Counting device for sand box or casting

A counting device and casting technology, applied in the field of casting, can solve the problems of waste and insufficiency of production arrangement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

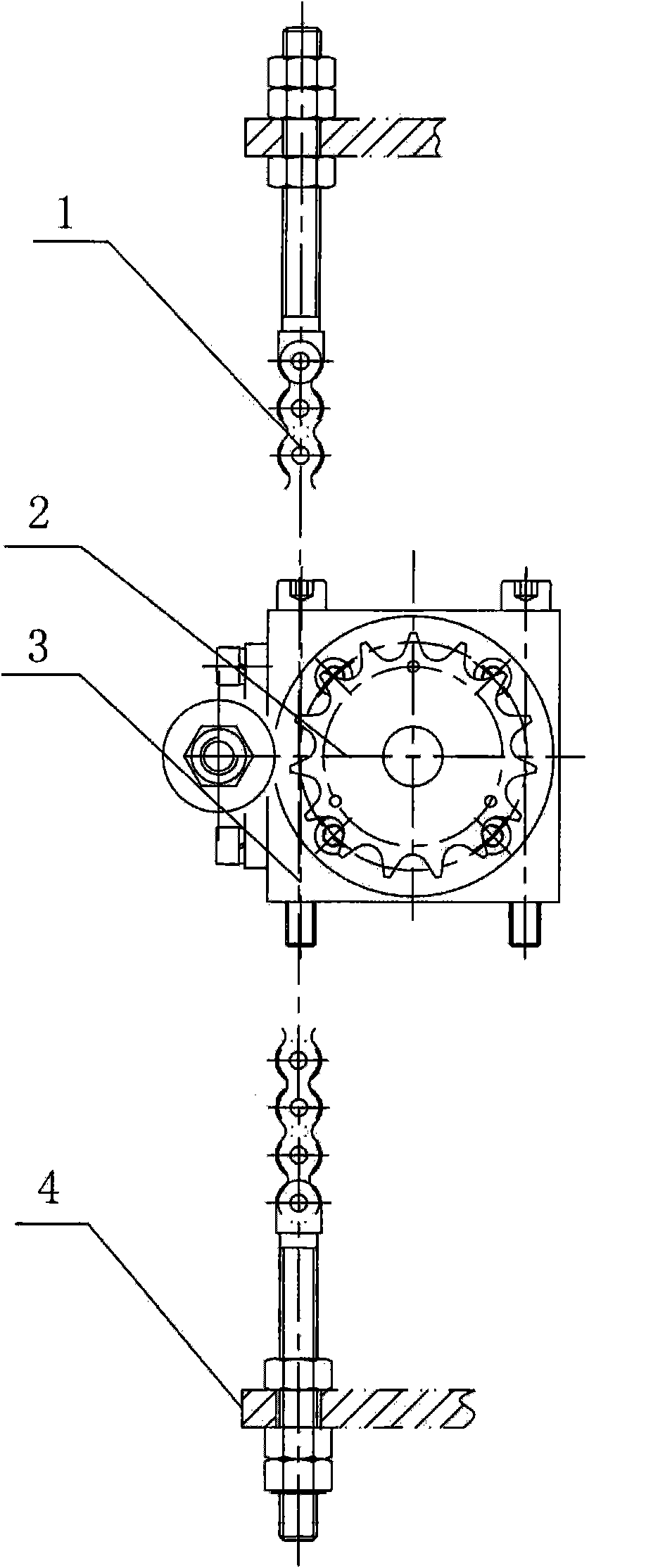

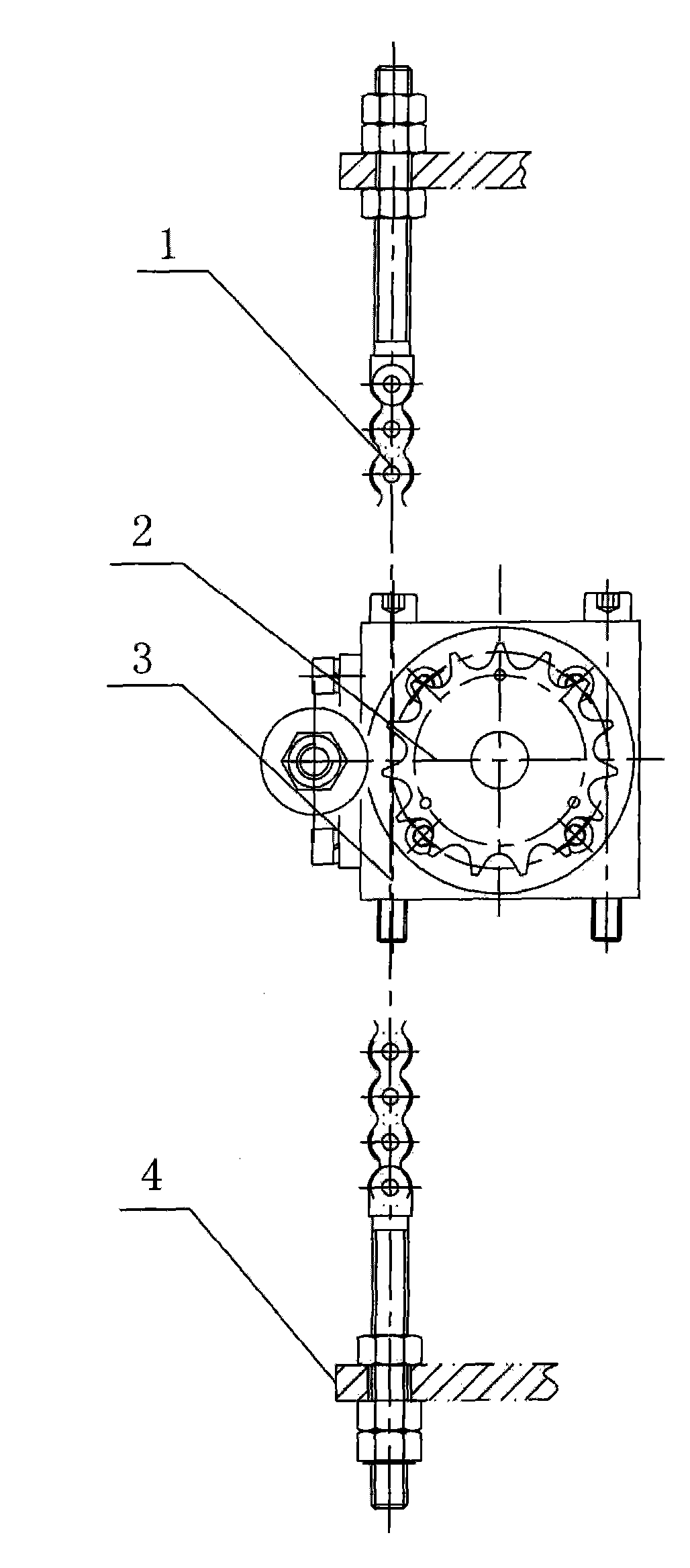

[0013] Such as figure 1 The shown sandbox or casting counting device is equipped with a vertically arranged chain 1 on the mounting bracket 4, and correspondingly provided with a sprocket 2 meshed with the chain 1, thus forming a molding machine working The lifting device of the table, because the sand box is usually transported and transferred through the lifting device of the workbench, it is equivalent to the production of a group of sandboxes or castings every time the workbench is lifted; At the same time, the form will also avoid the influence of operations such as downtime and maintenance due to other reasons on the final statistical data.

[0014] In this way, the encoder 3 and its corresponding modules can be arranged on the rotating shaft of the sprocket 2 to complete the statistics of the production quantity of the final flask or castings.

[0015] An encoder in a general sense is a device that compiles and converts signals or data into signal forms that can be use...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com