Method for checking electric fitting data of printed circuit board

A printed circuit board and printed circuit technology, applied in the computer field, can solve the problems of no assembly review, inability to directly extract assembly information, and no data storage format, so as to improve research and production efficiency and shorten design cycle. , the effect of saving design time and materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

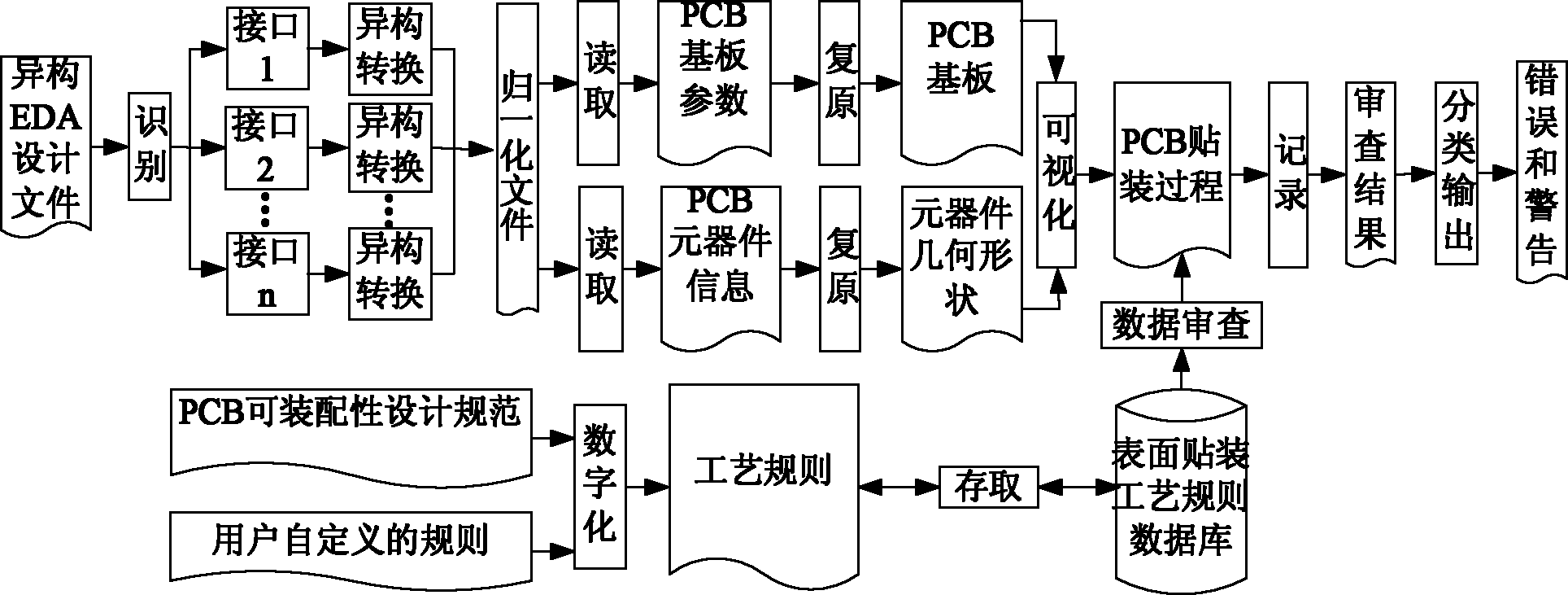

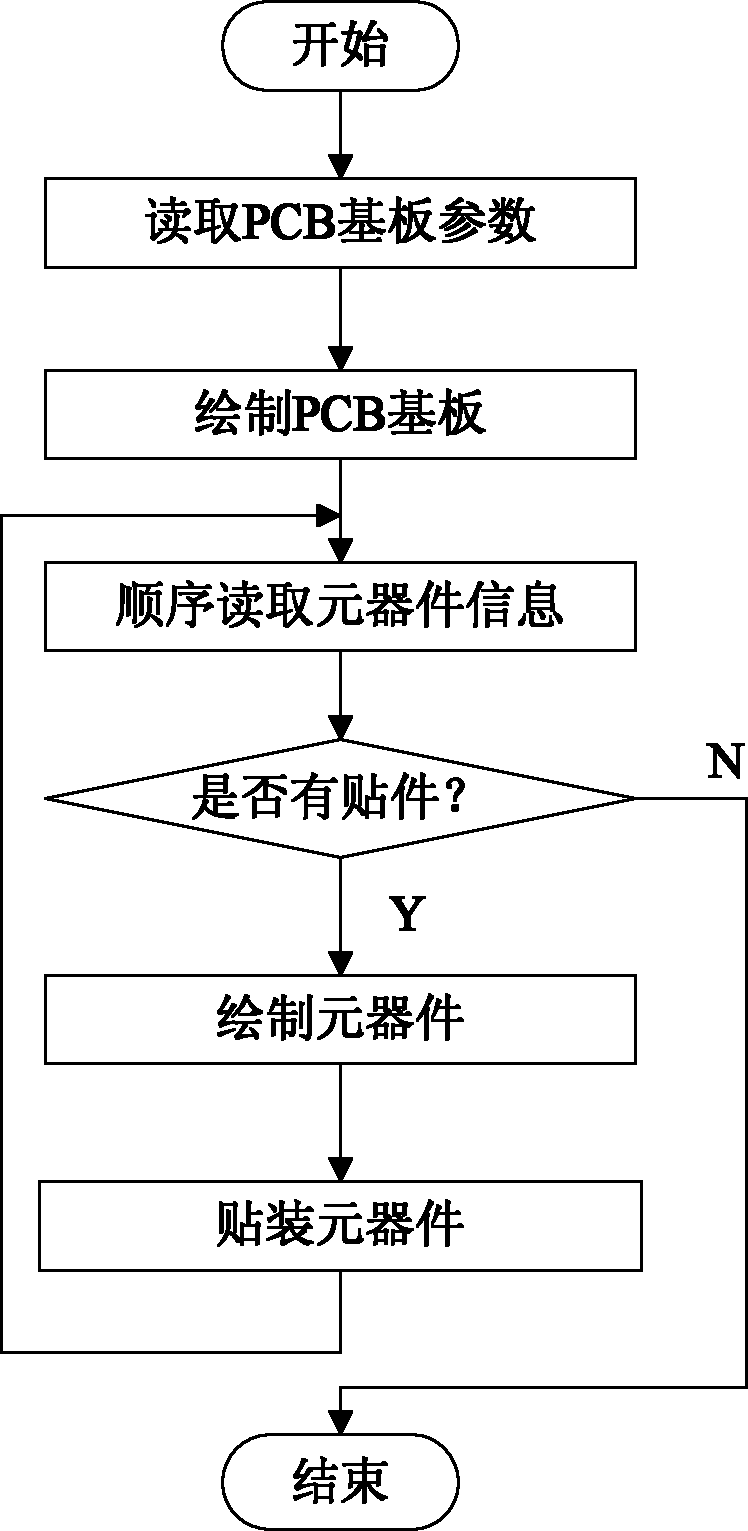

[0022] refer to figure 1 , the present invention examines the steps of printed circuit board electrical equipment data as follows:

[0023] Step 1. Identify the types of heterogeneous EDA design files, send the files to different interfaces, extract and convert electrical equipment data, and generate normalized files.

