Double-moving ring friction spot welding method

A friction point and moving ring technology, applied in welding equipment, non-electric welding equipment, metal processing equipment, etc., can solve problems such as low interface temperature, virtual connection, and poor forming conditions of the connection surface, and achieve high-quality connection and quality consistency Good, the effect of improving the tensile and shear strength of solder joints

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

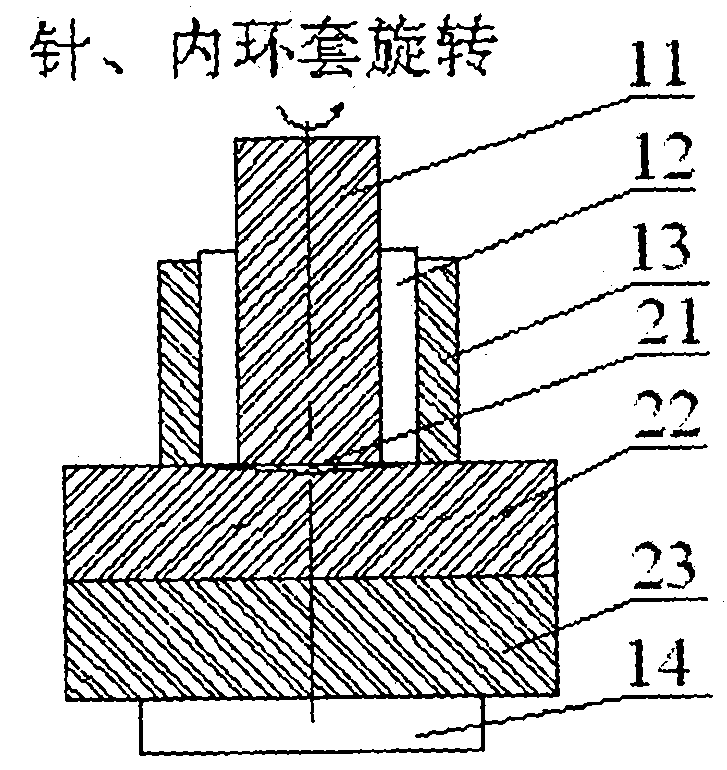

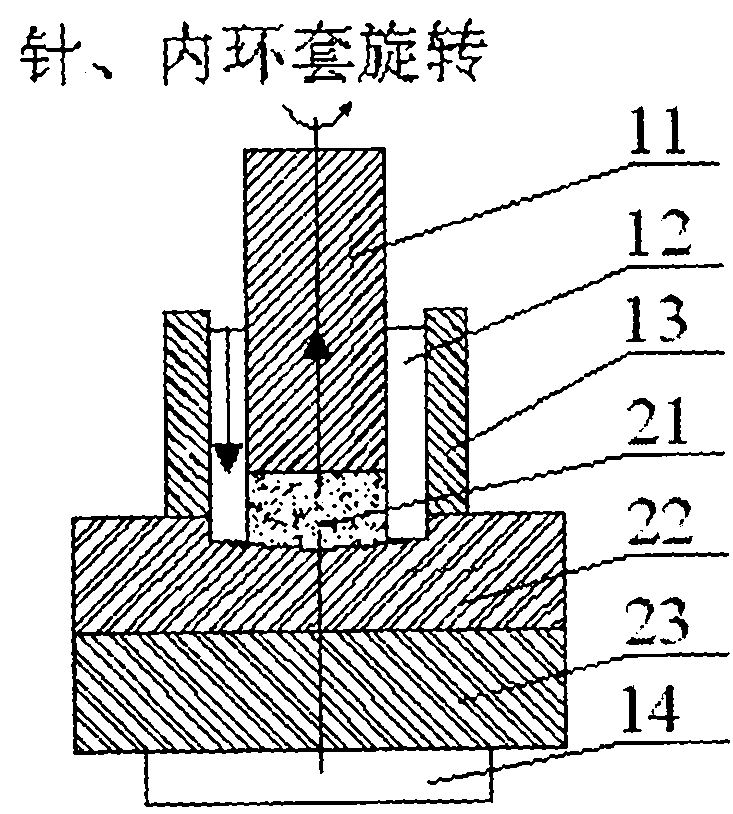

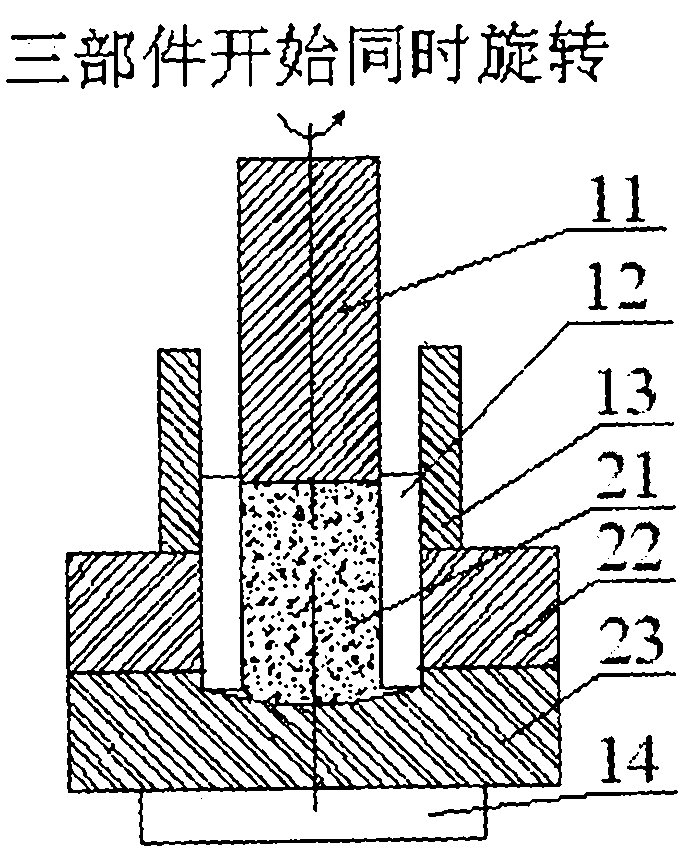

[0017] Such as Figure 1 to Figure 5 As shown, the double moving ring friction spot welding method provided by the preferred embodiment of the present invention includes the following steps:

[0018] 1) Friction heating stage: the outer ring 13 presses the surface of the workpiece to constrain the mold, the middle ring 12 and the central shaft 11 press and rotate against the surface of the workpiece, frictionally heats the part of the workpiece to be welded, and softens the metal material plastically;

[0019] 2) In-situ mixing stage: the middle collar 12 is extruded and rotated to press into the material, while the central shaft 11 rotates and rises, and the plastic material flows to the central shaft area;

[0020] The above two stages are the same as the traditional friction spot welding process. The outer ring sleeve 13 does not need to be rotated and pressed down. When the middle ring sleeve 12 reaches the position where the welding depth is set, the outer ring sleeve star...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com