Spray printer for large-area stone slabs

A technology for stone slabs and inkjet printers, which is applied to typewriters, special decorative structures, decorative arts, etc., can solve problems such as being difficult to apply to large-area slabs, and achieve the effect of simple structure and easy realization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

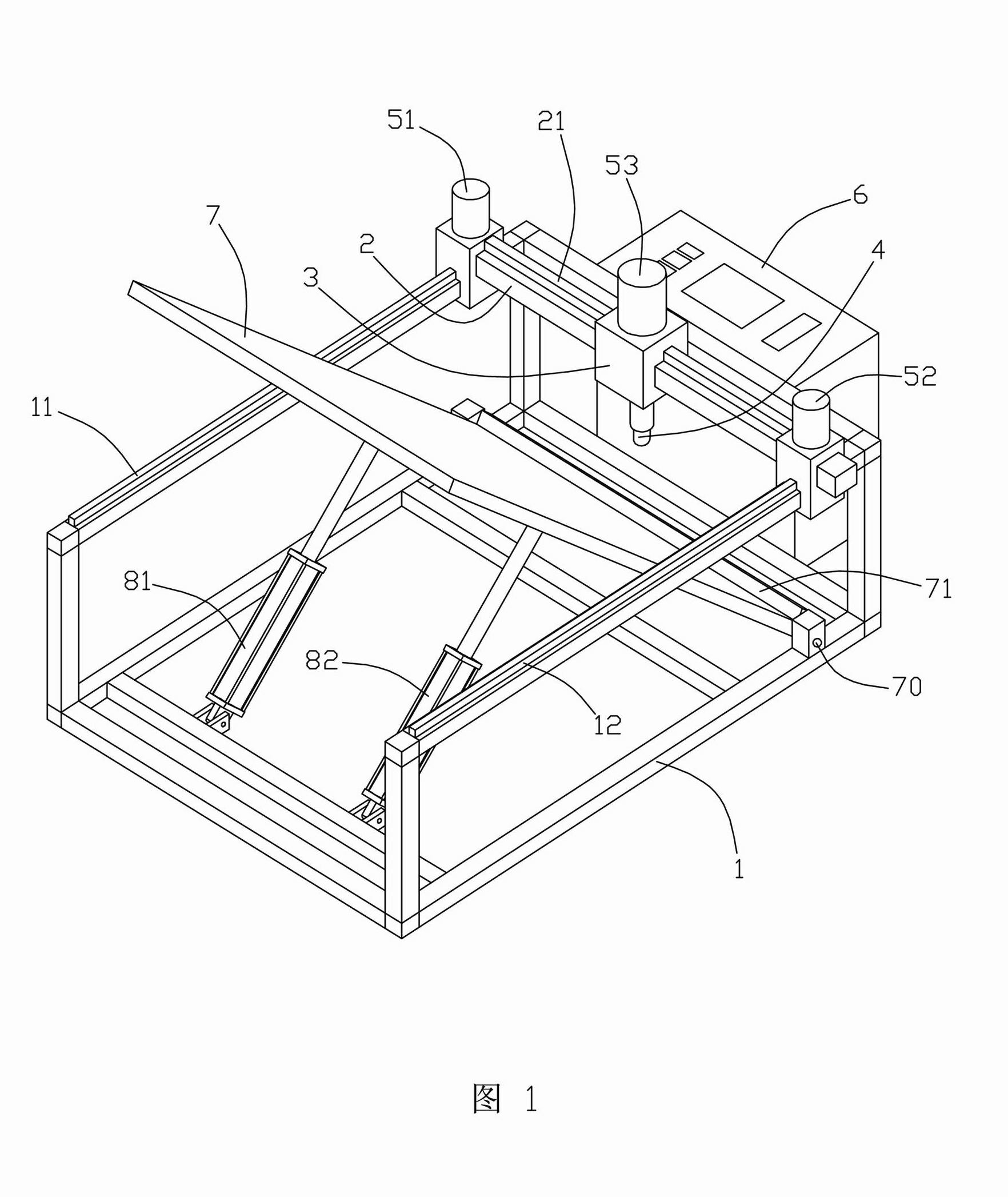

[0028] A large-area stone slab inkjet printer, refer to figure 1 , the main structure includes a base 1, a power system, and a control system 6. The base 1 has two parallel slide rails 11, 12 extending in the front-rear direction, a cross arm 2 is erected above the two parallel slide rails 11, 12, and the two ends of the cross arm 2 are connected to the on the slide rails 11 and 12. The horizontal arm 2 is provided with a slide rail 21 extending left and right, and the slide rail 21 is provided with a nozzle fixing frame 3 which can slide left and right, and the nozzle fixing frame 3 is provided with a nozzle 4 which can move up and down. The power system includes motors 51, 52, 53 for driving the cross arm 2, the nozzle holder 3, and the nozzle 4, and the control system 6 controls the power system and the nozzle 4 to print. The number of the nozzle fixing frame 3 and the nozzle 4 can be respectively set to two according to actual needs.

