Sealed spring box for connecting pantograph head of pantograph with pantograph connecting frame

A pantograph and connecting frame technology, applied in the field of connecting devices, can solve the problems of inability to effectively reduce pantograph-catenary impact and tremor, poor vibration attenuation ability of bow head body, unfavorable high-speed and stable operation of locomotives, etc., and achieve light weight and compact structure , Improve the effect of reliability and stability

Inactive Publication Date: 2011-06-15

SOUTHWEST JIAOTONG UNIV

View PDF7 Cites 6 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

After the speed of the locomotive exceeds 350 km / h, this kind of connection device, due to the large aerodynamic resistance of the suspension device, the bow body shakes and fluctuates greatly during high-speed movement, and because the damping of the tension spring suspension is small, it is not suitable for high-speed operation. The shock attenuation ability of the bow head body is poor, and the impact and tremor between the pantograph and catenary cannot be effectively weakened, so that the pantograph and catenary often go offline, causing sparks, which is not conducive to the stable flow of the locomotive, and is not conducive to the smooth operation of the locomotive at high speed

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

specific Embodiment approach

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

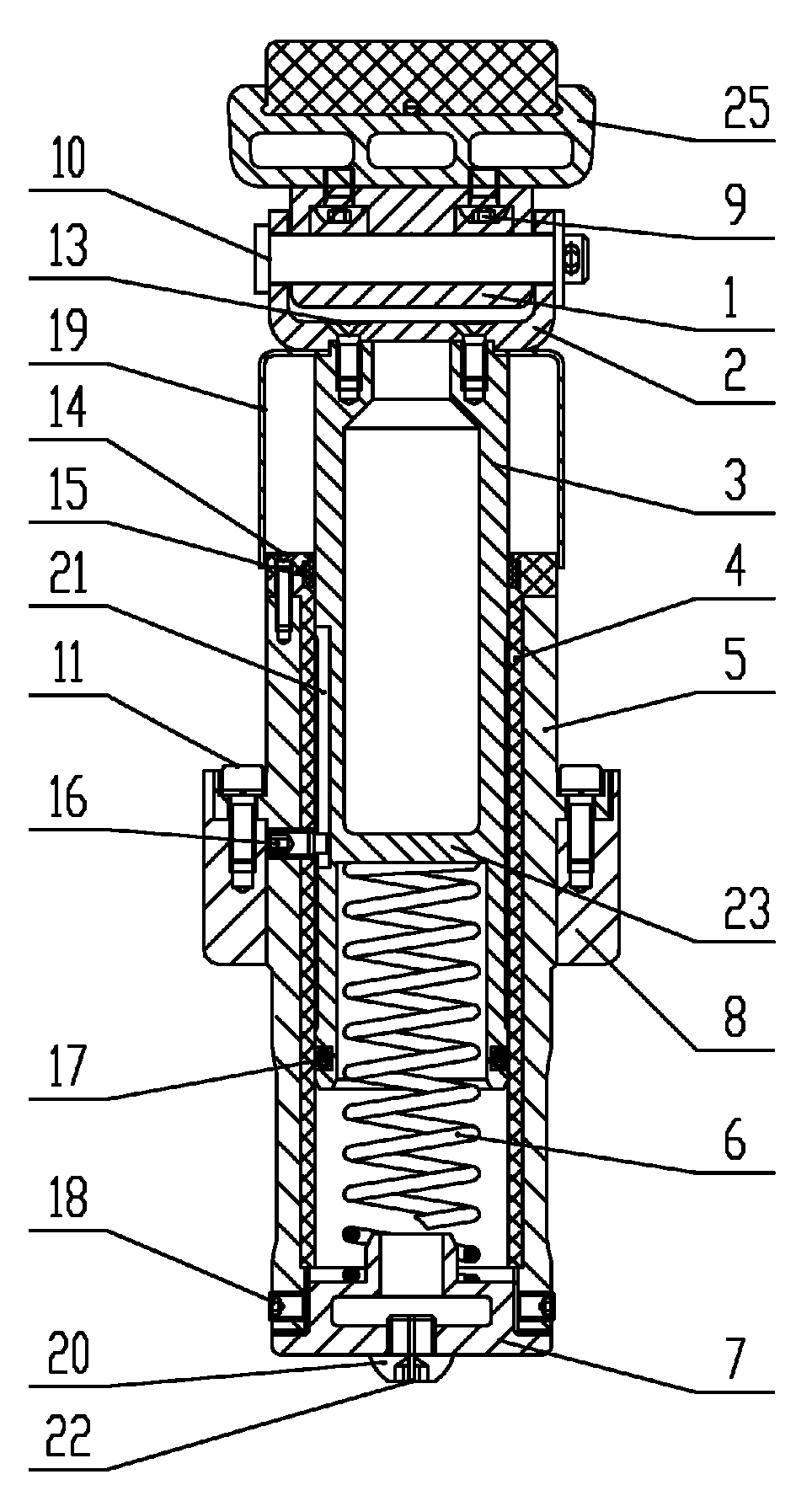

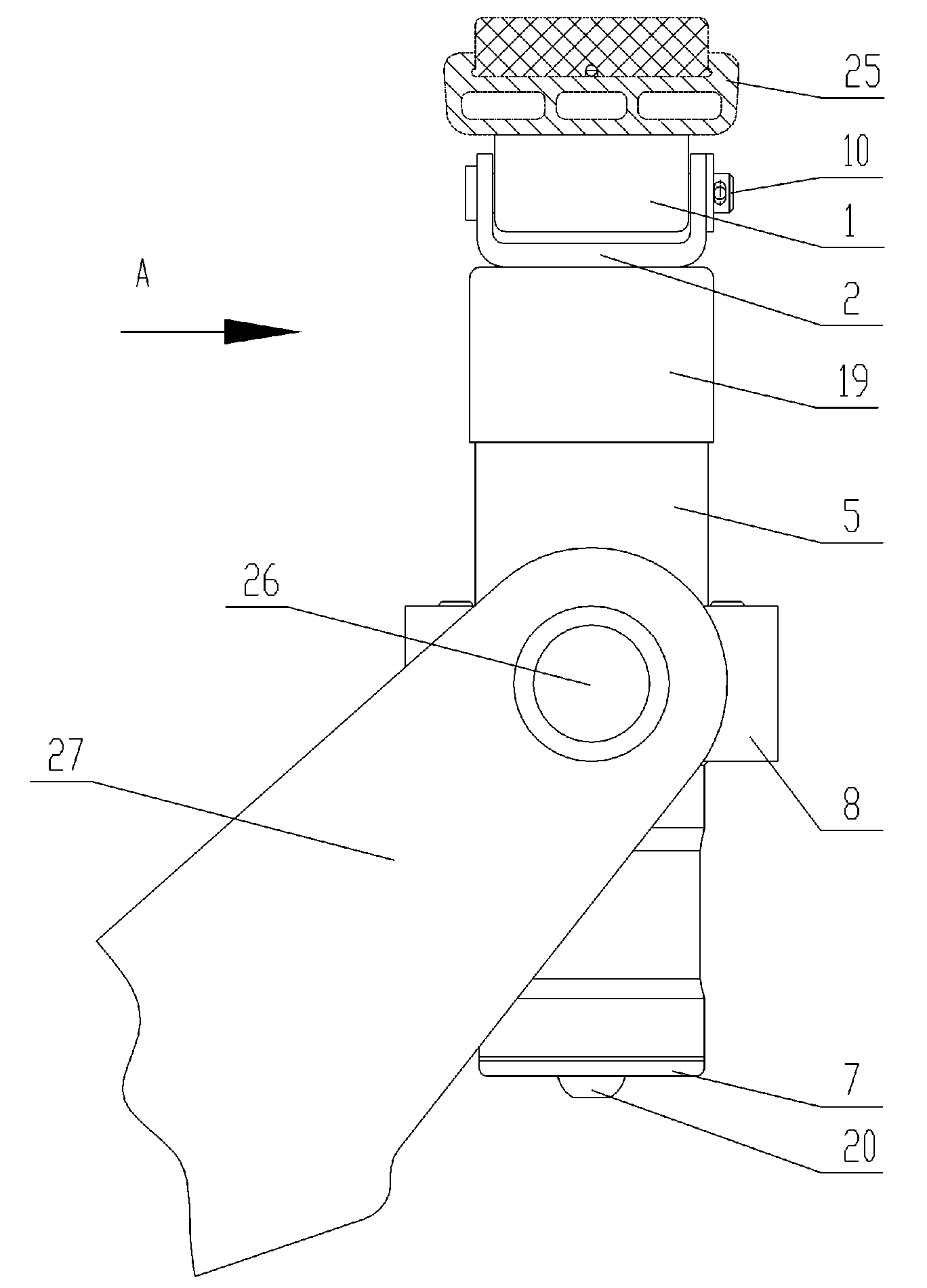

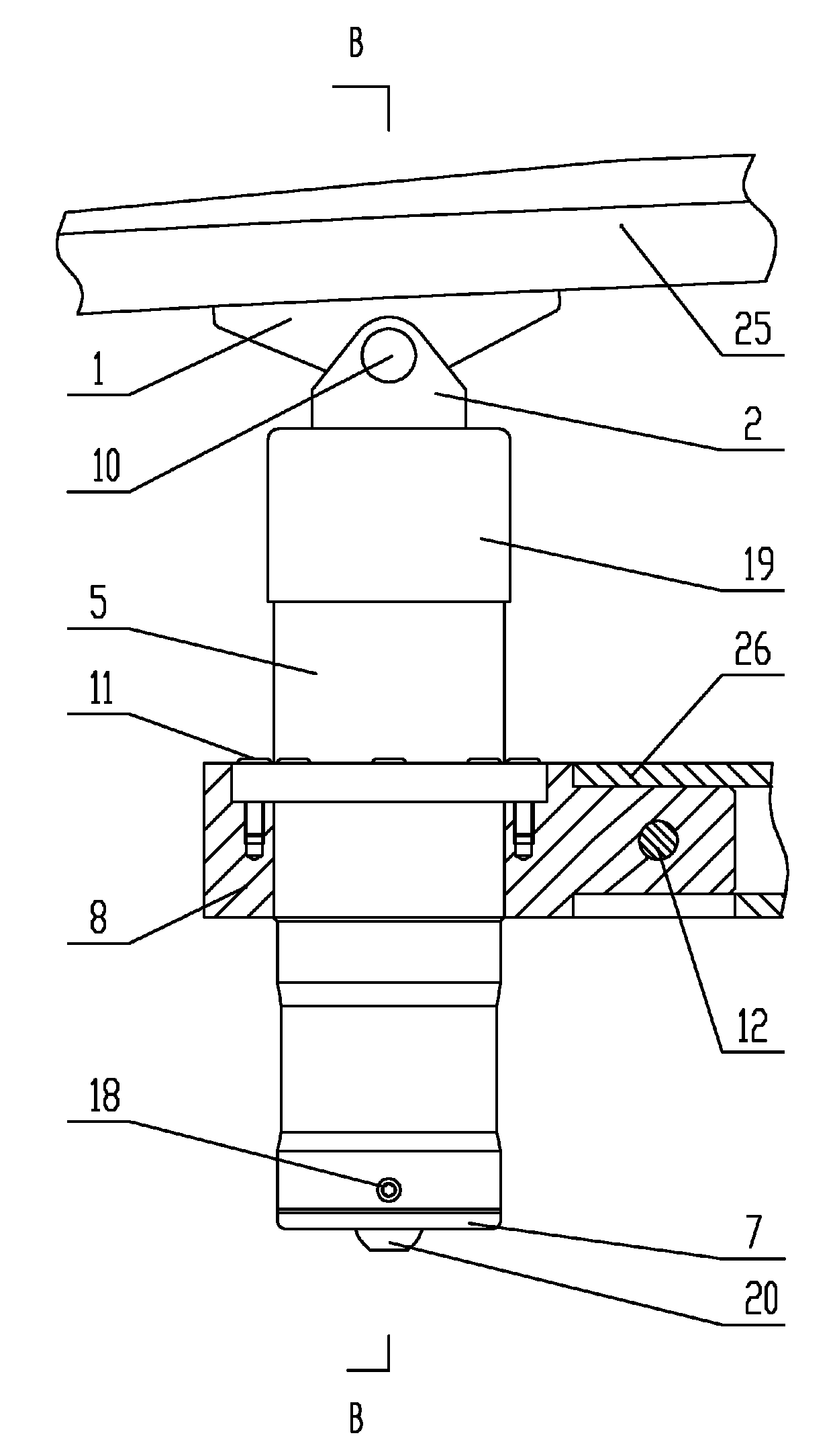

The invention relates to a sealed spring box for connecting a pantograph head of a pantograph with a pantograph connecting frame, and the composition is as follows: the upper part of a pantograph head coupling seat of the spring box is connected with a pantograph head carbon sliding plate through a bolt, the lower part is hinged with a U-shaped hinge support through a pin shaft, the lower part ofthe U-shaped hinge support is connected with the upper end of a piston rod through a screw, the piston rod is arranged in a piston barrel, the piston barrel is fixed on a support cylinder body through the screw, the middle part of the support cylinder body is fixed on a cylinder body mounting seat through the screw, the cylinder body mounting seat is further fixed and mounted on a pantograph headcross rod of the pantograph through the bolt, and the pantograph head cross rod is hinged with a upper arm rod of the pantograph connecting frame; and a spring is connected between the lower part of the piston rod and the bottom of the piston barrel. The device can realize self-adaption to fluctuations in hanging conducting wires of a contact net, enable the following performance between the pantograph and the net to be good, and effectively attenuate vibration caused by oscillation and impact between a vehicle body and the contact net; furthermore, the structure is compact, the weight is light, the windward is small, and the caused shaking and swing of a pantograph body are small. By adopting the sealed spring box, good current collection of a locomotive can be ensured, and the running is safe and smooth.

Description

A sealed spring box for connecting pantograph head and pantograph connecting frame technical field The invention relates to a connecting device between a pantograph head and a pantograph connecting frame of a high-speed electric locomotive. Background technique The electric locomotive obtains electric energy from the catenary through the pantograph installed on its roof to drive its operation. The electric receiving slide plate of the pantograph is in direct contact with the surface of the catenary wire under a certain pressure and slides relative to each other. When the locomotive is running at high speed, due to the vibration of the car body and the collision of the high and low fluctuations of the suspension wires of the catenary, the bow and the net are in the state of impact contact, shaking and vibration, so that the bow and the net may be in a state of intermittent connection, so that there is no It is beneficial for the locomotive to obtain electric energy smoothl...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B60L5/20

Inventor 张卫华马启文梅贵明

Owner SOUTHWEST JIAOTONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com