Roller with durable driving mechanism

A driving mechanism and roller skating technology, applied in skating, skating boards, sports accessories, etc., can solve problems such as inability to go uphill, slow forward speed, low mechanical efficiency, etc., to prolong service life, avoid rack breakage, and improve driving efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

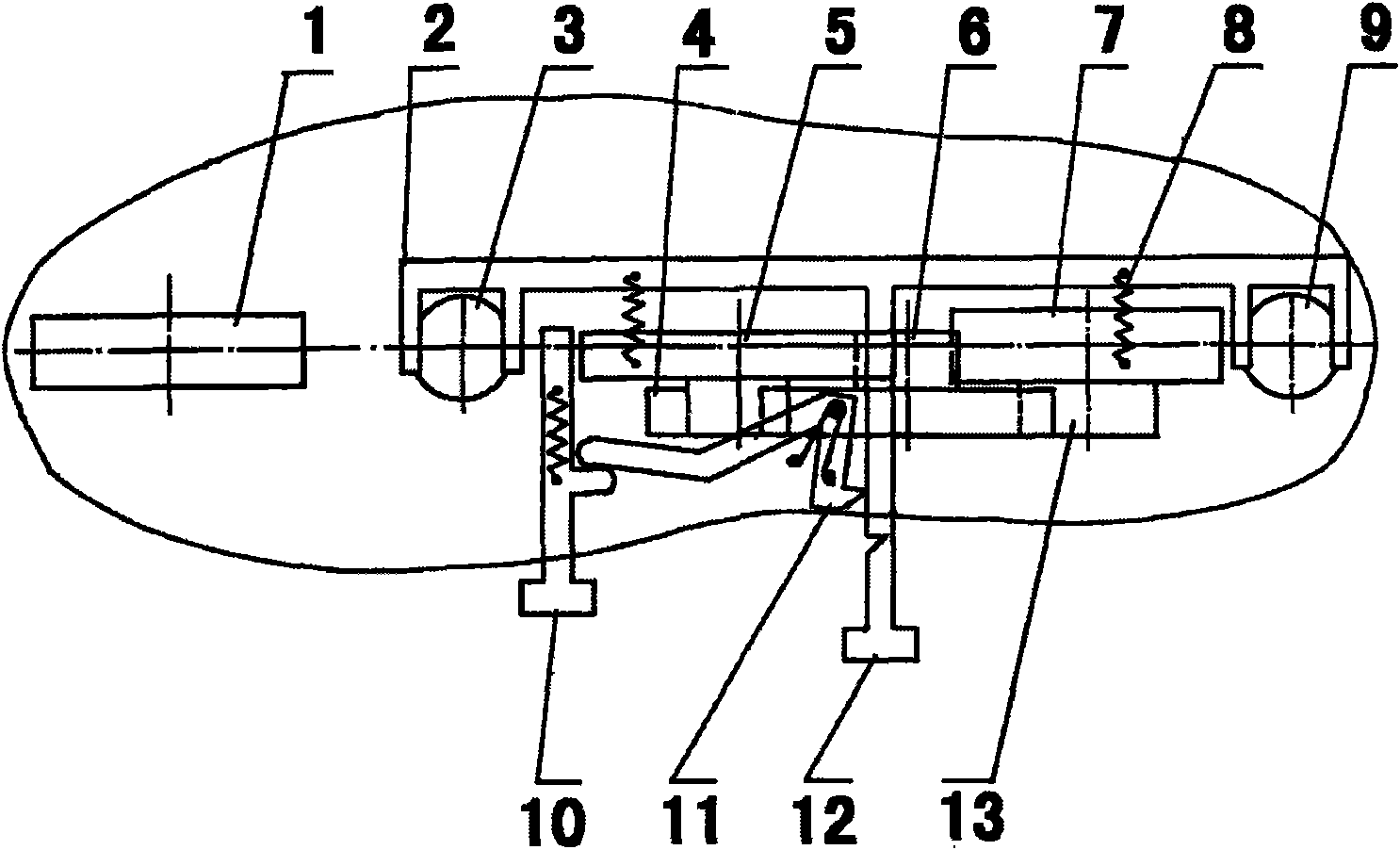

[0012] The invention provides a roller skating, which includes a board body, a driven front wheel and a driving rear wheel connected to the lower end surface of the board body; Bar and drive the ratchet wheel (being commonly called as " flywheel " bicycle part that is connected on the driving rear wheel by driving bar, because be well-known bicycle parts, describe its principle or internal structure no longer here) so as to drive rear wheel.

