Tire carcass cord structure

A cord structure and cord technology are applied in the reinforcement layers of pneumatic tires, tire parts, textiles, and papermaking, etc., and can solve problems such as shape boundaries.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Hereinafter, the present invention will be specifically described based on the accompanying drawings as examples.

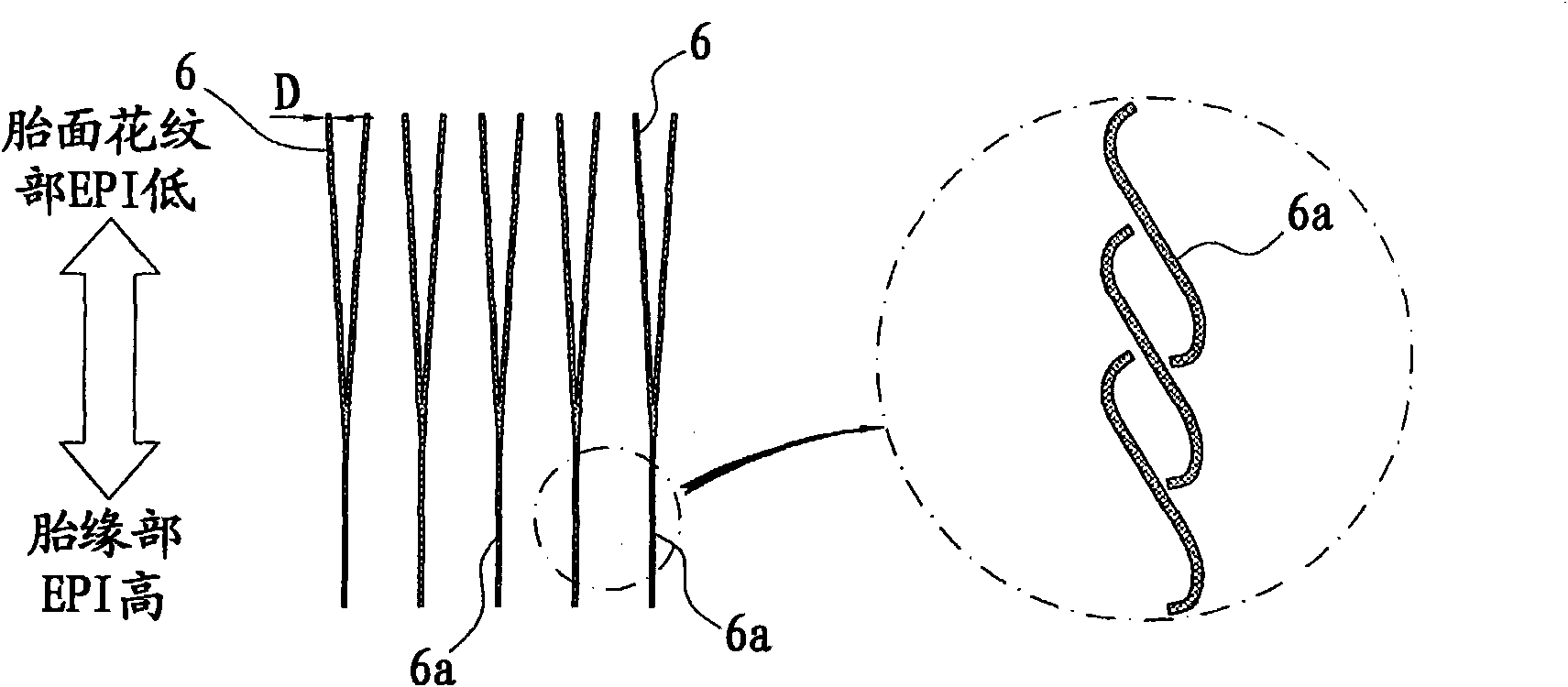

[0016] image 3 It is a cord arrangement diagram showing the carcass cord structure of the tire of the present invention in a planar manner.

