Sealing detection device of fuel filters and detection method thereof

A technology for fuel filter and tightness detection, which is applied in the direction of liquid tightness measurement using liquid/vacuum degree, and detecting the appearance of fluid at the leakage point, etc., which can solve the problems of affecting production efficiency, delaying working hours, and wrong order , to achieve the effect of improving the efficiency of sealing detection, accurate and fast sealing, and preventing the reduction of air pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

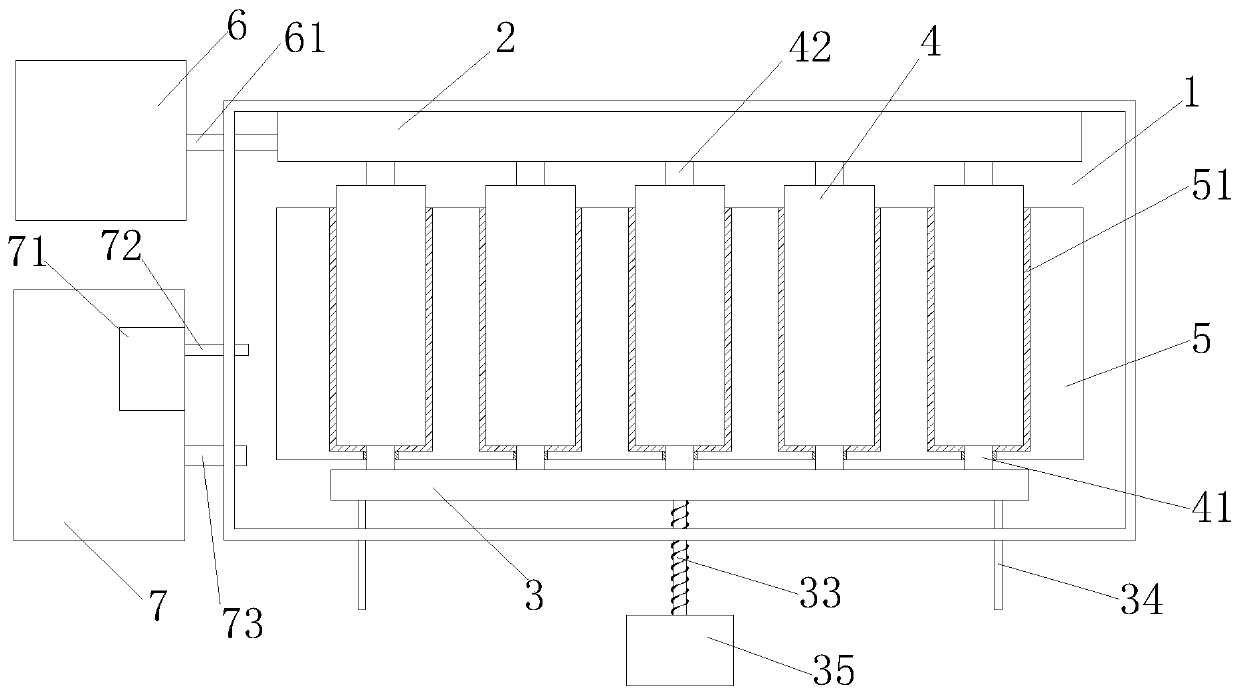

[0030] A fuel filter leak detection device,

[0031] Such as figure 1 As shown: including a pool 1, the two sides of the pool 1 are respectively provided with a sealing plate I2 and a sealing plate II3, and a supporting plate 5 for supporting the fuel filter 4 is arranged between the sealing plate I2 and the sealing plate II3 , the supporting plate 5 is provided with several tanks I51 for placing the fuel filter 4, the inner surface of the tank I51 matches the radian of the outer surface of the fuel filter 4;

