Processing method for glass substrate and device therefor

A technology of glass substrates and processing methods, applied in glass production, metal processing equipment, manufacturing tools, etc., can solve problems such as cost and achieve the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

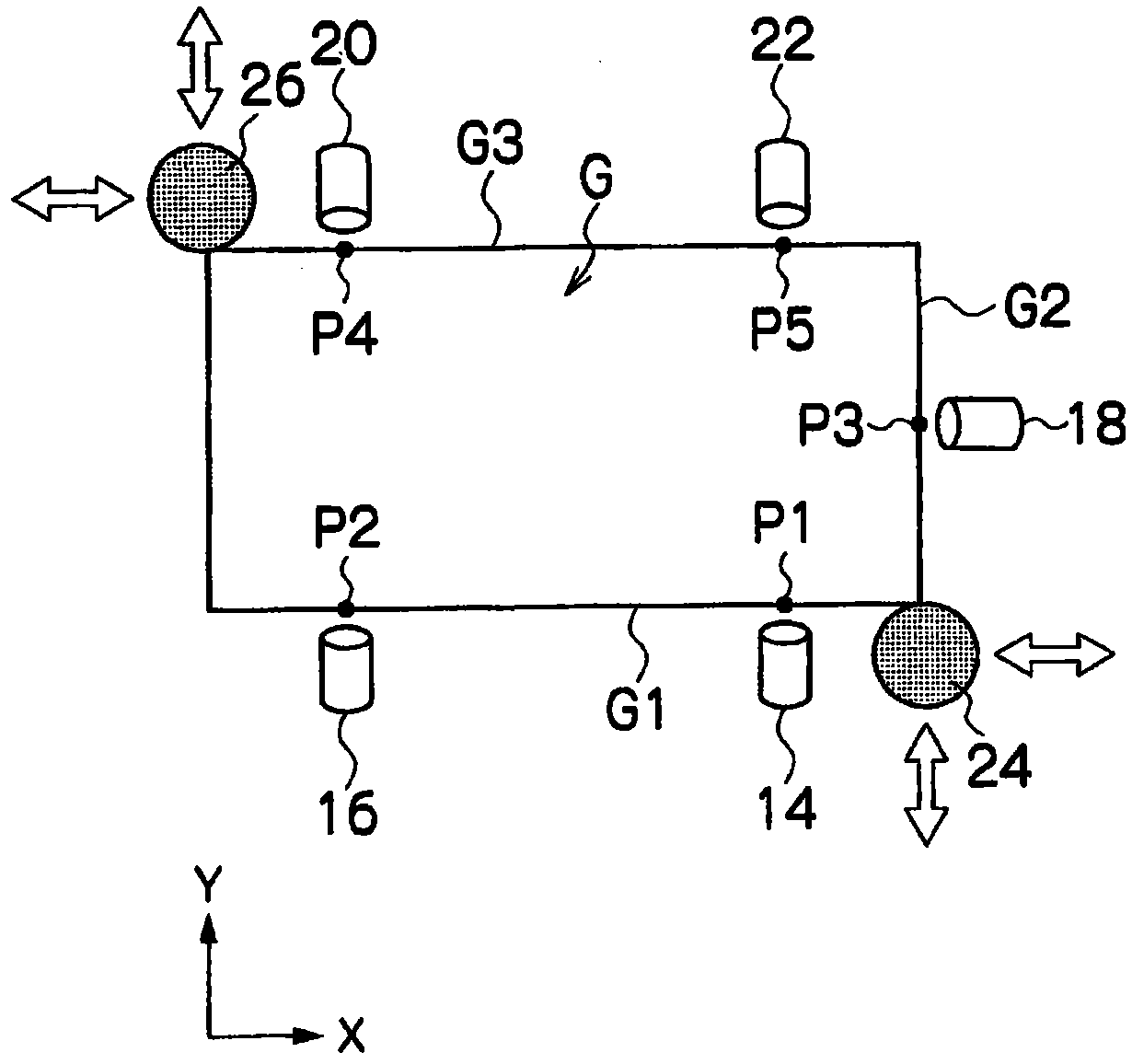

[0050] Hereinafter, the preferred form of the processing method of the glass substrate which concerns on embodiment of this invention, and its apparatus is demonstrated in detail based on drawing.

