Intelligent high-voltage vacuum circuit breaker

A vacuum circuit breaker and intelligent technology, applied in high-voltage air circuit breakers, high-voltage/high-current switches, instruments, etc., can solve the problems of instantaneous operation overvoltage, heat generation, and increased electrical resistance, and achieve enhanced safety and reliability. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

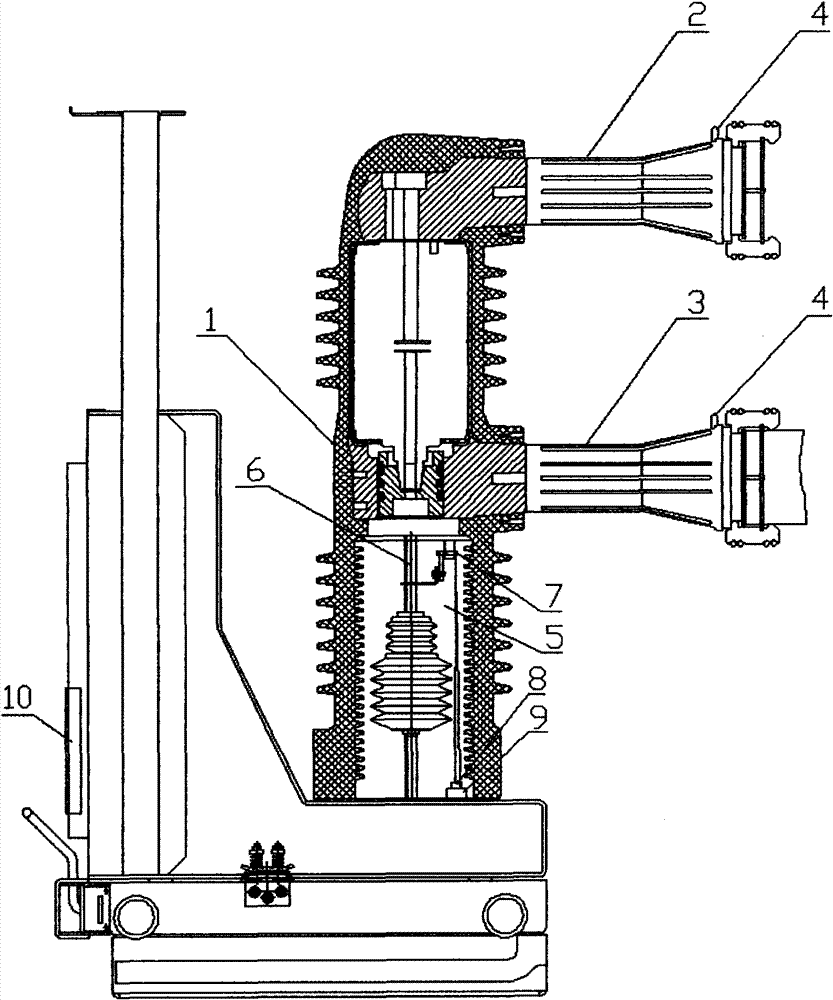

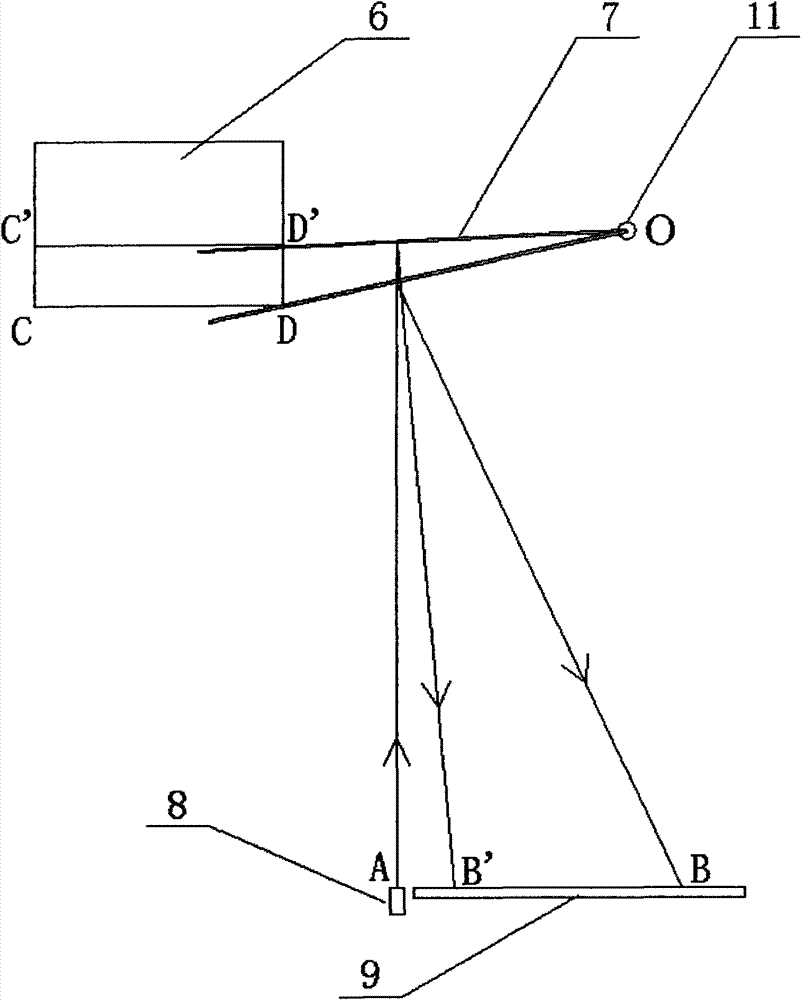

[0011] Such as figure 1 , figure 2 As shown, an intelligent high-voltage vacuum circuit breaker includes three arc extinguishing chamber poles 1, each arc extinguishing chamber pole has an upper bracket 2 and a lower bracket 3, and each arc extinguishing chamber pole 1 has a vacuum There is a moving conductive rod 6 in the arc extinguishing chamber 5, and a temperature measuring sensor 4 is installed at the fracture of the upper bracket 2 and the lower bracket 3 of the pole 1 of each arc extinguishing chamber. 5, a contact wear sensing device is installed inside, and the contact wear sensing device includes an incident light source 8, a reflector 7 and a light source receiving sensor 9, and the reflector 7 leans against the moving conductive rod 6 and revolves around a pivot 11 Rotate, the incident light source 8 and the light source receivi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com