Method of fabricating micro-electromechanical switches on cmos compatible substrates

A technology of micro-electronic machinery and switches, applied in the field of MEMS manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

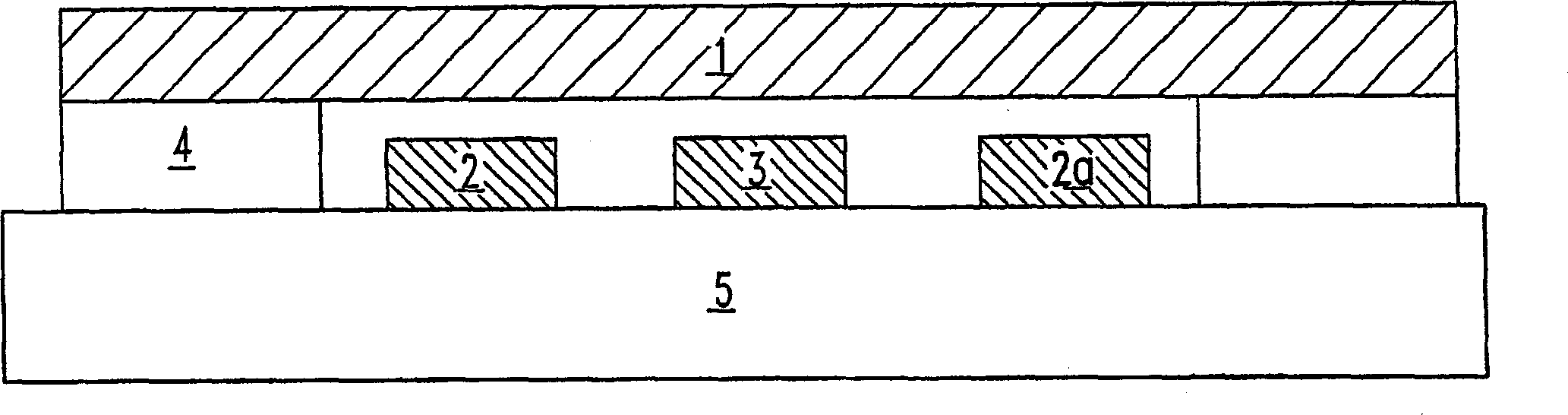

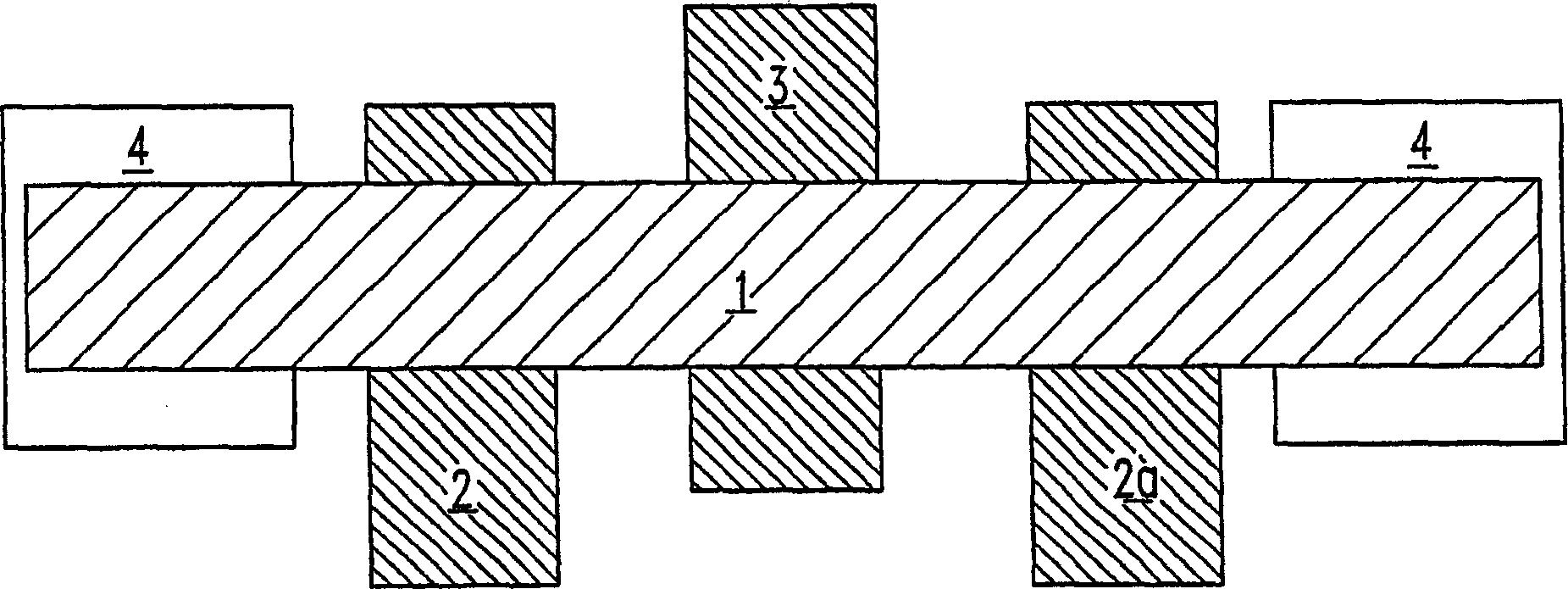

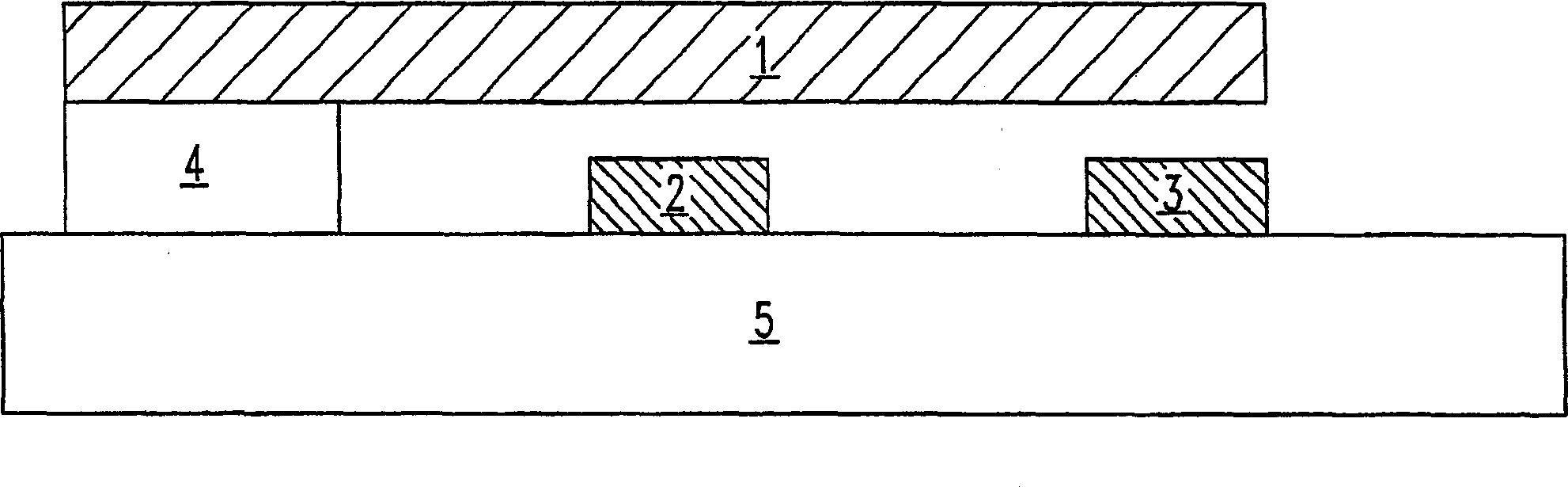

[0034] The main embodiments teach the fabrication of MEMS devices by methods that can be fully integrated with standard CMOS, bipolar, BiCMOS or other common semiconductor chip processes.

[0035] Figure 5 The initial structure, the copper damascene interconnect layer, is illustrated. Below this, on a silicon substrate or alternatively on a preferably SiO 2 Devices such as FETs, NPN transistors or HBT (Hetero-junction Bipolar Transistors, heterojunction bipolar transistors), resistors, etc. can be placed on the fabricated low-loss substrate. It consists of embedding in preferably SiO 2 The copper wirings 30, 40, and 50 in the dielectric layer 20 constituted. The area indicated by reference numeral 30 represents the landing metal for the via 110 buried in the dielectric layer 100 . The metal designated by reference numeral 40 forms the actuator or control electrode, and the metal 50 represents the signal electrode. The thickness of the metal is generally on the order of 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com