Vibrating micro-mechanical sensor of angular velocity

An angular velocity sensor, micro-mechanical technology, applied in the direction of gyroscopic effect for velocity measurement, velocity/acceleration/shock measurement, instruments, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

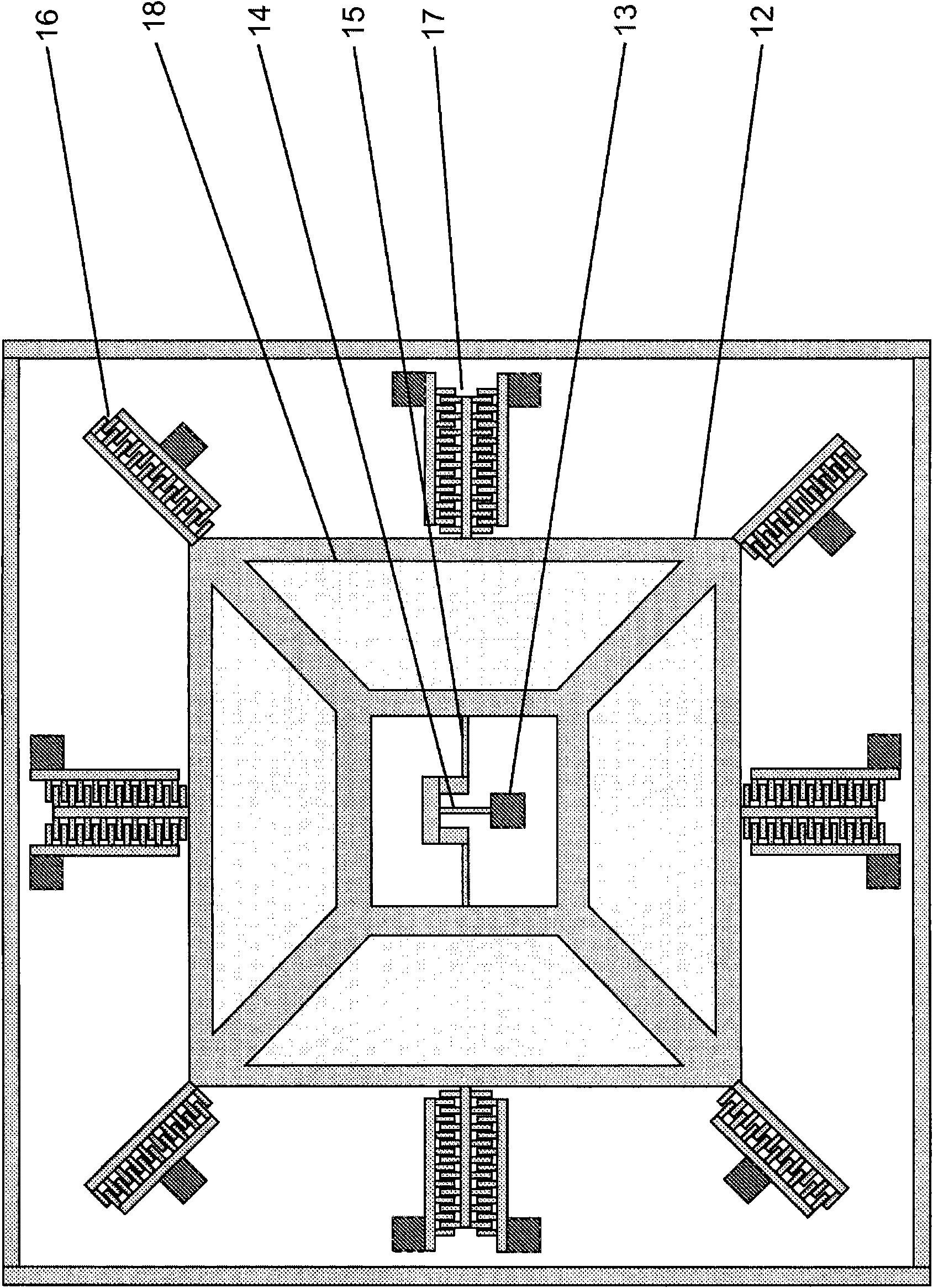

[0035] Figure 4 A functional structural diagram of the vibrating micromachined angular velocity sensor with three axes of the present invention is shown. The vibration-type micromechanical angular velocity sensor with three axes described in the present invention includes a rotating mass 34, which is supported by the support structure 19 at the center through springs 28 and 29, and is passed in the X-axis direction by Springs 30,31 are supported by excitation frame structures 32,33. The rotating block 34 also includes electrodes 37 - 40 . In addition, the three-axis vibrating micromechanical angular velocity sensor of the present invention also includes linear blocks 35 and 36 , and these linear blocks are supported by the excitation frame structures 32 and 33 via springs 45 and 46 in the X-axis direction. The excitation frame structures 32, 33 are supported by the frame 23 around the sensor through the bending springs 24-27 in the Y-axis direction. In addition, the vibrat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com