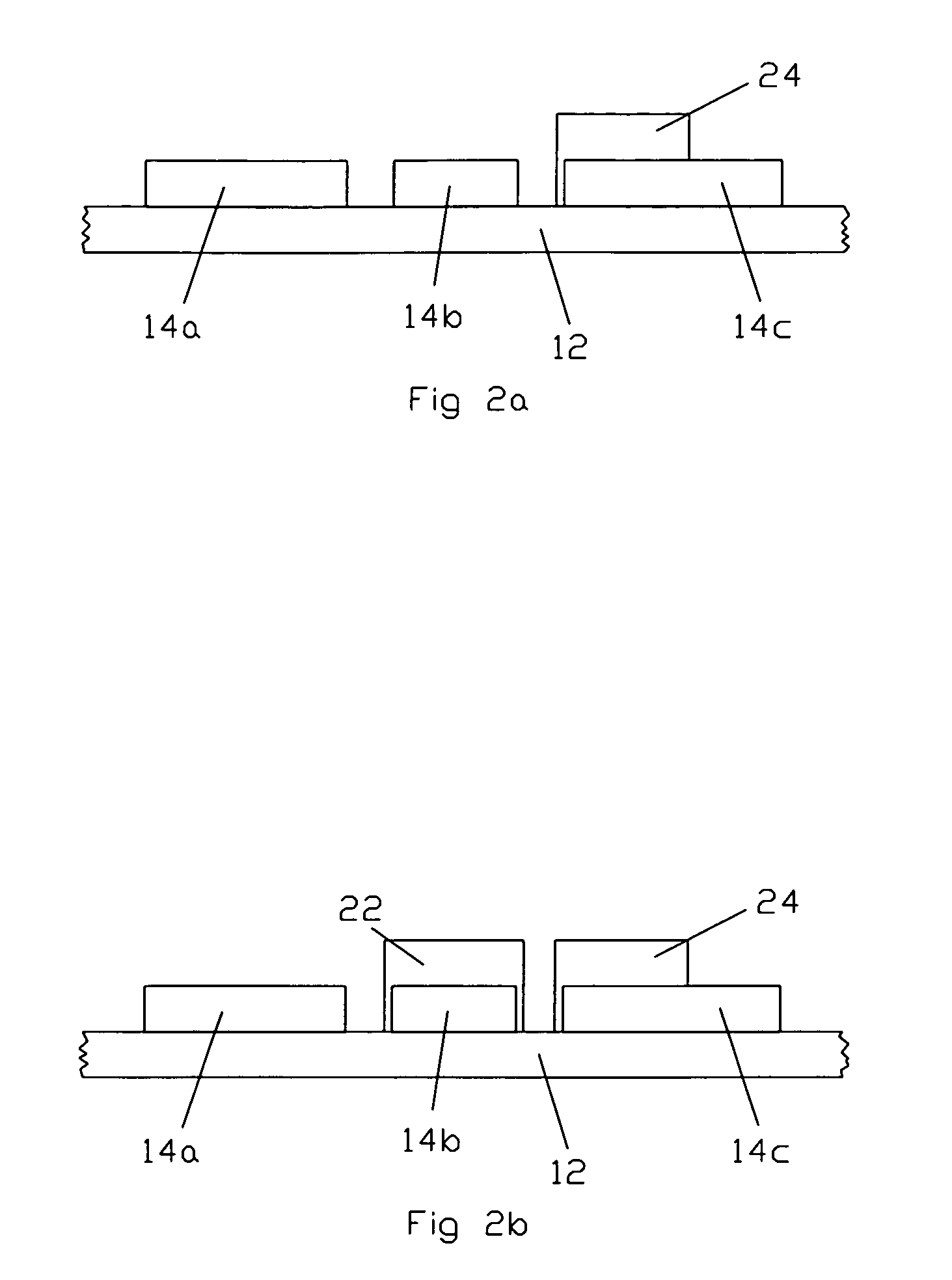

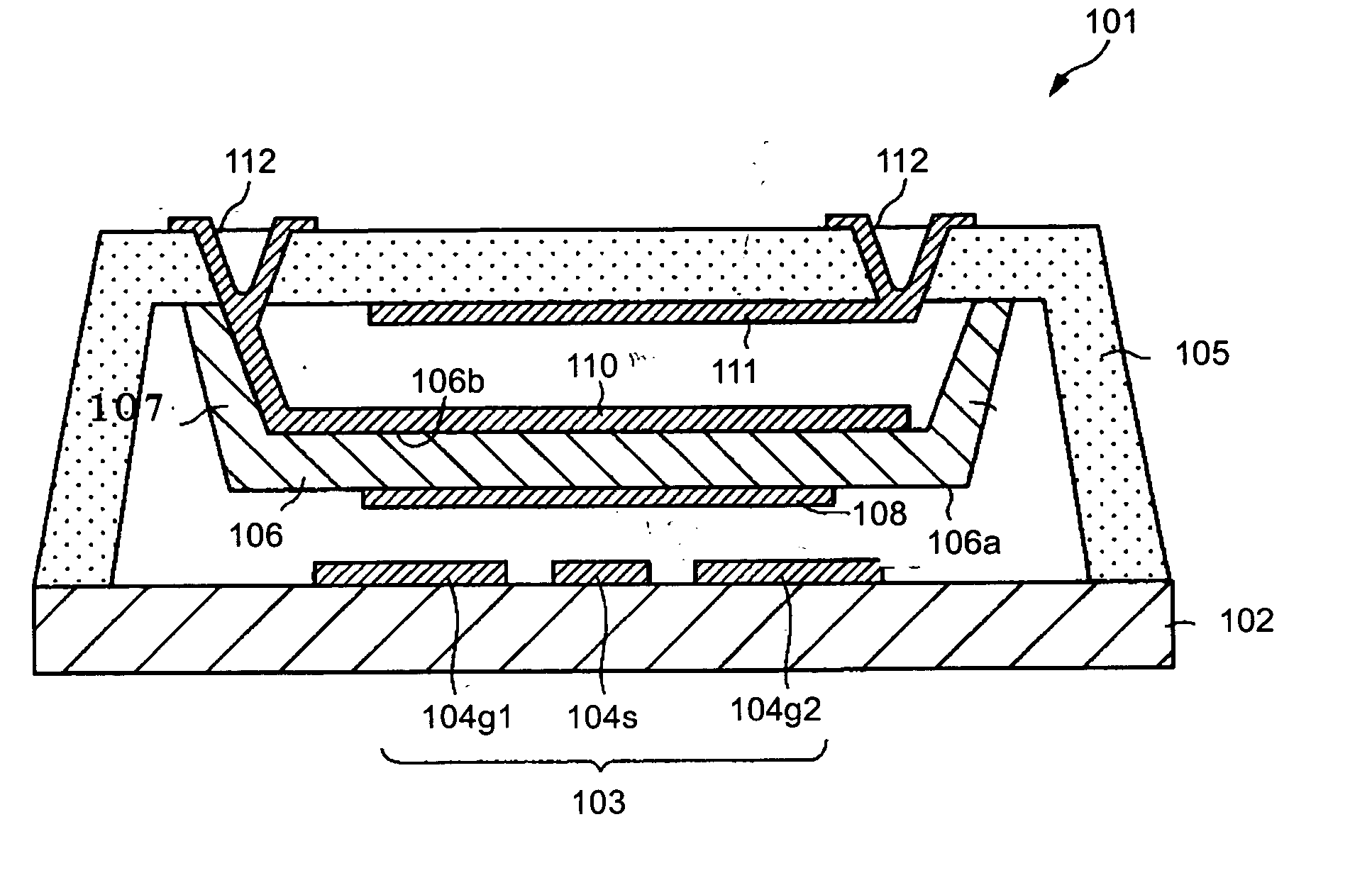

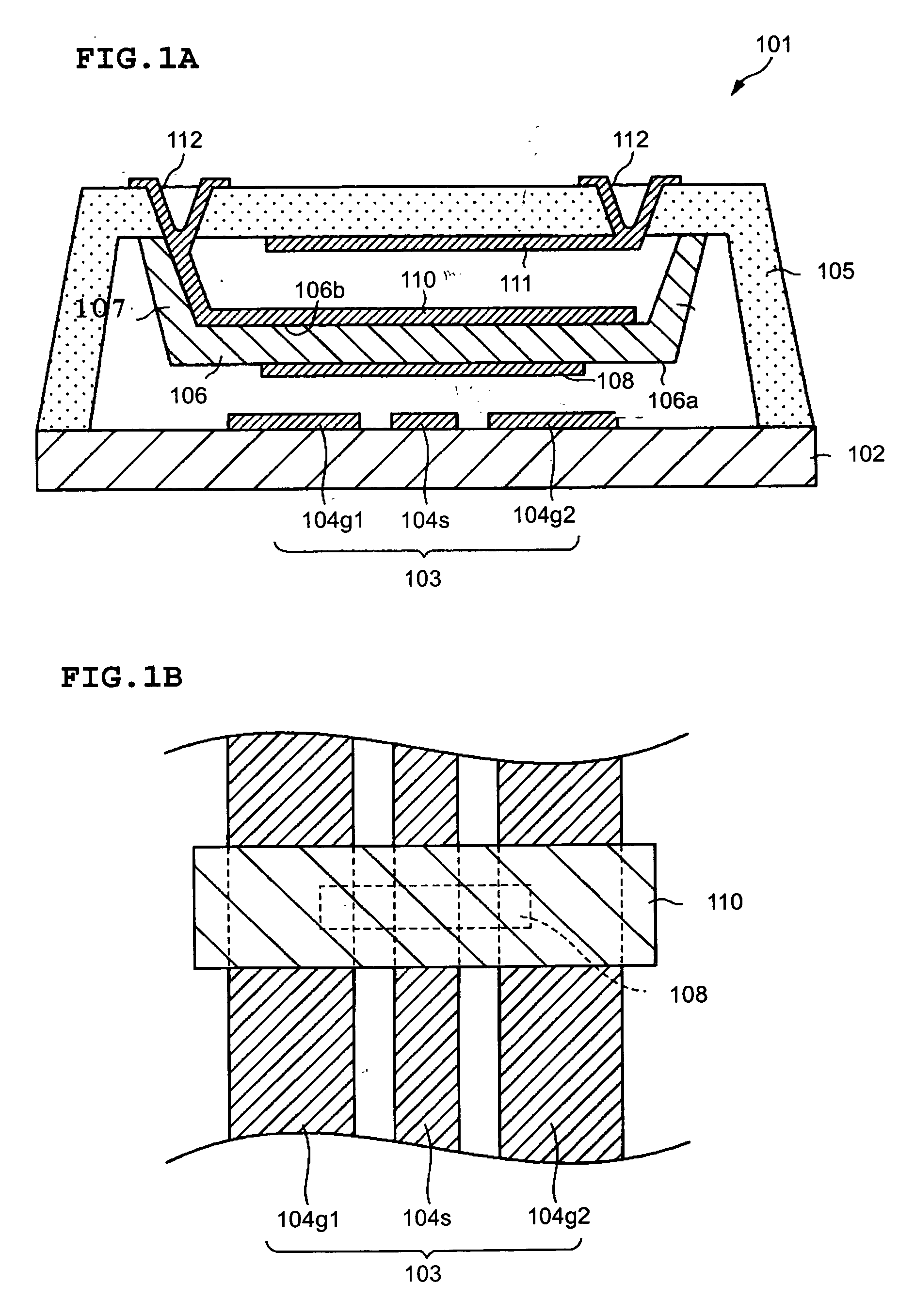

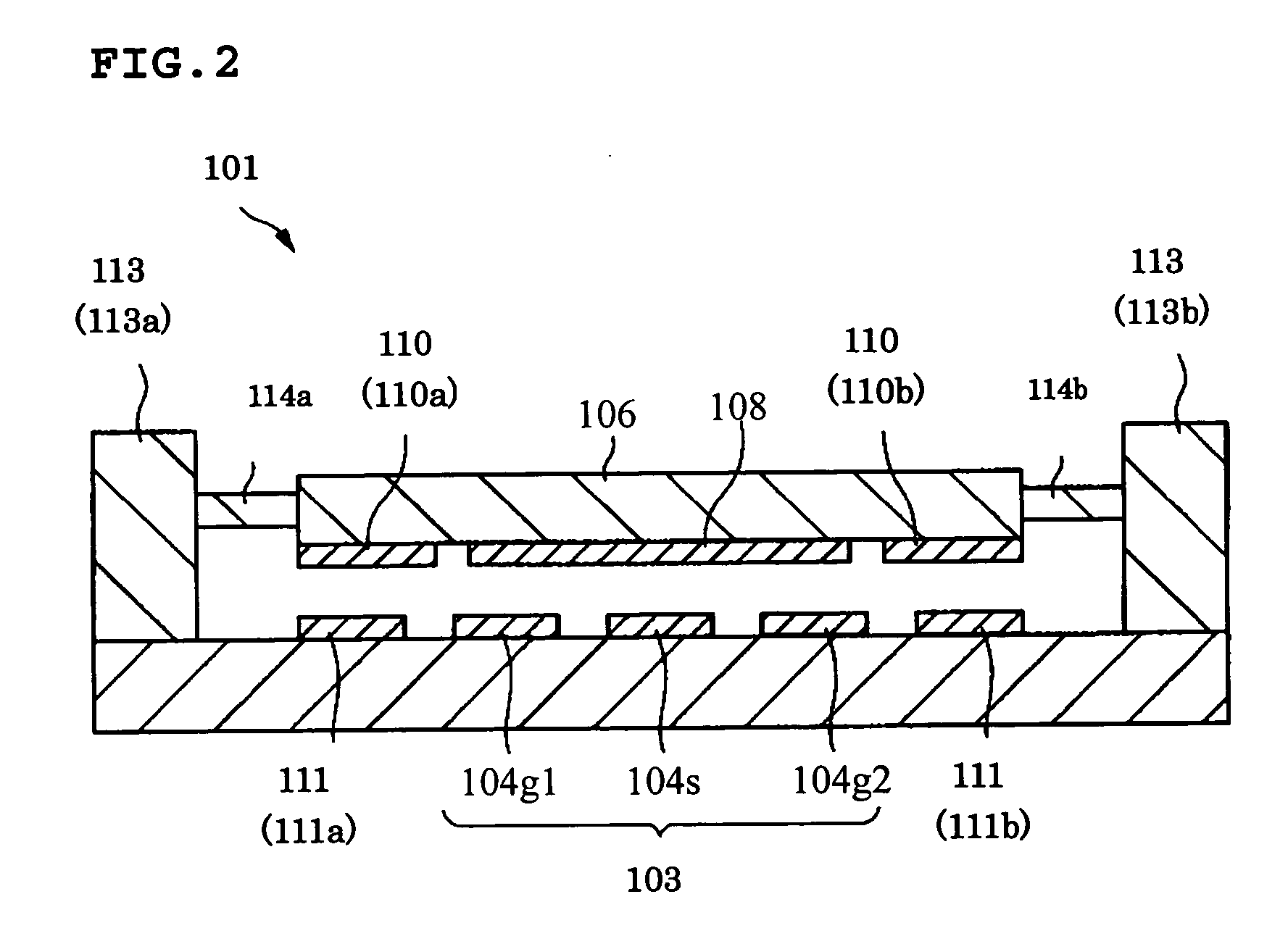

RF-mems switch

ActiveUS7126447B2Reduced insertion lossReduces loss return lossElectrostatic/electro-adhesion relaysCapacitor with electrode distance variationEngineeringRadio frequency

An RF-MEMS switch includes a plurality of movable electrodes disposed with a space provided therebetween in the direction of RF signal conduction of an RF signal-conducting unit which is provided above the RF signal-conducting unit. A movable electrode displacing unit for displacing all the movable electrodes at the same time in the same direction towards or away from the RF signal-conducting unit is provided. The electrical length of the RF signal-conducting unit sandwiched between the movable electrodes is set such that the amplitude of a combined signal including signals reflected in positions of the RF