Gutter snow melting system and snow melting control method thereof

A technology for melting snow and gutters, which is applied in roofing, buildings, building structures, etc. It can solve problems such as difficult replacement of system components, increased weight of gutters, complex construction, etc., to avoid circuit aging problems, and the process of snow melting is fast and automatic. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

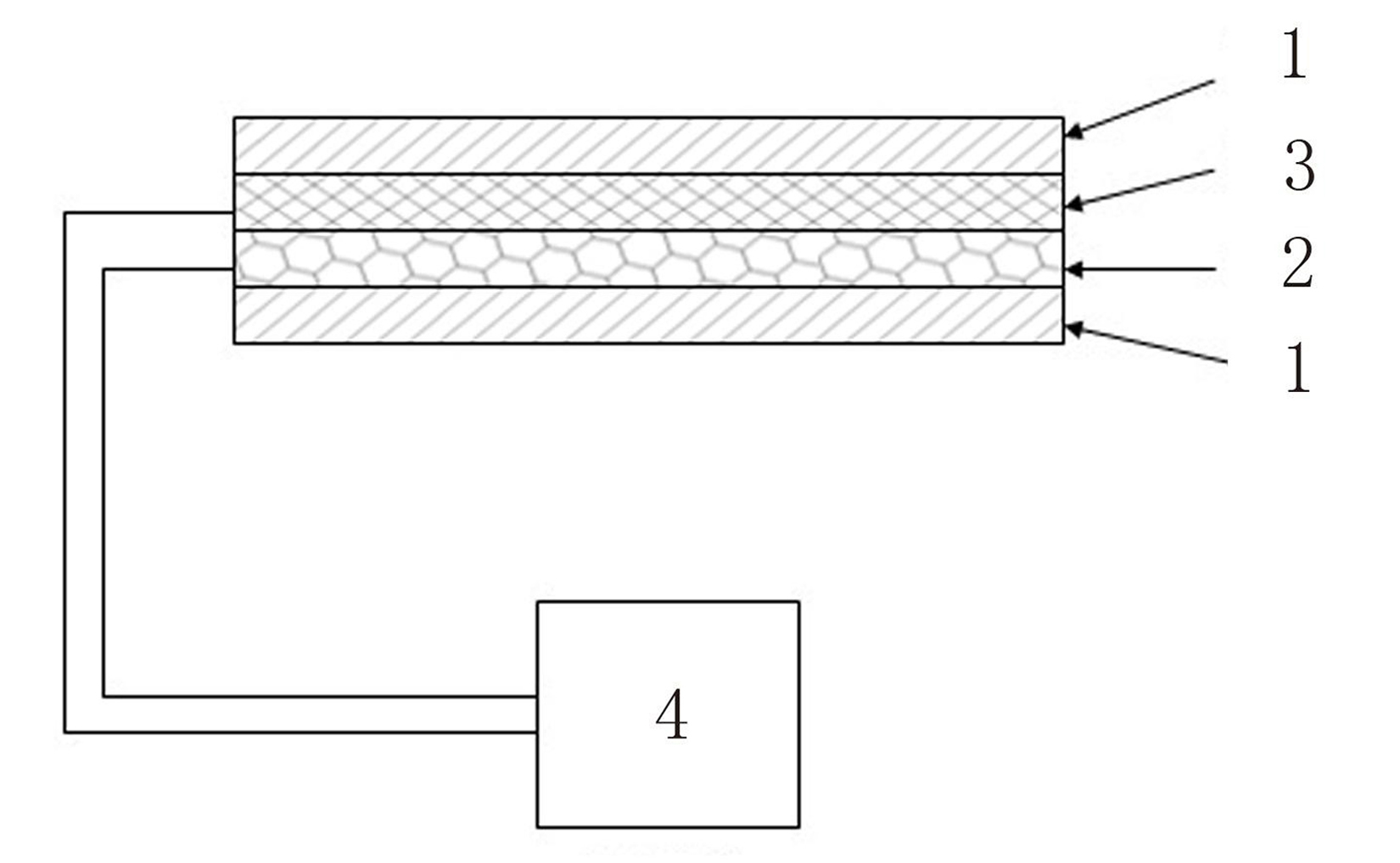

[0029] As shown in the figure, a gutter snow melting system includes a heat source layer 2 and a temperature control box 4; a protective layer 1 is fixed outside the heat source layer 2; The ports of the leakage protection layer 3 are fixed between the heat source layer 2 and the protective layer 1; the ports of the leakage protection layer 3 are connected with the ports of the temperature control box 4.

