A method for detection of tooth wear difference of high-speed milling cutter under vibration

A detection method and high-speed milling technology, applied in measuring/indicating equipment, metal processing mechanical parts, metal processing, etc. Problems such as shortening the service life of the knife

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

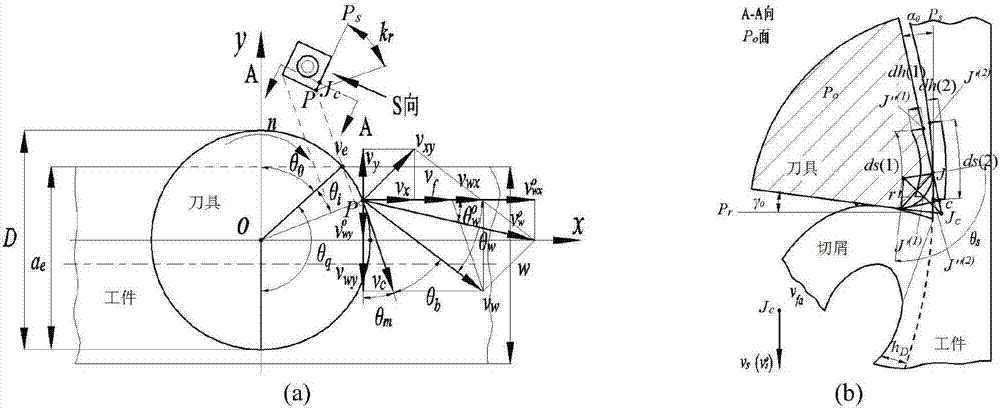

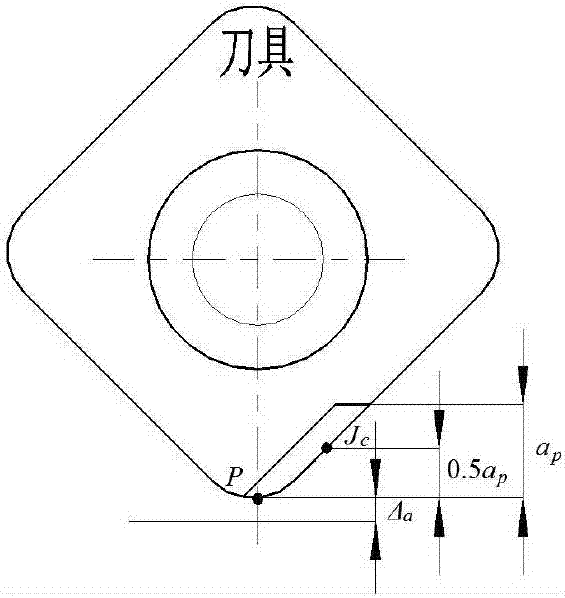

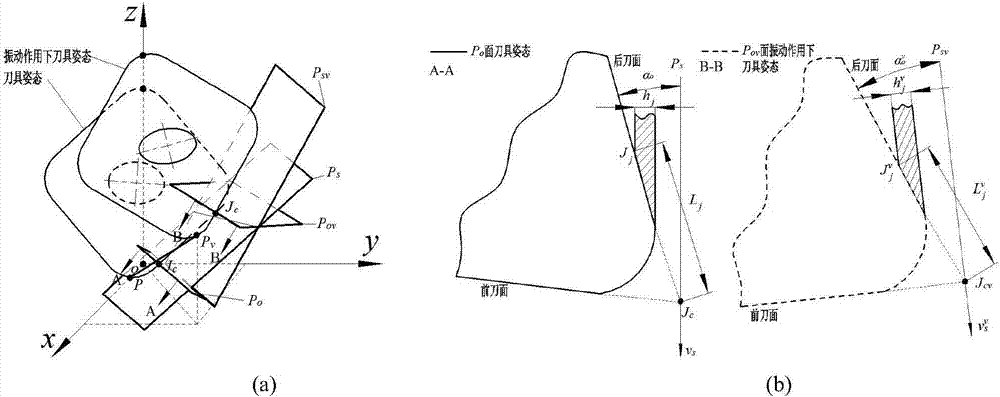

[0101] 1. Establish the relationship between the cutting motion speed of the high-speed milling cutter tooth and the tool contact under the action of vibration, such as figure 1 As shown, at the same time select the position of the maximum wear width on the cutting edge, that is, the middle section of the cutting edge as the base point J c ,Such as figure 2 shown.

[0102] figure 1 in, v f is the feed speed of the cutter teeth (m / s), v c is the cutting speed of the cutter tooth (m / s), v w is the cutting speed v in the feed plane c and feed rate v f The resultant velocity (m / s), v wx is the v of the feed plane w Velocity component in x direction (m / s), v wy is the v of the feed plane w Velocity component in y direction (m / s), v x is the velocity component of the vibration velocity in the x direction (m / s), v y is the velocity component of the vibration velocity in the y direction (m / s), v z is the velocity component (m / s) of the vibration velocity in the Z directi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com