signal-conducting unit facing the movable electrodes is less than the amplitude of each of reflected signals reflected in positions of the RE signal-conducting unit facing the movable electrodes when the movable electrodes are displaced away from the RF signal-conducting unit and signal conduction of the RF signal-conducting unit is switched on.

Owner:MURATA MFG CO LTD

Tunable dielectric radio frequency microelectromechanical system capacitive switch

InactiveUS20060208823A1Enhanced analog tuningBreakdown problemMultiple-port networksElectrostatic/electro-adhesion relaysDielectricRadio frequency microelectromechanical system

The invention is a tunable RF MEMS switch developed with a BST dielectric at the contact interface. BST has a very high dielectric constant (>300) making it very appealing for RF MEMS capacitive switches. The tunable dielectric constant of BST provides a possibility of making linearly tunable MEMS capacitive switches. The capacitive tunable RF MEMS switch with a BST dielectric is disclosed showing its characterization and properties up to 40 GHz.

Owner:NGIMAT CO 1ST JOINT ASSIGNEE

Micro-mechanical device, micro-switch, variable capacitor high frequency circuit and optical switch

InactiveUS7567018B2Disposition/mounting of recording headsPiezoelectric/electrostriction/magnetostriction machinesPiezoelectric actuatorsControl theory

A micro-mechanical device includes a first piezoelectric actuator including a piezoelectric film, and lower and upper electrodes interleaving the piezoelectric film, and extending from a first fixing part on a substrate to a first operating end, and a second piezoelectric actuator connected to the first piezoelectric actuator via a connecting part at the first operating end of the first piezoelectric actuator, and extending from the connecting part to a second operating end, the second piezoelectric actuator being shorter than the first piezoelectric actuator.

