Sealing system between a shroud segment and a rotor blade tip and manufacturing method for such a segment

A blade tip, segment technology, used in the production of shell segments, can solve problems such as failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

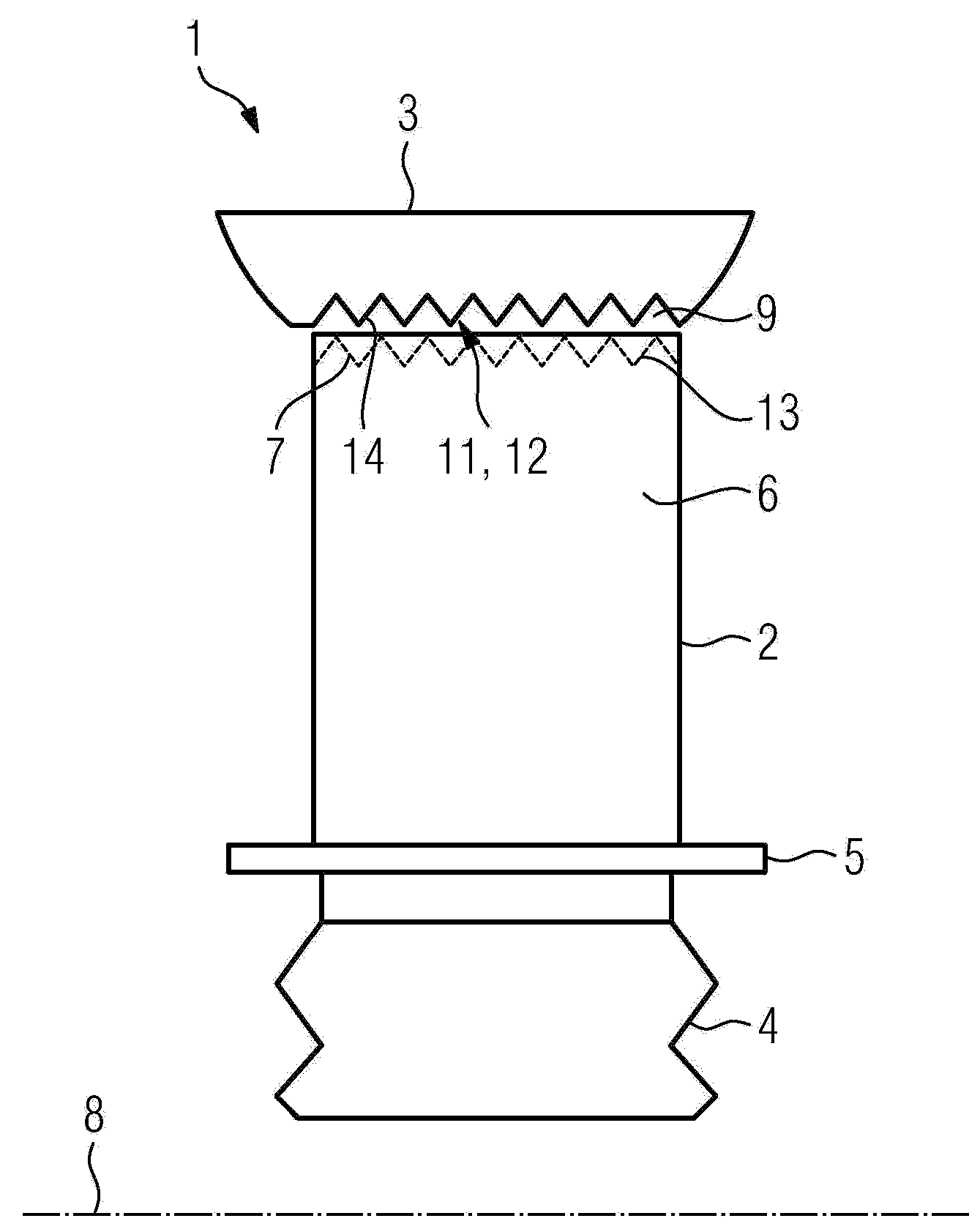

[0027] figure 1 An arrangement 1 according to the invention is shown, comprising a gas turbine blade 2 and a casing section 3 .

