Structure for preventing dislocation of container, and sealing pump-up device

A container and anti-dropping technology, applied in tires, household appliances, external accessories, etc., can solve problems such as separation and loose threads, and achieve the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

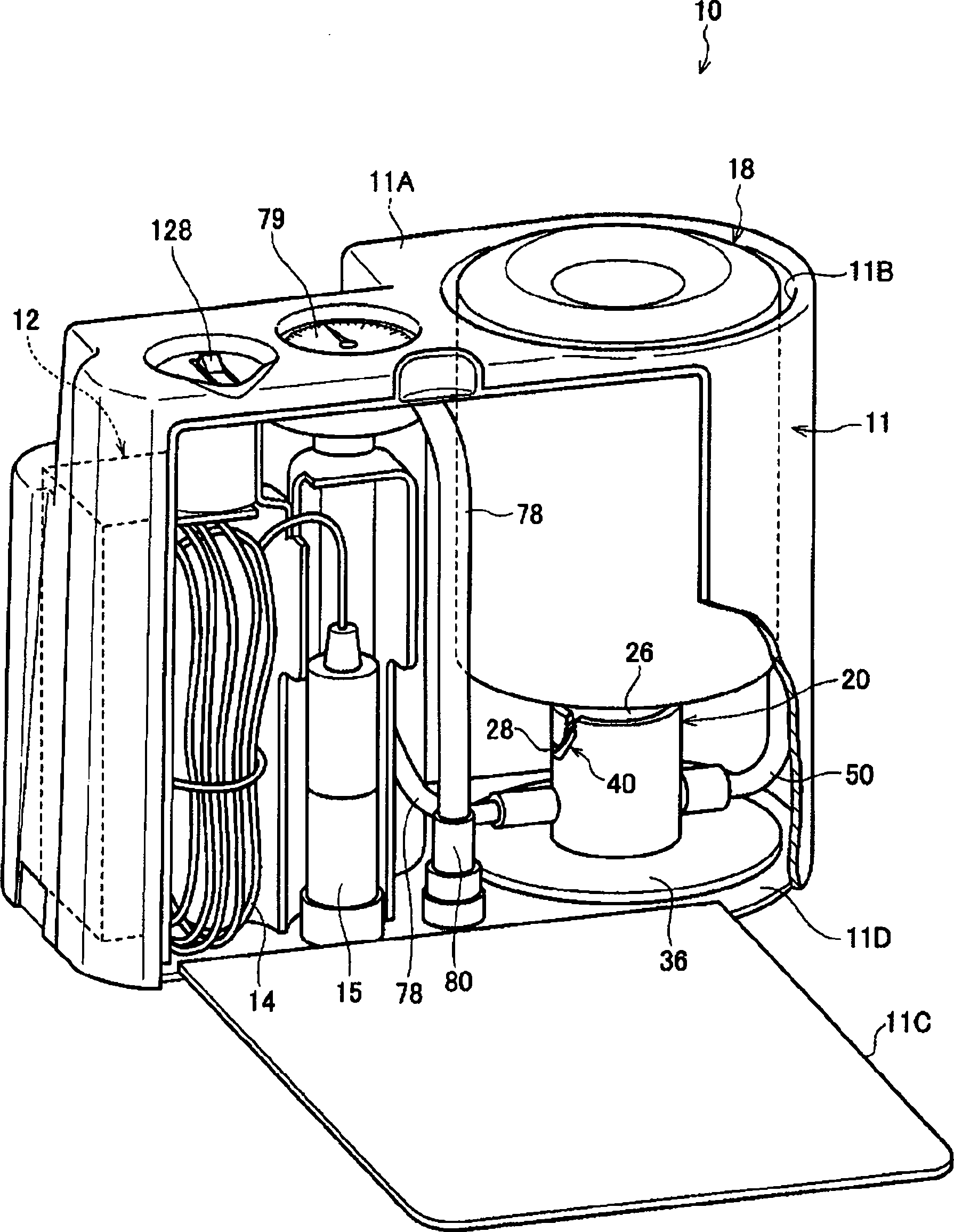

[0042] Next, a first embodiment of the sealing pumping device of the present invention to which the container detachment prevention structure of the present invention is applied will be described.

