Permanent magnet rotor, and rotating machine comprising such a rotor

A technology of permanent magnets and rotors, applied in the direction of magnetic circuit rotating parts, magnetic circuits, electromechanical devices, etc., can solve problems such as limiting the power of magnets

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

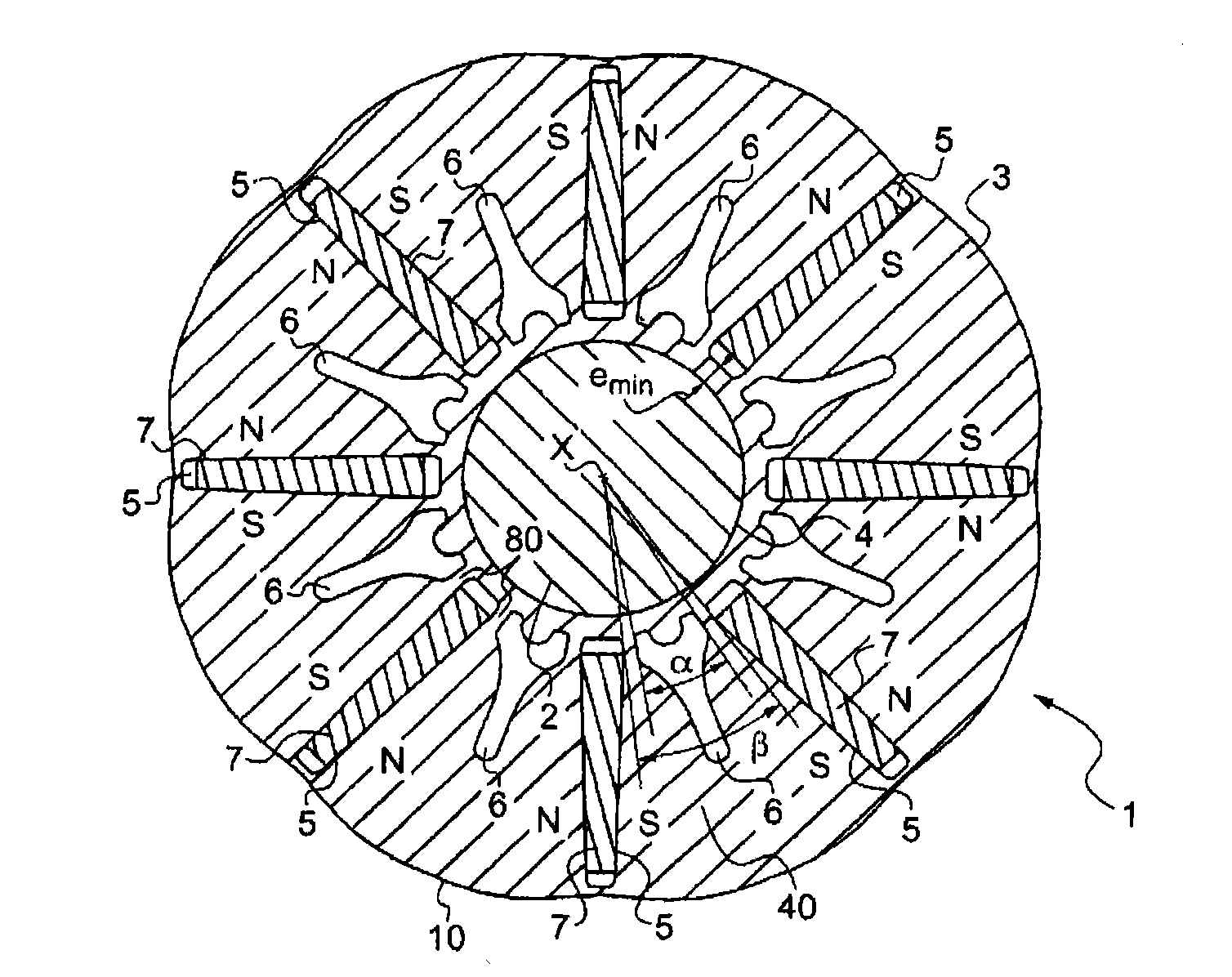

[0071] figure 1 The rotor 1 shown comprises a magnetic rotor mass 3 extending axially along the axis of rotation X of the rotor, for example formed by a stack of laminations stacked along the axis X, said laminations being for example all identical and are precisely stacked together.

[0072] The rotor 1 has a plurality of permanent magnets 7 arranged in corresponding accommodations in the magnetic rotor mass, such that two consecutive magnets 7 have the same magnetic poles on their facing faces.

[0073] A rotor mass 3 is mounted on a shaft 2 which, in the described embodiment, is made of a magnetic material such as steel.

[0074] The rotor mass 3 has a central opening 4 for receiving the shaft 2 .

[0075] The rotor 1 is housed in a stator (not shown) comprising, for example, windings which may be concentrated or dispersed. When used as a synchronous motor, the stator is used to generate a rotating magnetic field that drives the rotor to rotate, and when used as an alter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com