Material requirement suggestion making method

A material demand and demand technology, applied in the formulation of material demand proposals, can solve problems such as prone to errors, chaotic production arrangements, and influence of material demand plans, so as to achieve the effect of ensuring the realization and rationally arranging production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

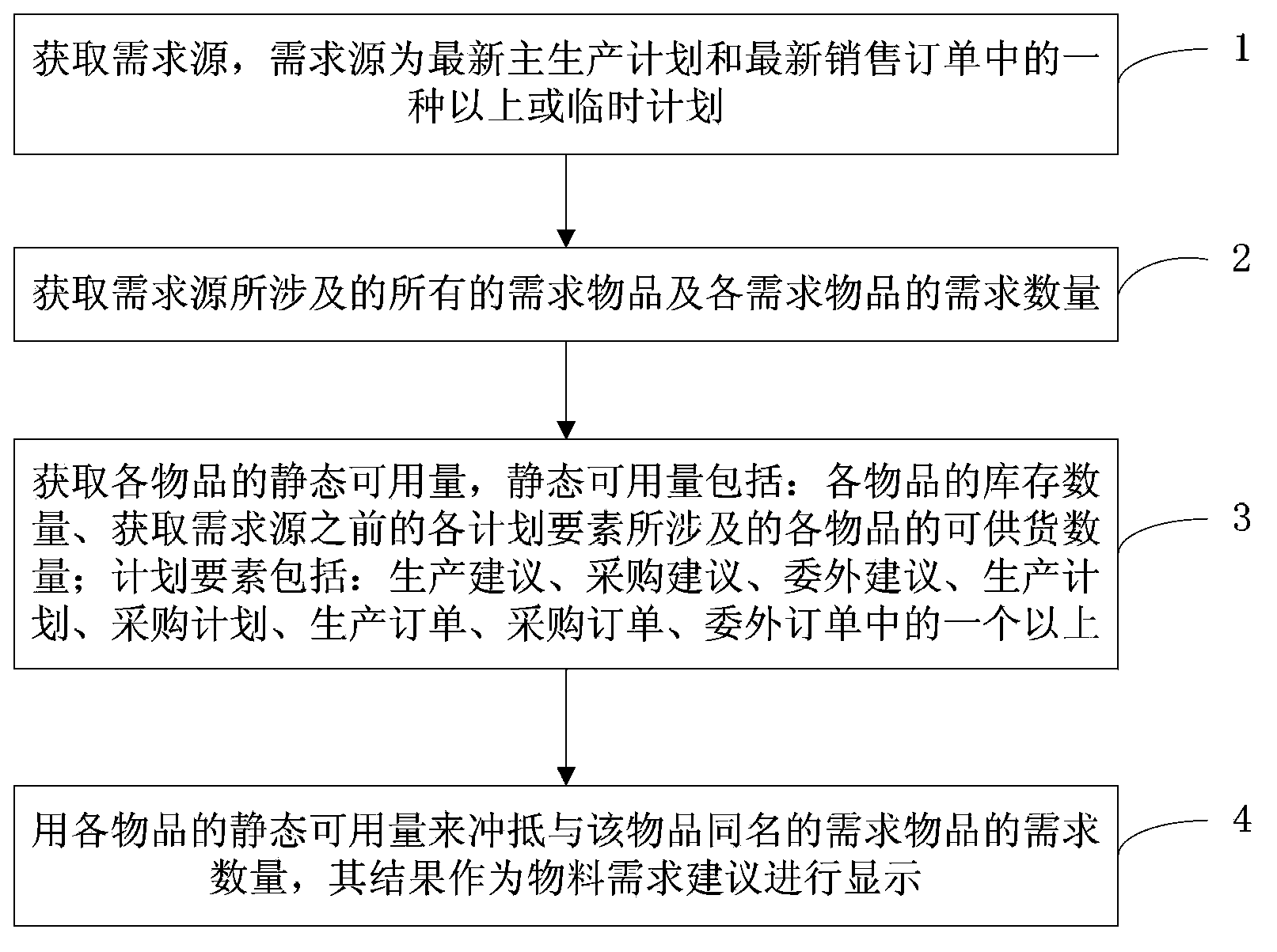

[0030] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

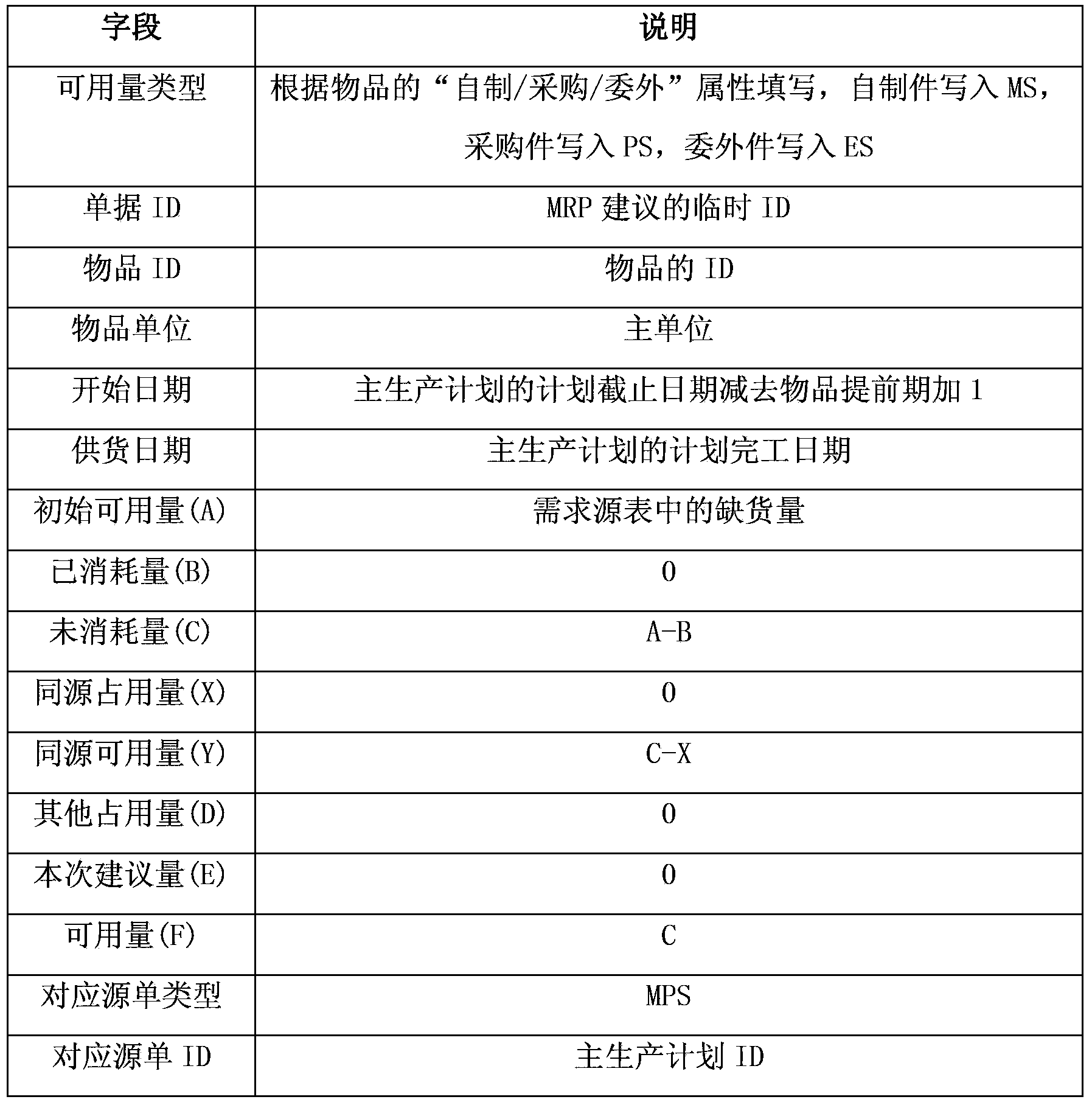

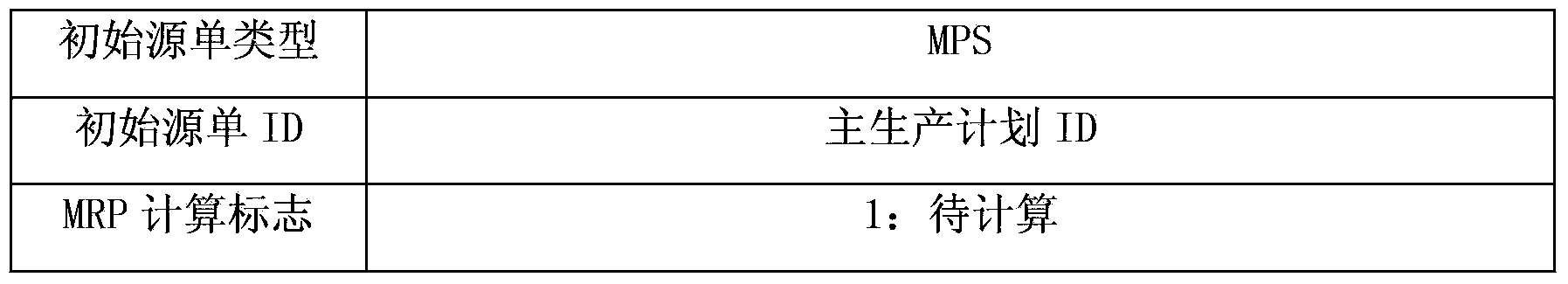

[0031] The present invention proposes a method for formulating material demand suggestions. The method is established after the master production plan and sales order have been established, that is, the inventory quantity of each item (that is, material) and the supplyable quantity of each item involved in each planning element When all are known, it is enabled when the master production plan, sales order or manual modification of the master production plan is required. The planning elements here include: one or more of production suggestion, purchase suggestion, subcontract suggestion, production plan, purchase plan, production order, purchase order, and subcontract order.

[0032] figure 1 It is a flowchart of a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com