Control method and controller for crane and its composite actions of crane

A technology of compound action and control method, applied in the field of controller, crane and its compound action control method, can solve the problems of stop action, failure of pressure reducing valve, inconsistency, etc. The effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

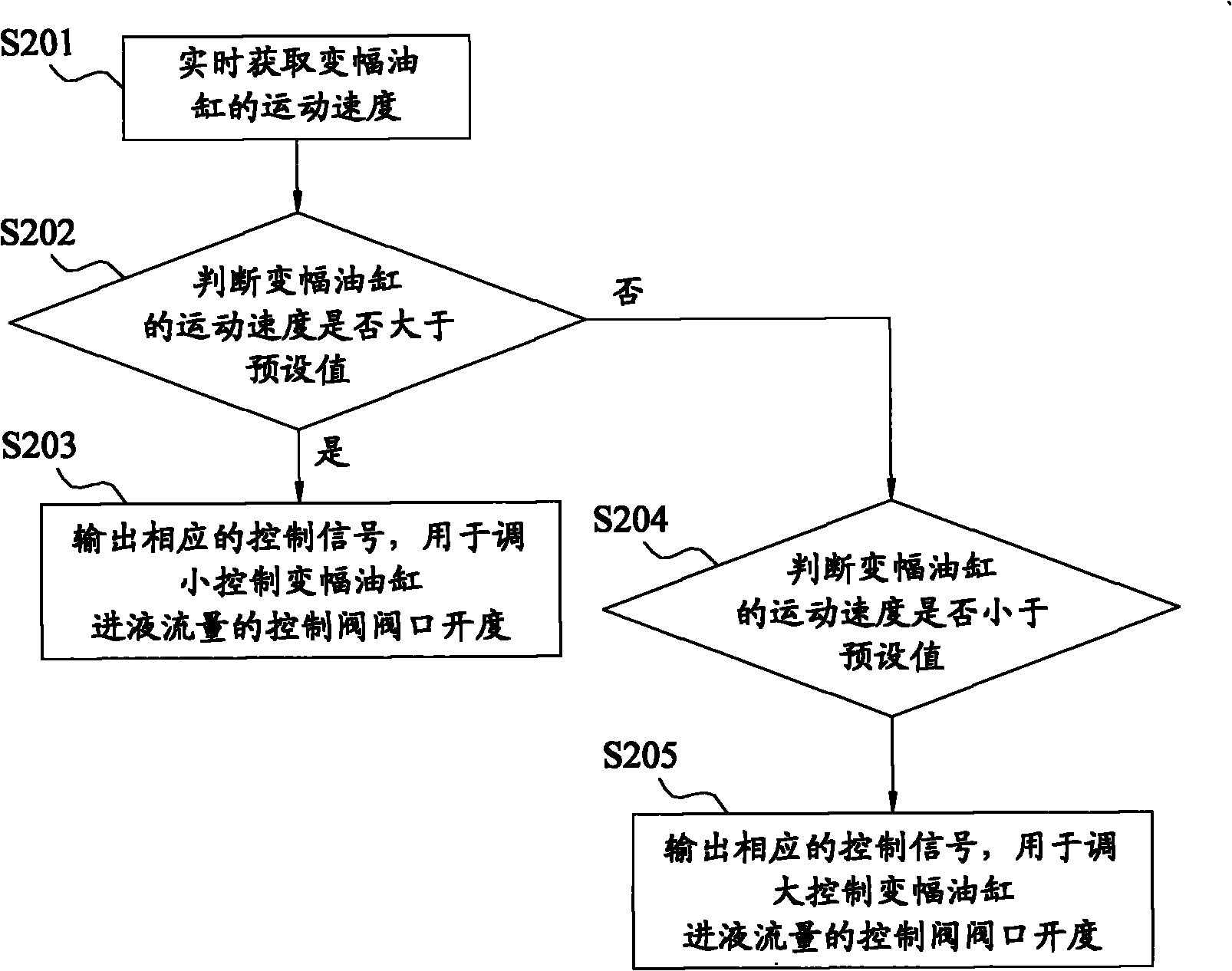

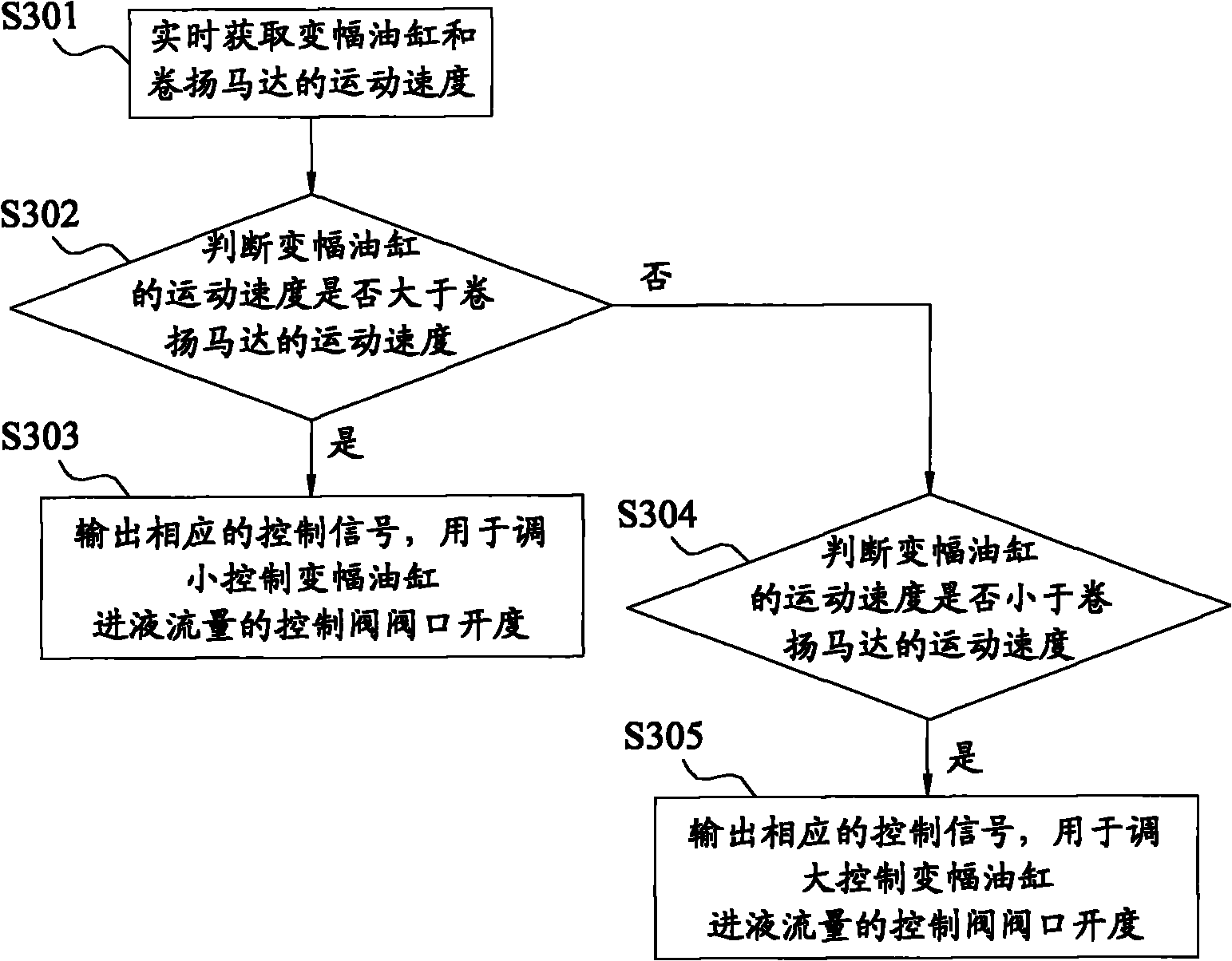

