Optical detection-based E type magnet sorting method

A technology of optical detection and magnetic materials, which is applied in sorting and other directions, can solve the problems of low detection efficiency and poor detection accuracy, and achieve the effects of strong real-time detection, high detection accuracy and high detection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

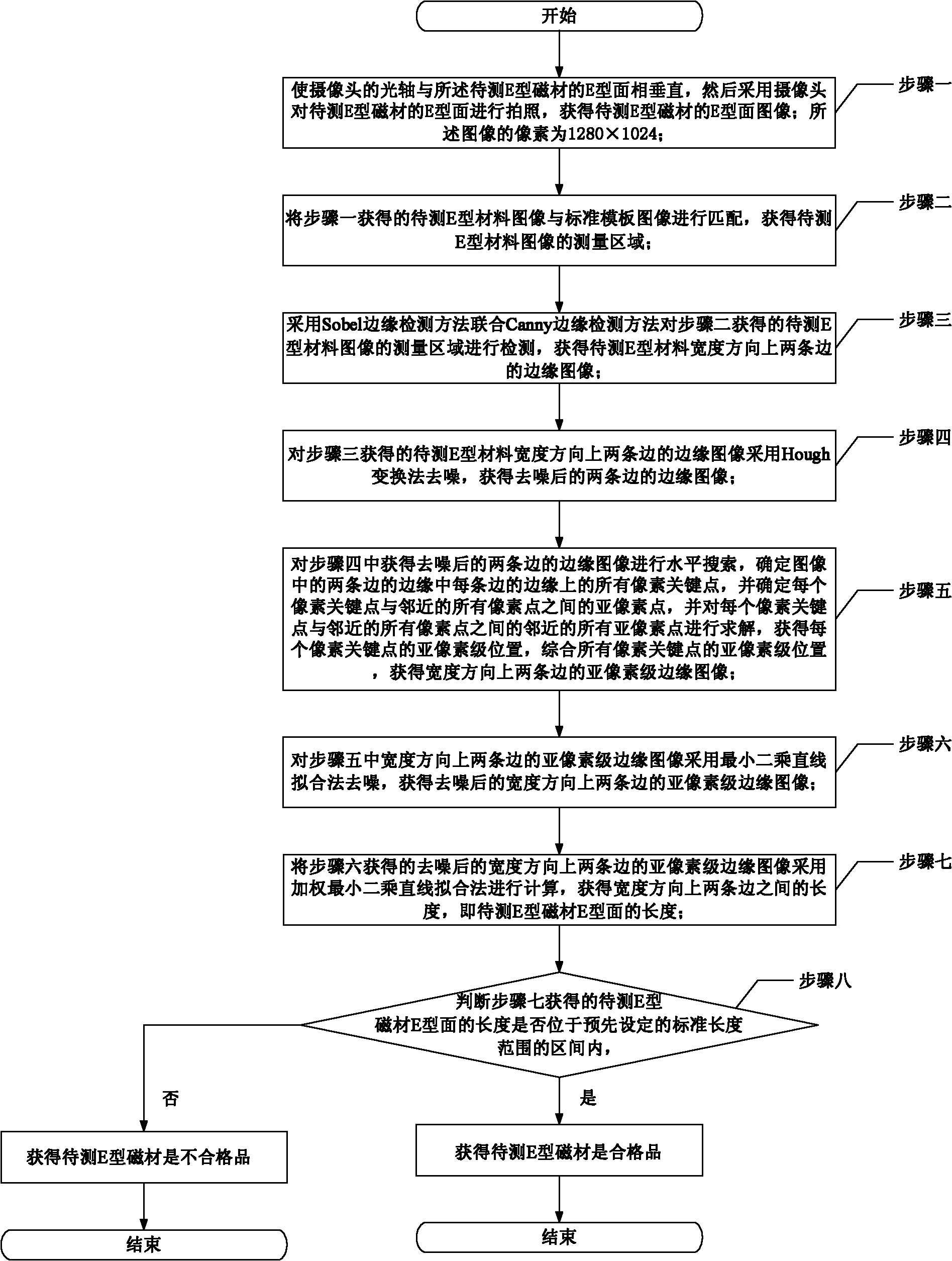

[0038] Specific implementation mode 1. Combination figure 1Illustrate this specific embodiment, based on the E-type magnetic material sorting method of optical detection, it is realized by the following steps:

