Virtual vehicle and virtual component-based engine control model (ECM) calibration and verification system

A virtual vehicle and electronic control system technology, applied in general control systems, control/regulation systems, simulators, etc., can solve the problems of considerable cost, high development cost, and considerable time, and achieve transplantation costs and transplantation work The effect of small quantity, improved development quality and shortened development cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

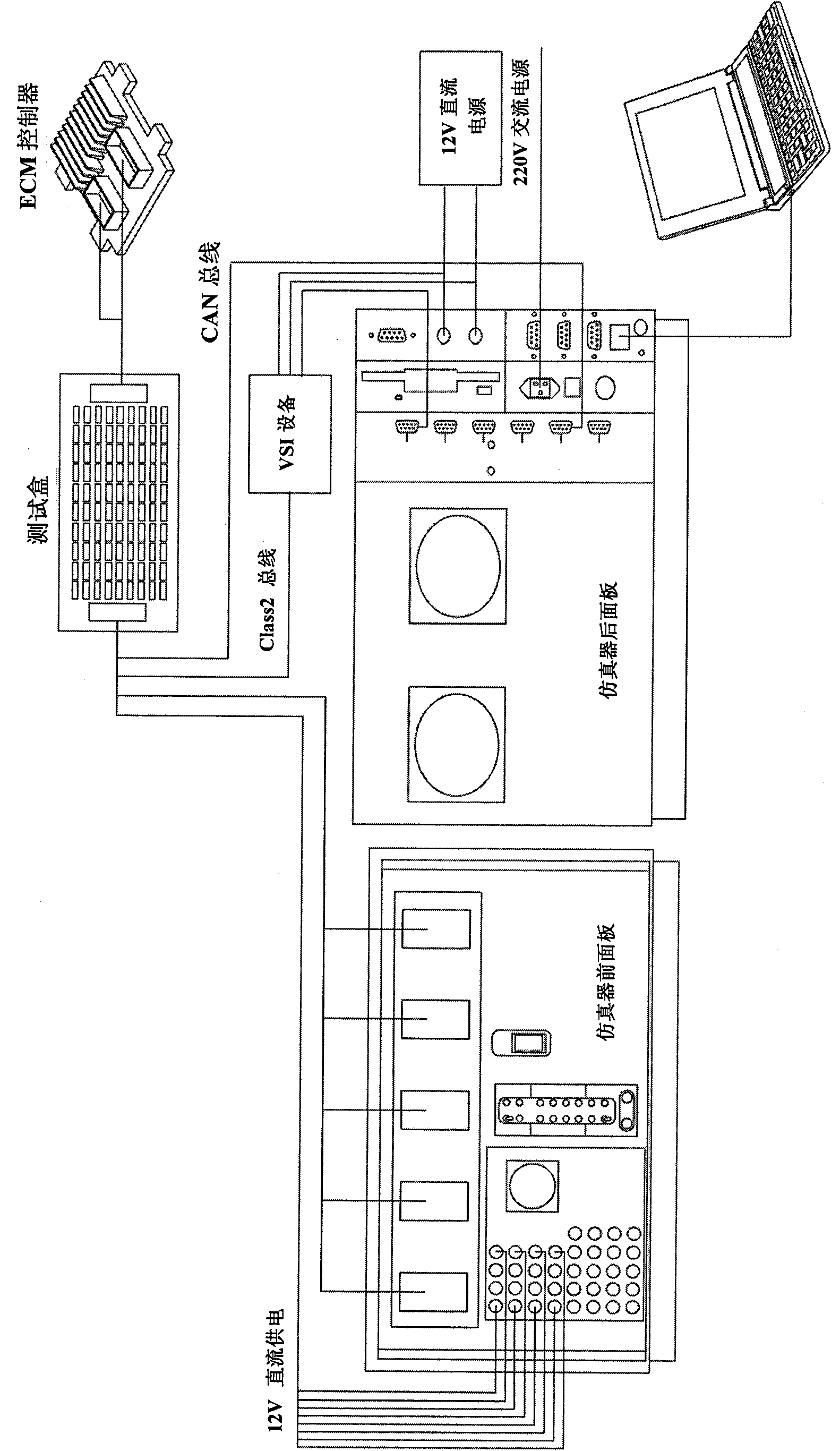