Owner:KK TOSHIBA

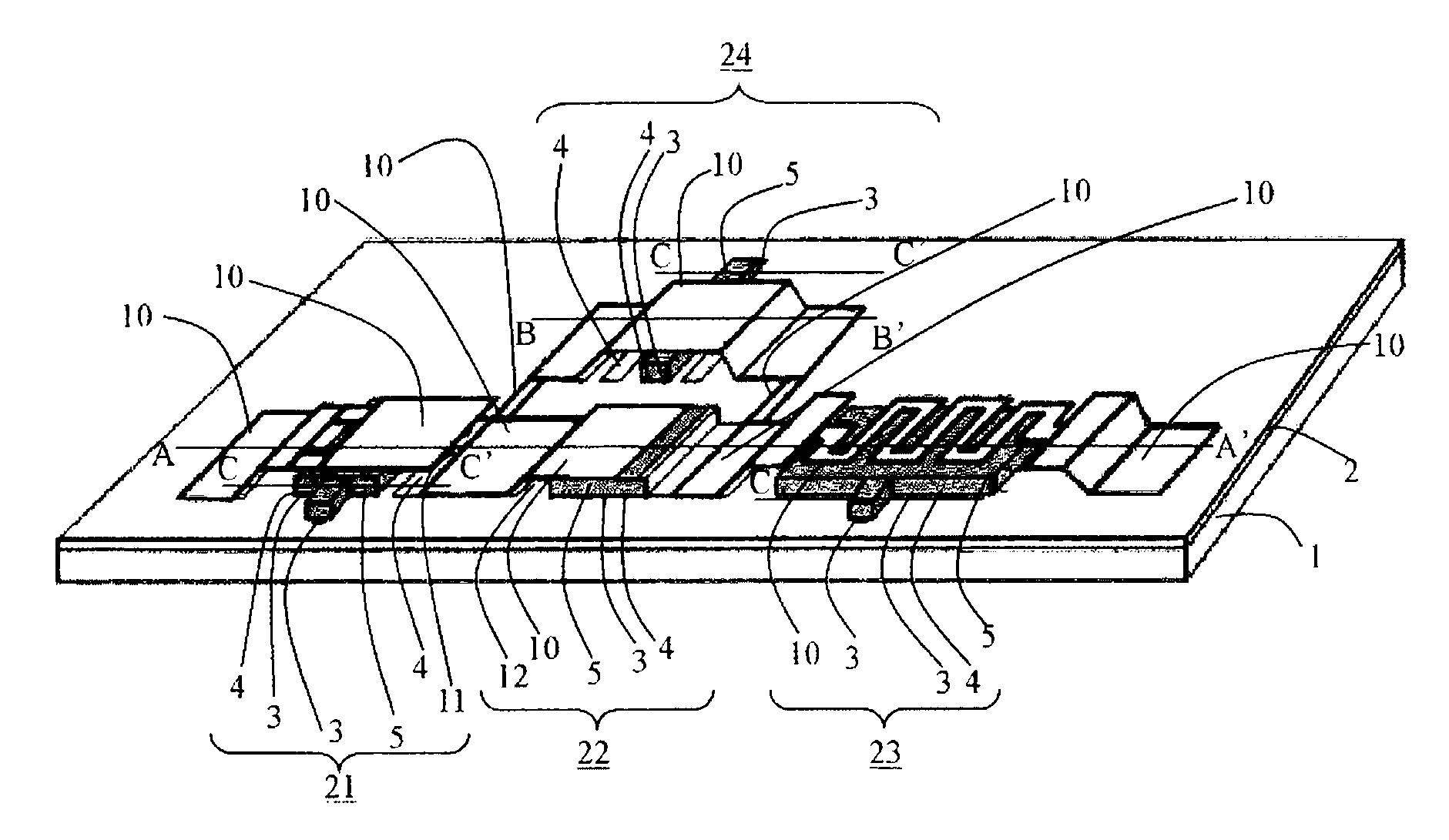

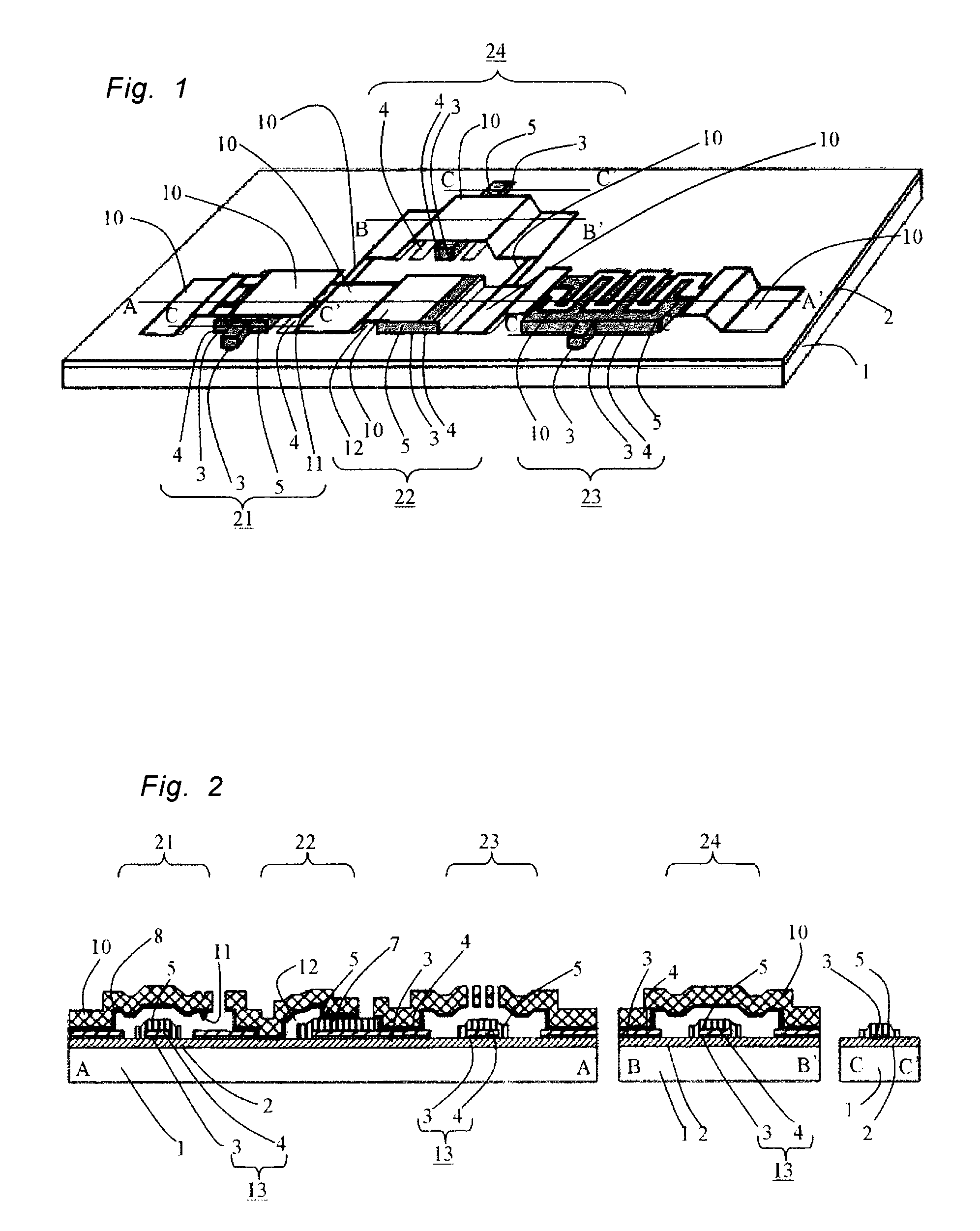

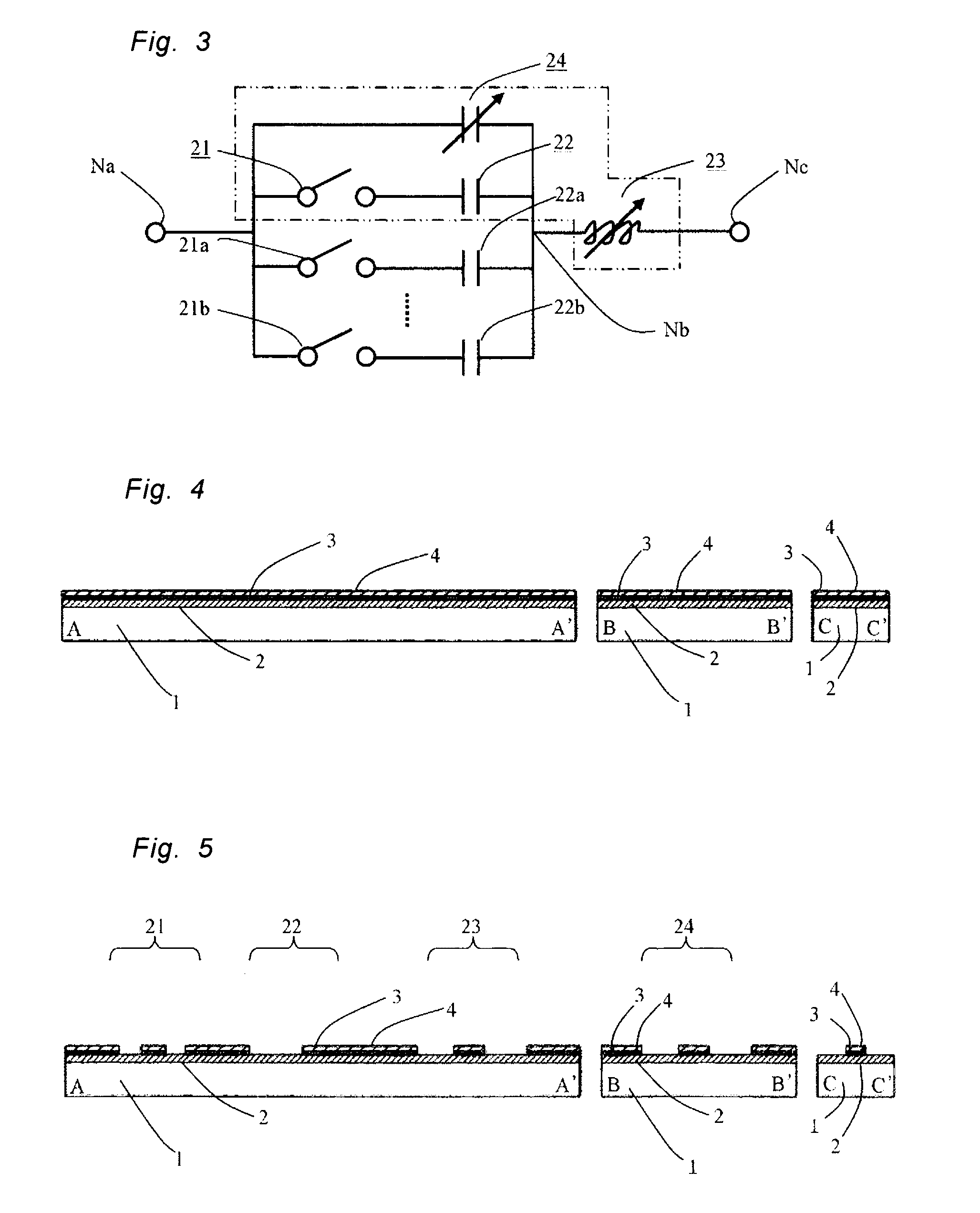

Variable device circuit and method for manufacturing the same

InactiveUS20080247115A1Reduce manufacturing costStable characteristicsMultiple-port networksCapacitor with electrode area variationFixed capacitorDevice form

There is provided a variable device circuit according to the present invention, including: a substrate; at least one movable switch device formed on a first principal surface of the substrate; at least one fixed capacitor device formed on the first principal surface of the substrate; at least one variable capacitor device formed on the first principal surface of the substrate; at least one variable inductor device formed on the first principal surface of the substrate; and wiring lines for electrically connecting the devices to one another, the wiring lines being formed on the first principal surface of the substrate; wherein electrical connections among the devices can be selected by operation of the movable switch device, whereby achieving stable, low-loss circuit characteristics with lower manufacturing cost.

