Diaphragm pump diaphragm with combined sealing structure and diaphragm pump

A combined sealing and diaphragm pump technology, applied to pumps with flexible working elements, pumps, liquid displacement machinery, etc., can solve the problems of reducing the performance of diaphragm pumps, water leakage, air leakage, damage to diaphragm pumps, etc., and achieve extended use Longevity, avoiding air leakage, and improving the effect of sealing ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

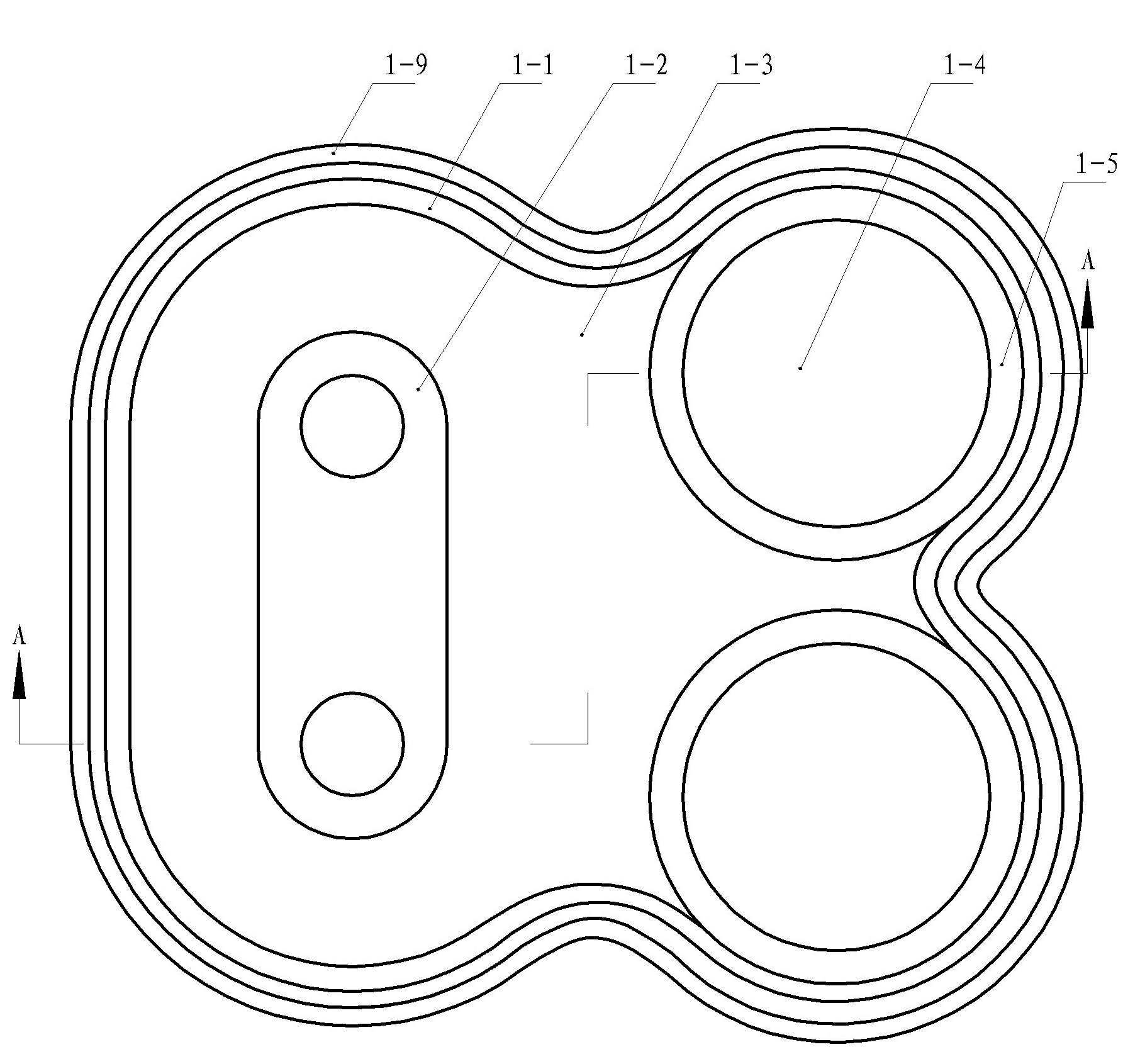

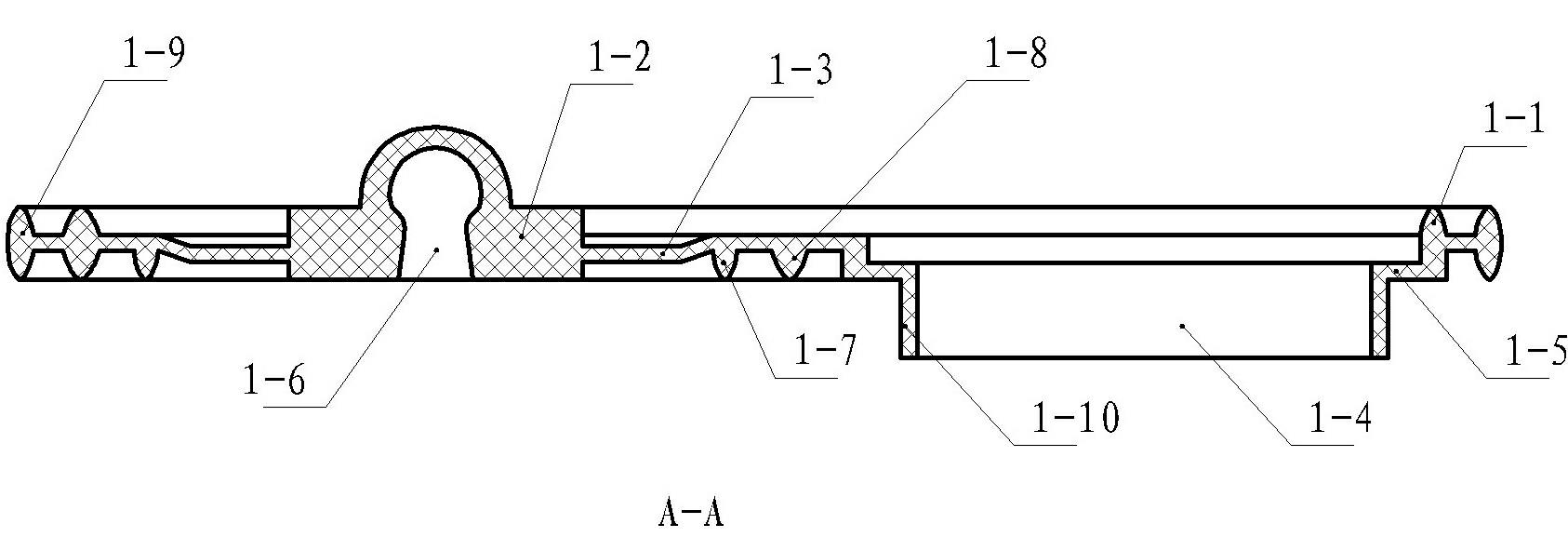

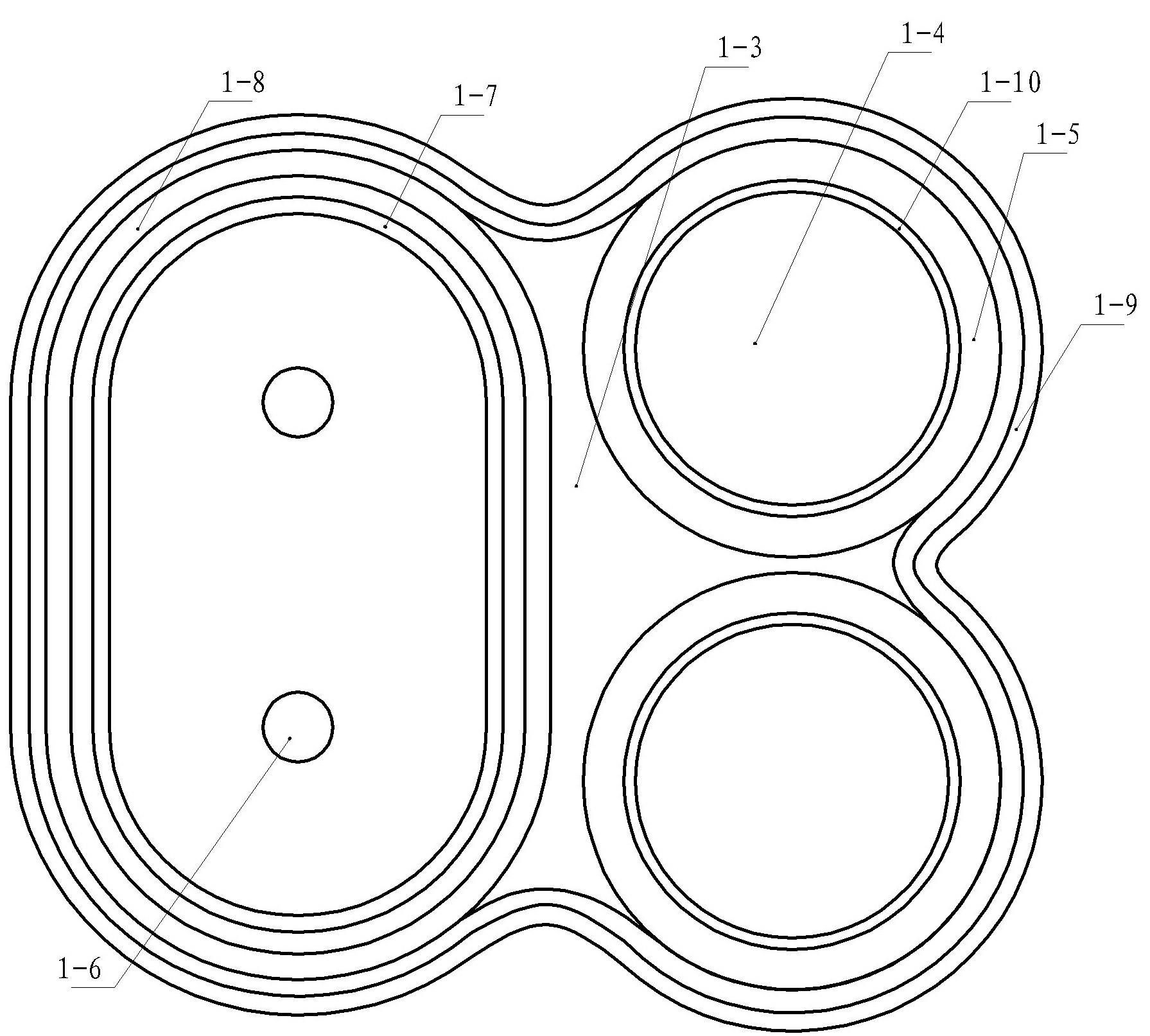

[0023] Embodiment one: see Figure 1-Figure 3 , a diaphragm pump diaphragm with a combined sealing structure in the figure. The diaphragm is formed as an integral diaphragm, including an outer sealing ring and an inner diaphragm body. The diaphragm body is provided