[0030] The protection layer 1 of the present invention can be made of plastic or rubber polymer material. The heat source layer 2 of the present invention adopts a resistive heating plate.

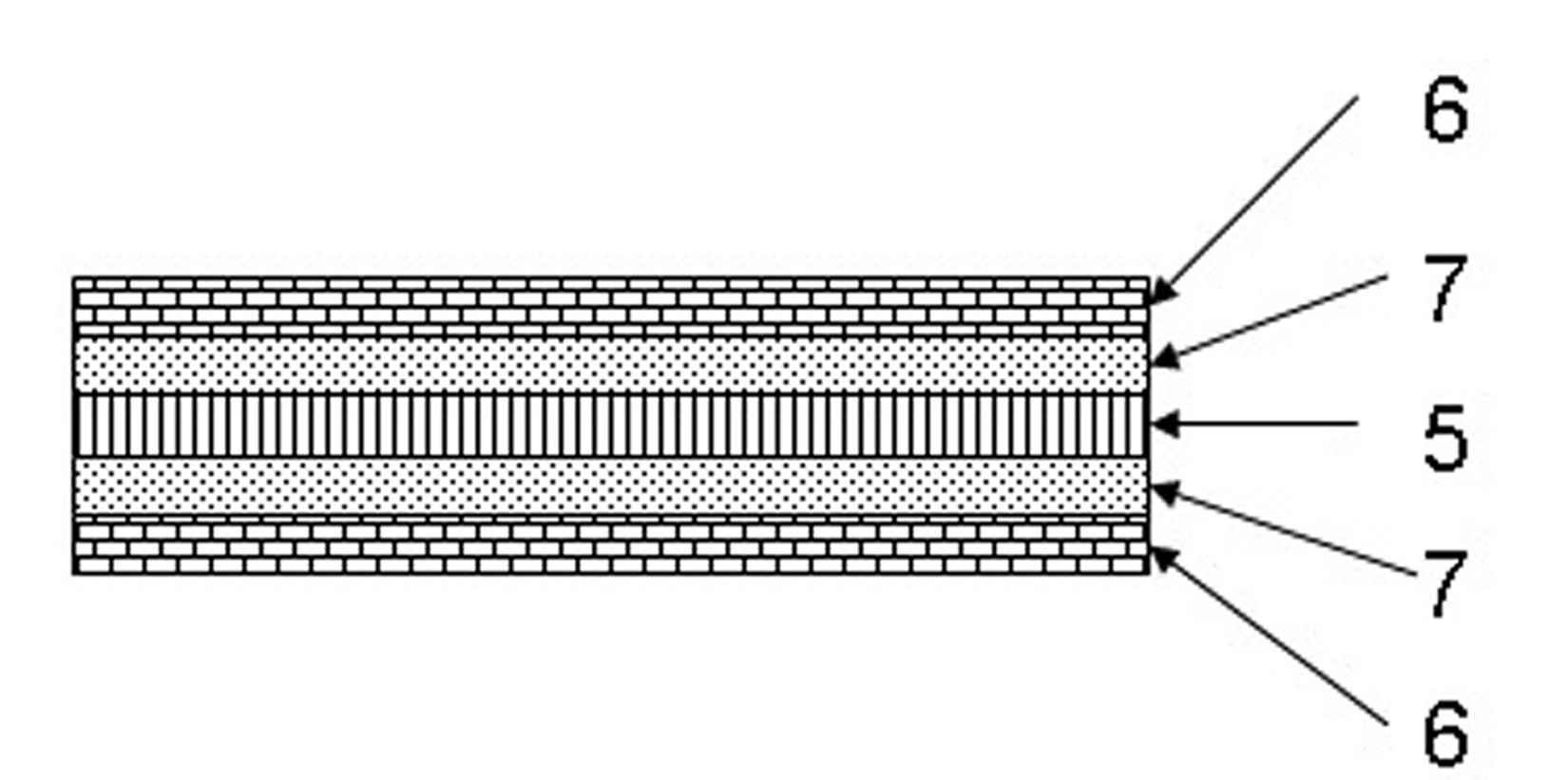

[0031] The heat source layer 2 of the present invention includes a base layer 5 , a heating layer 7 and an insulating layer 6 ; the heating layer 7 is fixed between the base layer 5 and the insulating layer 6 .