Owner:MITSUBISHI ELECTRIC CORP

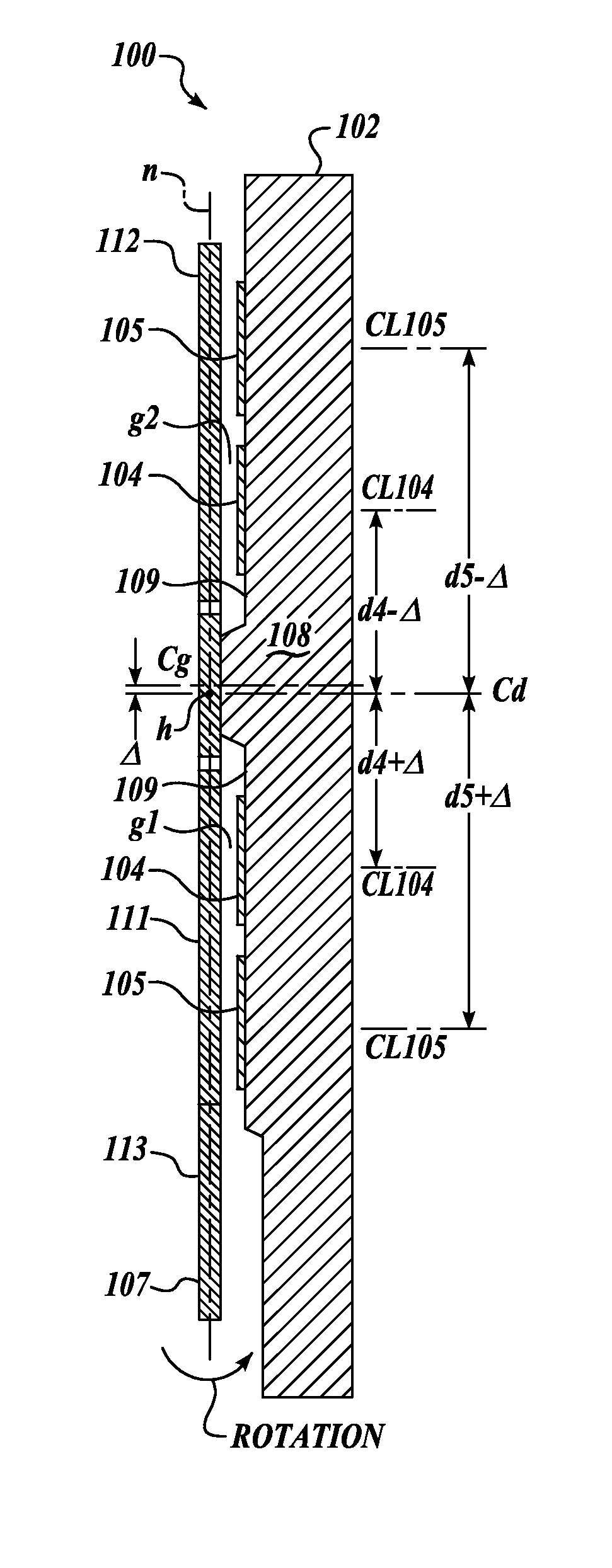

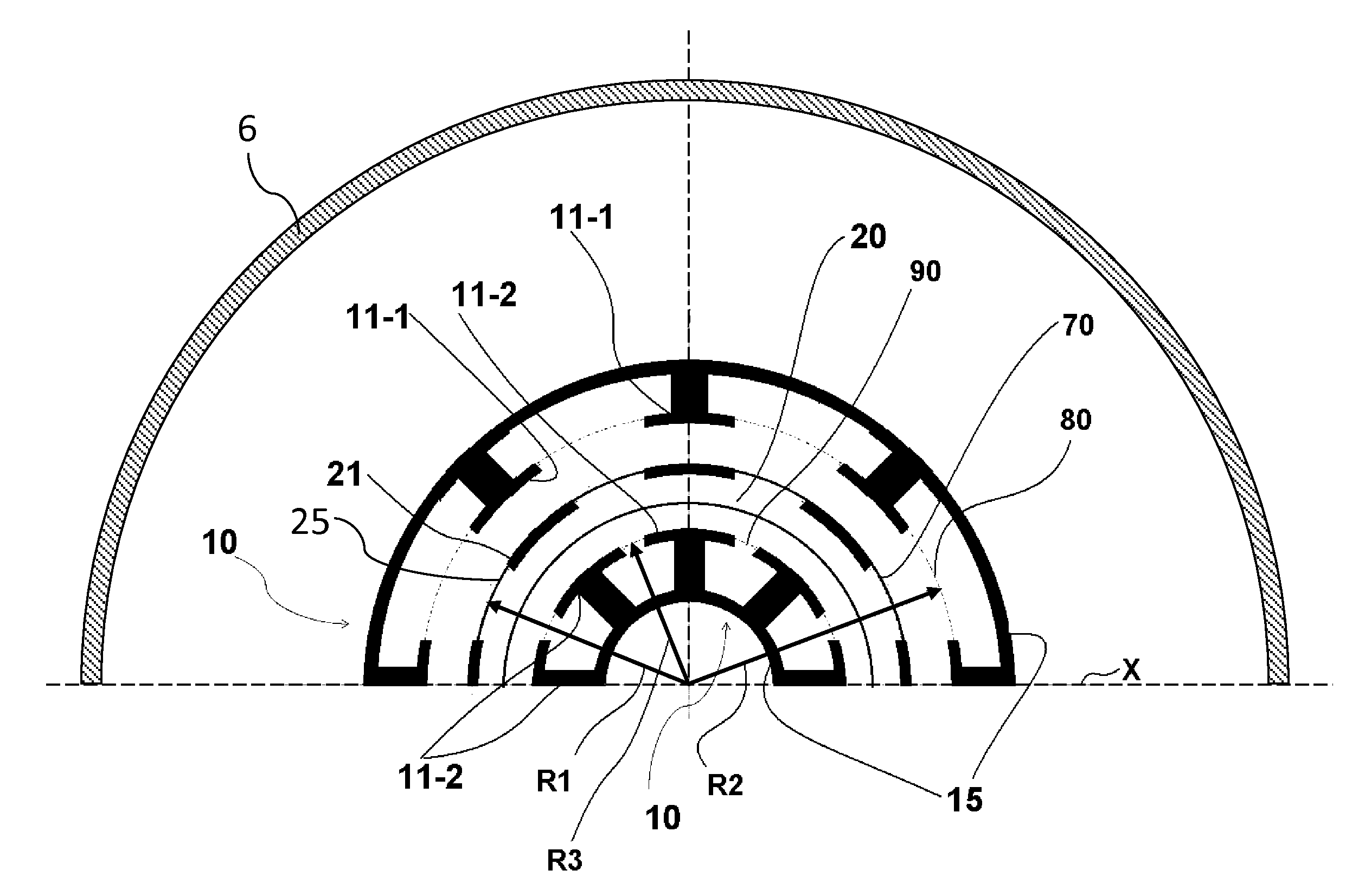

Variable rotating capacitor for synchrocyclotron

ActiveUS9355784B2Speed up the flowReducing local overheatingCapacitor with electrode area variationMagnetic resonance acceleratorsEngineeringCapacitor

A variable rotating capacitor or RotCo 5 that can be connected via a transmission line 3 to the dee 2 of a synchrocyclotron 1 so as to adjust a resonant frequency of the synchrocyclotron as a function of time and which comprises a cylindrical rotor 10 and a cylindrical stator 20 that are coaxial with the Z axis. The rotor comprises a plurality of circumferentially-distributed rotor electrodes 11 extending parallel to its rotation axis Z. The stator comprises a plurality of circumferentially-distributed stator electrodes 21 extending parallel to the rotation axis Z. Each stator electrode 21 consists of a single metal plate and all said plates are distributed over one and the same stator circumference 25. This makes it possible for the RF currents in the electrodes to be better distributed and thus reduces the local overheating.The present invention also relates to a synchrocyclotron comprising such a RotCo.

