Distributed and adaptive smart logic with multi-communication apparatus for reliable safety system shutdown

一种安全逻辑、逻辑的技术,应用在通用控制系统、安全安排、控制/调节系统等方向,能够解决缺乏跳闸等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Reference will now be made in detail to the implementation of the invention, examples of which are illustrated in the accompanying drawings.

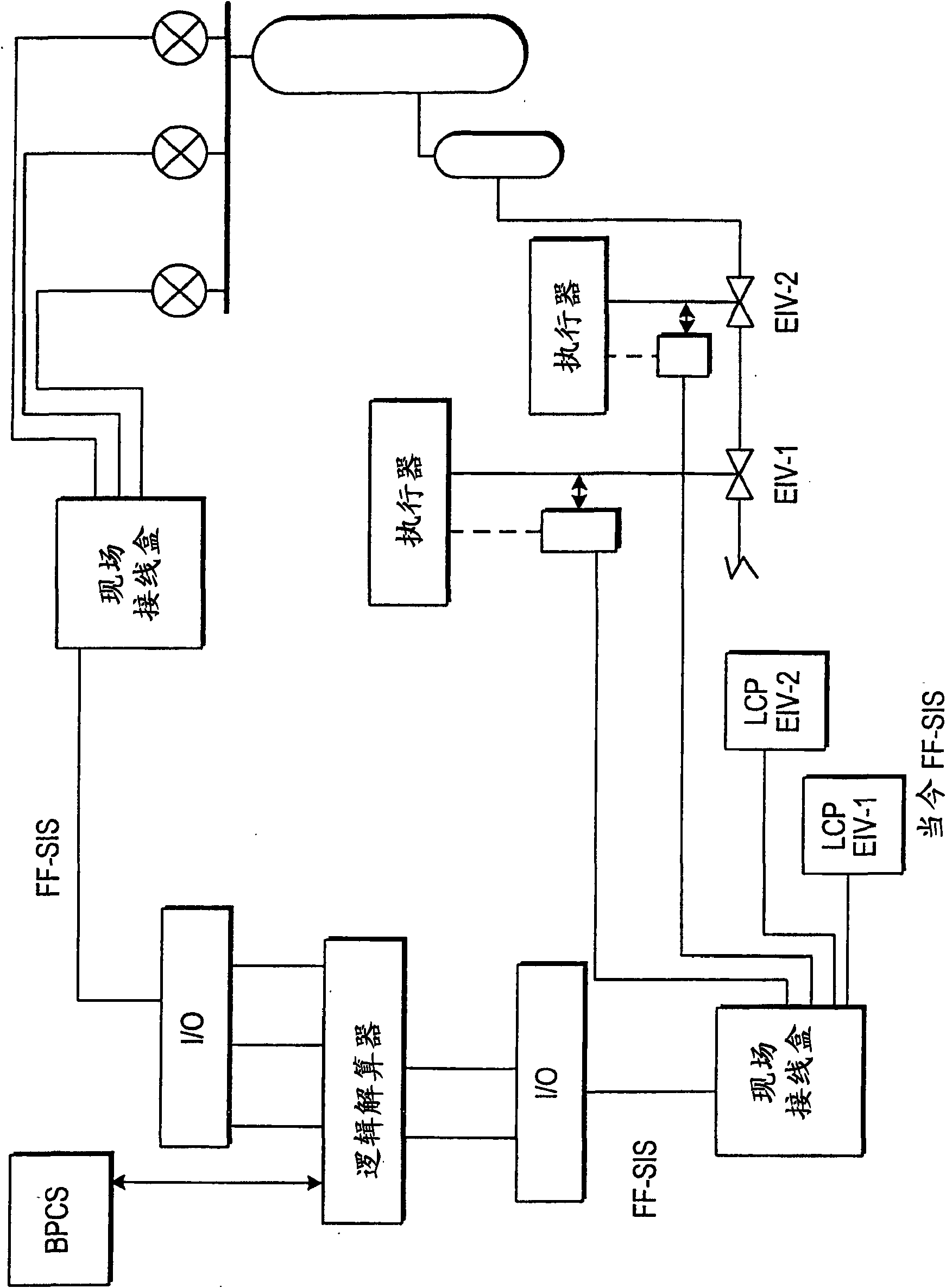

[0035] figure 1 Represents the topology of a typical prior art safety instrumented system employing FF-SIS networks. Safety logic solvers are hardwired to field devices via input / output ("I / O") racks. These field devices include sensors that monitor process variables such as pressure, temperature, fluid level, and flow, which are represented above pressure vessels. The field devices also include terminal elements such as valve actuators and local control panels shown associated with isolation valves EIV-1 and EIV-2. As can be seen, a break in a wire can result in a loss of signal from a sensor or terminal element, or loss of a control signal to a terminal device. Similarly, degradation of the signal can result in a false trip initiated by the SLS.

[0036] As an example, an EIV is open during normal operation and closed durin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com