Method for adjusting welding parameters based on large step pitch calibration and Newton interpolation

A technology of welding parameters and adjustment methods, applied in welding equipment, arc welding equipment, manufacturing tools, etc., to achieve the effects of reduced development cycle and development cost, good weld formation, and welding parameter coverage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

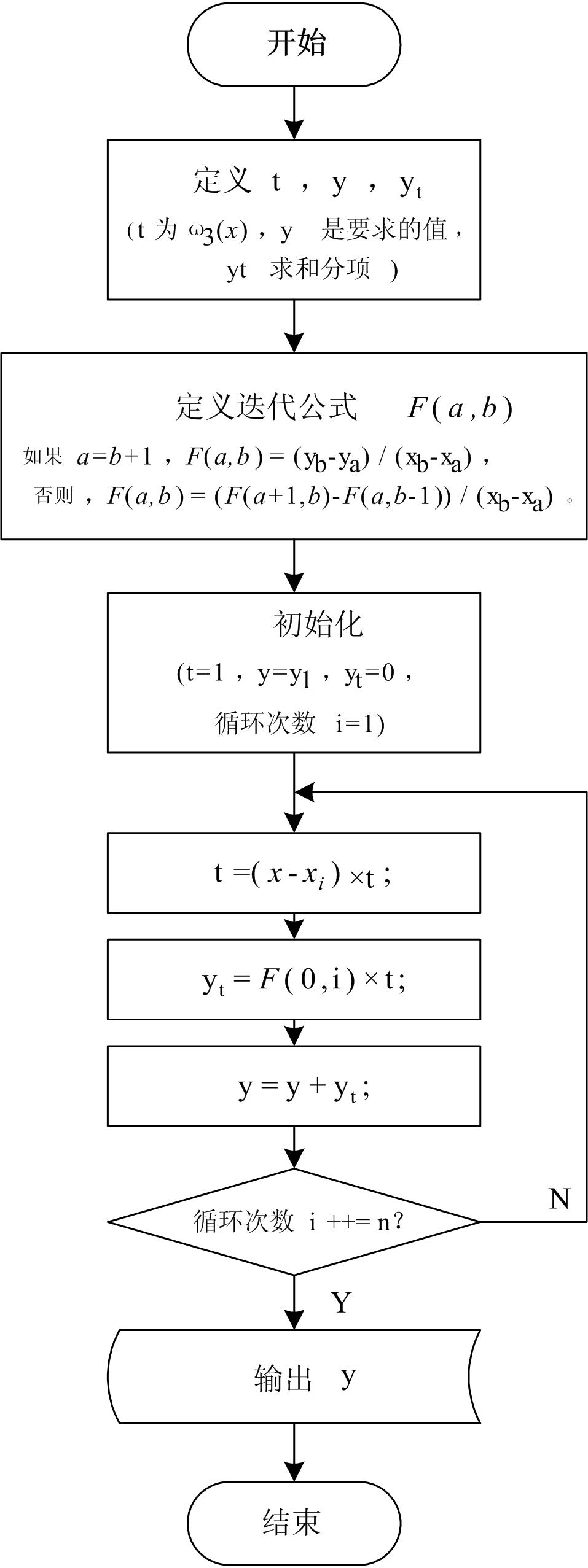

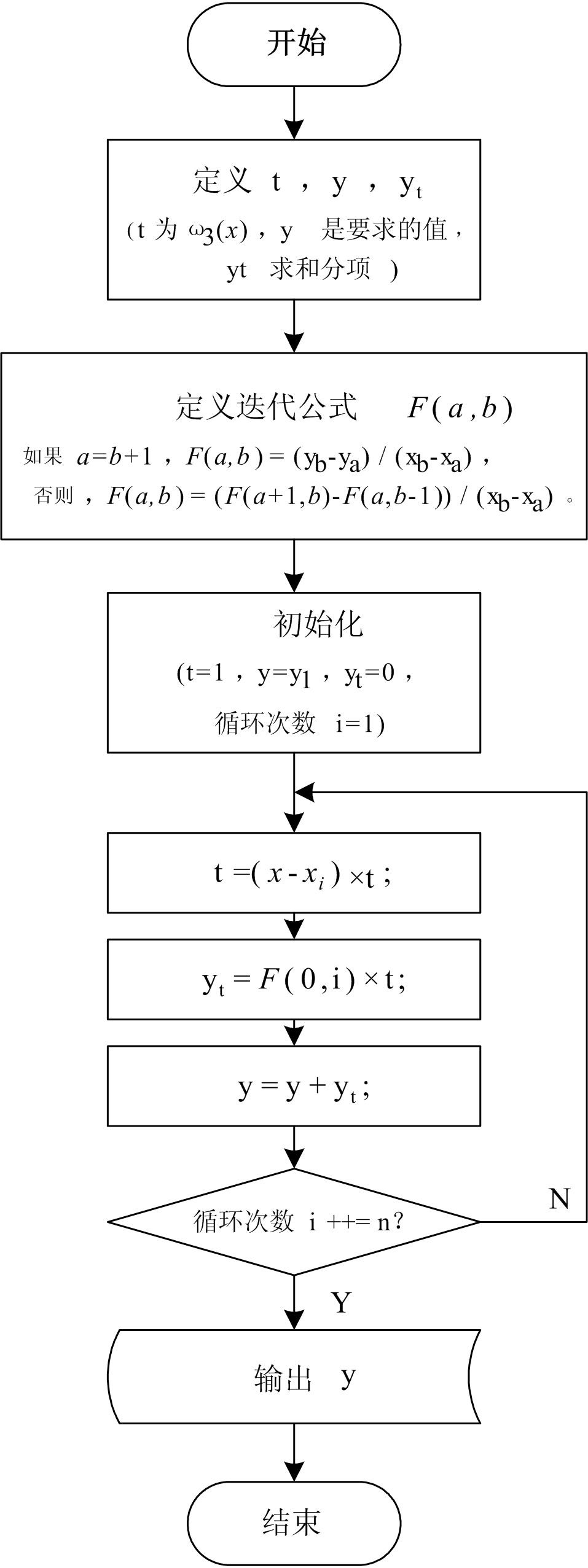

Image

Examples

Embodiment Construction

[0021] The following describes the present invention in further detail with reference to the accompanying drawings and embodiments, but the implementation method and the scope of protection of the present invention are not limited to this.

[0022] 1. Principle of large-step calibration: The goal of large-step calibration is to determine the direction and skeleton of the expert database, determine the initial value of the parameters for the intelligent welding machine, and the refined expert data is generated through self-adjustment. Large-step calibration means that when the digital welding machine database is initialized, its fine calibration strategy is changed, and only a few typical parameters are calibrated. For example, take the P-GMAW welding with 1.2mm carbon steel wire as an example, assuming that the welding current adjustment range is 80A to 350A, then the step distance can be set to 20A, that is to say, the welding parameters corresponding to the current of 80A to 35...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com