Laser ultrasonic metal composite plate thickness measuring device and method with light path alignment self-adjusting function

A metal composite plate, laser ultrasonic technology, which is applied to measuring devices, adopts optical devices, and uses ultrasonic/sonic/infrasonic waves, etc., can solve problems such as inability to maintain collinearity, long propagation distance, and difficulty in ensuring that two laser beams are coaxial. Achieve the effect of improving detection accuracy and detection efficiency, and protecting the laser

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0119] In order to further illustrate the technical solutions of the present invention, the present invention will be further described below through examples.

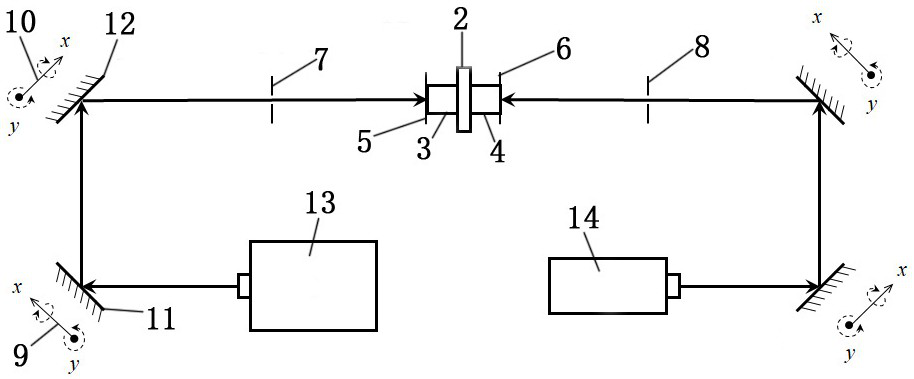

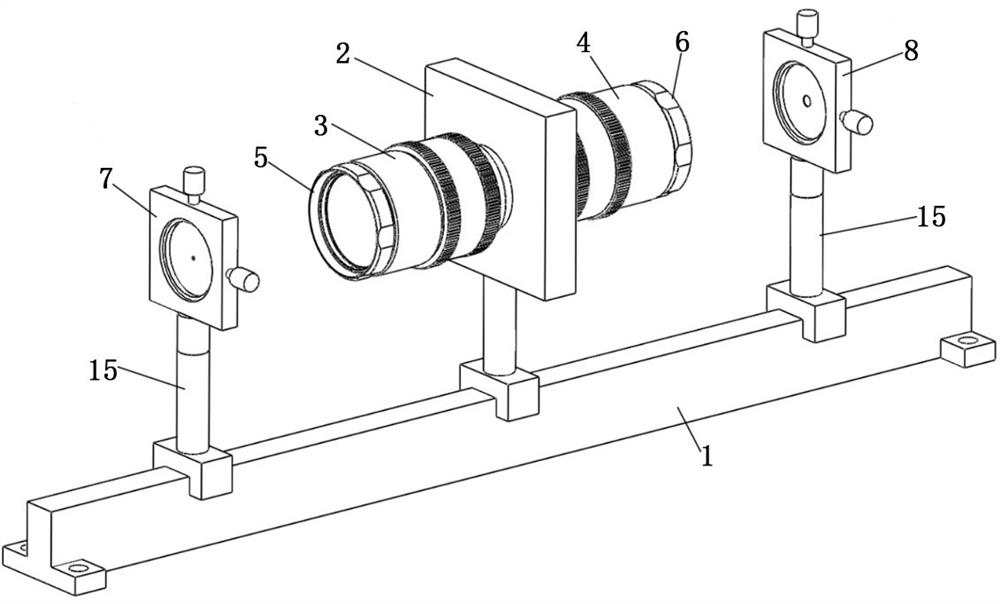

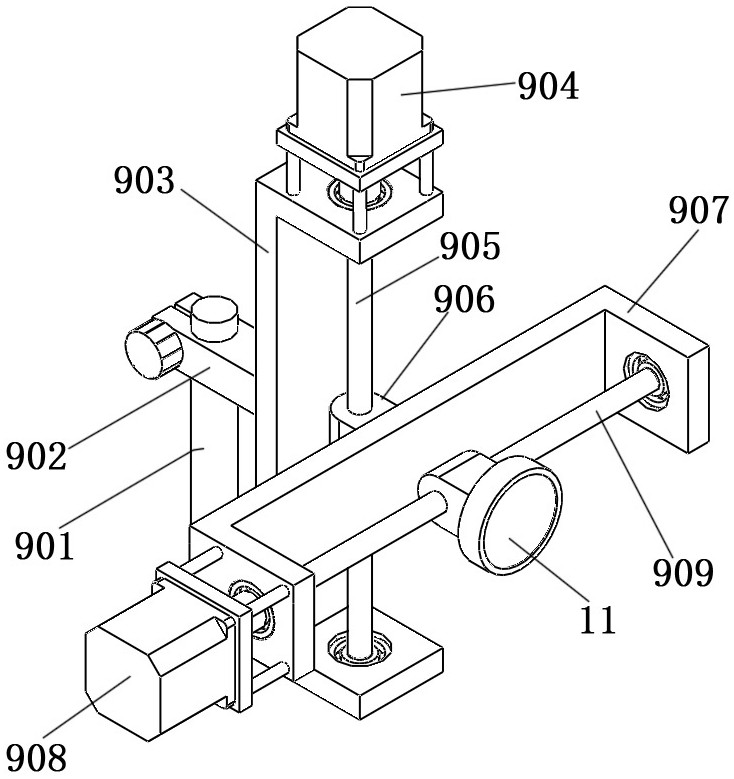

[0120] like Figure 1 to Figure 3 As shown in the figure, the laser ultrasonic metal clad plate thickness measuring device with optical path alignment self-adjustment, including operation platform, slide rail 1, camera coaxial mounting block 2, sample holder, pulsed laser CCD camera 3, continuous laser CCD camera 4, pulsed laser Development screen 5, CW laser development screen 6, pulsed laser aperture 7, CW laser aperture 8, No. 1 angle adjustment mechanism 9, No. 2 angle adjustment mechanism 10, No. 1 mirror 11, No. 2 mirror 12, pulse laser 13 and the optical interferometer 14, the slide rail 1 is installed on the operating platform, the camera coaxial mounting block 2 or the sample holder is installed in the middle of the slide rail 1, and the camera coaxial mounting block 2 is used for alignment of the optical pat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com