Sliding bearing of spiral floating bushing

A sliding bearing and floating sleeve technology, applied in sliding contact bearings, rotating bearings, bearings, etc., can solve the problems of large floating sleeve bearing, contact corrosion on the bearing surface, oil film rupture, etc., and achieve uniform and synchronous bearing wear and tear. The effect of uniform synchronization and improved lubrication

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

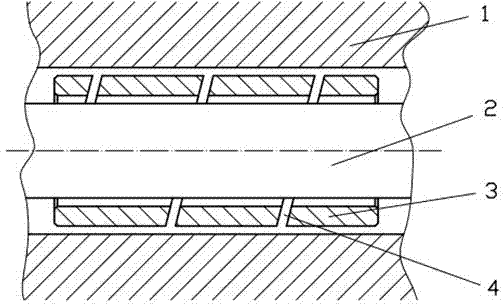

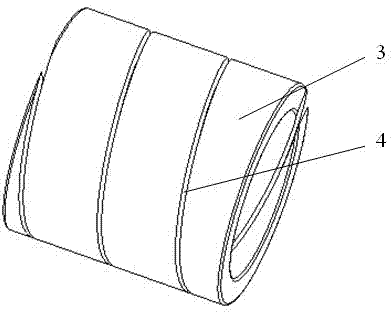

[0023] Such as figure 1 , 2 , 3, 4, and 5: a spiral floating sleeve sliding bearing, including a bearing outer ring 1, a journal 2 and a floating sleeve 3, and the floating sleeve 3 is installed between the journal 2 and the bearing outer ring 1 , A helical groove 4 is opened on the floating sleeve 3, and the helical groove 4 penetrates radially.

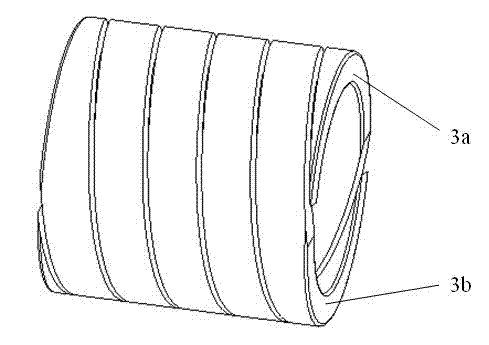

[0024] At least two sections of floating sleeves 3 are arranged between the bearing outer ring 1 and the journal 2 , and the floating sleeves 3 are arranged side by side along the axial direction of the journal 2 .

[0025] Such as Figure 5 : Multi-stage floating sleeves are independently arranged side by side along the axial direction of the journal 2, and each section can rotate freely without affecting each other. Each floating sleeve can automatically adjust the floating according to the working conditions through the running-in of the bearing, so that the bearing is worn Uniform synchronization to extend service life.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com