Machining electrode for annular holes and machining method

A processing method and annular hole technology, applied in electrode manufacturing, electric machining equipment, metal processing equipment, etc., can solve the problems of difficult machining of annular holes, electrode wear, low machining accuracy, etc., to reduce uneven wear and ensure uniformity. Sexual, easy-to-use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

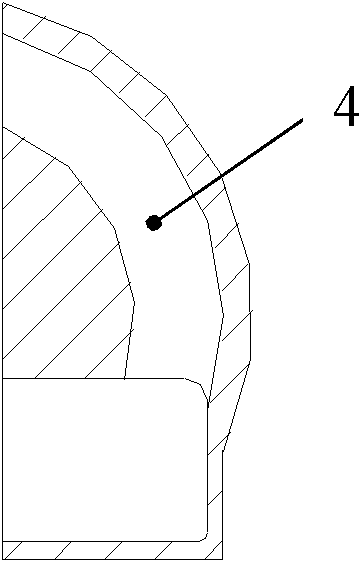

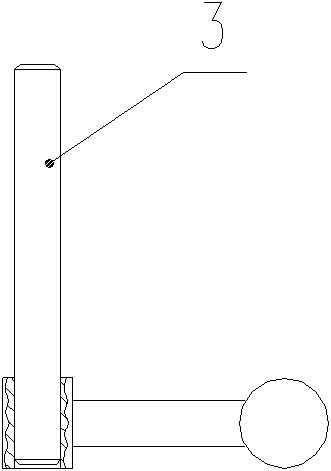

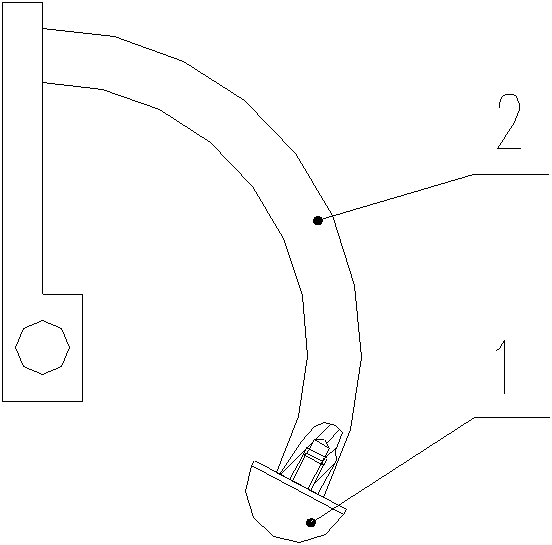

[0024] see figure 1 , 2 as well as image 3 , the processing electrode of the annular hole involved in the present invention includes an electrode head 1, a connecting rod 2 and an electrode rod 3, wherein one end of the connecting rod 2 is connected to the electrode rod 3 by interference or through a screw thread, and the other end is connected to the electrode head through a thread 1 connection. The connecting rod 2 is an arc-shaped rod and a cylindrical rod, that is, the end connecting the connecting rod 2 and the electrode head 1 is set in an arc shape, and the end used for fixing is a columnar structure, and the end of the electrode head 1 is spherical. The end of the connection between the head and the connecting rod is provided with a 0.1-0.2mm wide cylindrical processing ligament, which can reduce the wear of the electrode head 1, ensure the service life of the electrode and the processing quality of the inner surface of the annular hole 4; the material of the electr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com