Optical cable splitting box

A fiber distribution box and optical cable technology, applied in the direction of fiber mechanical structure, etc., can solve the problems of unclear routing, low installation efficiency, inconvenient maintenance and operation, etc., and achieve the effect of flexible and convenient configuration, good sealing performance, and strong versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

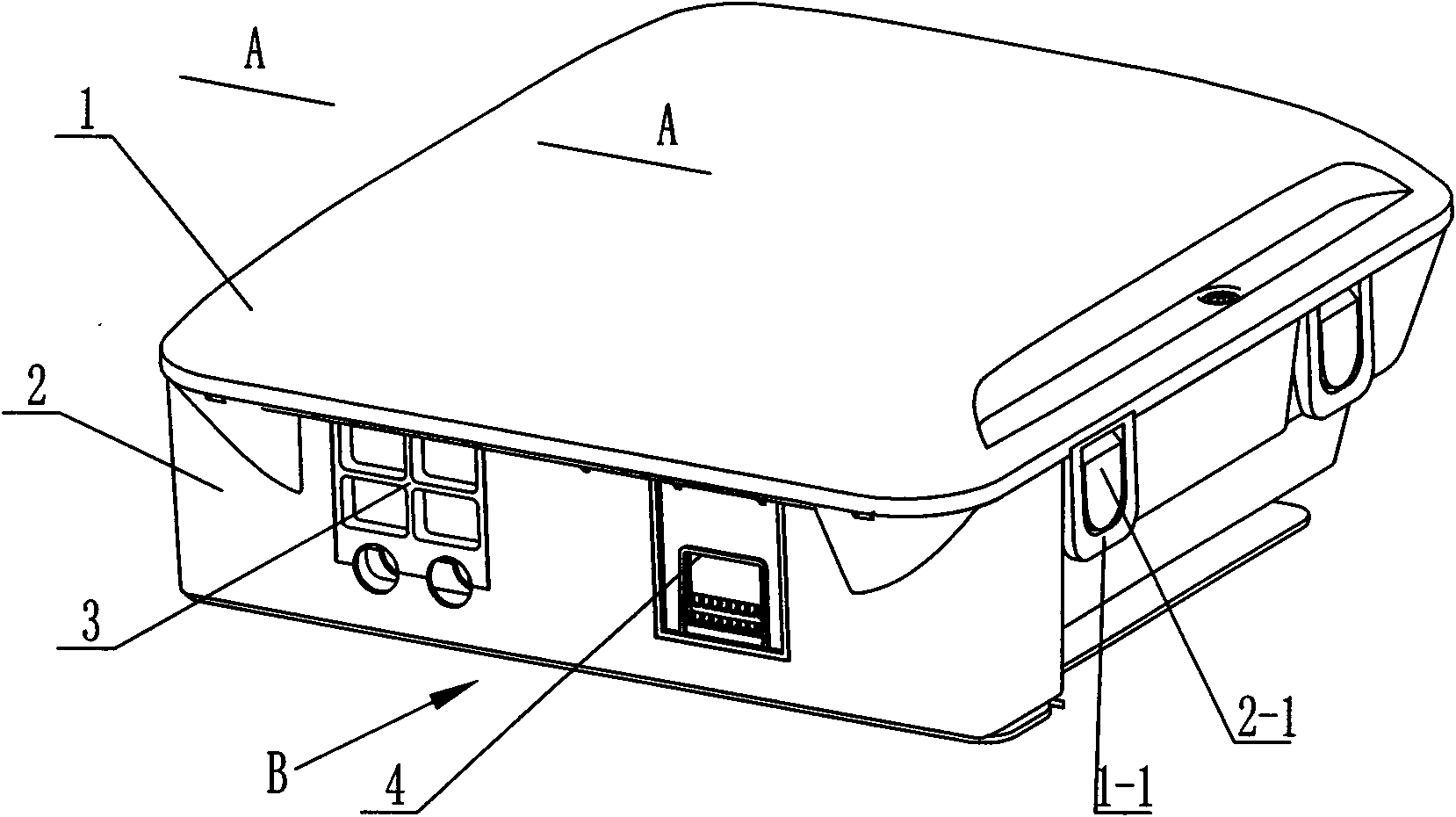

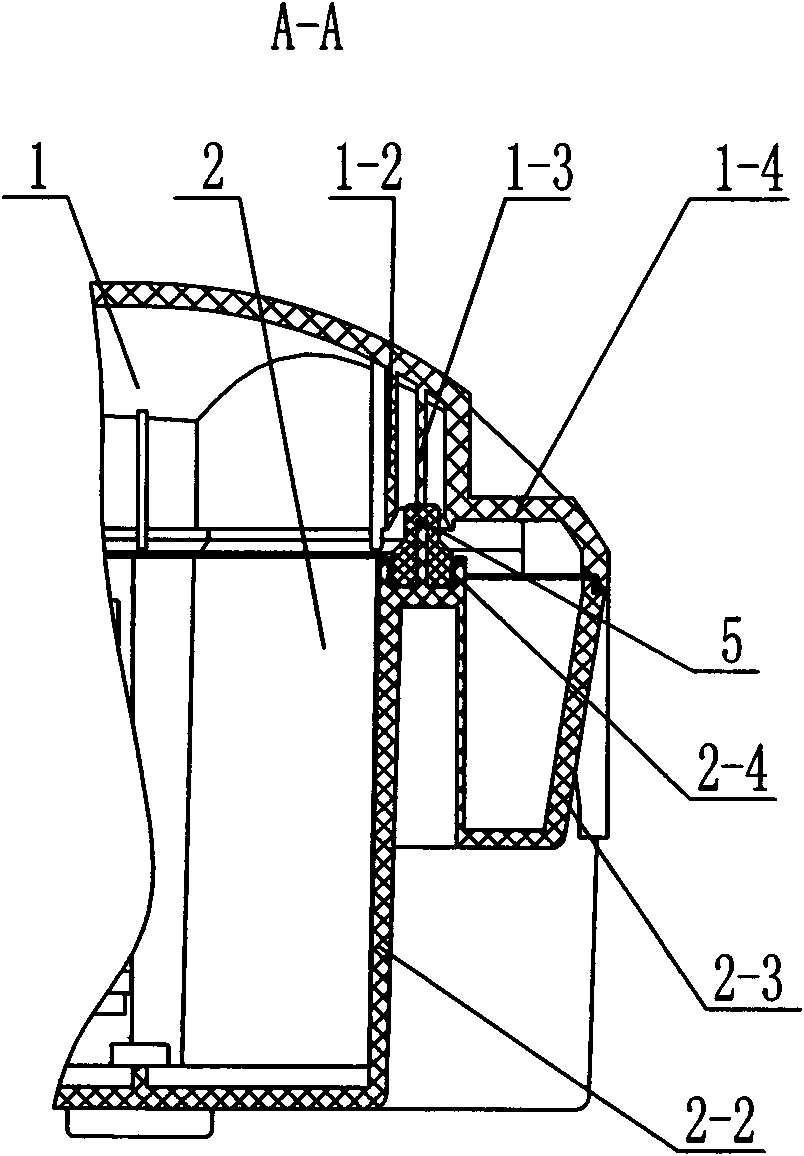

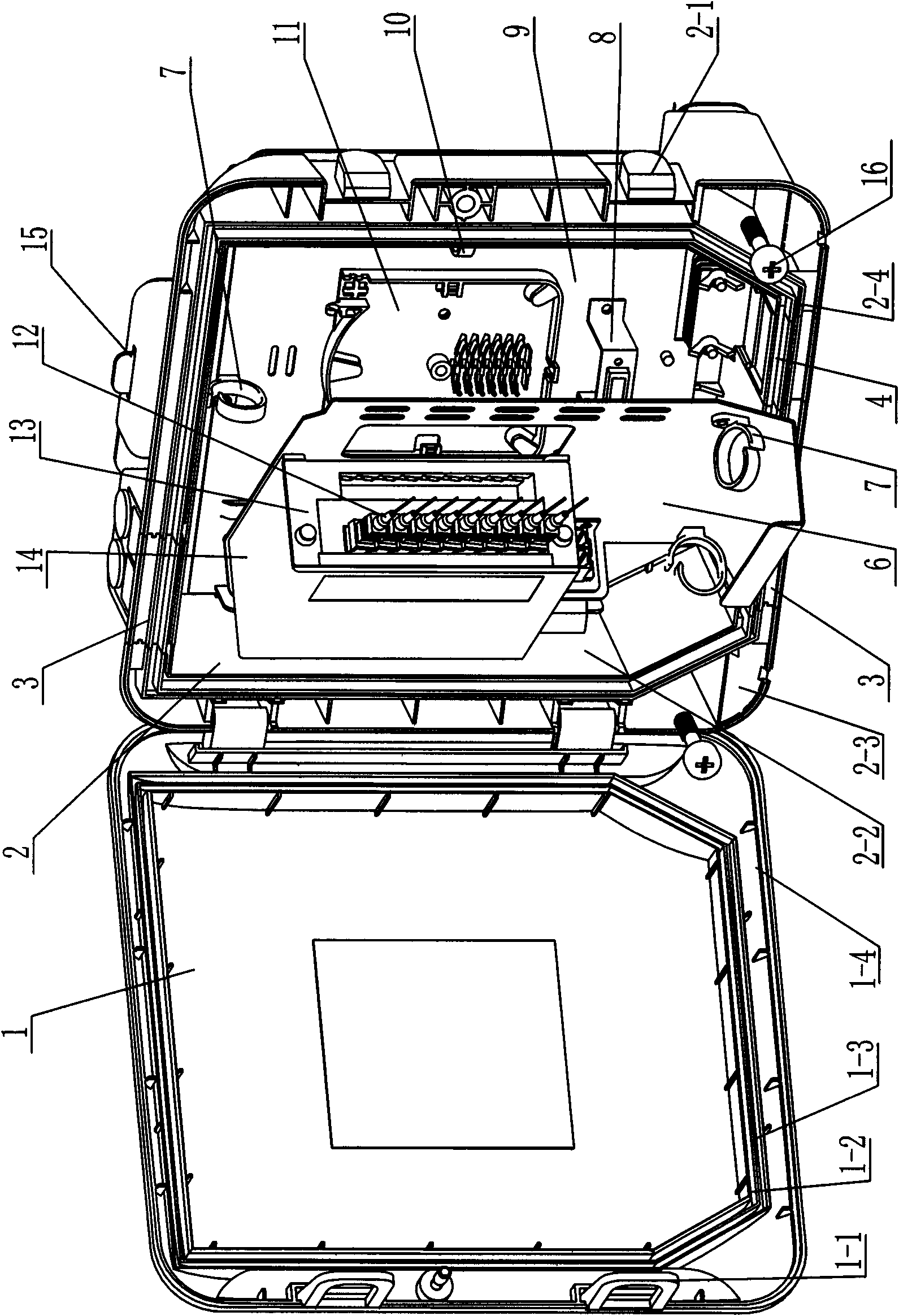

[0037] See Figure 1-12 As shown, the fiber distribution box of the present invention includes a box body 2, a box cover 1, a middle flap 6, a bottom plate 9, a splice tray 11, an optical splitter box 13, a mounting bracket 14 and a threading mechanism 4.

[0038] See Figure 1-7 Shown, box body 2 of the present invention and box cover 1 can adopt non-metallic high-strength material to make, and the box wall 2-2 periphery of box body 2 has to be connected with box wall 2-2 peripheral wall 2-3, and peripheral wall 2 A plurality of reinforcing ribs are connected between -3 and the box wall 2-2 and between the peripheral wall 2-3, and the top of the box wall 2-2 of the box body 2 is provided with a mountain-shaped annular sealing groove 2-4, and the peripheral wall 2 -3 The top is provided with a lower stop, and the cover wall of the box cover 1 is also provided with an outer side wall 1-4 connected with the cover wall. The box cover 1 is located on the inner side of the cover w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com