Heat pipe test method

A test method and heat pipe technology, applied in the direction of thermal development of materials, etc., can solve the problems of central processing unit operation error, permanent failure of central processing unit, failure and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

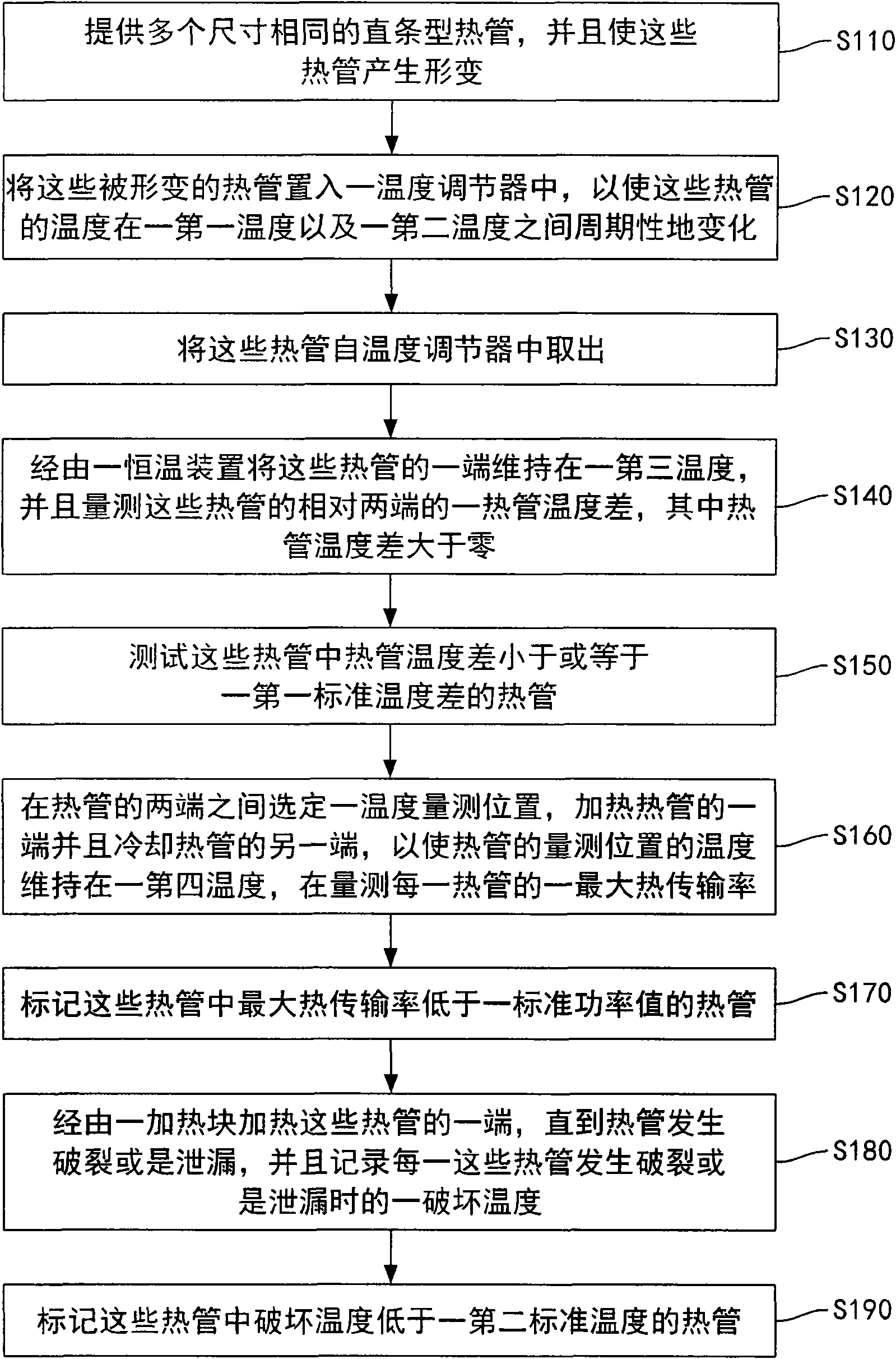

[0063] Below in conjunction with accompanying drawing, structural principle and working principle of the present invention are specifically described:

