Nozzle plate of color sorter

A nozzle plate and color sorter technology, applied in the field of color sorters, can solve problems such as unsmooth air flow, affecting production stability, unreasonable design, etc., and achieve the effect of improving efficiency

Inactive Publication Date: 2011-05-25

ANHUI JIEXUN OPTOELECTRONICS TECH

View PDF6 Cites 1 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The nozzle is the main working part of the color sorter. The air intake of the original nozzle needs to be turned 90° and then ejected from the nozzle. Due to the structural limitation of the machine, the air inlet can only enter from the lower part, so the design is not reasonable enough, resulting in unsmooth air flow. Affect the stability of production

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

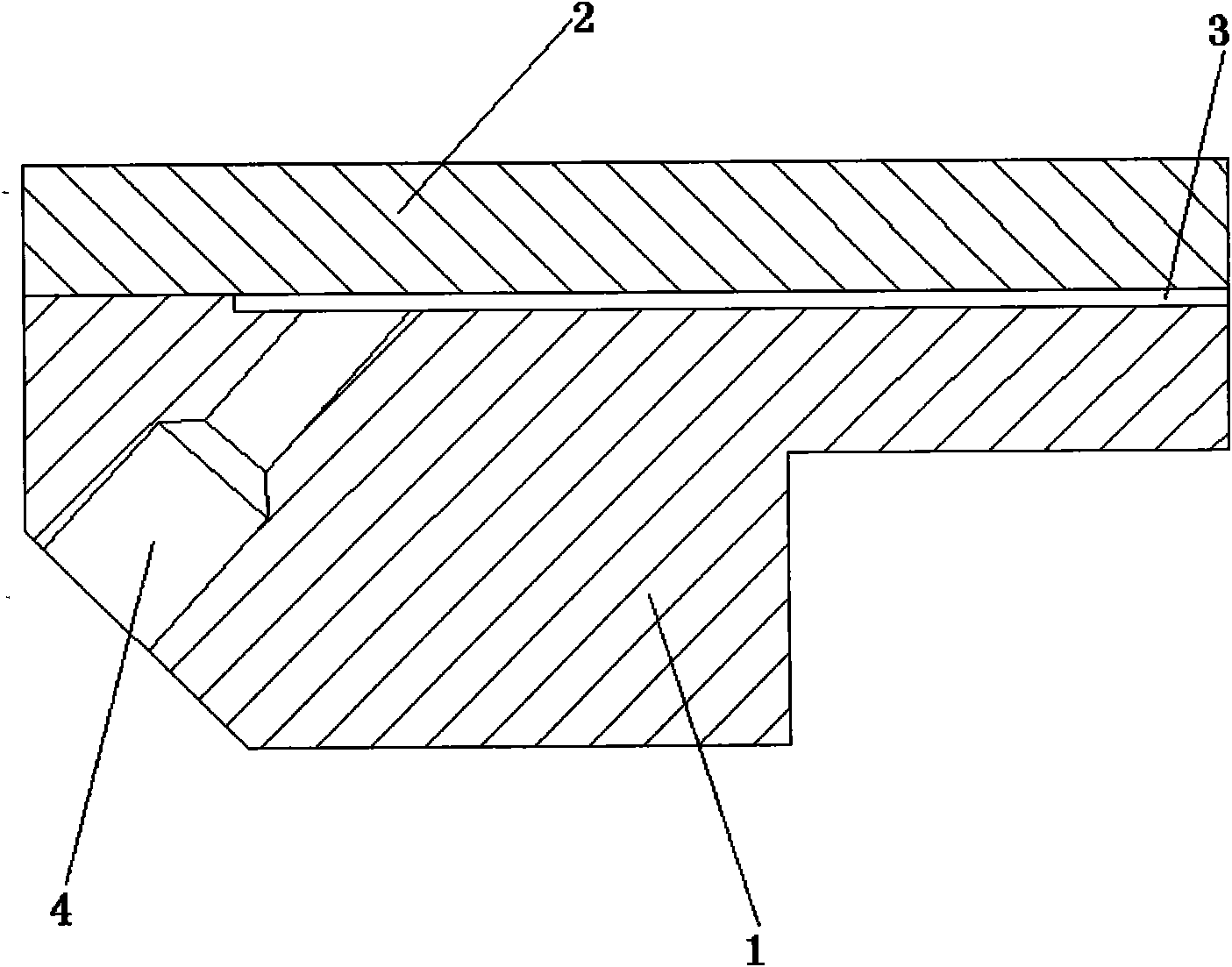

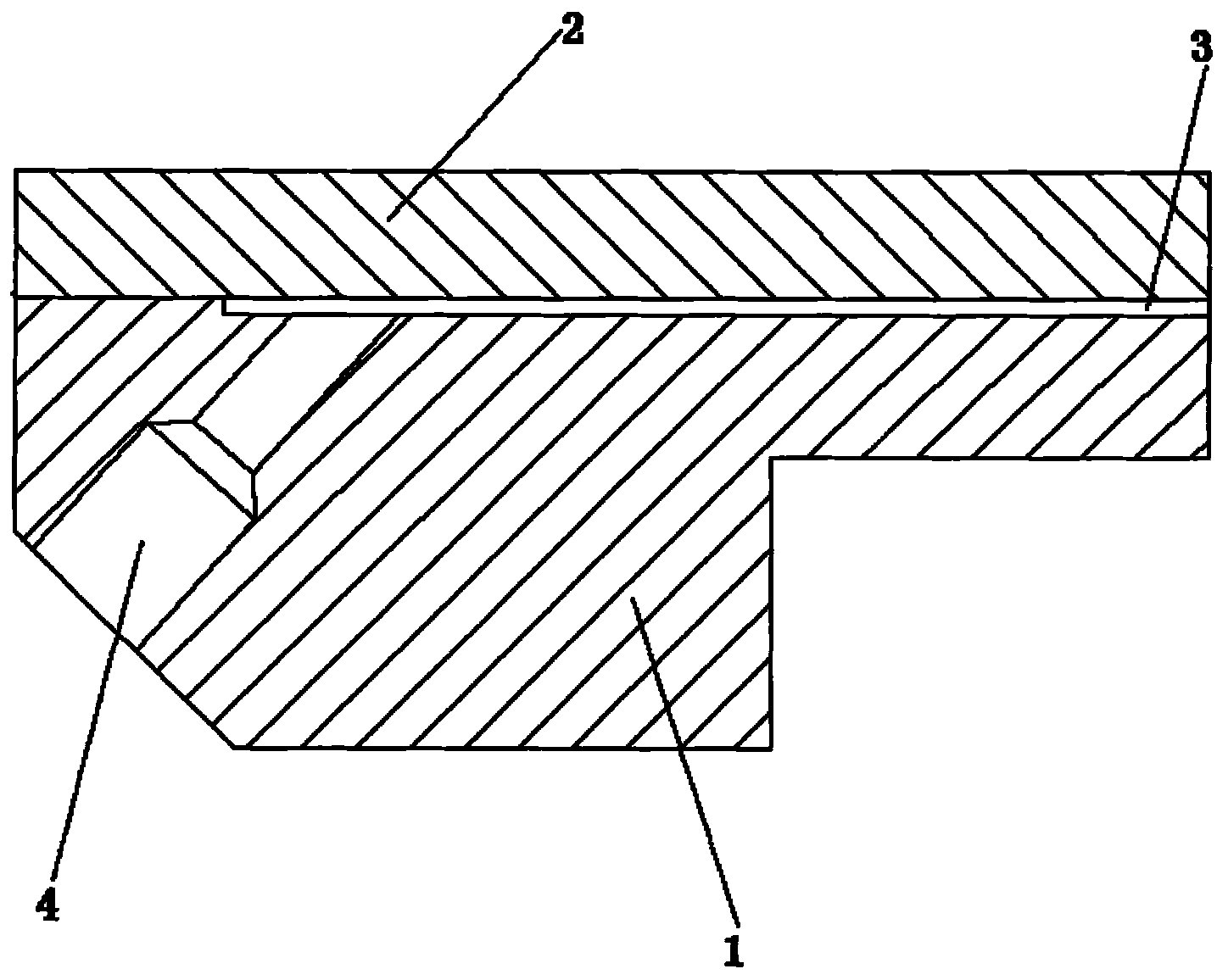

[0009] Referring to the accompanying drawings, the nozzle plate of the color sorter includes a nozzle plate body 1 and a nozzle cover 2. The gap between the nozzle plate body 1 and the nozzle cover 2 is the nozzle opening 3, and there are multiple inclined inlets in the nozzle plate body. Air port 4, the end of air inlet 4 communicates with nozzle port 3, and the inclination angle of air inlet 4 is 52 °.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| Slope | aaaaa | aaaaa |

Login to View More

Abstract