Owner:ION BEAM APPL

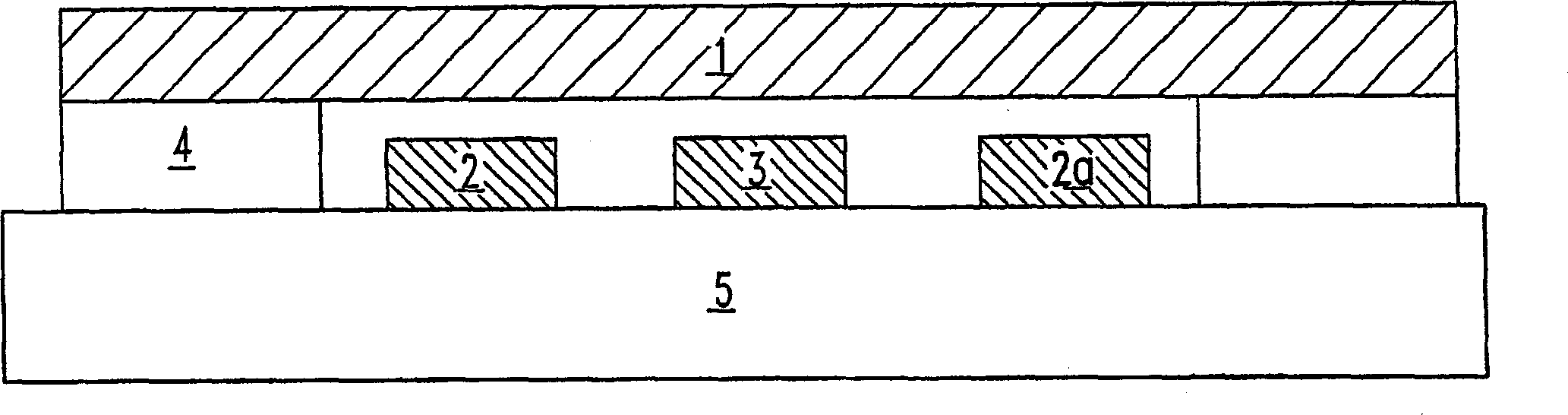

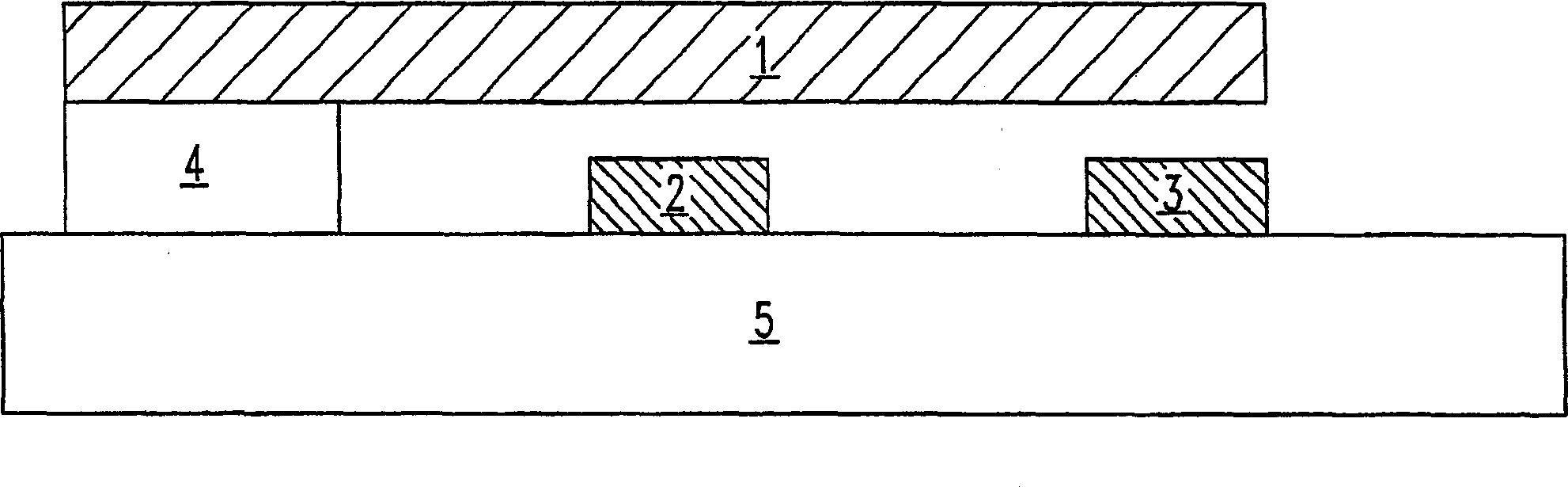

Variable capacitance element

InactiveUS20050052821A1Guaranteed uptimeImprove vibration resistanceMechanically variable capacitor detailsElectrostatic/electro-adhesion relaysCapacitanceCoplanar lines

A variable capacitance element includes a coplanar line or signal conduction and a movable body, which are vertically displaced through a supporting bar and which are provided on a substrate. A movable electrode is provided between a first driving electrode and second and third driving electrodes which are movable electrodes. Voltage is applied between the movable electrodes, such that one of the movable electrodes is pressed against the coplanar line through a dielectric film. Thus, high frequency signals conducting through the coplanar line are shut off. When voltage is applied between the other electrodes, the movable electrode and the dielectric film are moved apart from the coplanar line. Thus, high frequency signals are conducted through the coplanar line.

Owner:MURATA MFG CO LTD

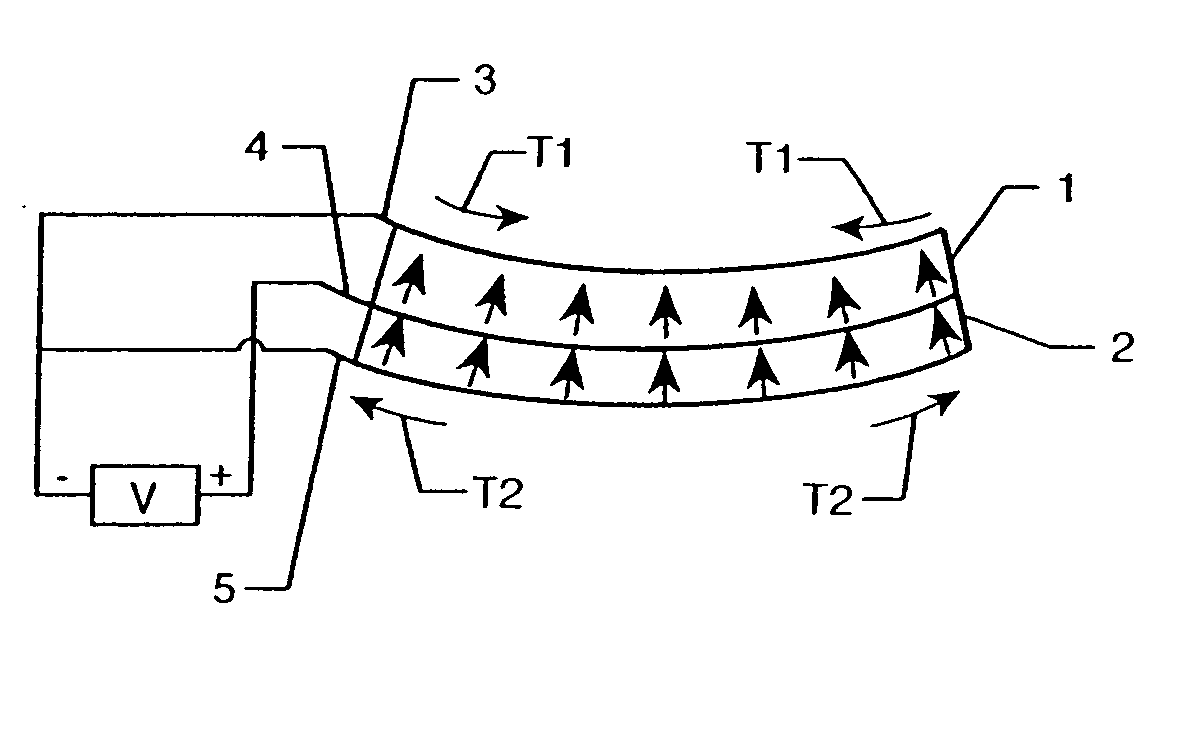

Piezoelectric switch for tunable electronic components

InactiveUS20050151444A1Reduce the starting voltageReduce horizontal sizePiezoelectric/electrostriction/magnetostriction machinesElectrostatic/electro-adhesion relaysElectricityContact pad

A piezoelectric switch for tunable electronic components comprises piezoelectric layers, metal electrodes alternated with the layers and contact pads. Cross voltages are applied to the electrodes, in order to obtain an S-shaped deformation of the switch and allow contact between the contact pads. Additionally, a further electrode can be provided on a substrate where the switch is fabricated, to allow an additional electrostatic effect during movement of the piezoelectric layers to obtain contact between the contact pads. The overall dimensions of the switch are very small and the required actuation voltage is very low, when compared to existing switches.

Owner:HRL LAB

Popular searches

Solid-state devices Semiconductor/solid-state device manufacturing Variable capacitor structural combinations Fluid speed measurement Flexible microstructural devices Microstructural device manufacture Semiconductor devices Microelectromechanical systems Chemical vapor deposition coating Piezoelectric/electrostrictive devices

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com