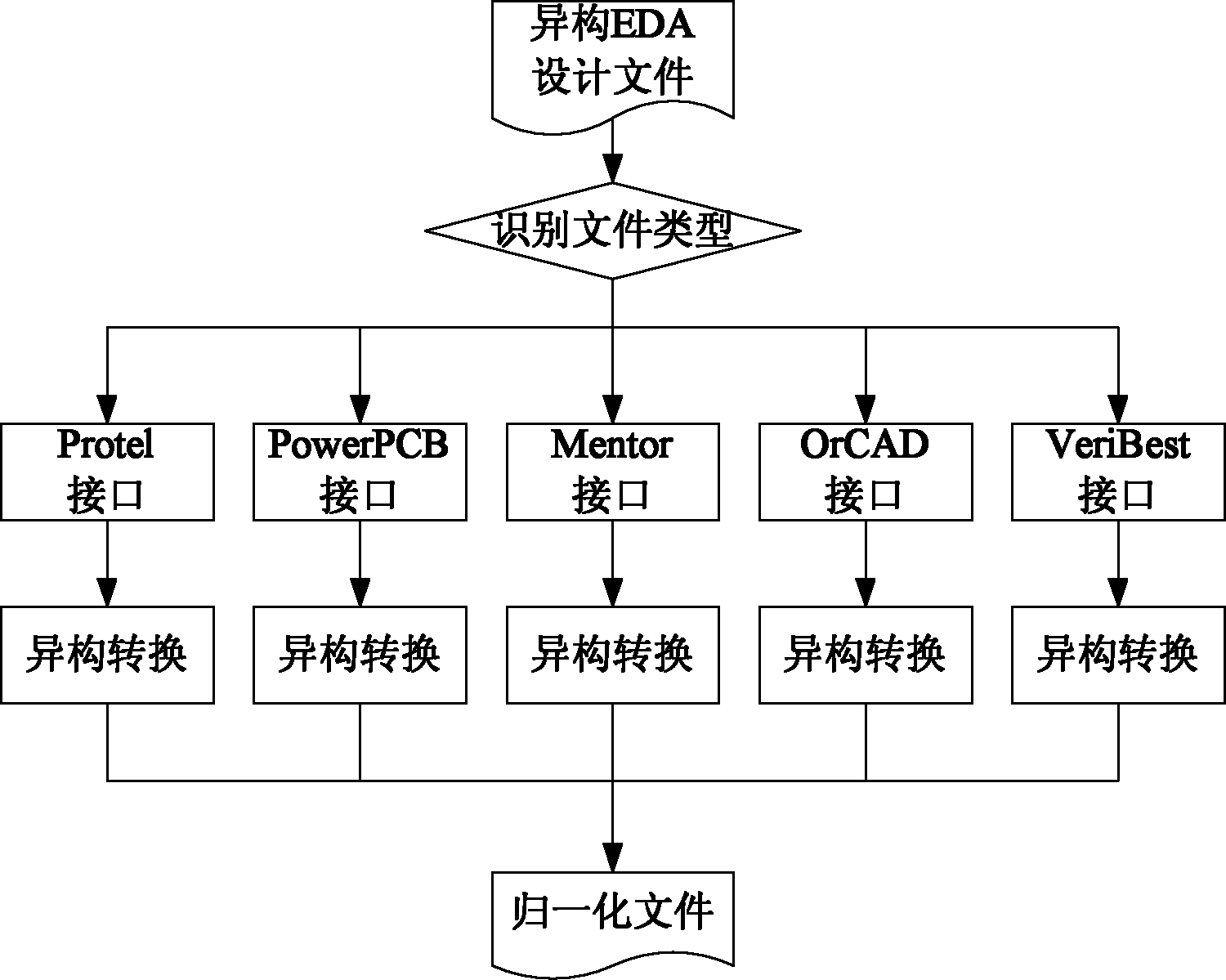

[0024] refer to figure 2 , the specific implementation of this step is as follows:

[0025] (1a) Identify file types according to different EDA design file suffixes.

[0026] Among them, the heterogeneous EDA design file refers to the design file given by Protel, PowerPCB, Mentor, OrCAD and VeriBest software; the file suffix is the suffix in the file name, that is, the suffix of the Protel file is .pcb, and the suffix of the PowerPCB file is . asc, the suffix of Mentor files is .mgc_component.attr, the suffix of OrCAD files is .min, and the suffix of VeriBest files is .prj.

[0027] (1b) Transfer different EDA design files to the corresponding interfaces...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com