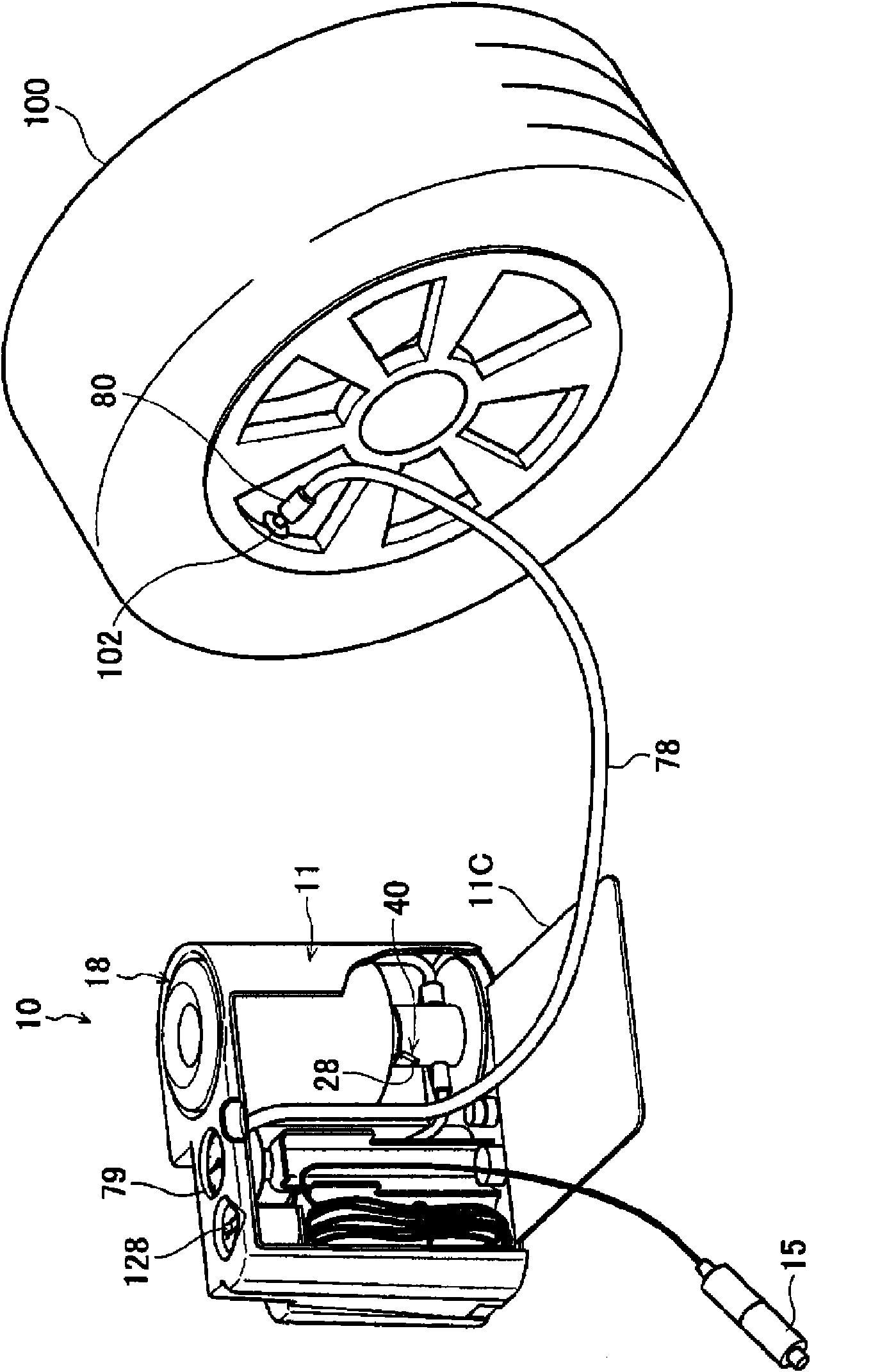

[0043] figure 1 A perspective view showing the sealing and pumping device 10 (hereinafter simply referred to as "sealing device") of the first embodiment viewed from the front side, figure 2 It is a perspective view showing the connection state between the sealing device 10 and the pneumatic tire 100 (hereinafter simply referred to as "tire"). The sealing device 10 is used in the following situations: when a tire installed on a vehicle such as an automobile leaks air, the puncture of the tire is repaired with a tire sealant without replacing the tire and the wheel hub, and the internal pressure of the tire is repressurized (inflated) to a specified value. pressure.

