Lifting platform

A lifting platform and platform technology, which is applied in the direction of lifting frame, lifting device, etc., can solve the problems of workpiece falling off, inconvenient taking of workpiece, smashing workers, etc., and achieve the effect of safe operation, convenient and quick replacement of fixtures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

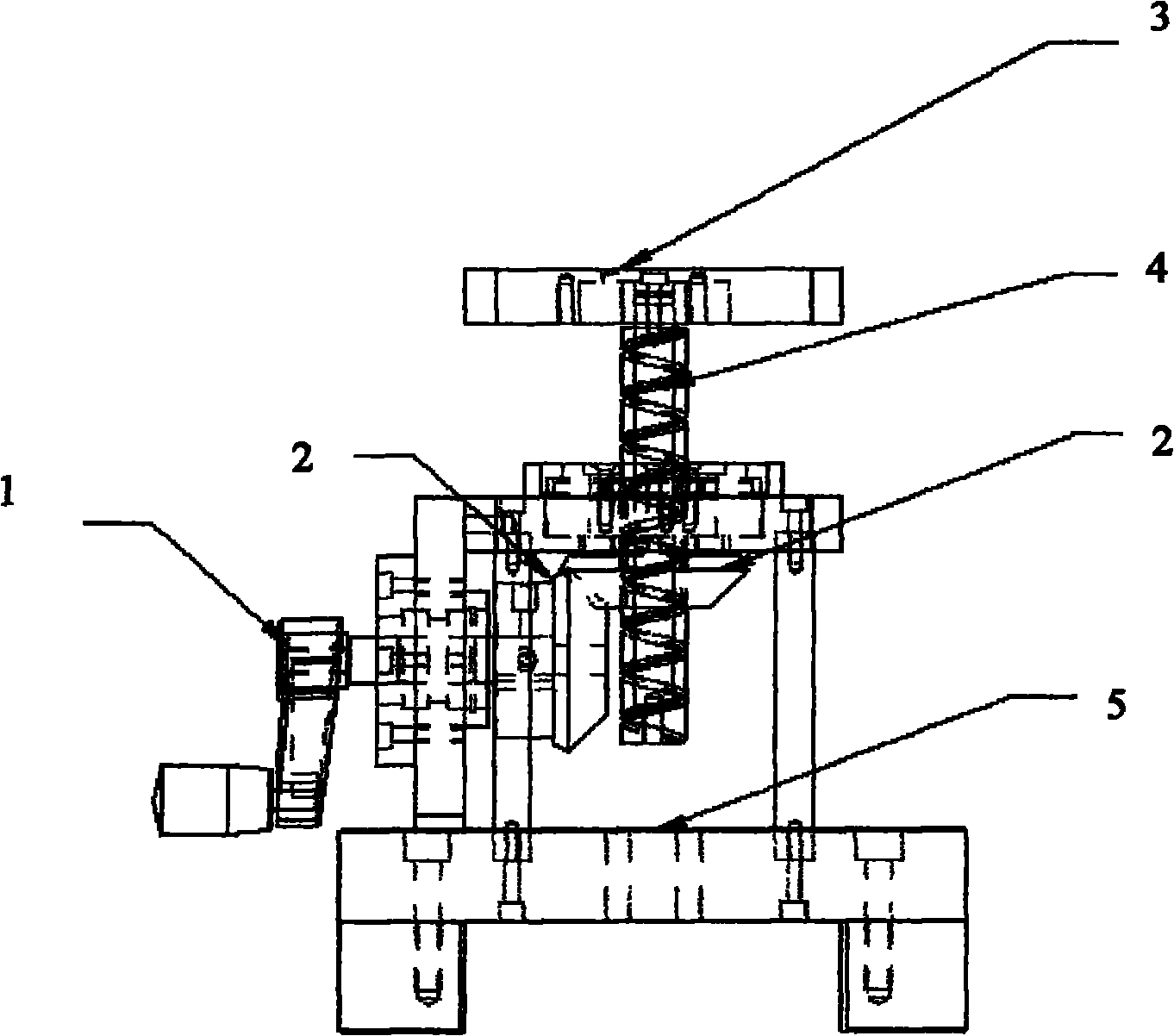

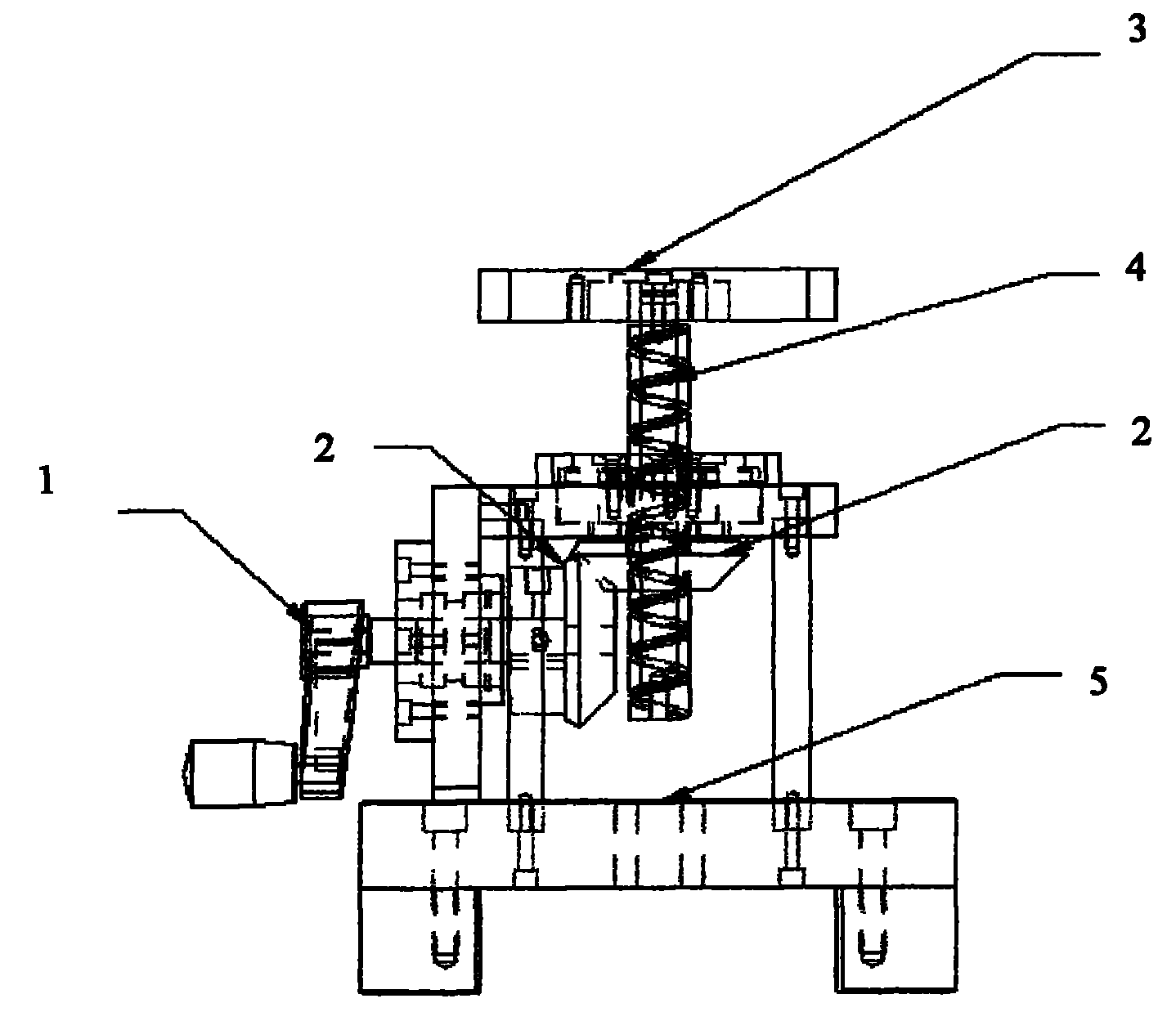

[0009] See figure 1 As shown, the lifting platform of a preferred embodiment of the present invention includes a base 5, a workpiece receiving platform 3, a bevel gear matching mechanism 2, a rocking handle 1, and a threaded rod 4, and the rocking handle 1 is connected to the The bevel gear matching mechanism 2, the bevel gear matching mechanism 2 is connected to the screw rod 4, the workpiece receiving platform 3 is installed on the upper end of the screw rod 4, and the above-mentioned mechanism is installed on the base 5.

[0010] The lifting platform of the present invention operates as follows:

[0011] When the present invention moves to the working position, shake the handle 1 to drive the rotation of the bevel gear matching mechanism 2, and the rotating screw 4 of the bevel gear mechanism 4 is pushed upward, and the upward advancement of the screw 4 makes the workpiece receiving platform rise To a suitable position, an operator can unload the workpiece fixture onto the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com