Temperature-controllable self-positioning bar hot rolling transportation roller way

A technology of conveying rollers and positioning rods, which is applied in the field of metal pressure processing, and can solve problems such as indentation, bar surface scratches, damage, etc., and achieve the effects of prolonging service life, reducing uneven wear, and improving yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

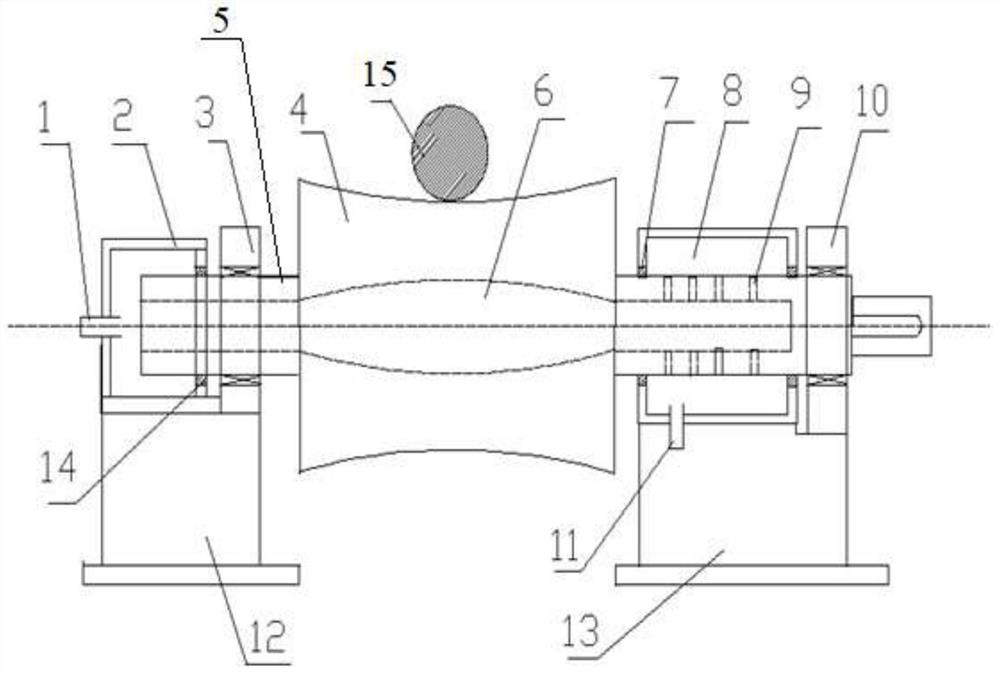

[0023] Such as figure 1 As shown, a temperature-controllable self-positioning bar hot-rolled transport roller table, the transport roller table includes a water inlet pipe 1, a water inlet tank 2, a fixed end bearing housing 3, a roller table 4, a roller table shaft 5, and a cooling pipe Road 6, water outlet tank sealing ring 7, water outlet tank 8, drain hole 9, transmission end bearing housing 10, drain pipe 11, fixed end base 12, transmission end base 13, water inlet tank sealing ring 14;

[0024] The water inlet tank 2 and the fixed end bearing seat 3 are arranged on the fixed end base 12, and the water outlet tank 8 and the transmission end bearing seat 10 are arranged on the transmission end base 13;

[0025] The surface of the roller table 4 is a concave arc-shaped surface, the roller table shaft 5 passes through the center of the roller table 4, and the inside of the roller table shaft 5 is provided with a cooling pipeline 6; one end of the roller table shaft 5 passes ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com