Electric drive earthmover travelling driving device

A walking drive and electric motor technology, which is applied to power units, electric steering mechanisms, pneumatic power units, etc., can solve the problems of high cost and complex hydraulic system structure, and achieve low cost, high transmission efficiency, simple and compact structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

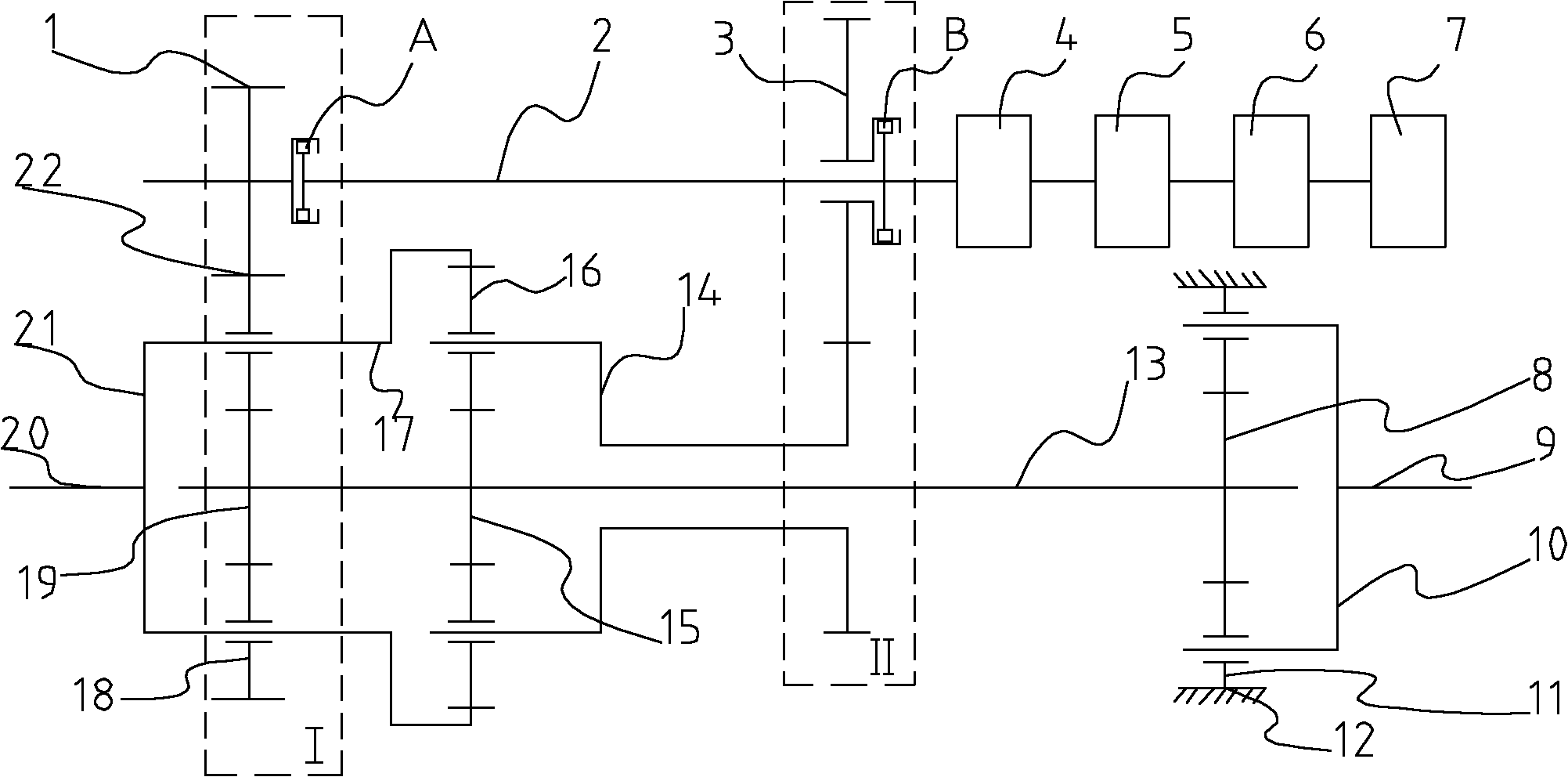

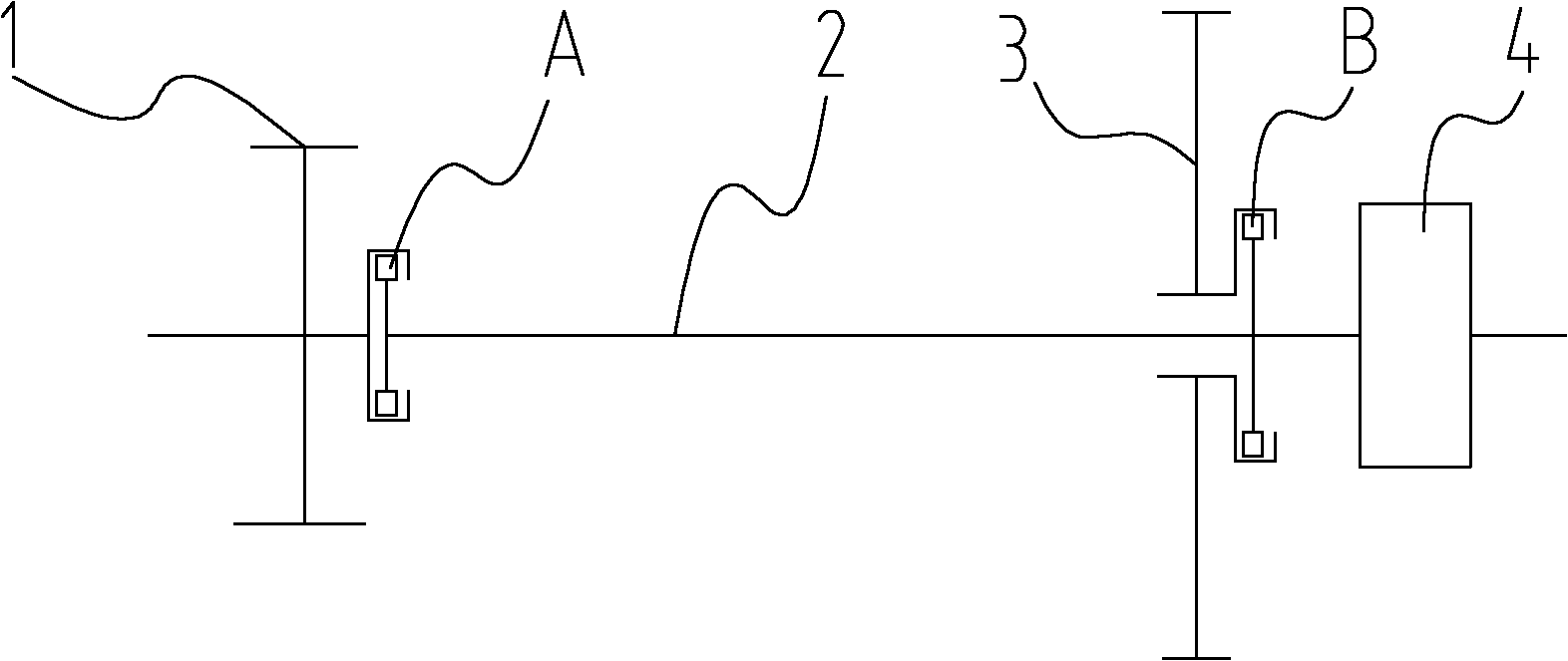

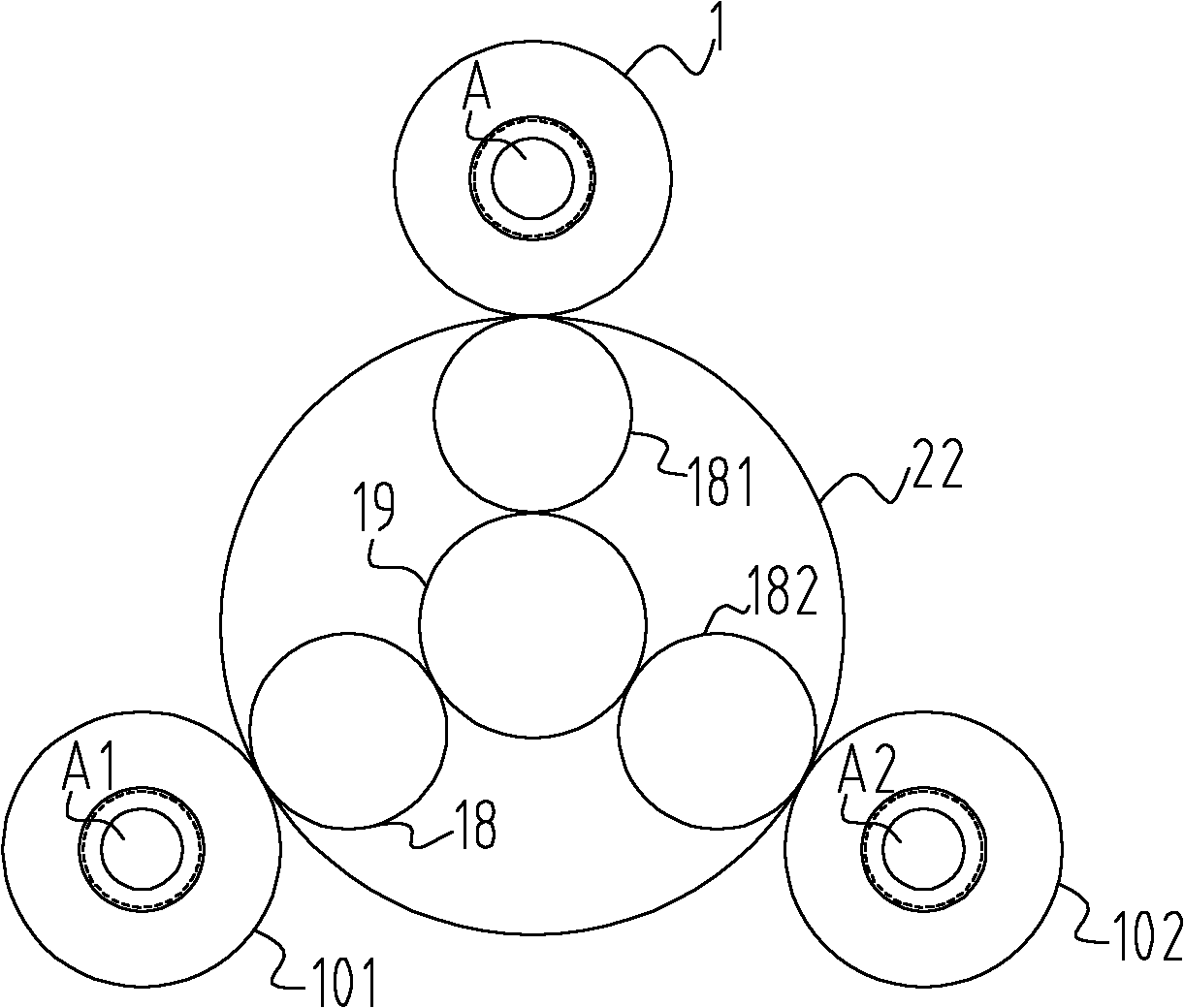

[0021] The present invention is made up of engine 7, generator 6, power inverter 5, electric motor, two-way clutch assembly, differential steering mechanism, wherein motor is three, two-way clutch assembly is three groups, electric motor 4, power inverter 5 , generator 6 and engine 7 are connected in series, the first group of two-way clutch assembly is composed of gear 1, front clutch A, shaft I2, rear clutch B, gear 3 and motor 4, shaft I2 is fixedly connected with clutch A and clutch B respectively , and the right end of the shaft I2 is connected to the motor 4, the shaft II13 is parallel to the shaft I2, the sun gear 19, the sun gear 15 and the sun gear 8 are all fixedly connected to the shaft II13; the first group of two-way clutch assemblies are respectively controlled by the control system Combination or disengagement of clutch A and rear clutch B, when front clutch A is engaged, gear 1 meshes with planetary ring gear 22, at this time rear clutch B is in a disengaged sta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com