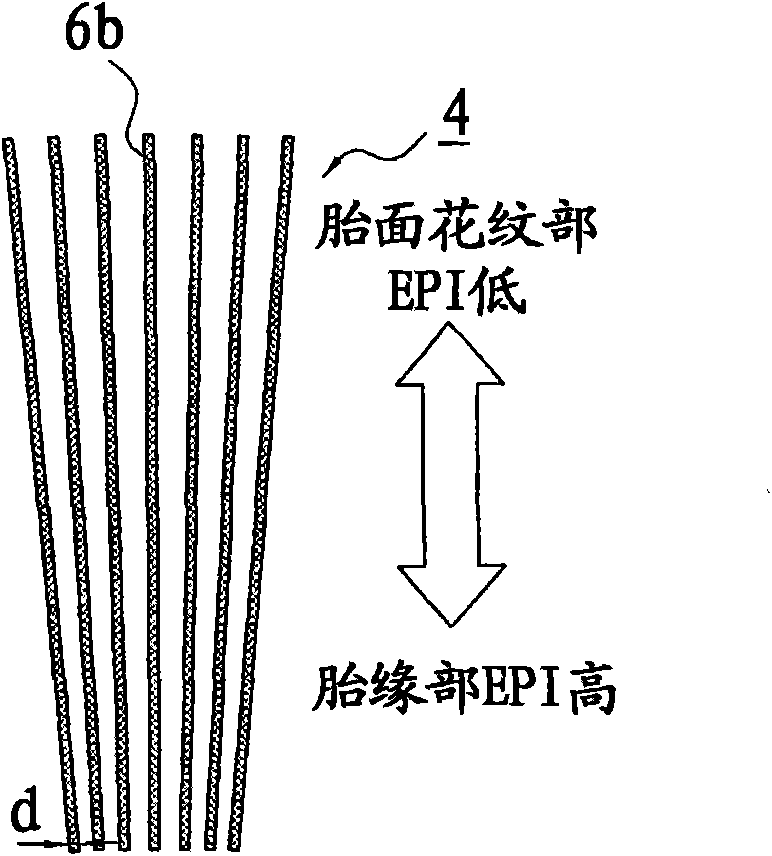

[0017] The present invention relates to a cord structure of a carcass in which a top surface (topping) is formed by rubber between cords 6 arranged at a constant EPI pitch and above and below the cords 6 , and the cords 6 The diameter D of the cord 6b is smaller than the diameter d of the cord 6b in the past. The cord 6 is arranged in a larger number than the cord in the past. Two cords 6 adjacent to each other in a certain section are helically wound and arranged as one cord 6a.

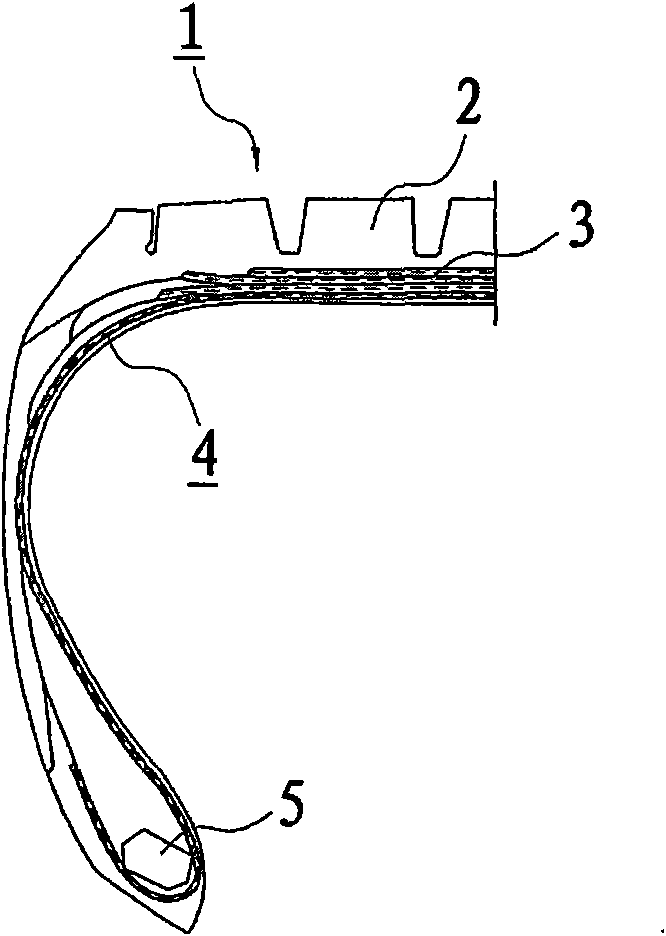

[0018] That is, in the cord structure of the carcass of the present invention, a pair of cords in the carcass 4 are formed into one unit, and the cords in a certain section are wound around the bead portion 5 to form a helical cord 6a. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com