with a vibration clamping part and a valve seat. In the installation hole, the vibration clamping part is provided with a vibrating body sealing ring, the vibrating body sealing ring is below the diaphragm, and the outer edge sealing ring is on the top of the diaphragm, and the outside of the outer edge sealing ring is also provided with An additional sealing ring on the outer edge matching the shape of the diaphragm, and the additional sealing ring on the outer edge is integrated with the outer sealing ring; The sealing ring of the vibrating body is similar in shape; the lower side of the valve seat installation hole is provided with a protruding valve seat sealing sleeve.

[0024] The vibration clamping part is a...

Embodiment 2

[0026] Embodiment two: see Figure 1-Figure 7 , a diaphragm pump with a combined sealing structure in the figure, including a pump body, a pump cover, a vibrating body, a diaphragm, and a valve seat; the valve seat and the vibrating device are installed in the pump body, and the diaphragm passes through the pump The cover is press-fitted on the end of the pump body; a volume-variable cavity is formed between the pump cover and the diaphragm as the pump chamber; the pump body is provided with two symmetrical valve chambers, and the two valve chambers are respectively connected to the The water inlet pipe on the pump body communicates with the water outlet pipe, and two valve seats are installed in each valve chamber; the diaphragm is integrally formed, including an outer sealing ring and an inner diaphragm body, on the diaphragm body There is a vibrating clamping part and a valve seat installation hole, the vibrating clamping part is provided with a vibrating body sealing ring,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com