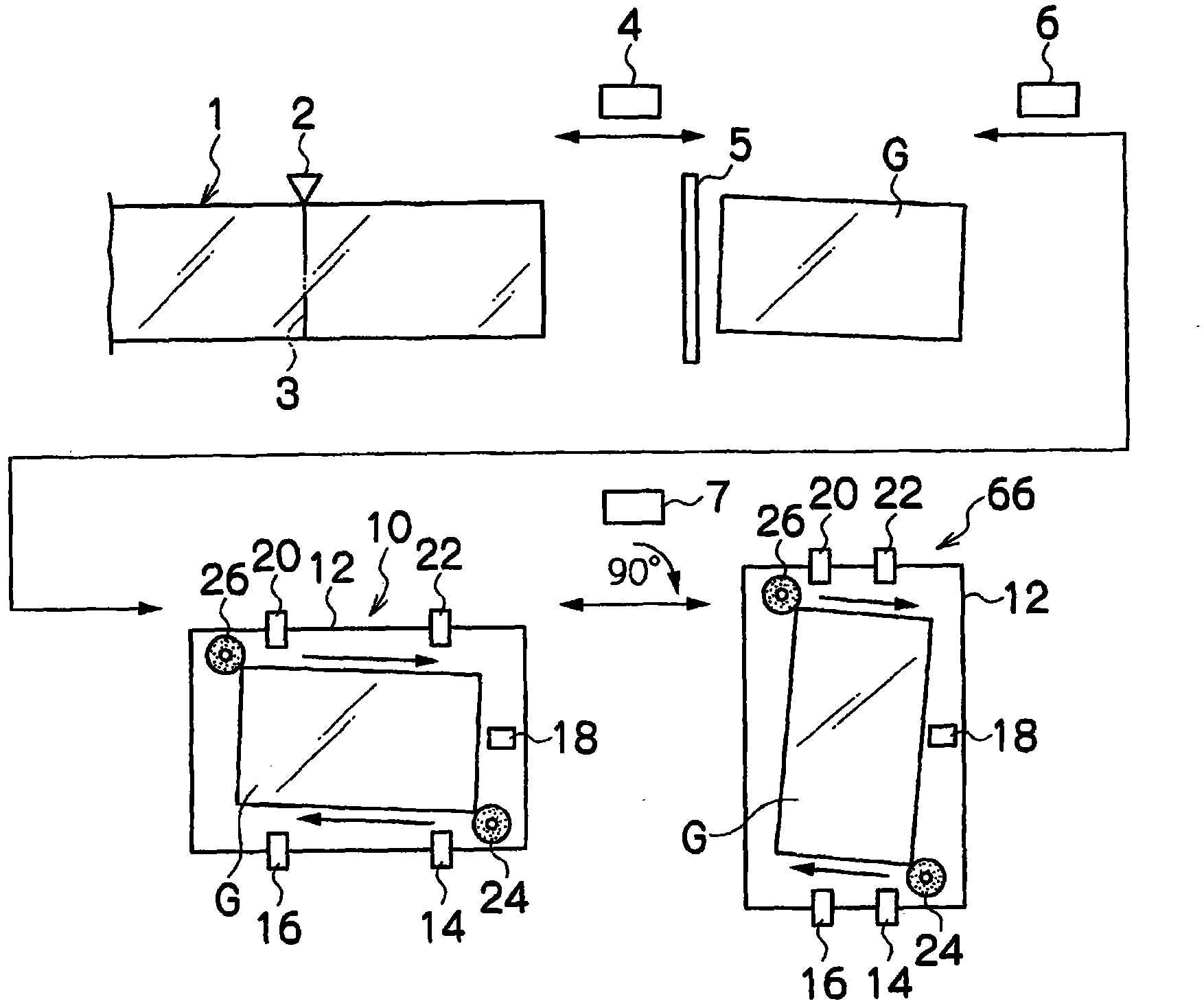

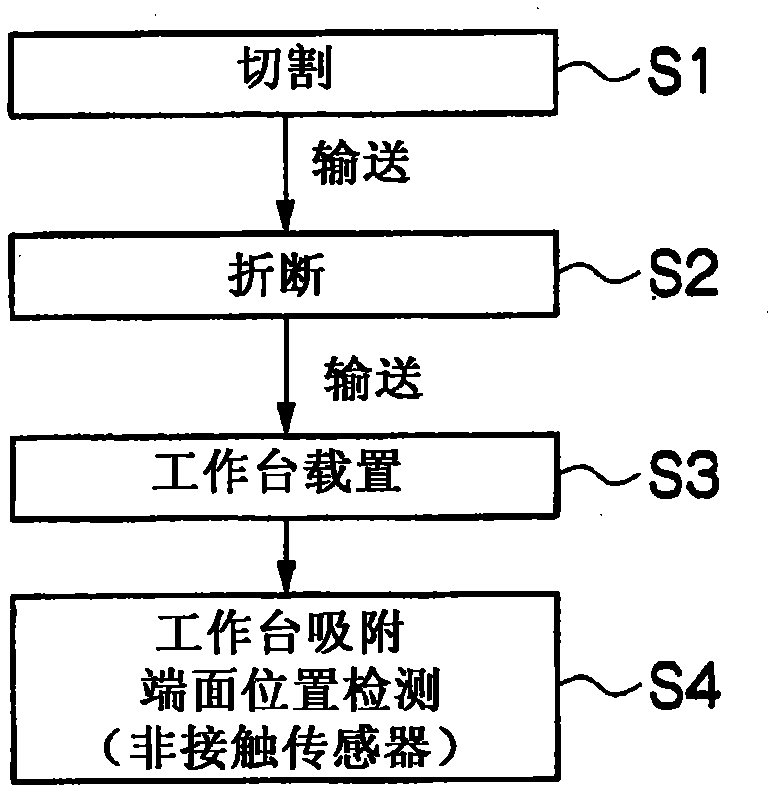

[0051] figure 1 It is a process explanatory drawing which shows the cutting and breaking process and chamfering process for demonstrating the glass substrate G which concerns on embodiment. in addition, figure 2 It is a flowchart showing the flow of the glass substrate in the cutting and breaking step and the chamfering step.

[0052] As shown in these figures, the glass ribbon 1 formed into a ribbon by a glass ribbon forming device such as a float furnace is processed with a cutting knife 2 of a cutting machine in a direction perpendicular to the longitudinal direction 3 (step S1). Thereafter, the glass ribbon 1 is transported to the breaking machine by the transfer machine 4, and the part of the tangent line 3 is lifted up by the lifting member 5 of the breaking machine, so as ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com