Rotary compressor

A compressor and double-rotation technology, applied in the direction of rotary piston machinery, mechanical equipment, machines/engines, etc., can solve the problems of increased refrigerant leakage, compressor loss, etc., reduce the contact area, improve compression efficiency, The effect of reducing leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

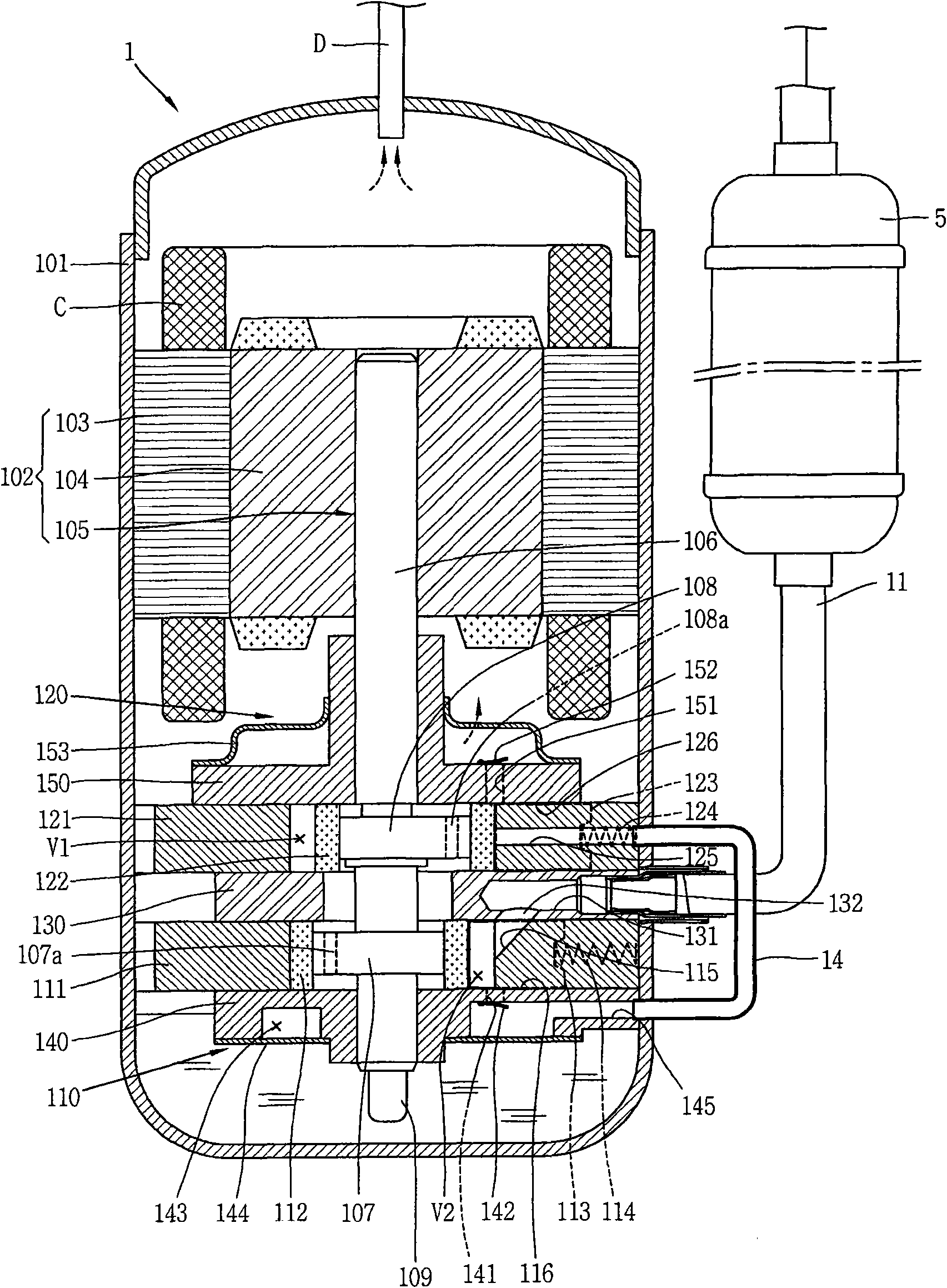

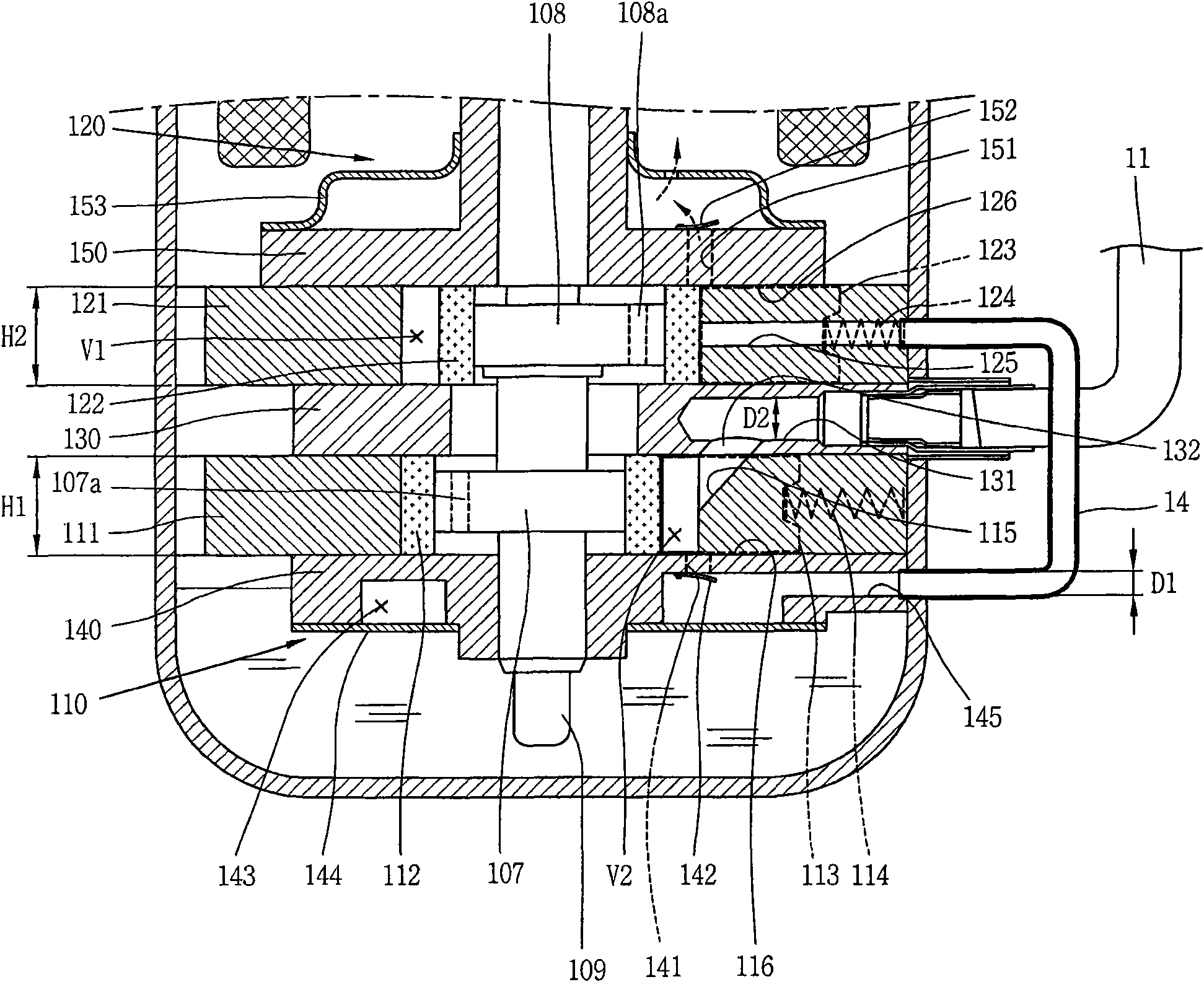

[0020] Details of a double rotary compressor according to an exemplary embodiment will now be described with reference to the accompanying drawings. For brief description with reference to the drawings, the same or equivalent components are given the same reference numerals, and their description will not be repeated.

