Control system of automatic hydraulic torque wrench testing device

A torque wrench and control system technology, applied in the direction of electrical program control, sequence/logic controller program control, etc., can solve the problems of relying on manual work, and achieve the effect of improving detection efficiency and detection accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The technical solution of the present invention will be further described below in conjunction with the drawings and specific embodiments.

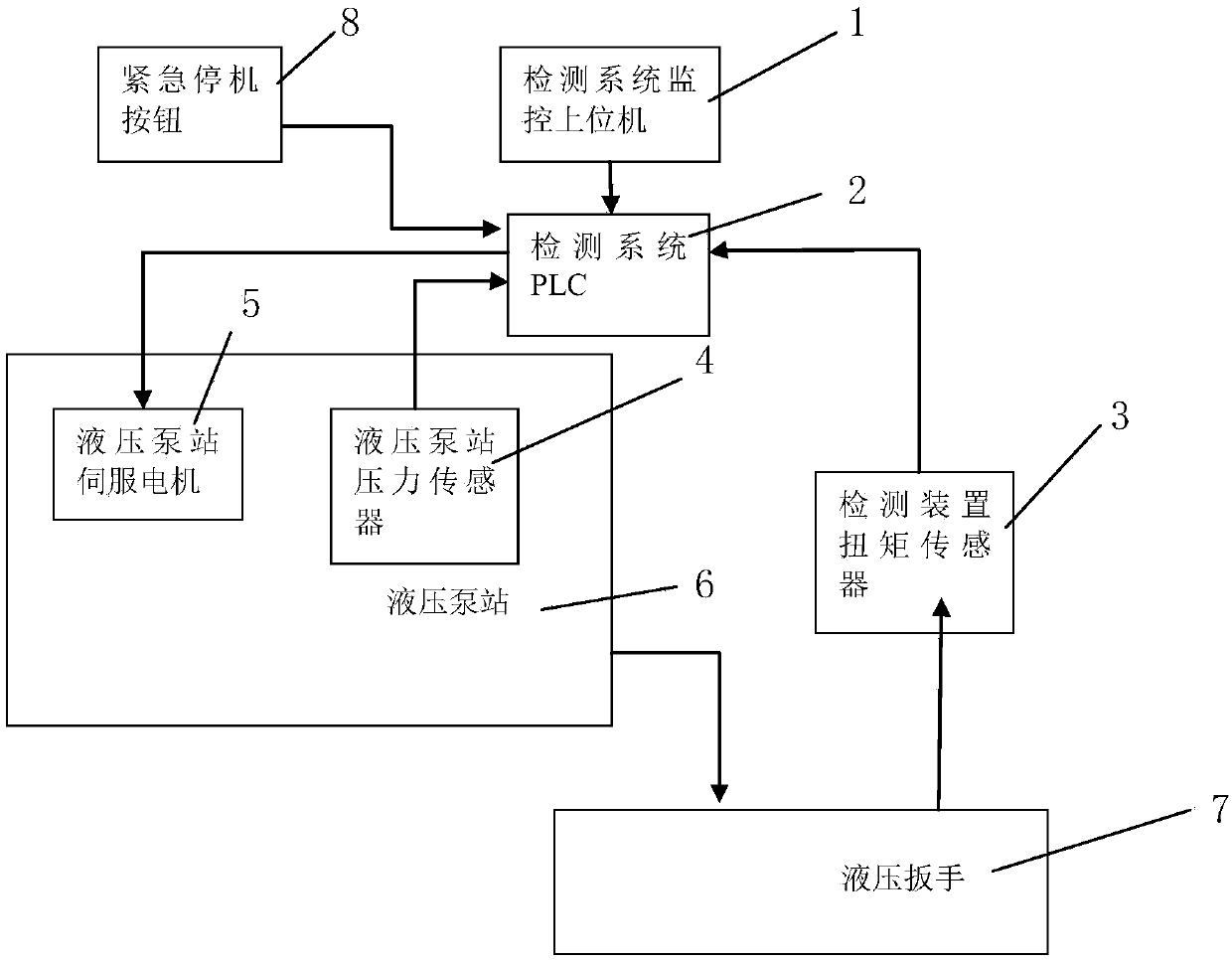

[0031] Such as figure 1 As shown, a kind of automatic hydraulic torque wrench testing device control system of the present invention, described control system comprises: detection system monitoring upper computer (1), detection system PLC (2), detection device torque sensor (3), hydraulic pump station Pressure sensor (4), hydraulic pump station servo motor (5), emergency stop button (8);

[0032] The detection system monitoring host computer (1) is connected to the detection system PLC (2) through a network cable, and the detection system PLC (2) is connected to the hydraulic pump station servo motor (5) of the actuator through a wire, and the detection system The PLC (2) is connected to the detection device torque sensor (3) through a wire, the detection system PLC (2) is connected to the hydraulic pump station pressure sensor (4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com