[0028] The gas turbine blade 2 is composed of a blade root 4 , a platform 5 and an airfoil 6 terminating radially at a blade tip 7 . The blades 2 are mounted in a not shown manner in a not shown rotor extending along a machine axis 8 (respectively the rotor's axis of rotation). The housing section 3 surrounds the rotor circumferentially.

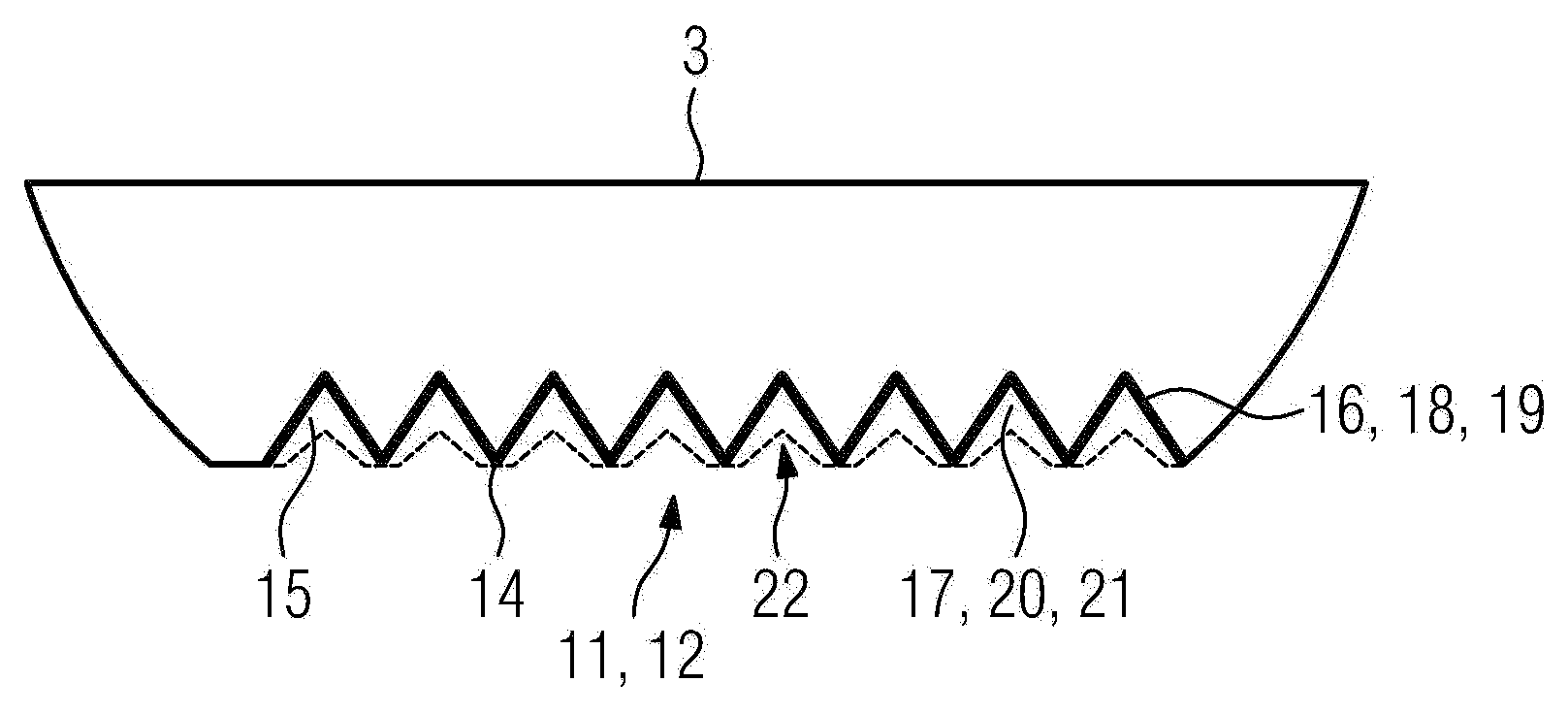

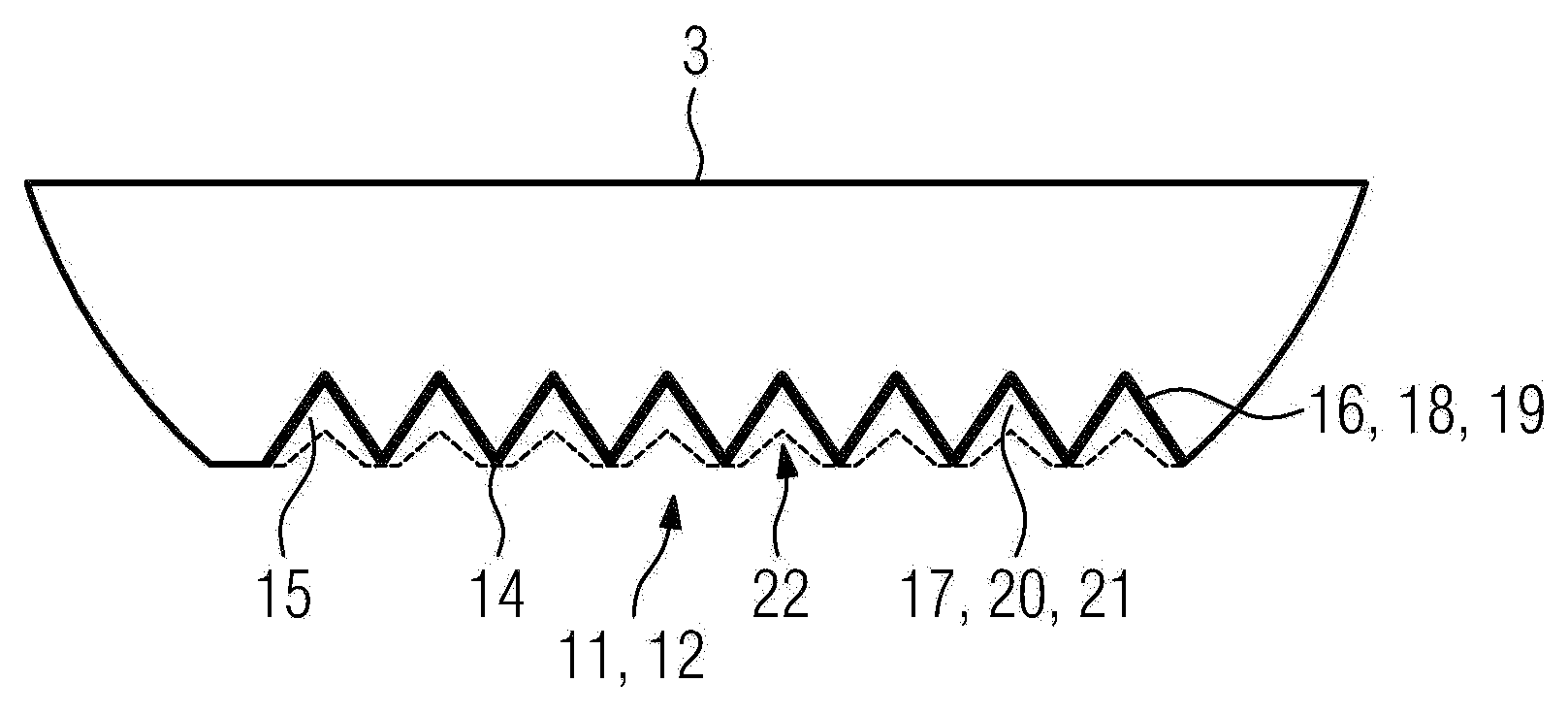

[0029] A gap 9 is provided between the blade tip 7 and the surface 11 of the shell section 3 facing the blade tip 7 to maintain the necessary clearance between the rotating part and the fixed part. The surface 11 has a first surface structure 12 which improves the aerodynamic efficiency by inhibiting the secondary flow over the blade tip 7, the bypassing of which reduces the power output. The serration 12 is formed by circumferential grooves 22 having a triangular cross-sectional shape separating triangular cir...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com