[0029] The base 1 is provided with...

Embodiment 2

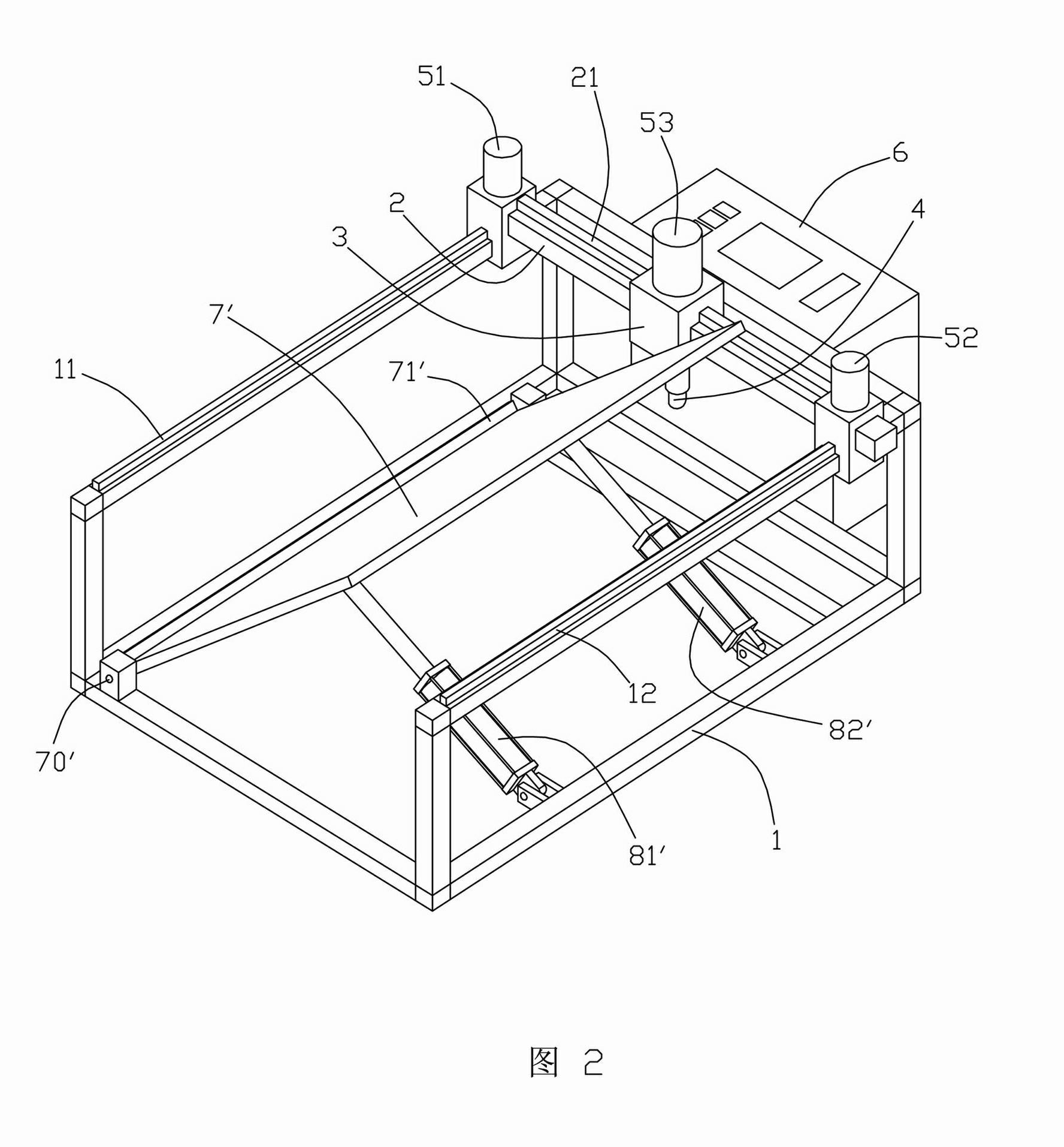

[0032] A large-area stone slab inkjet printer, refer to figure 2 , the main structure includes a base 1, a power system and a control system 6. The base 1 has two parallel slide rails 11, 12 extending in the front-rear direction, a cross arm 2 is erected above the two parallel slide rails 11, 12, and the two ends of the cross arm 2 are connected to the on the slide rails 11 and 12. The horizontal arm 2 is provided with a slide rail 21 extending left and right, and the slide rail 21 is provided with a nozzle fixing frame 3 which can slide left and right, and the nozzle fixing frame 3 is provided with a nozzle 4 which can move up and down. The power system includes motors 51, 52, 53 for driving the cross arm 2, the nozzle holder 3, and the nozzle 4, and the control system 6 controls the power system and the nozzle 4 to print. The number of the nozzle fixing frame 3 and the nozzle 4 can be respectively set to two according to actual needs.

