Method of fabricating radio frequency microelectromechanical systems (MEMS) devices on low-temperature co-fired ceramic (LTCC) substrates

a technology of microelectromechanical systems and substrates, applied in the direction of relays, waveguide devices, semiconductor/solid-state device details, etc., can solve the problems of insufficient reduction for many applications, incur significant additional costs, and the cost of reducing is somewhat lower, so as to achieve the effect of low cost and low cos

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

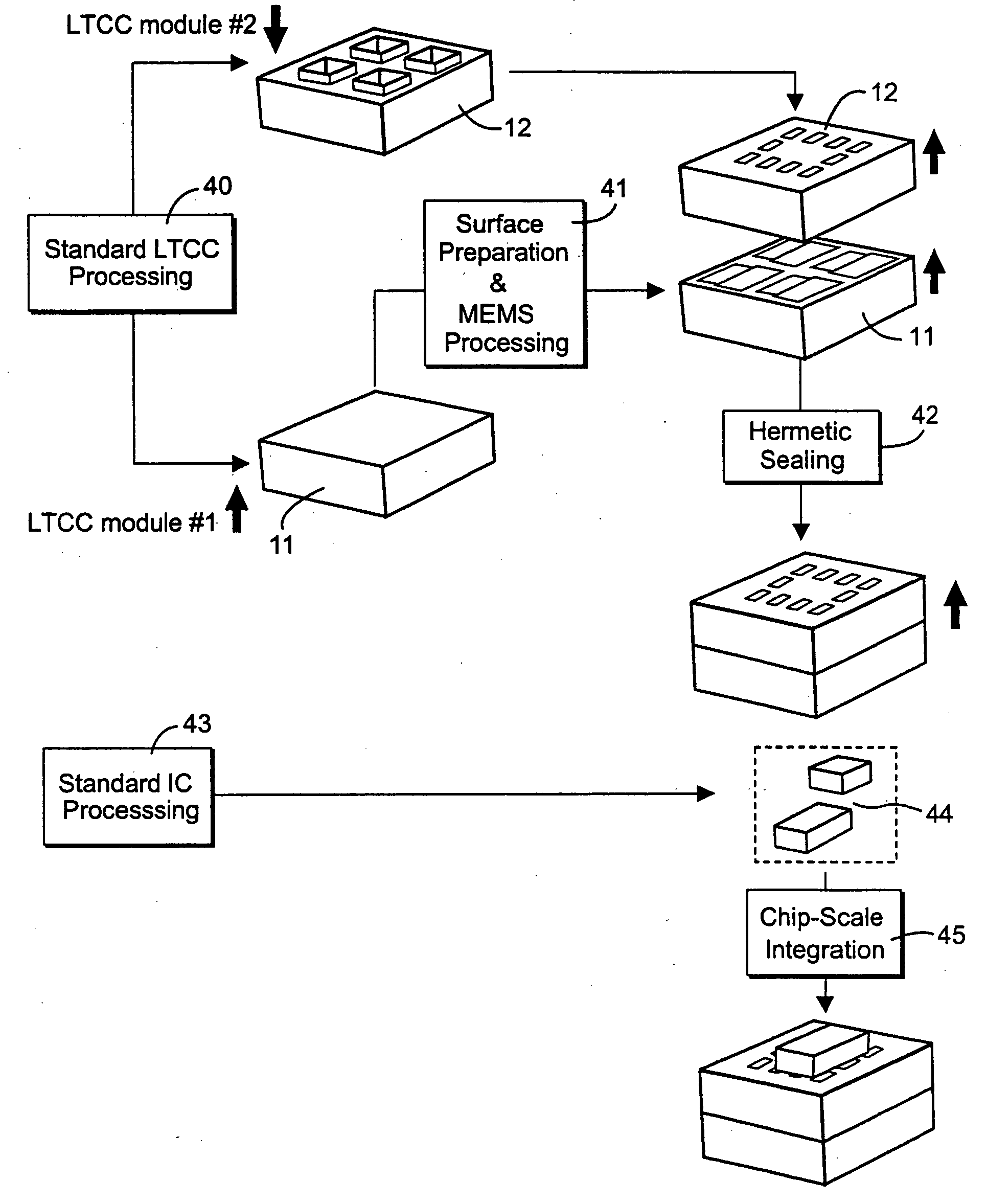

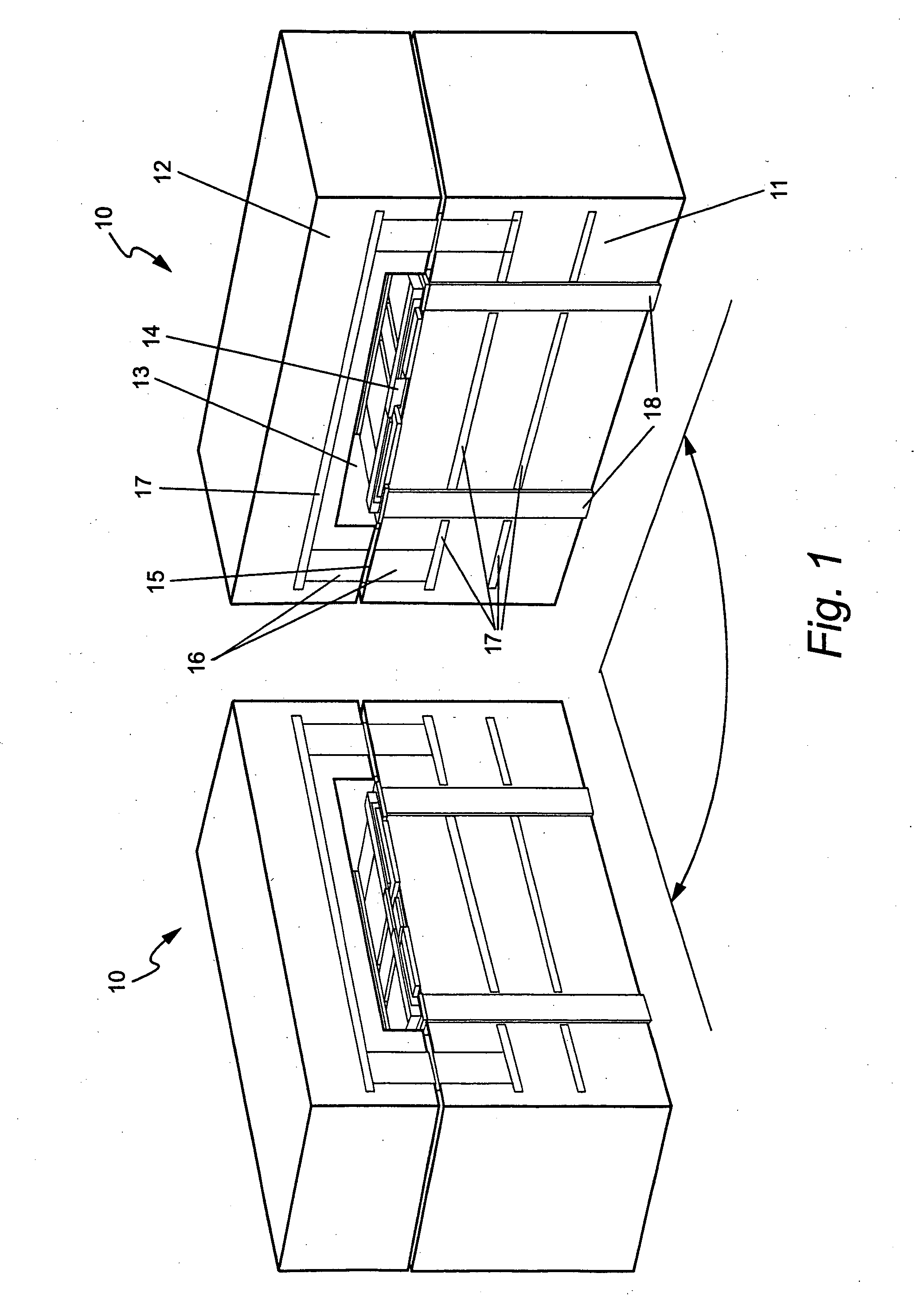

[0072]FIG. 1 shows two perspective views of a sliced open generalized MEMS RF device or system (“module”) 10 fabricated on a stack of multiple layers of an LTCC material which serve as a substrate 11 for a fabricated MEMS RF device 14. FIG. 1 also illustrates the packaging of the MEMS RF device wherein a cavity 13 is formed in a stack of LTCC layers 22 which are mated together to form a second substrate 12. The two substrates are then bonded or affixed together so as to enclose the MEMS RF device 14 within the cavity formed 13 in the upper LTCC substrate 12 prior to bonding the two LTCC substrates together to form device 10.