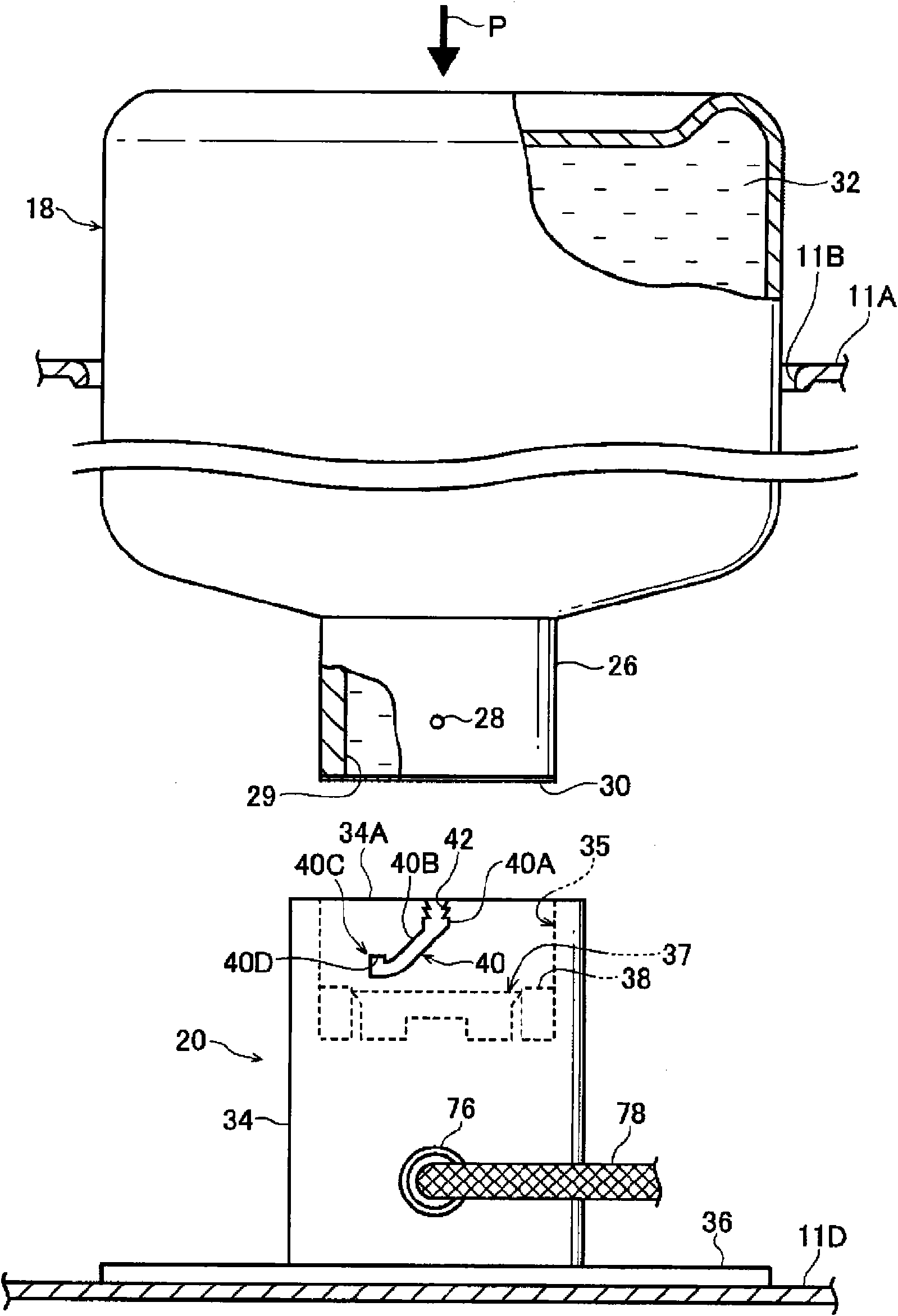

[0044] Such as figure 1 and figure 2 As shown, the sealing device 10 includes a box-shaped casing 11, and a co...

no. 2 Embodiment approach

[0079] Next, a second embodiment of the seal pumping device will be described. In addition, the same reference numerals are assigned to the same components as those in the first embodiment, and description thereof will be omitted. Such as Figure 11 As shown, in the sealing device 130 of the second embodiment, instead of the protrusion 28, the claw portion 42, and the slit hook portion 40C of the first embodiment, a first protrusion 150, a second protrusion 152 and a first protrusion described later are provided. The hooking part 132 .

[0080] Such as Figure 11 As shown, on the neck portion 26 of the liquid container 18 , annular protrusions having a triangular cross-section are formed at two places in the axial direction (vertical direction). The protrusion on the side of the outflow port 29 is referred to as the first protrusion 150 , and the protrusion above the protrusion 150 (that is, on the side away from the outflow port 29 ) is referred to as the second protrusion...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com