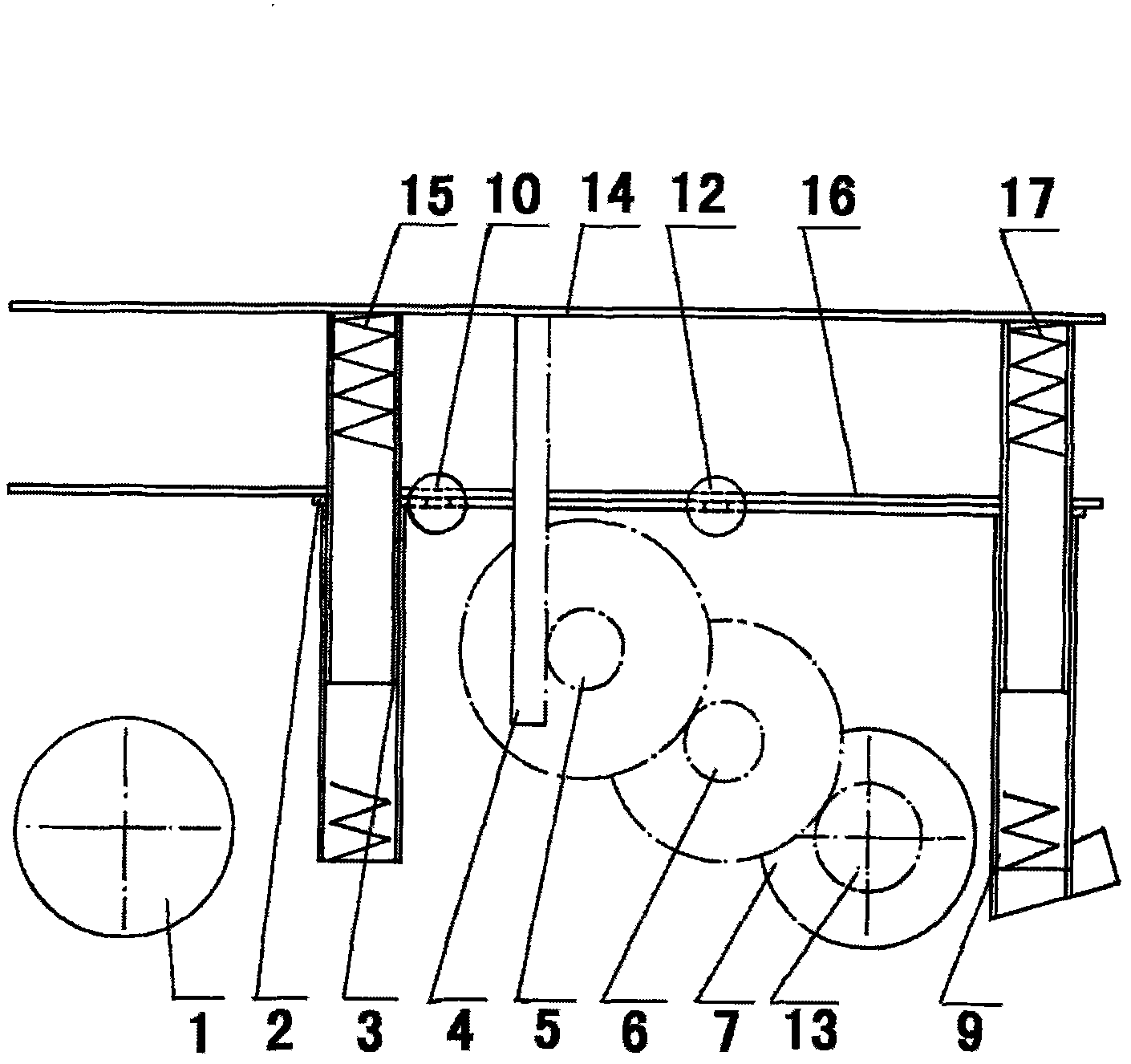

[0013] please see figure 2 , figure 2 Showed the method that drive bar drives the right wheel slip rear wheel, among the figure pedal 14 is in rising state under spring 15, spring 17 effects, because ratchet 13 exists when pedal 14 moves upwards, rear wheel 7 has no influence. When the pedal 14 is moved downward by the active force of the pin, the drive bar 4 drives the ratchet 13 through the A gear set 5 and the B gear set 6 to drive the rear wheel 7 to rotate, and the wheel slide moves forward.

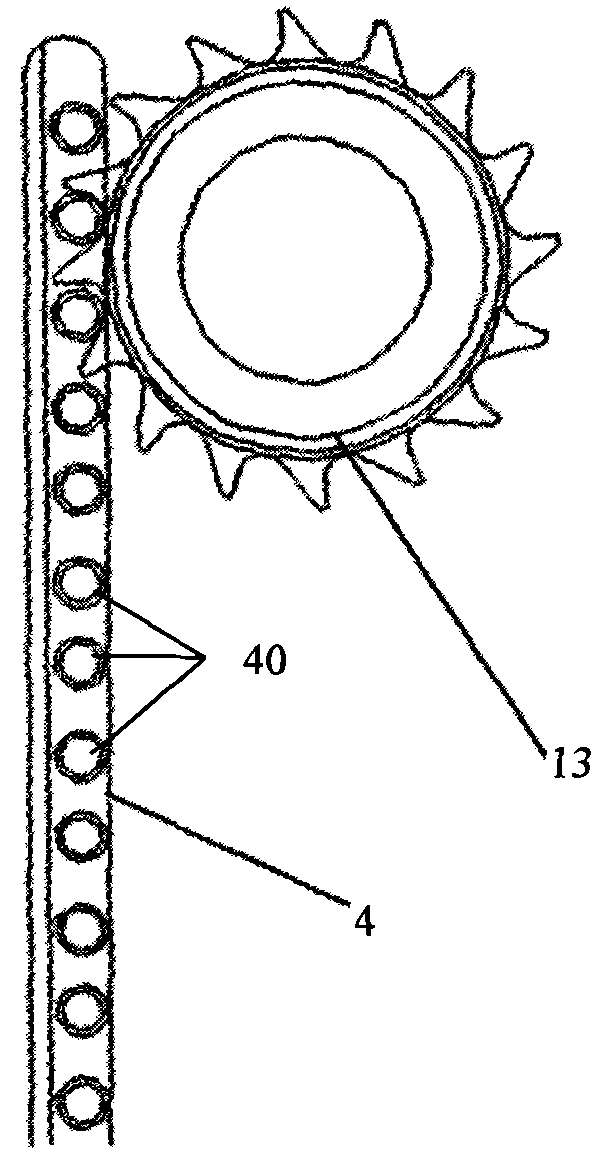

[0014] like image 3 As shown: the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com