[0032] The leakage protection layer 3 of the present invention adopts steel metal mesh.

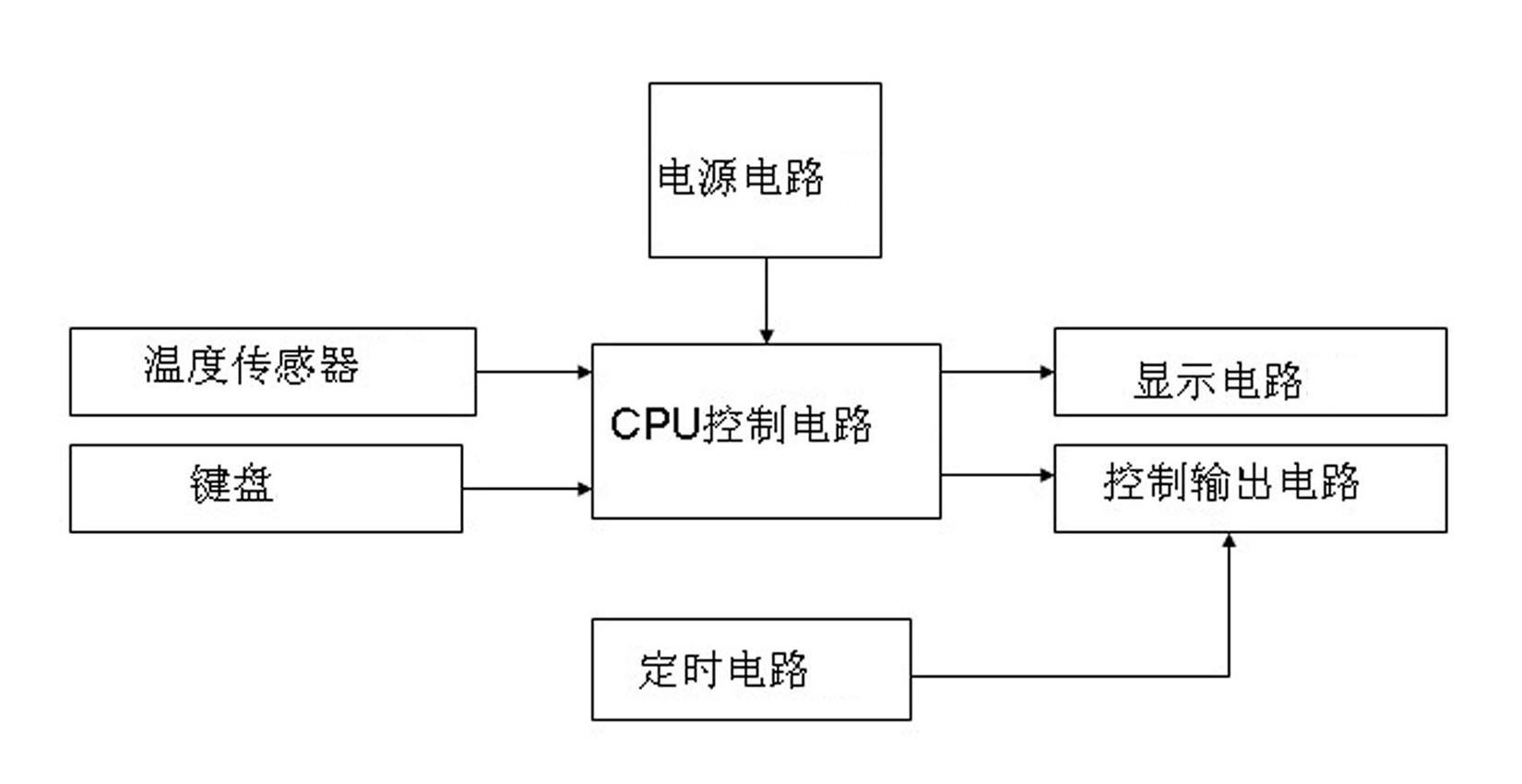

[0033] The temperature control box 4 of the present invention includes a te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com