Method for obtaining fire detection signal of cylinder of engine with speed sensor arranged in front

A technology of speed sensor and detection signal, which is applied in internal combustion engine testing, vibration measurement in solids, instruments, etc., can solve problems such as the inability to guarantee the quality of the misfire detection signal, the deterioration of the quality of the misfire detection signal, and the impact on the matching quality of the misfire detection. The effect of the amplitude of the misfire detection signal, improving the quality of the misfire detection signal, and reducing the segmental time difference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

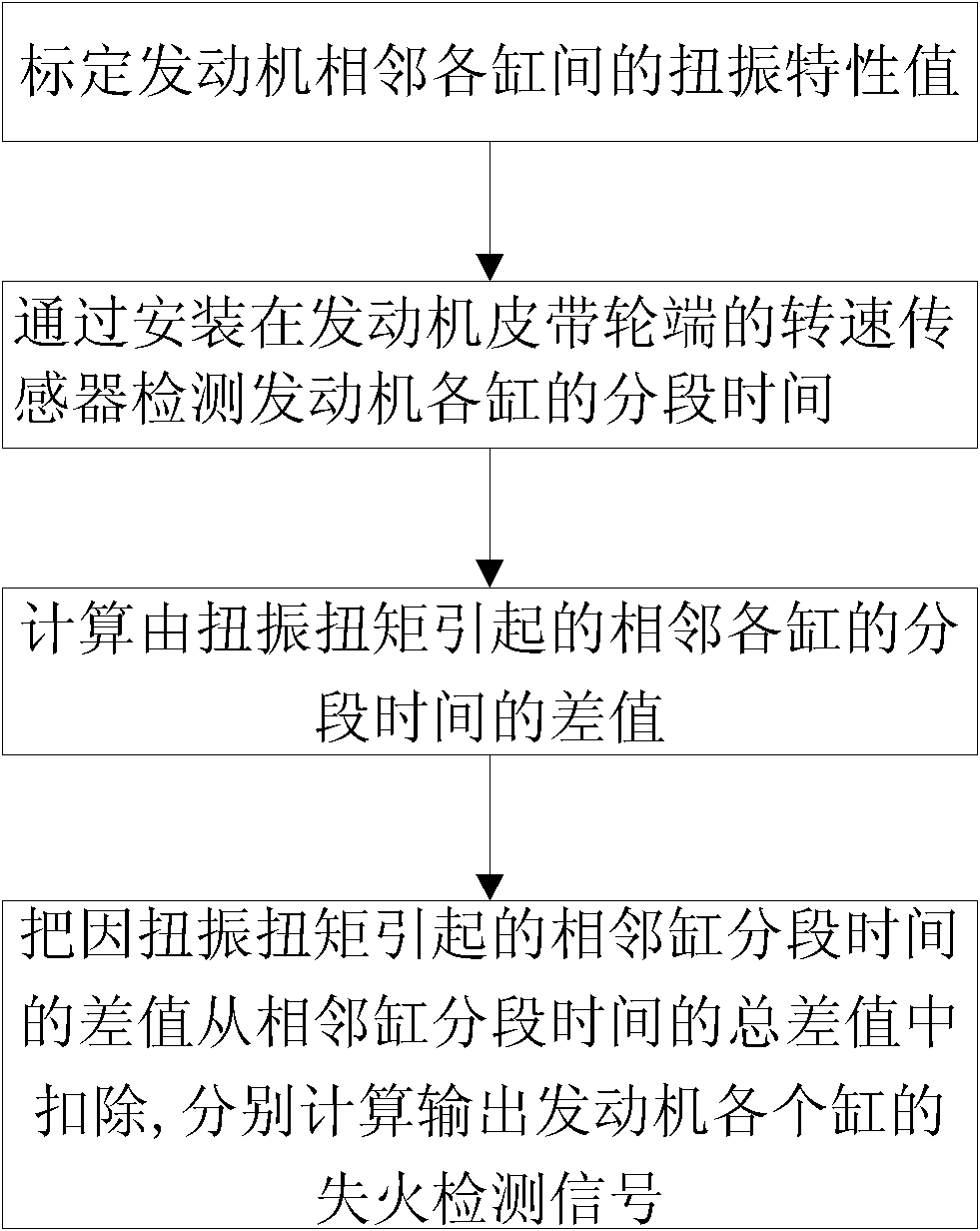

[0030] The misfire detection principle of common automotive EFI on-board diagnostic systems (such as BOSCH system) is as follows:

[0031] When the engine misfires, due to power interruption, the angular acceleration of the engine crankshaft will change, and the angular acceleration change is proportional to the square difference of the rotational speed. A period of time, and then determine the misfire detection signal luts of each cylinder of the engine,

[0032] luts ( 0 ) = tsk ( 0 ) - tsk ( N - 1 ) tsk ( 0 ) 3 ,

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com