Railway vehicle linear motor bogie and manufacturing method thereof

A technology of linear motors and rail vehicles, applied in bogies, railway car body parts, transportation and packaging, etc., can solve problems such as large vibration at the shaft end, achieve improved stress state, optimize linear motor suspension parameters, and increase rigidity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

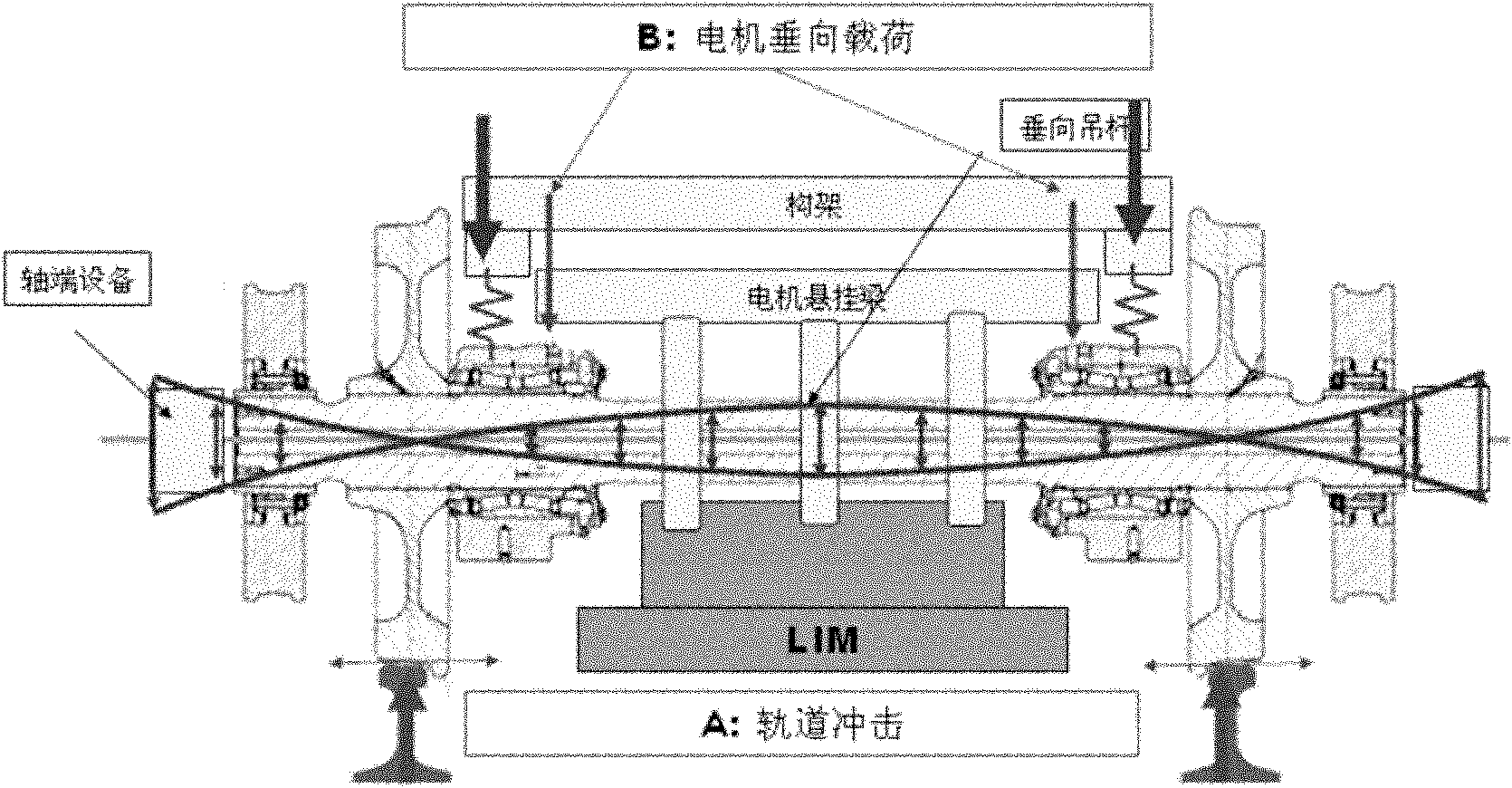

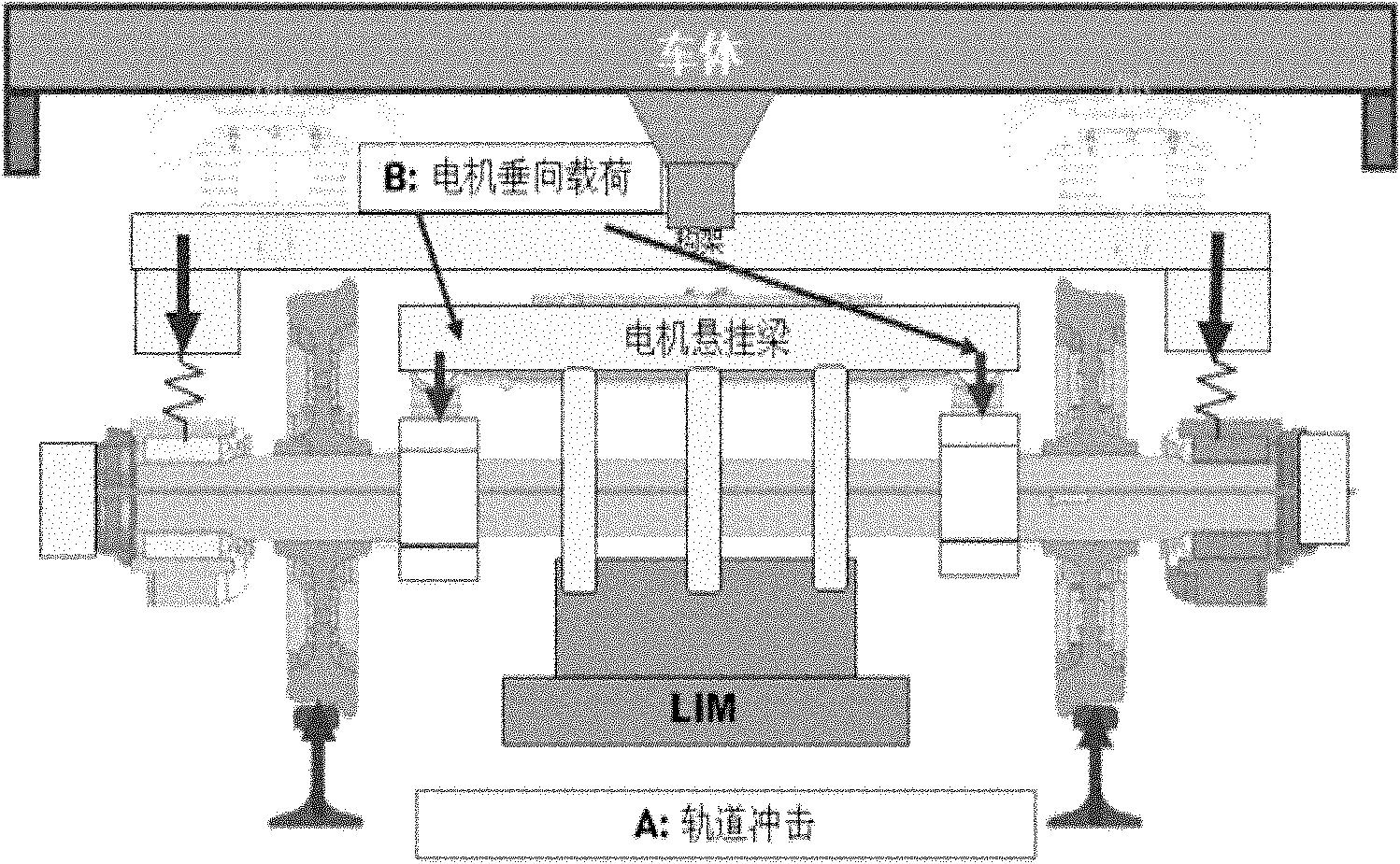

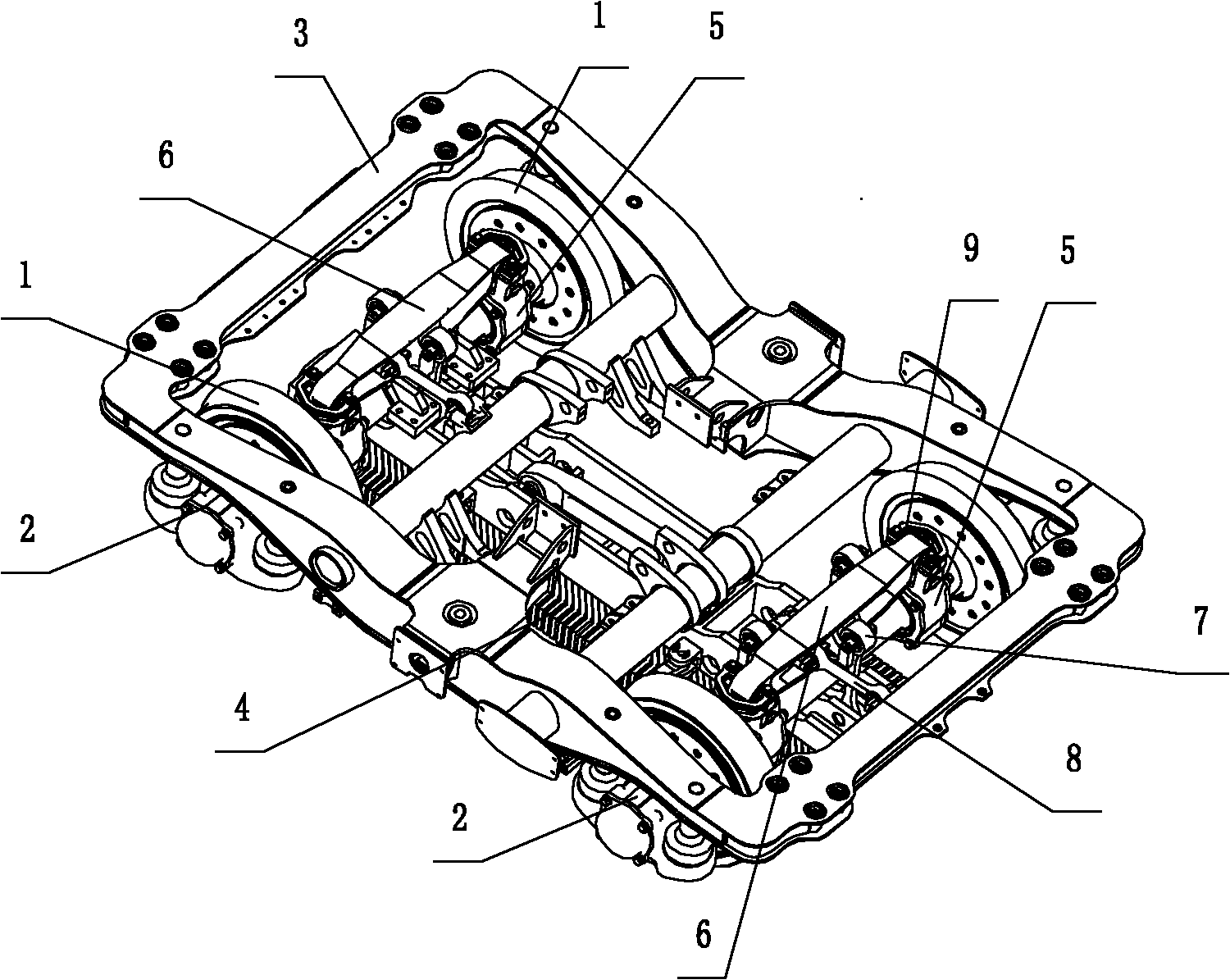

[0060] Example 1, such as Figure 3 to Figure 5 As shown, the rail vehicle linear motor bogie mainly includes two sets of wheelsets 1, and the axles 11 of each set of wheelsets 1 are carried on two symmetrically arranged axle boxes 2 through bearings;

[0061] A frame 3, the frame 3 is supported on the axle box body 2 through the primary suspension device, and the frame 3 is supported on the vehicle body (not shown in the figure) through the secondary suspension device (not shown in the figure);

[0062] On the wheel shaft 11 of each group of wheel pairs 1, two symmetrically arranged support boxes 5 are installed through bearings,

[0063] Both ends of the transverse suspension beam 6 are respectively screwed to the support box 5 through a connecting seat 9;

[0064] A gasket 10 for adjusting the vertical height of the end of the transverse suspension beam 6 is lined between the connecting seat 9 and the supporting box body 5;

[0065] Several vertical suspenders 7 suspend a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com