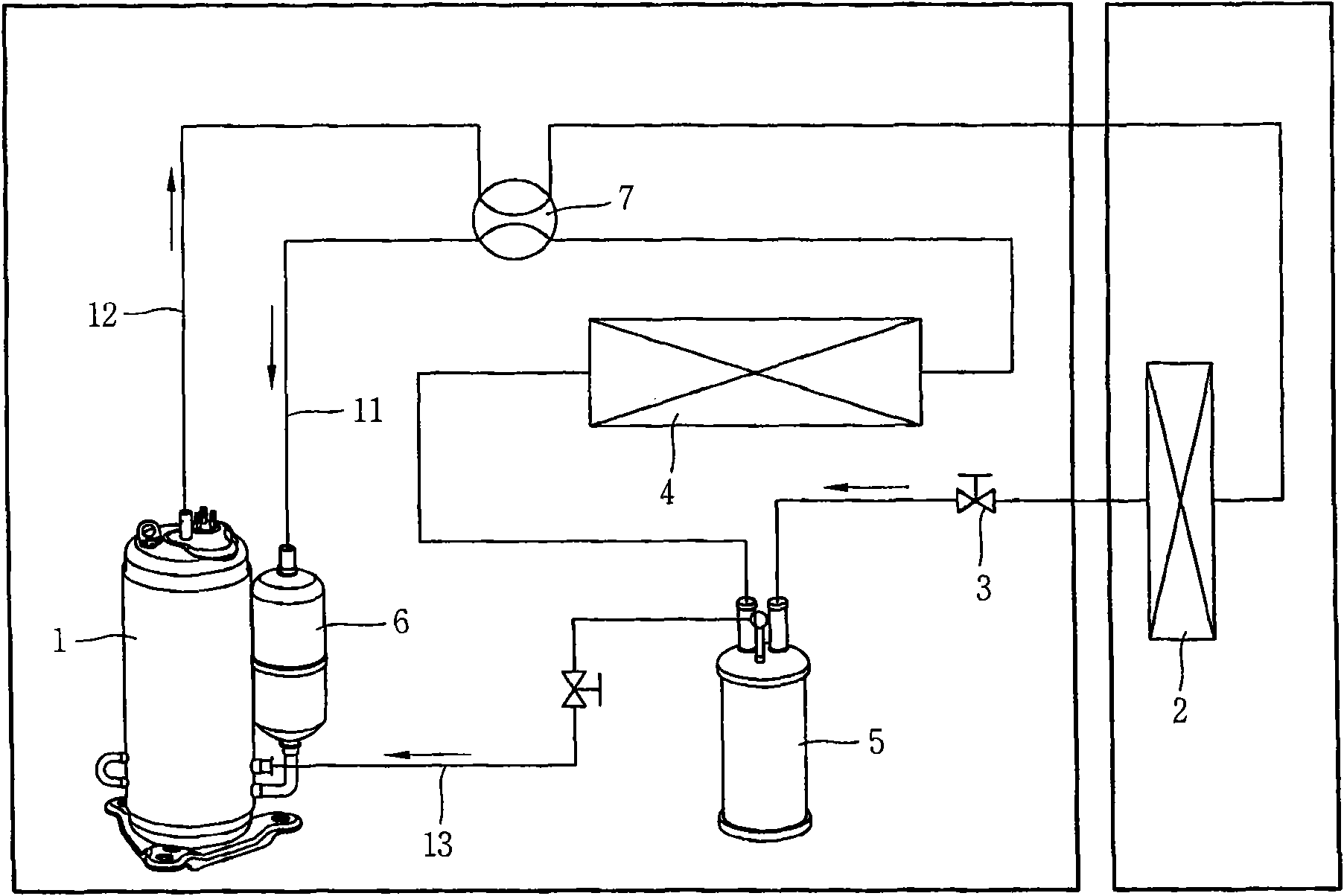

[0021] figure 1 is a schematic diagram showing a refrigeration cycle having a two-stage type rotary compressor for sequentially compressing refrigerant as one type of double rotary compressor according to an exemplary embodiment.

[0022] Such as figure 1 As shown, a refrigeration cycle having a two-stage type rotary compressor according to an exemplary embodiment may include components such as a compressor 1 , a condenser 2 , an expansion valve 3 , an evaporator 4 , and a phase separator 5 . The refrigerant compressed in the compressor 1 is introduced into the condenser 2 to exchange heat with surrounding air, thereby being condensed. The condensed refriger...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com