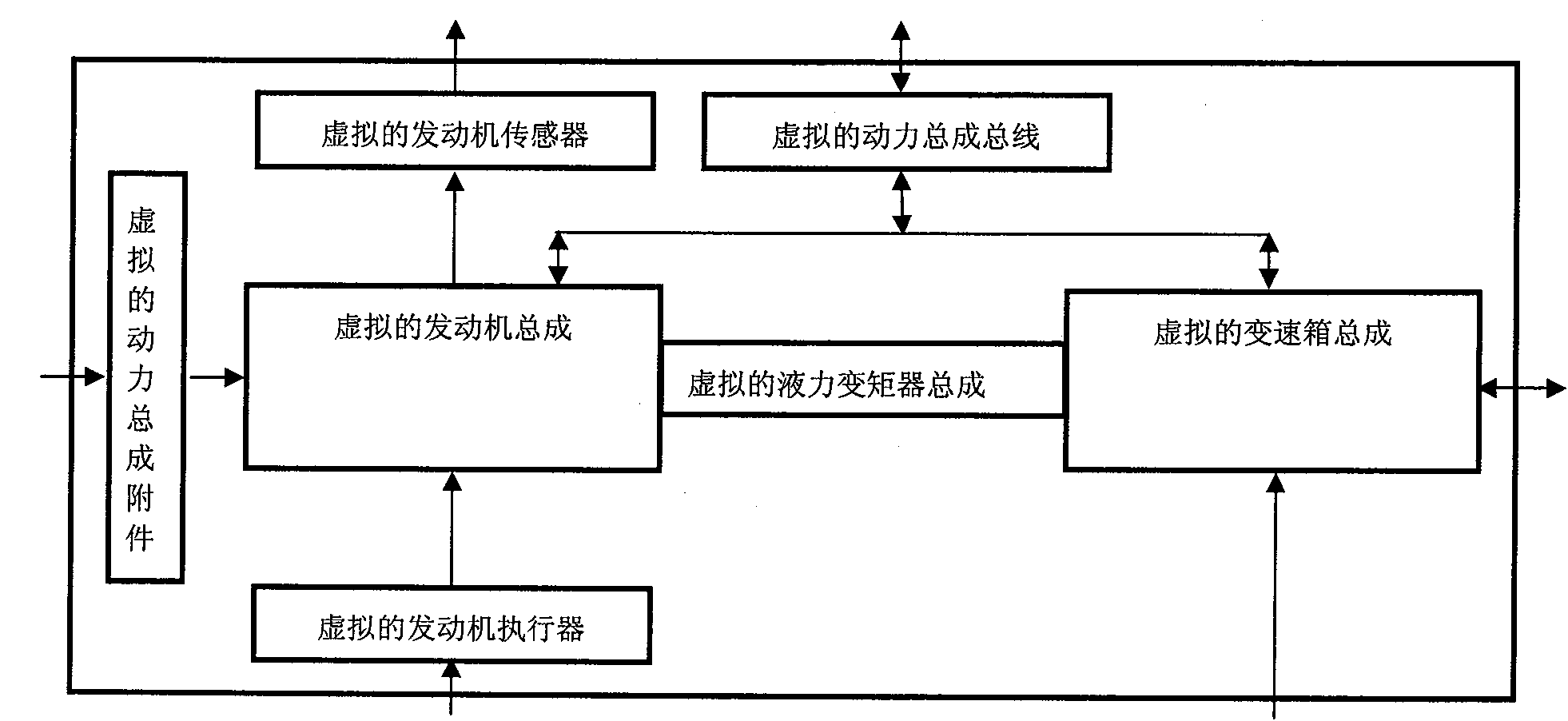

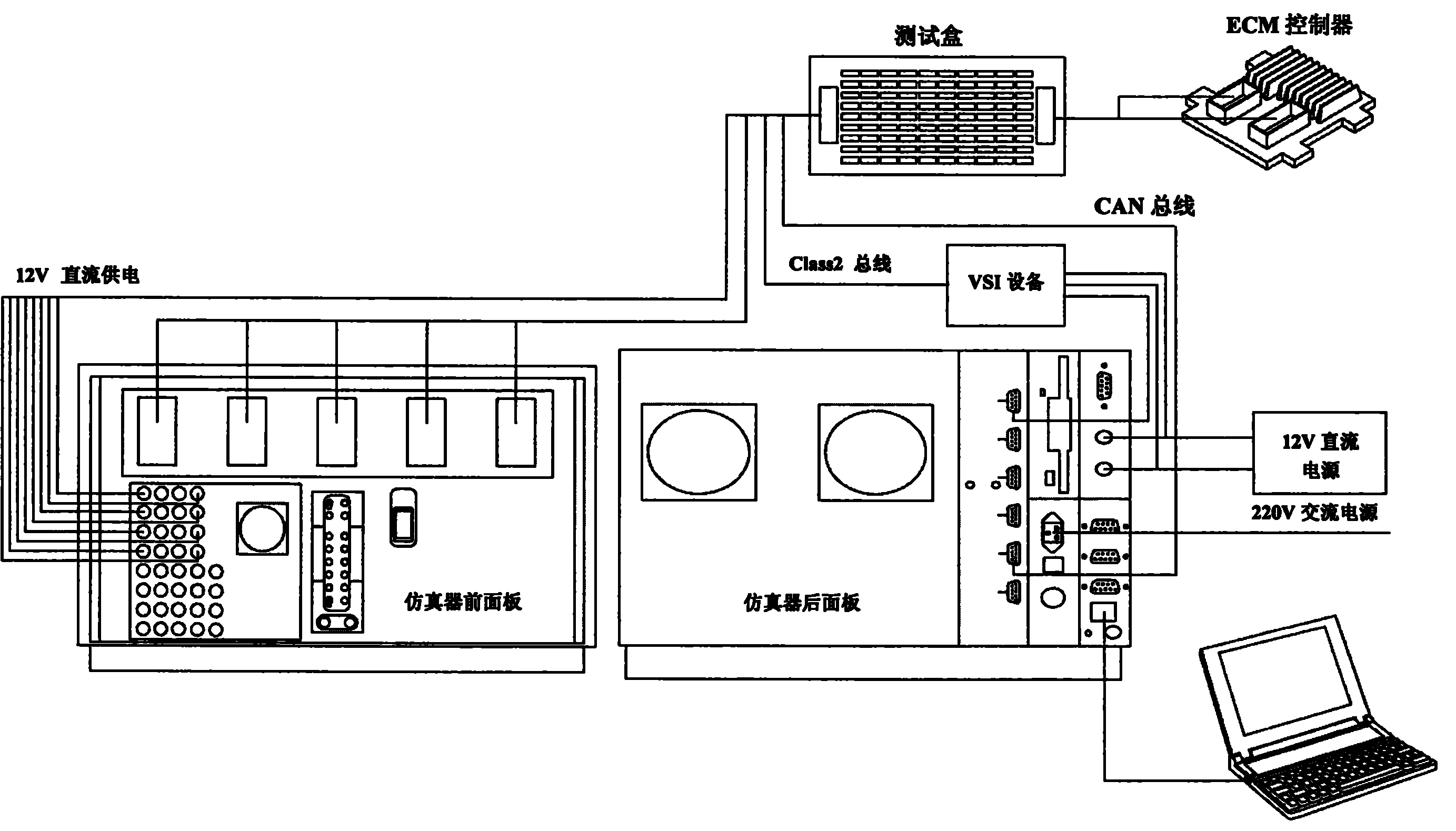

[0018] The technical solution of the present invention is characterized in that it utilizes the test data of the engine bench, ECM (Engine Control Model, engine control module) and TCM (Transmission ControlModel, gearbox control module) related control strategy and control algorithm to construct a working in various State of the virtual engine and virtual gearbox, and according to the working characteristics of the sensors and actuators in the simulator (such as Pi AutoSim simulator) to build all the virtual sensors and virtual actuators for the vehicle and powertrain electronic control system, and then Output the electrical signal of the virtual sensor and obtain the electrical control signal of the ECM through the emulator to make the virtual actuator perform virtual actions, and at the same time build a virtual vehicle for the vehicle according to the enterprise protocol of the data link layer and execution layer of Class2 and CAN bus In-vehicle communication network, and fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com