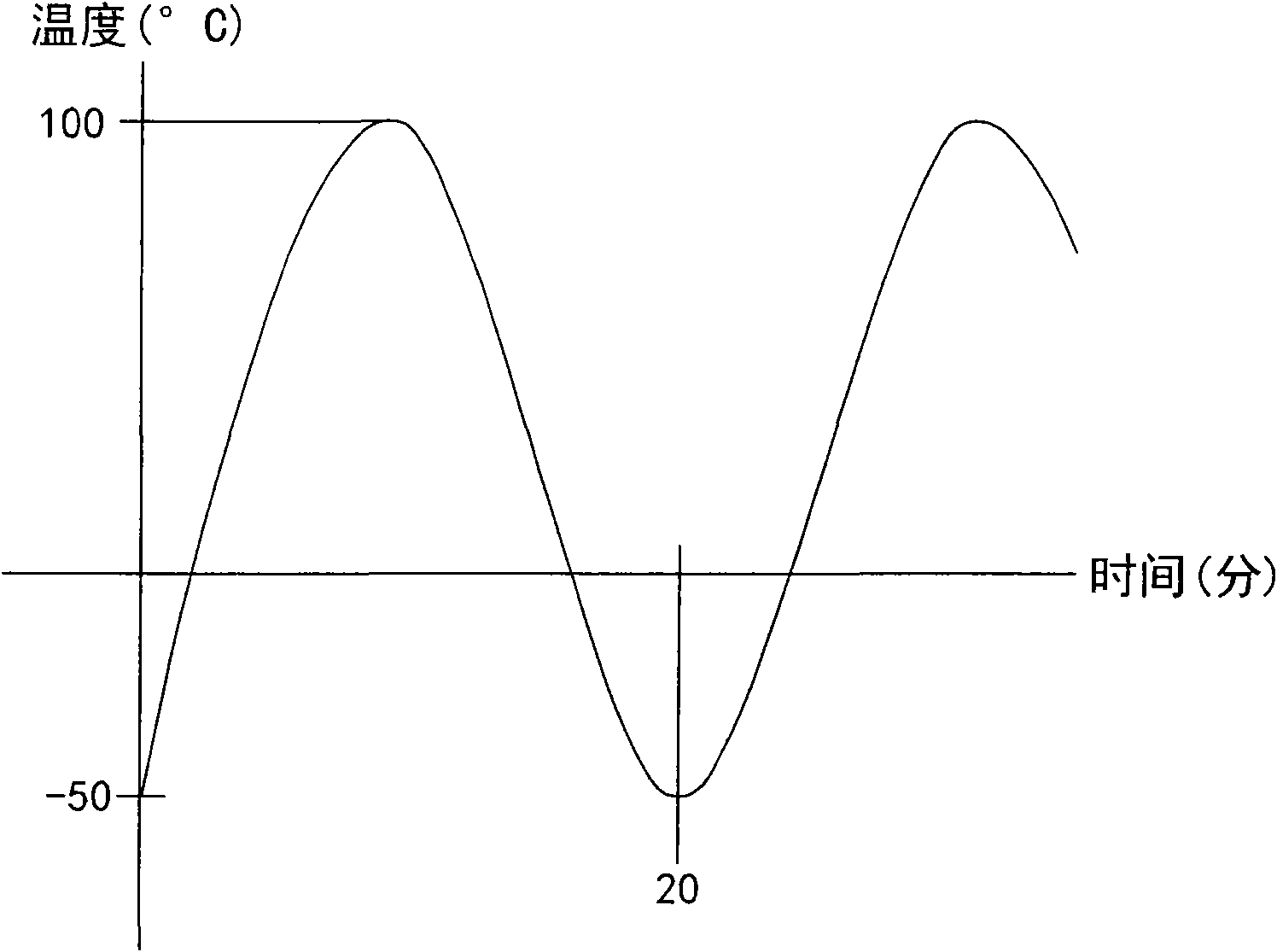

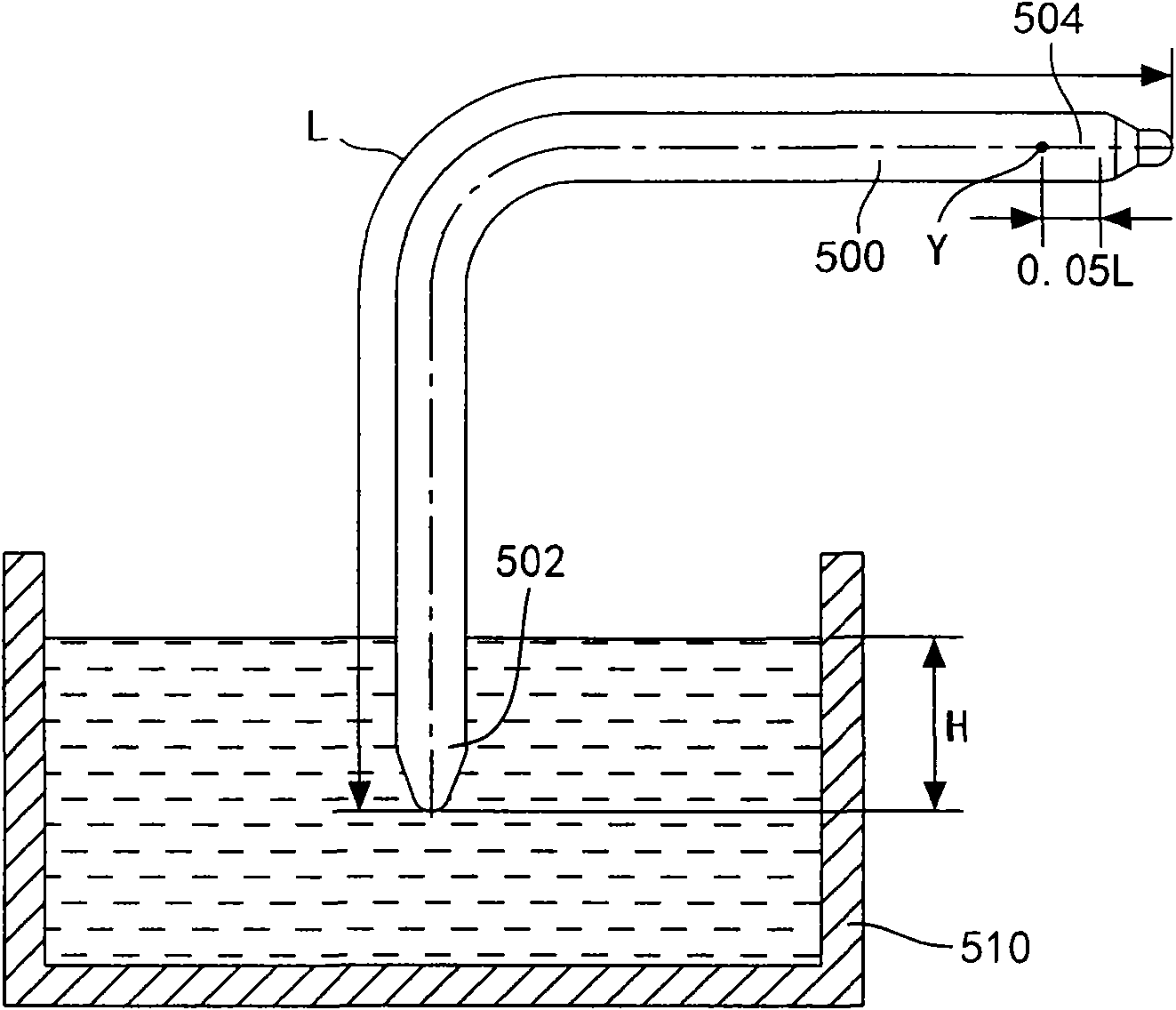

[0064] Please refer to figure 1 , which is a schematic diagram of a heat pipe testing method according to an embodiment of the present invention. First, as shown in step S110, a plurality of heat pipes having the same shape and the same size are provided. In this embodiment, the length of each heat pipe is L, and the shape of each heat pipe is a straight cylinder. After that, These heat pipes are deformed, and the position and size of the deformed part of each heat pipe are consistent. If the deformation is a bending deformation, the curvature of the bending is the same. If the deformation is extrusion deformation, the thickness of the extruded heat pipes is the same, that is, the shape and size of the heat pipes after deformation treatment are the same. In this embodiment, the end portion 502 of the heat pipe 500 is extrud...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com