[0033] The base 1 is provided with...

Embodiment 3

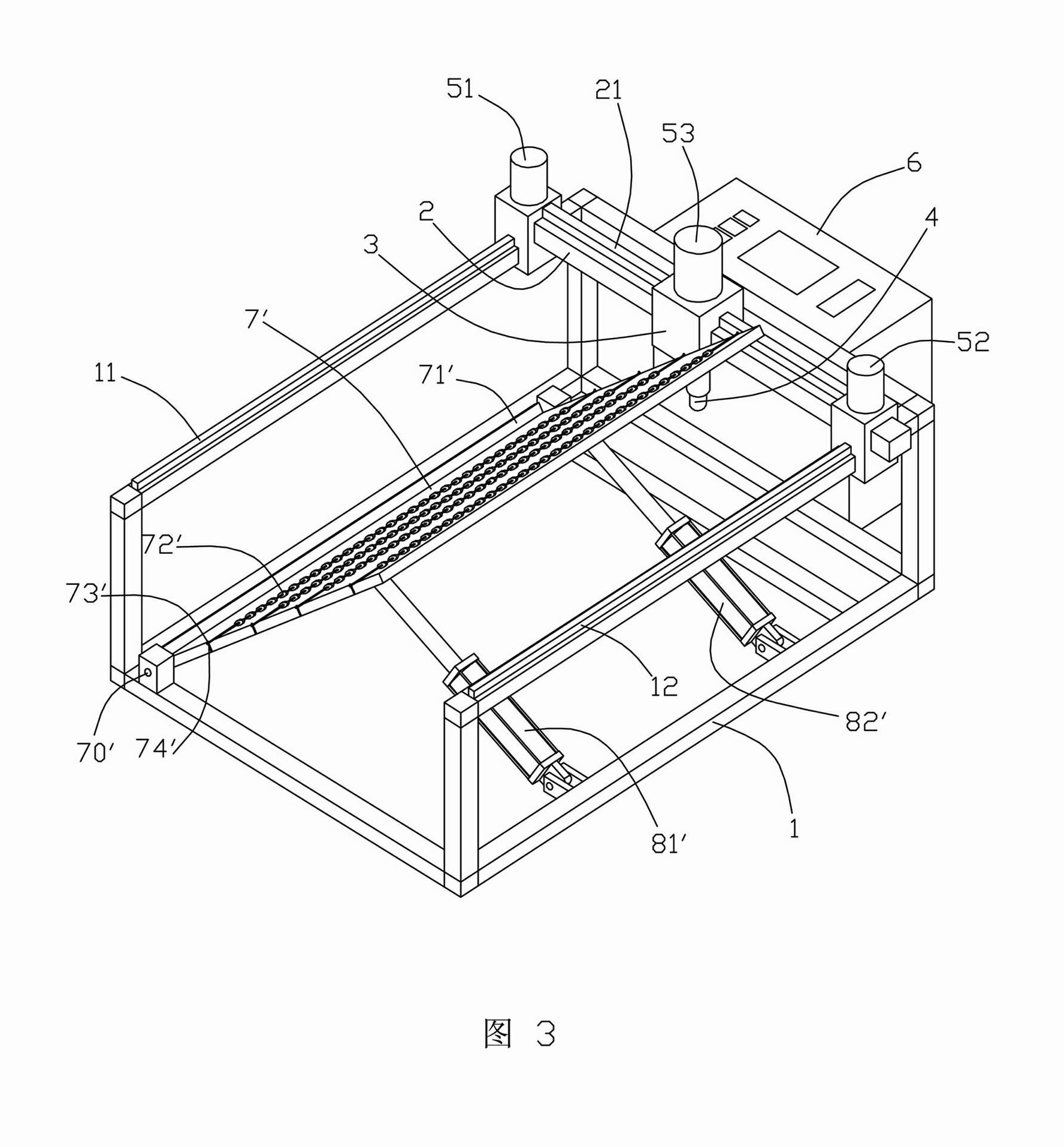

[0037] A large-area stone slab inkjet printer, refer to Figure 5 , the main structure includes a base 1, a power system and a control system 6. The base 1 has two parallel slide rails 11, 12 extending in the front-rear direction, a cross arm 2 is erected above the two parallel slide rails 11, 12, and the two ends of the cross arm 2 are connected to the on the slide rails 11 and 12. The horizontal arm 2 is provided with a slide rail 21 extending left and right, and the slide rail 21 is provided with a nozzle fixing frame 3 which can slide left and right, and the nozzle fixing frame 3 is provided with a nozzle 4 which can move up and down. The power system includes motors 51, 52, 53 for driving the cross arm 2, the nozzle holder 3, and the nozzle 4, and the control system 6 controls the power system and the nozzle 4 to print. The number of the nozzle fixing frame 3 and the nozzle 4 can be respectively set to two according to actual needs.

[0038]This inkjet machine also com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com