The invention discloses a nozzle plate of a color sorter, which comprises a nozzle plate body and a nozzle cover, wherein a gap between the nozzle plate body and the nozzle cover is a nozzle exit, the inside of the nozzle plate body is provided with a plurality of inclined air inlets, and the tail s of the air inlets are communicated with the nozzle exit. The nozzle plate disclosed by the invention has the advantages that because a 52-degree included angle is formed between the air inlets and a horizontal line, the gas injection is smoother, and to airflows with an injection time of three-thousandths seconds, the structures of airflow channels are extremely sensitive, thereby improving the production efficiency.

Description

technical field [0001] The invention relates to the technical field of color sorters, in particular to the nozzle plate of the color sorter. Background technique [0002] Color sorter is an effective sorting equipment used for quality testing and grading of bulk materials. It is widely used in grain, food, pigment chemical industry and other industries. According to the difference in the optical characteristics of the material, the equipment that uses photoelectric technology to automatically sort out the heterochromatic particles in the granular material. The nozzle is the main working part of the color sorter. The air intake of the original nozzle needs to be turned 90° and then ejected from the nozzle. Due to the structural limitation of the machine, the air inlet can only enter from the lower part, so the design is not reasonable enough, causing the airflow to be blocked. affect the stability of production. Contents of the invention [0003] The object of the present...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): B07C5/342

Inventor 高小荣王志平卢萍

Owner ANHUI JIEXUN OPTOELECTRONICS TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com