Three-plane concurrent construction method and star wheel of single-screw compressor constructed by same

A construction method and construction technology, applied in the field of the star wheel of a single screw compressor, can solve the problems such as the inability to accurately obtain the contact sealing working area, deviating from the meshing law of the space conjugate meshing pair, and unable to obtain the instantaneous contact area, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] In order to clearly understand the present invention, it is further described with an embodiment:

[0037] 1. Construct the primary envelope surface B of the cylindrical surface on the screw.

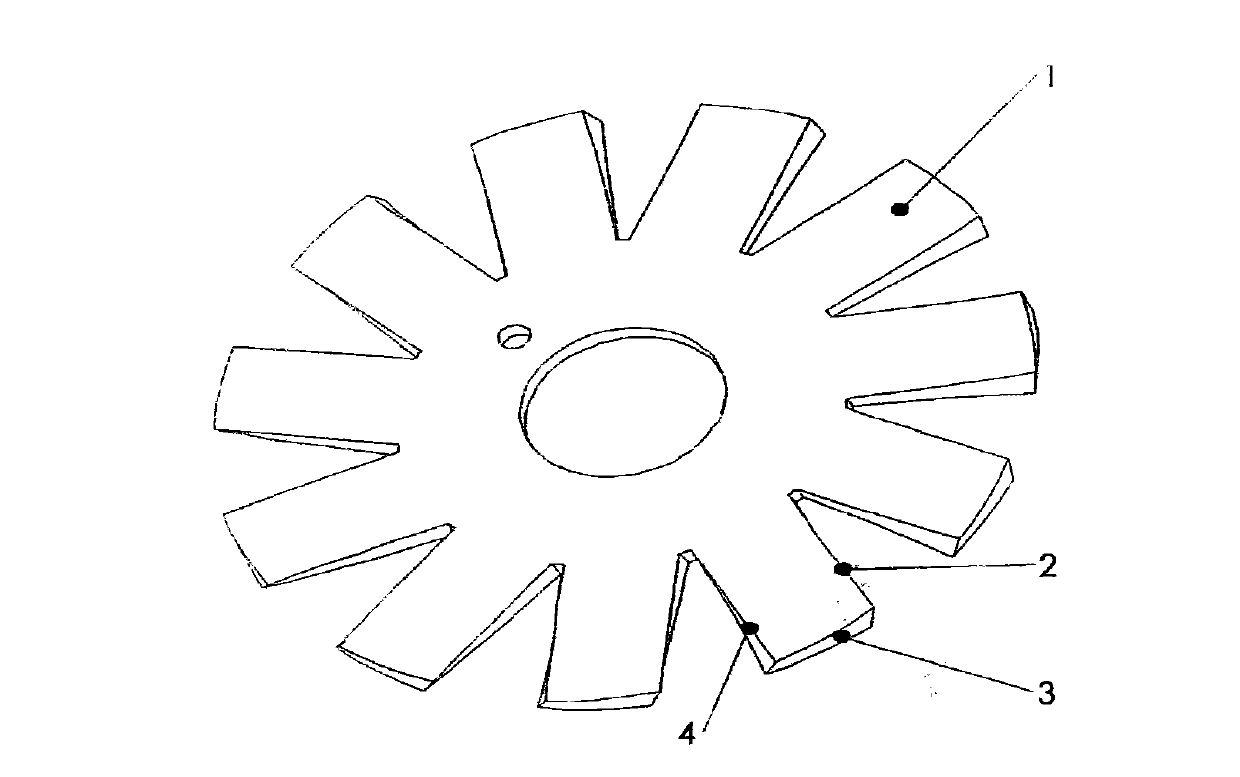

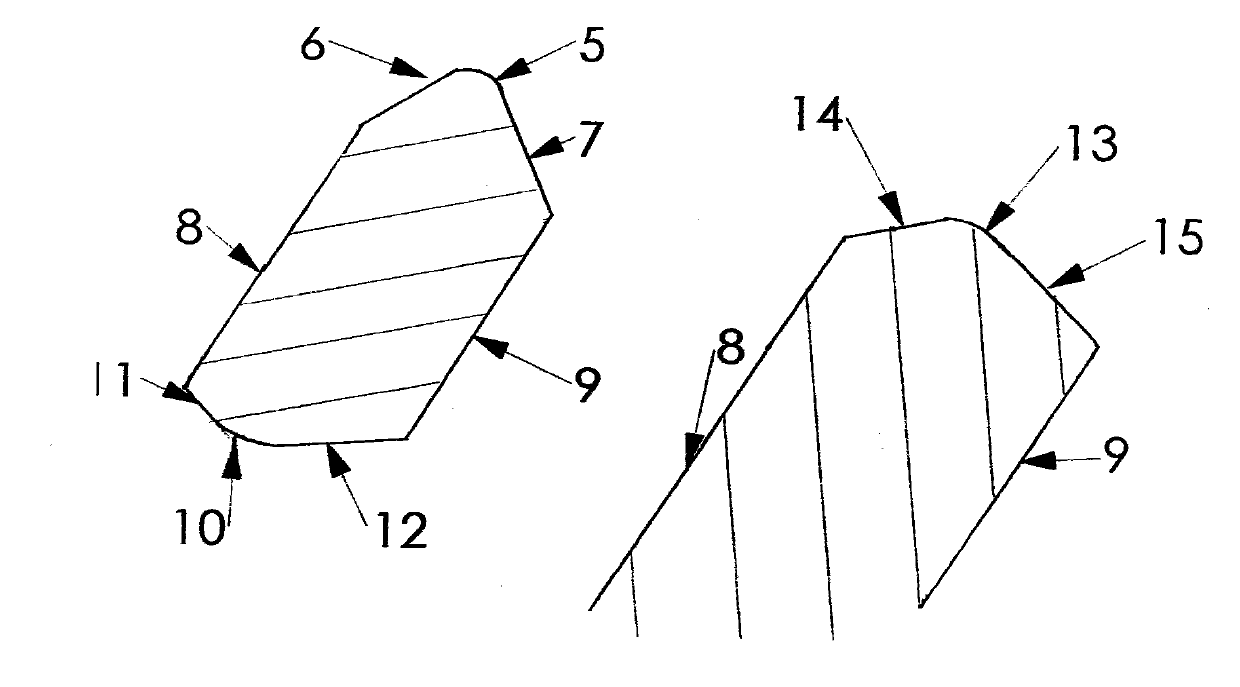

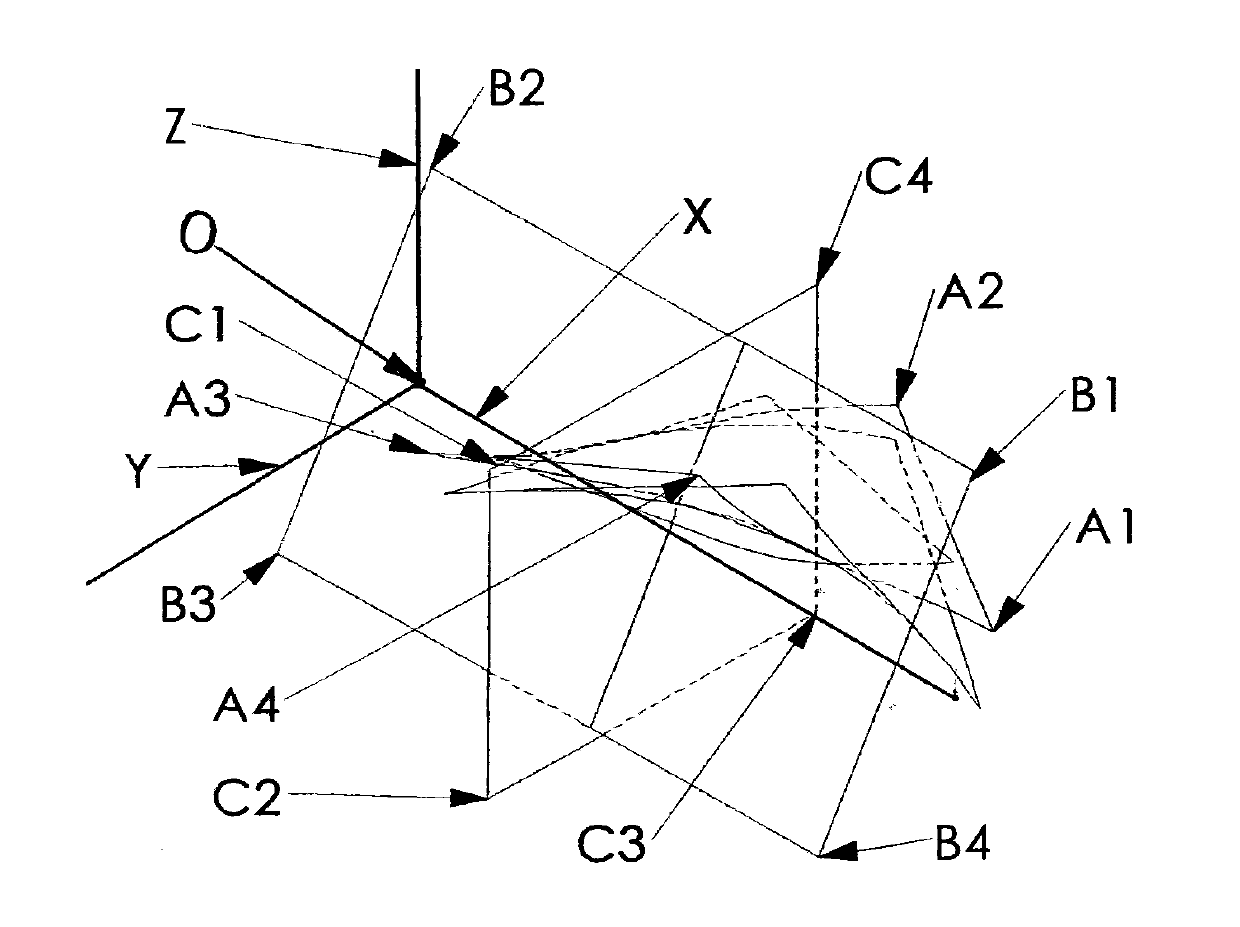

[0038] In the single-screw compressor system represented by three spaces O, I, and II, the reference space or static space represented by O is the body, the motion space represented by I is the star wheel, and the motion space represented by II is the screw. A cylindrical surface is used as the production surface to replace a tooth of the star wheel, and the star wheel is pressed against the casing movement, the screw relative to the housing does sports, The cylindrical production surface envelops the primary envelope surface B on the screw, and the vector function of the primary envelope surface B is The meshing equation N·V=0 that satisfies the primary envelope, N is the normal vector of a point on the primary envelope surface B, and V is the relative motion velocity of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com