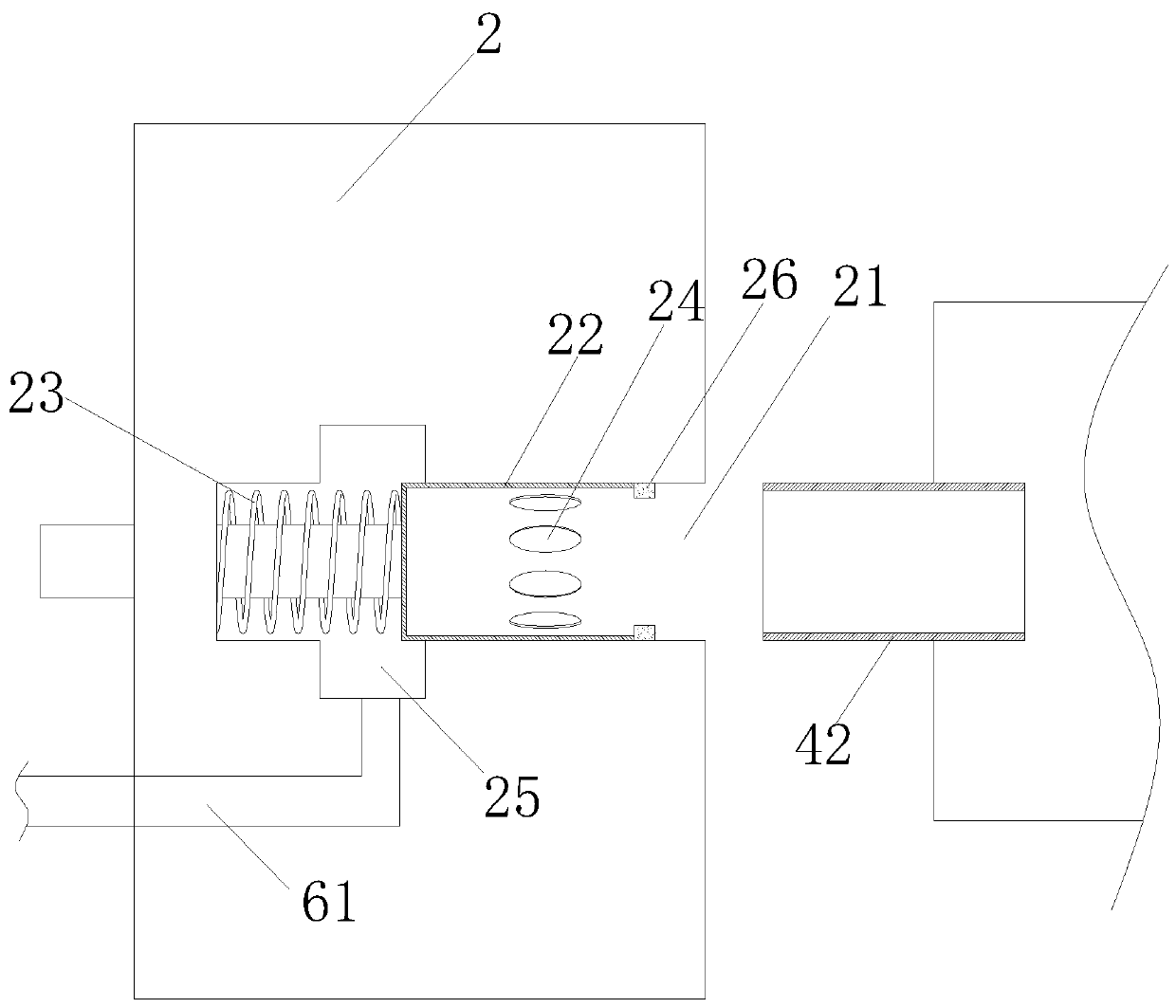

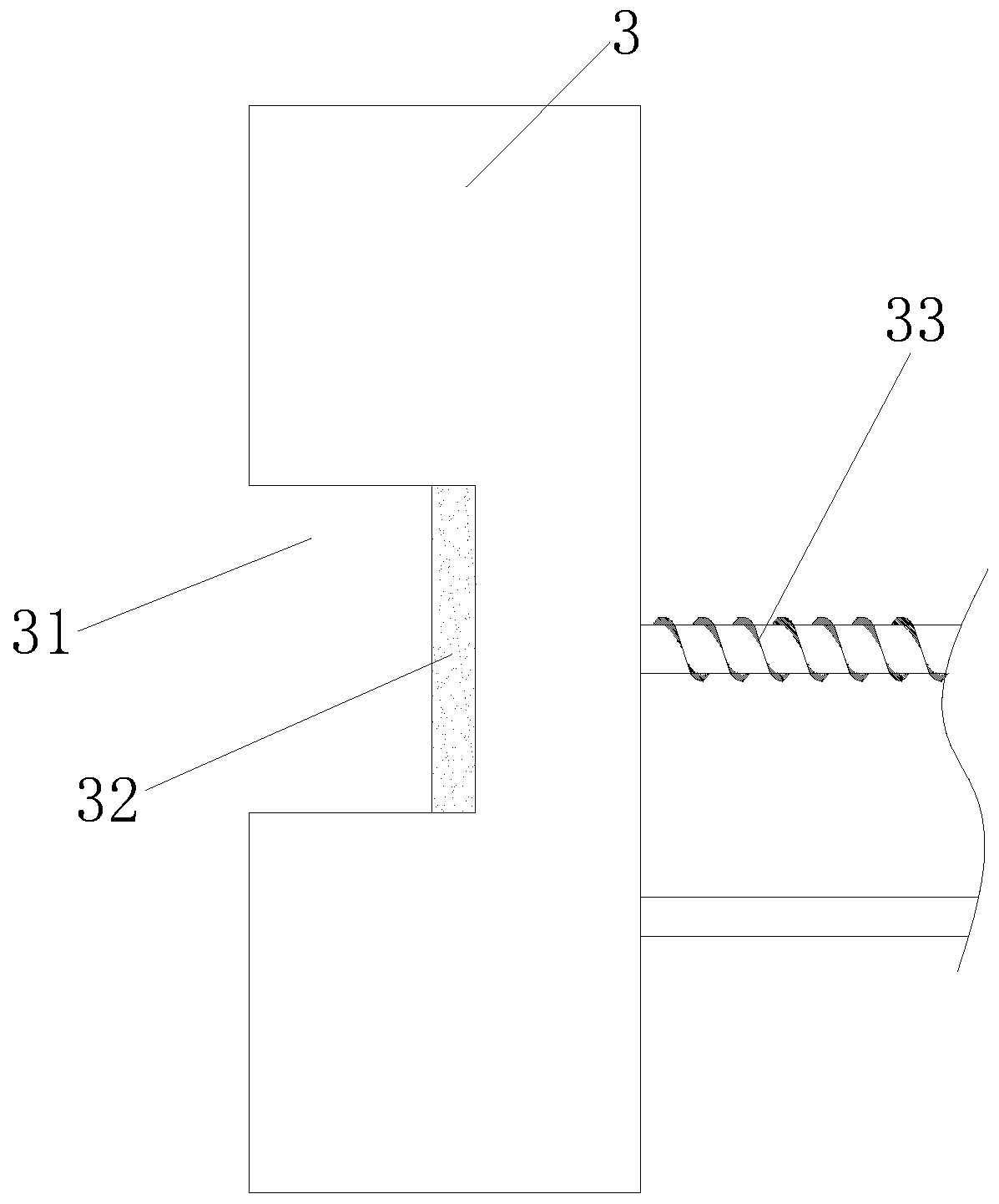

[0032] Such as figure 2 As shown: the two sides of the fuel filter 4 are respectively provided with an oil inlet pipe 41 and an oil outlet pipe 42, and the position of the oil outlet pipe 42 corresponding to the sealing plate I2 is provided with a blind hole I21, and the blind hole I21 is provided with a A tube body 22 with one end sealed, a spring 23 is arranged between the sealed end of the tube body 22 and the bottom of the blind hole I21, the outer side wall of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com