Motor cover

A technology of motor cover and front cover, which is applied in the direction of casing/outer cover/support, electrical components, electromechanical devices, etc., which can solve problems such as unsatisfactory effects, improve sound quality, expand noise reduction frequency band, and improve airflow divergence Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The motor cover structure of the present invention will be further described in detail in conjunction with the accompanying drawings and specific embodiments:

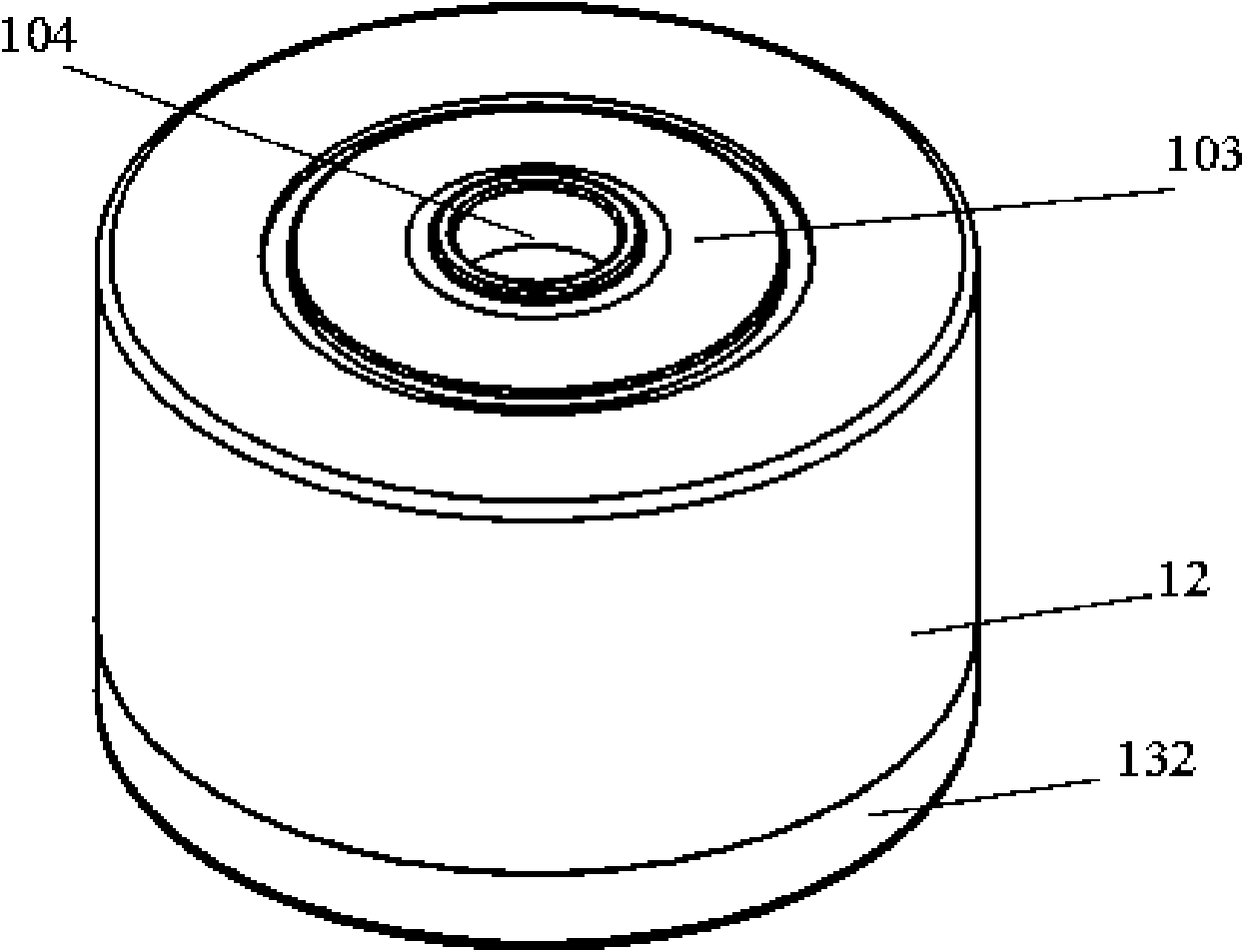

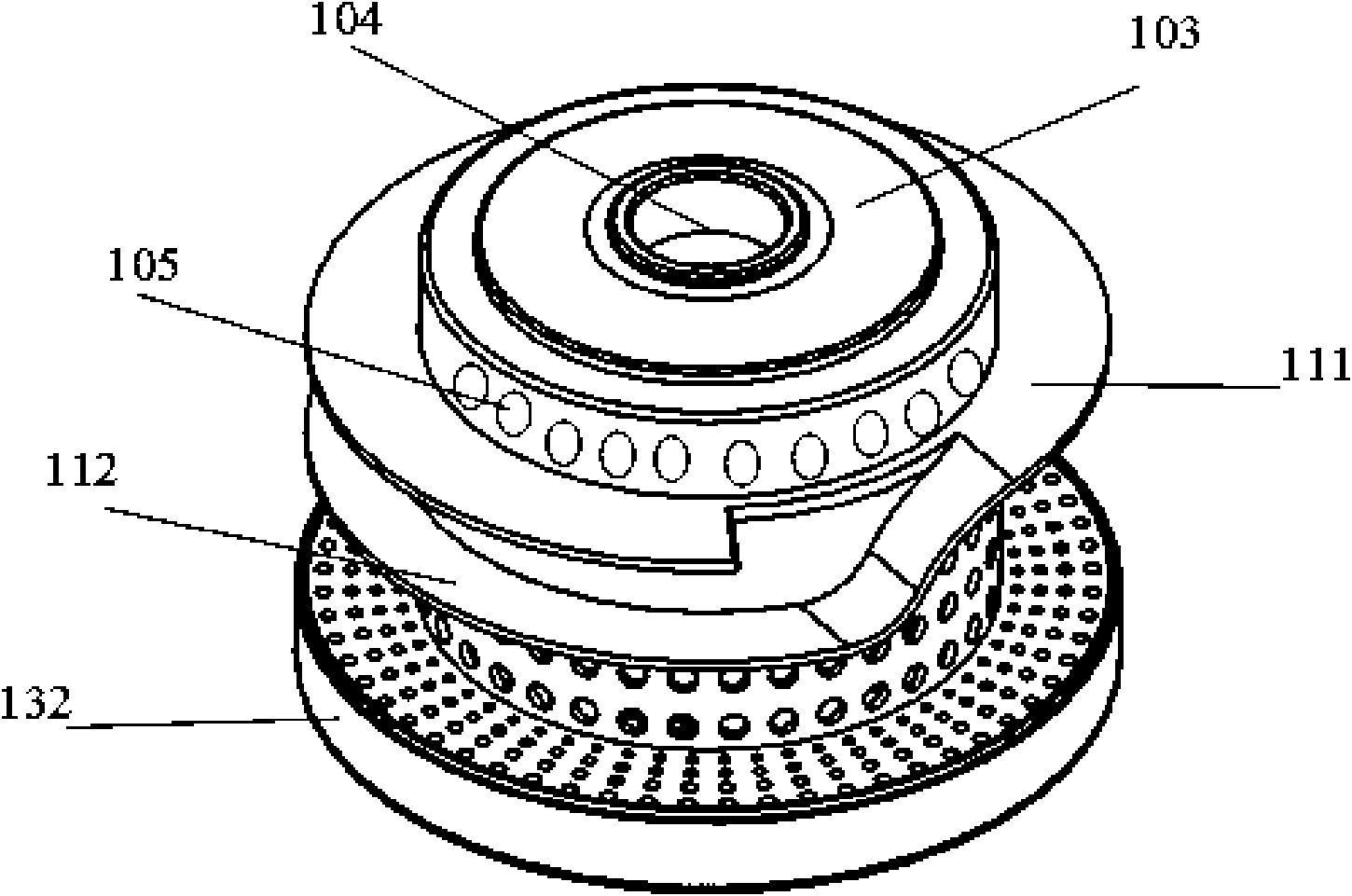

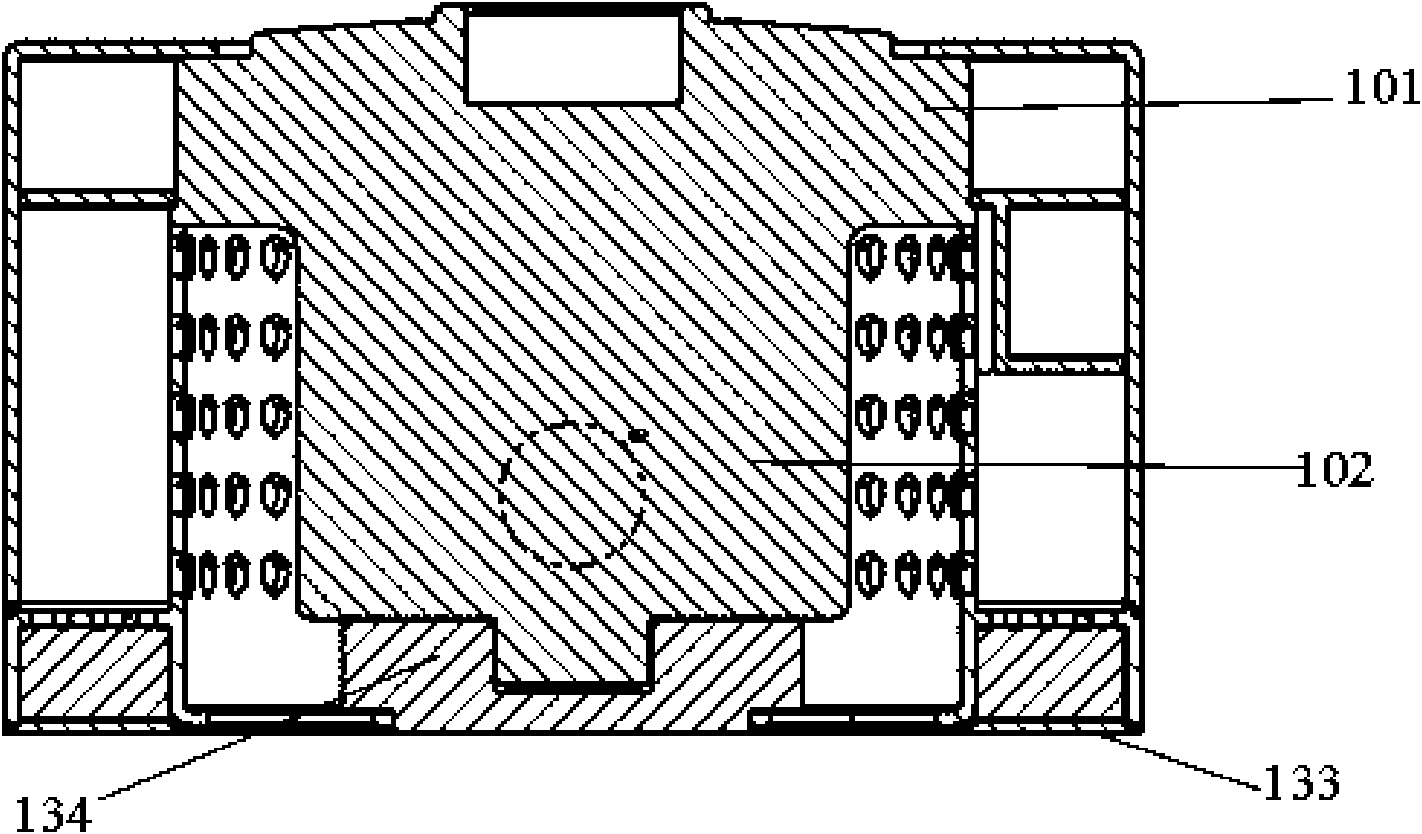

[0028] Such as Figure 1-5 As shown, the motor cover of the present invention includes a motor front cover 12 , an air filter cover 13 and a cyclone shaper 11 . The motor 10 includes two coaxially arranged cylindrical structures, and a boss 103 is formed at the top center of the large-diameter cylindrical end 101 of the working impeller inside, and a suction hole 104 is formed in the middle of the boss 103. The large-diameter cylinder 101 Limiting ribs or protrusions (not shown in the figure) are arranged below the exhaust hole 105 of the exhaust hole. The small-diameter cylindrical end 102 is provided with a rotor stator and control elements and the like.

[0029] The motor front cover 12 is a cylindrical structure with one end closed, and a circular through hole is formed in the middle of the closed end of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com