Accurate desulfurization system based on dense flow absorber desulfuration process

A desulfurization process and precise technology, applied in the direction of dispersed particle separation, chemical instruments and methods, separation methods, etc., can solve the problems of large randomness, low bucket elevator current and water addition requirements, and inability to achieve continuous and stable desulfurization. Accurate desulfurization, avoiding the effect of system desulfurization instability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

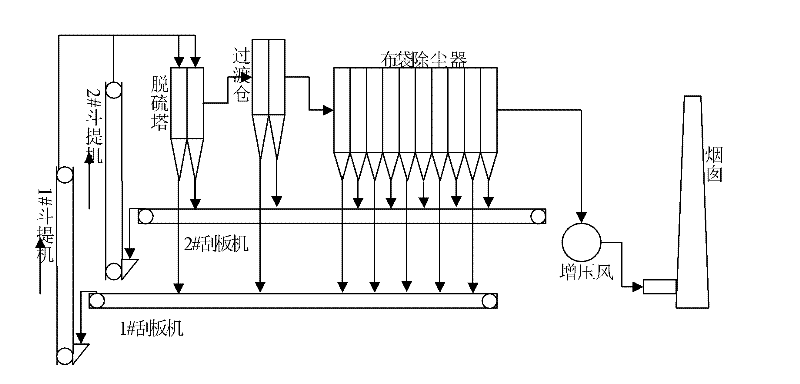

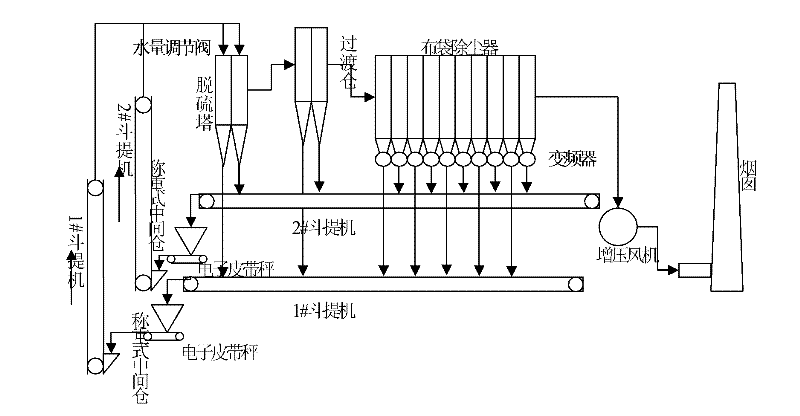

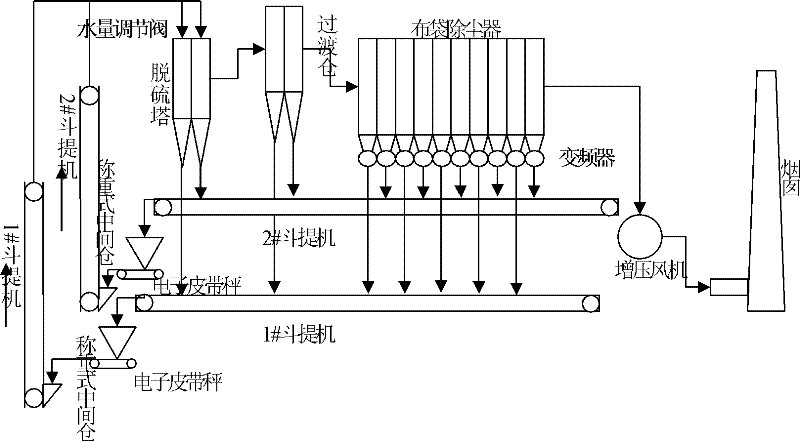

[0017] figure 1 , figure 2 It is a specific embodiment of the present invention.

[0018] The invention includes a frequency converter, an intermediate bin, an electronic scale belt, a water volume regulating valve, and a PLC control system; a frequency converter is added to the star feeder at the lower part of the ash hopper of the dust collector, and an intermediate bin is added at the lower part of the scraper machine. The electronic belt scale is set; the inverter is used to control the star feeder to unload the ash. The intermediate warehouse is a weighing intermediate warehouse to control the storage position. The electronic scale belt controls the amount of ash added, the water volume regulating valve controls the water volume, and the PLC control system forms a closed loop. Control loop.

[0019] 1. Frequency converter: add frequency converter control to the star feeder at the lower part of the ash hopper of the dust collector, and change the speed of the star feede...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com