[0039] Step 1, make the optical axis of the camera perpendicular to the E-shaped surface of the E-shaped magnetic material to be tested, then use the camera to take pictures of the E-shaped surface of the E-shaped magnetic material to be tested, and obtain the E-shaped surface of the E-shaped magnetic material to be tested Image; the pixel of the image is 1280×1024;

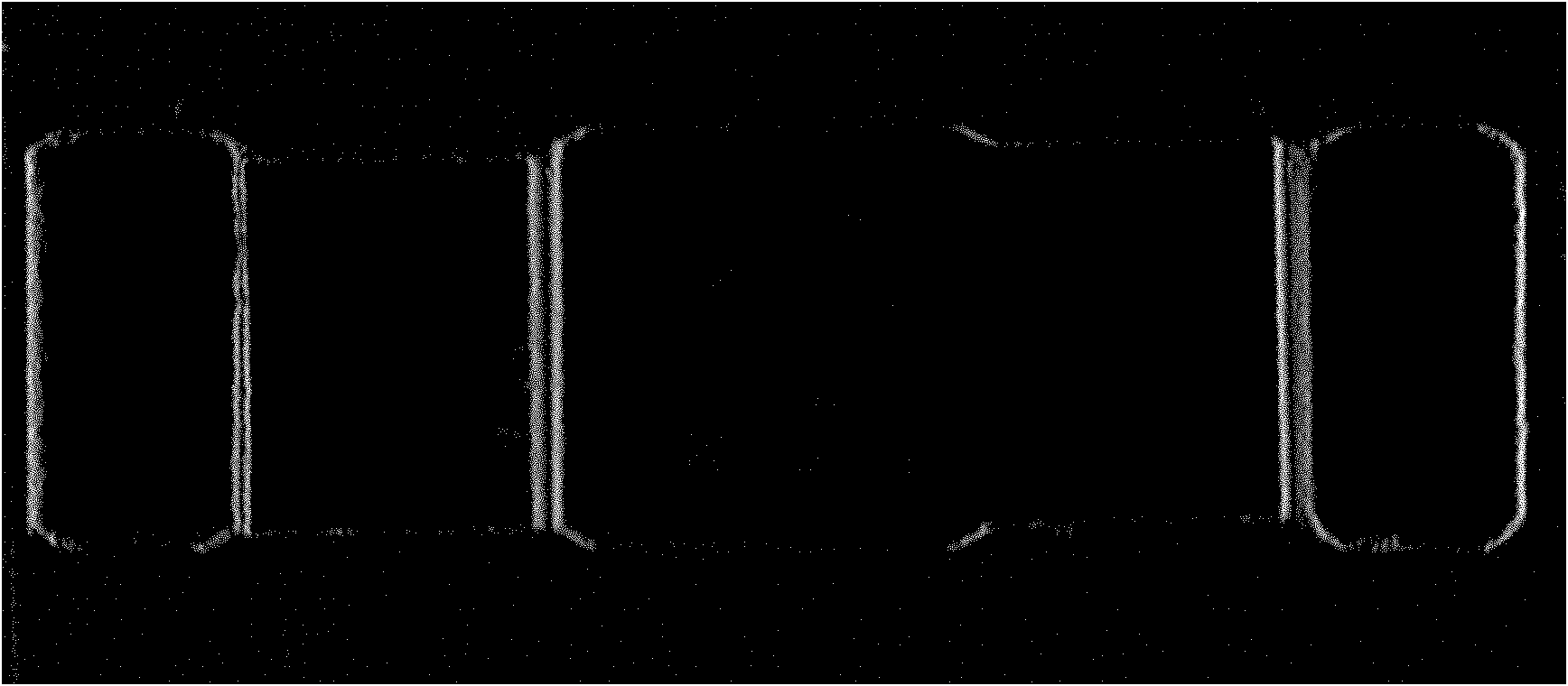

[0040] Step 2, matching the image of the E-type material to be tested obtained in step 1 with the standard template image to obtain the measurement area of the E-type material image to be tested;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com