Fast hole-alignment assembly method

An assembly method, hole-to-hole technology, applied to workpiece clamping devices, manufacturing tools, etc., can solve problems affecting production efficiency, assembly trouble, time-consuming, etc., to improve production efficiency, align accurately and quickly, and reduce manpower The effect of material input

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

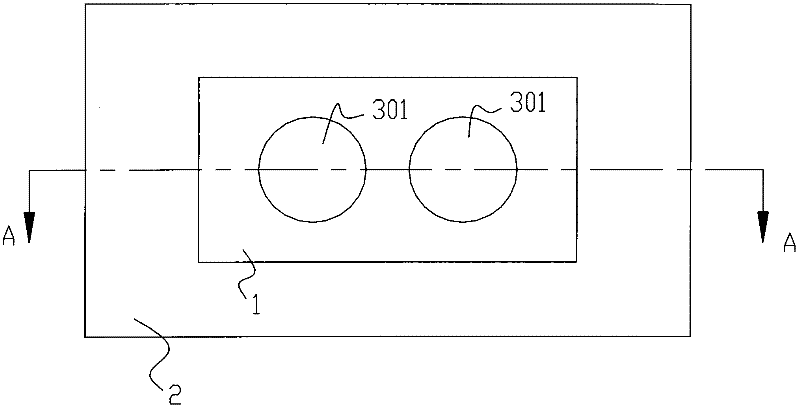

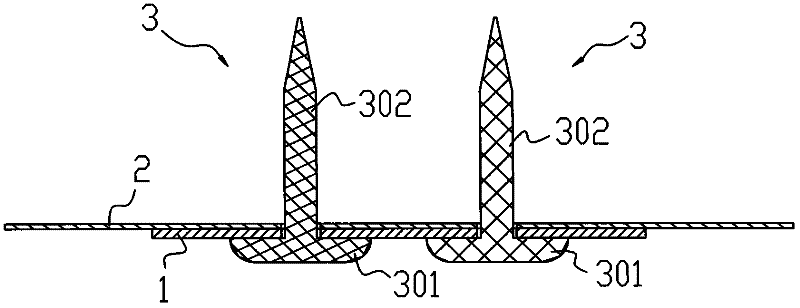

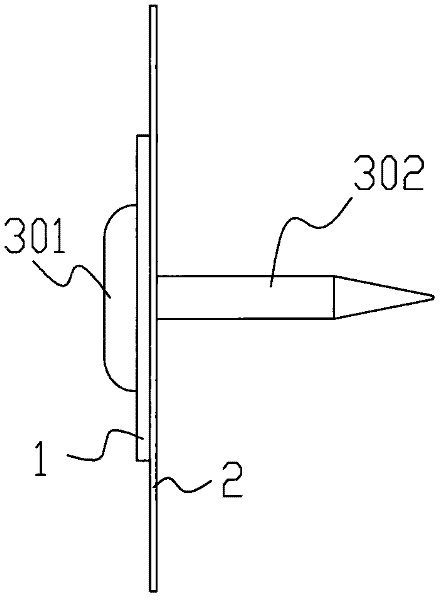

[0020] see figure 1 , figure 2 and image 3 , a quick hole-to-hole assembly method comprising the steps of:

[0021] Several positioning bodies 3 are provided. The positioning bodies 3 are preferably made of elastic rubber. The overall structure of the positioning bodies 3 is similar to that of a tack, including a pin 302 and a protruding head 301 at the base of the pin. In this step, the quantity of the positioning body 3 can be enough, and it is the principle to meet the actual needs. The size specification of the positioning body 3 can also be provided with various according to the actual needs of the assembly hole of the workpiece to be assembled, such as the aperture of the assembly hole The size and the shape of the hole are used as a reference basis to design its size and specification. The pin 302 of each positioning body 3 is preferably able to form an interference fit with the corresponding assembly hole.

[0022] For the multiple workpieces with assembly holes t...

Embodiment 2

[0025] see figure 1 , figure 2 and image 3 , a quick hole-to-hole assembly method comprising the steps of:

[0026] Several positioning bodies 3 are provided. The positioning bodies 3 are preferably made of elastic rubber. The overall structure of the positioning bodies 3 is similar to that of a tack, including a pin 302 and a protruding head 303 at the base of the pin. In this step, the quantity of the positioning body 3 can be enough, and it is the principle to meet the actual needs. The size specification of the positioning body 3 can also be set according to the actual needs of the assembly hole of the workpiece to be assembled, such as the aperture size of the assembly hole And the shape of the hole as a reference basis to set the size and specification, the pin 302 of each positioning body 3 is preferably able to form an interference fit with the corresponding assembly hole.

[0027] For the multiple workpieces with assembly holes to be assembled, in this example th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com