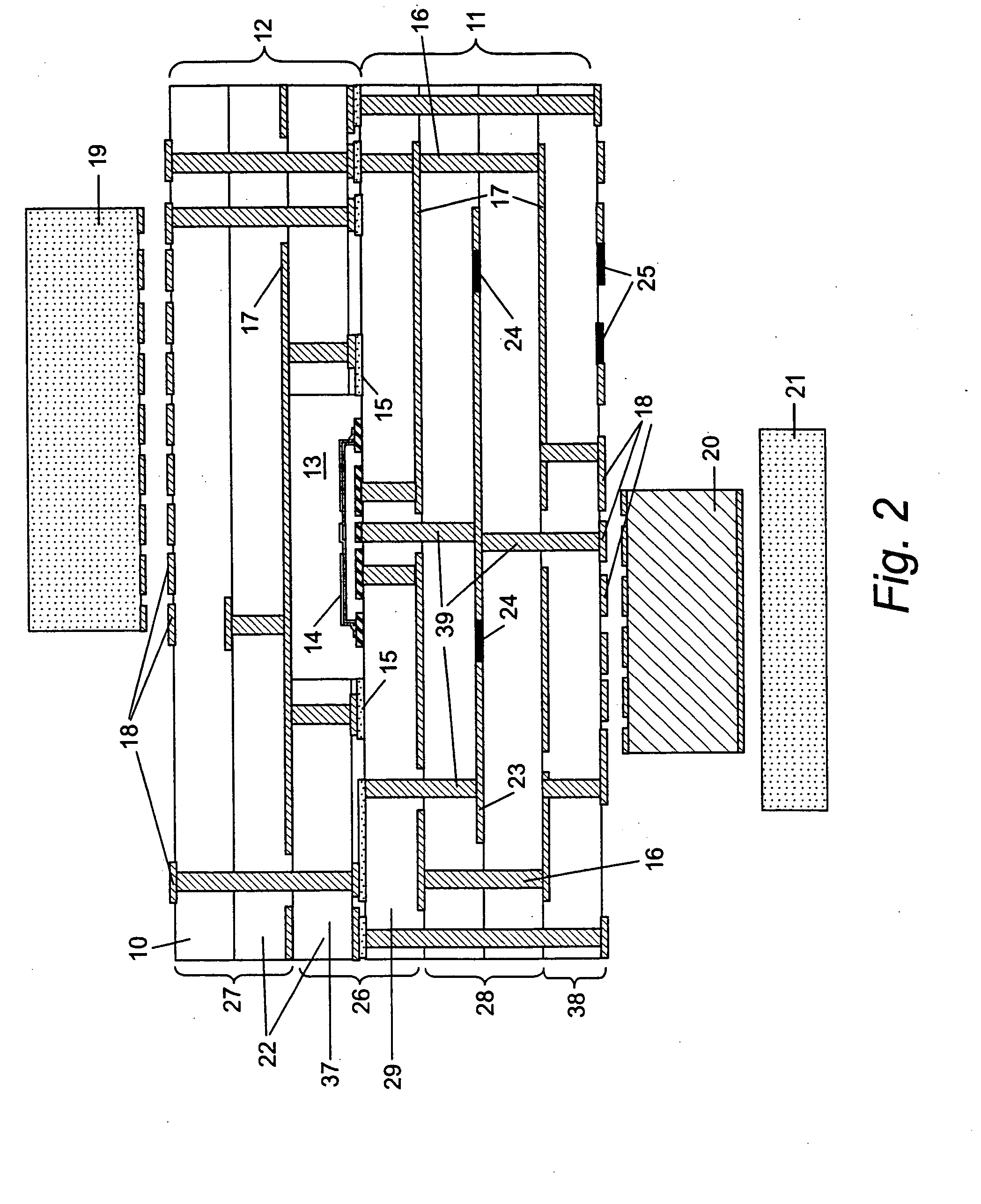

[0073]FIG. 2 illustrates a cross-sectional view of the preferred embodiment of a single generalized MEMS RF device 10 fabricated on a stack of multiple layers of LTCC material 22 and demonstrates the ability of providing suitable electrical connections 16 and 39 through a multiplicity of layers of the LTCC substrate 11 as well as the ability to form electrical c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com