[0035] The control method of the compound action of the crane provided by the present invention is used to control the distribution of the total flow of hydraulic oil to multiple actuators, and the inflow flow of the actuators is controlled by adjusting the opening of the control valve; its core is to obtain at least one actuator in real time The movement speed of the element, and according to whether the movement speed of the at least one executive element meets the preset judgment condition, obtains the judgment result of adjusting the valve port opening of the control valve that controls the liquid intake flow of the actuator. The control signal output by the present invention is obtained by calculation using the PID algorithm, and the speed feedback of the actuator is used to control the liquid inlet flow rate to meet the speed requirements of the synchronous compound action.

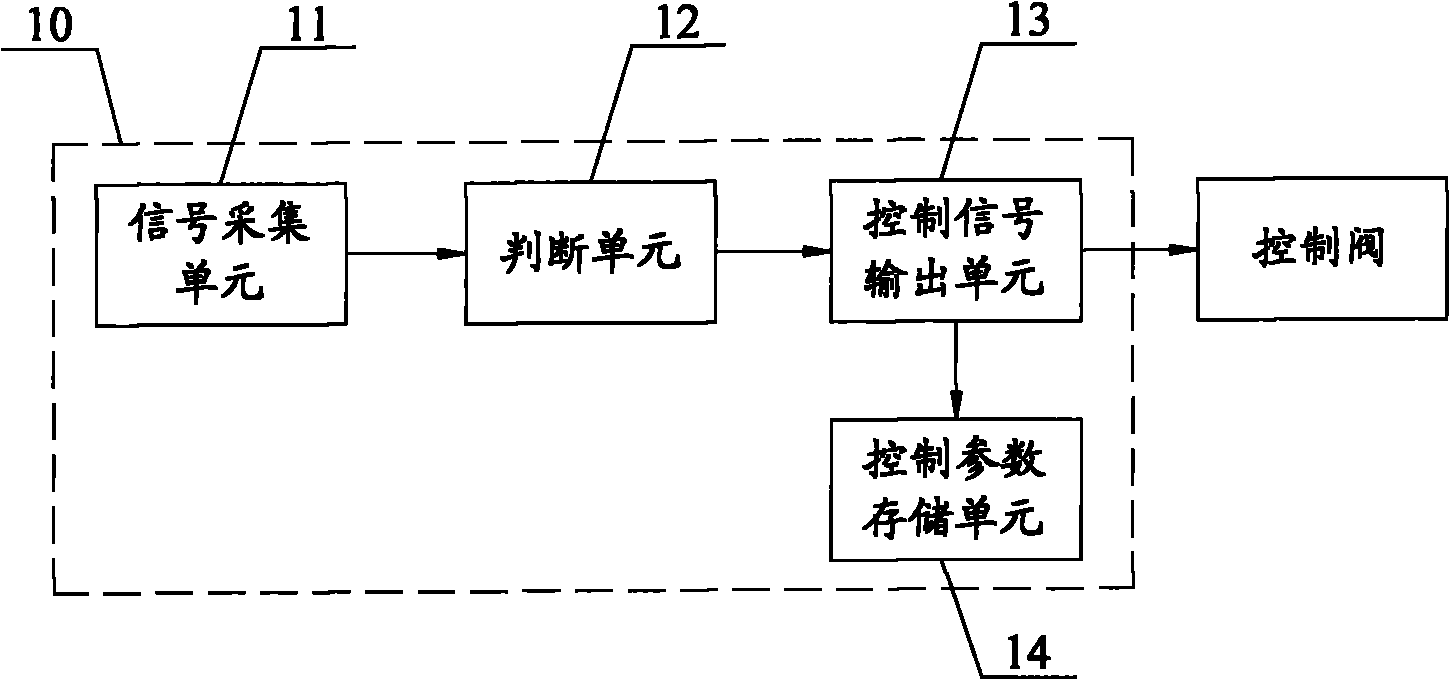

[0036] Based on the design idea of the aforementioned control method, the controller used to co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com