Method for performing model simulation and code generation on custom hardware by using Simulink

A model simulation and code generation technology, applied in software simulation/interpretation/simulation, program control devices, etc., can solve problems such as time-consuming system development and custom hardware models

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

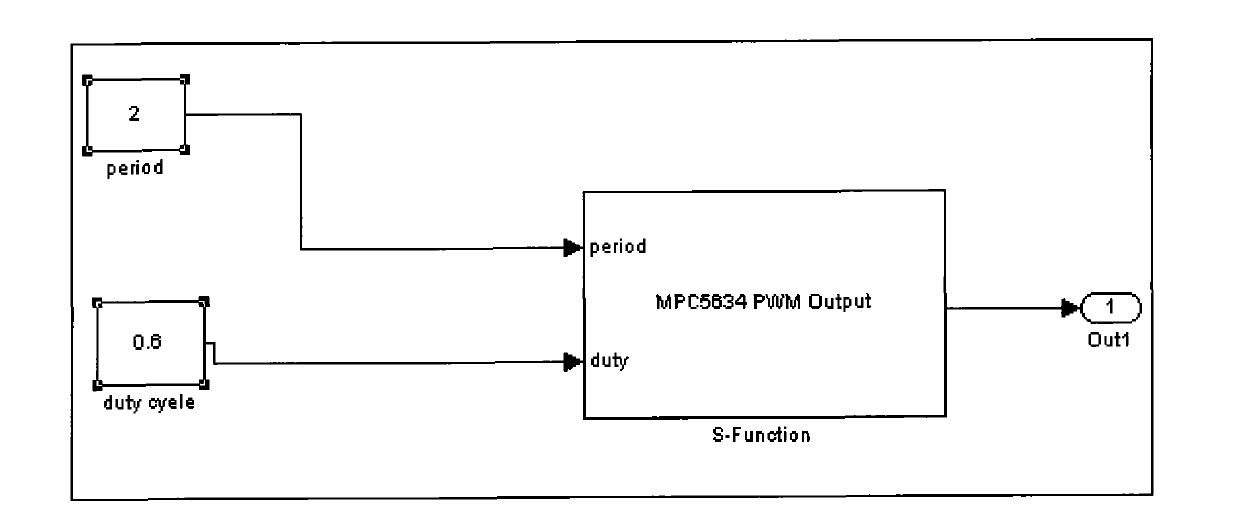

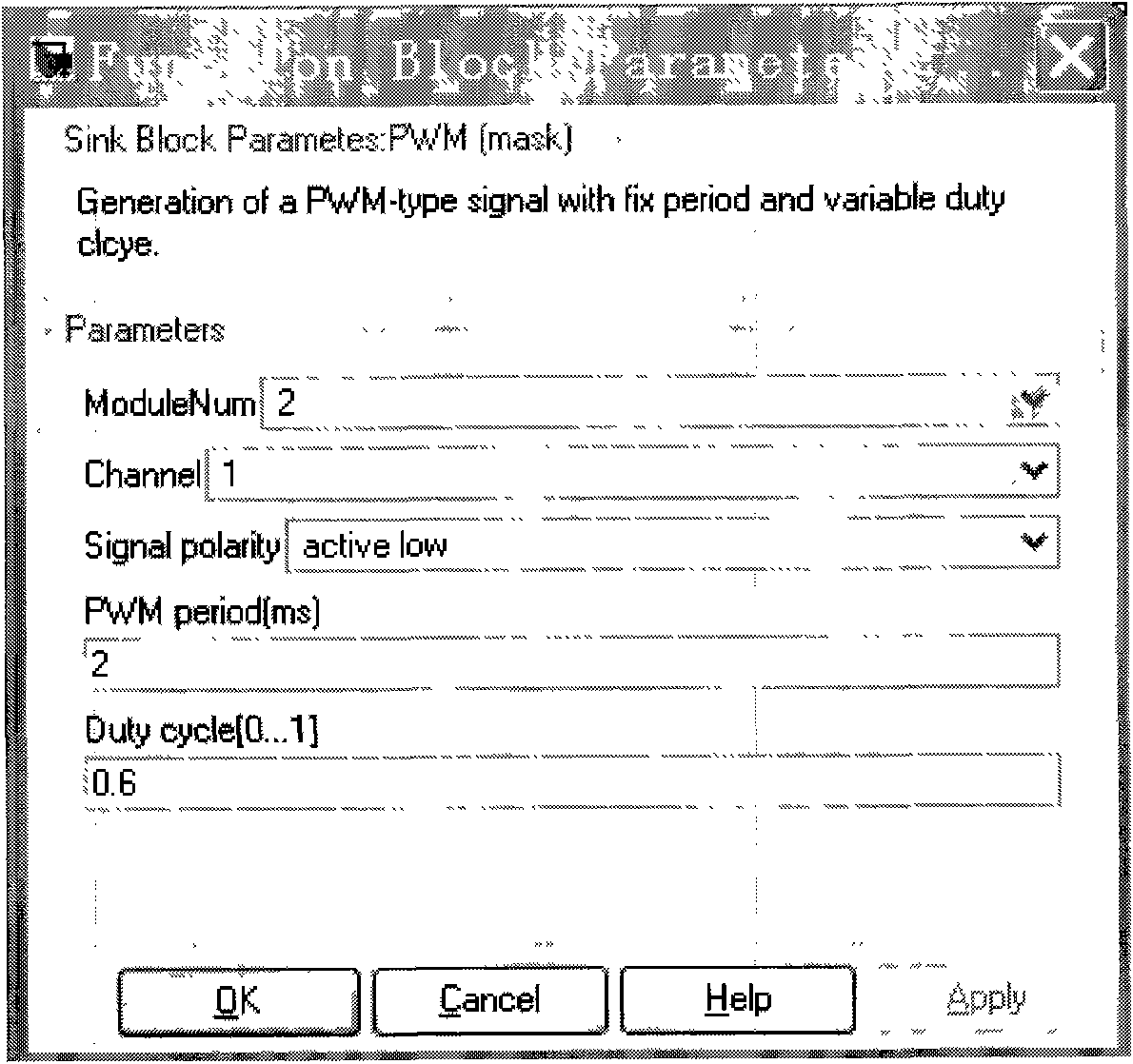

[0029] The present invention utilizes Simulink to carry out model simulation and code generation method one embodiment of custom hardware as Figure 7 shown, including the following steps:

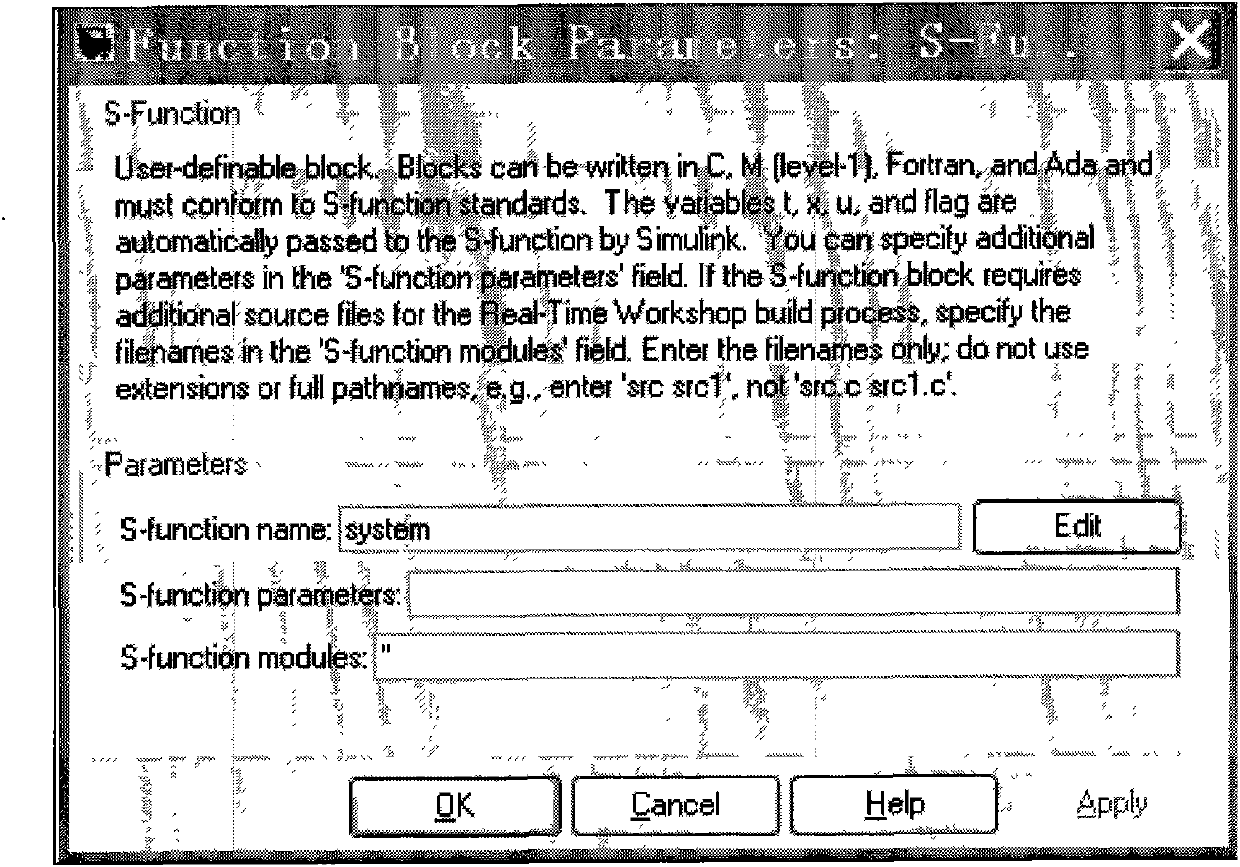

[0030] 1. Write custom hardware-specific device driver codes, that is, header files, macro definitions, and I / O device code libraries for certain custom hardware; write custom hardware C MEX S files, and the C MEXS files include descriptions of custom hardware-specific input , output, model sampling time, etc. and the transformation relationship between the output and the input, the extension is "c"; write a TLC file, the TLC file is the same as the file name of the C MEX S file, and the extension "TLC ”; save the three files in a specific folder;

[0031] Two. With the specific folder as the current path, input the mexC MEX S file name in the MATLAB command window, at this moment the mex command can generate a C MEX S file name .mexw32 file in the specific folder, in Matlab / During simu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com