Slide device for vehicle

A technology for sliding devices and vehicles, which is applied to special positions of vehicles, vehicle seats, vehicle components, etc., and can solve the problems of upper rails that hinder the front and rear movement, increase in size, and hinder the front and rear movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

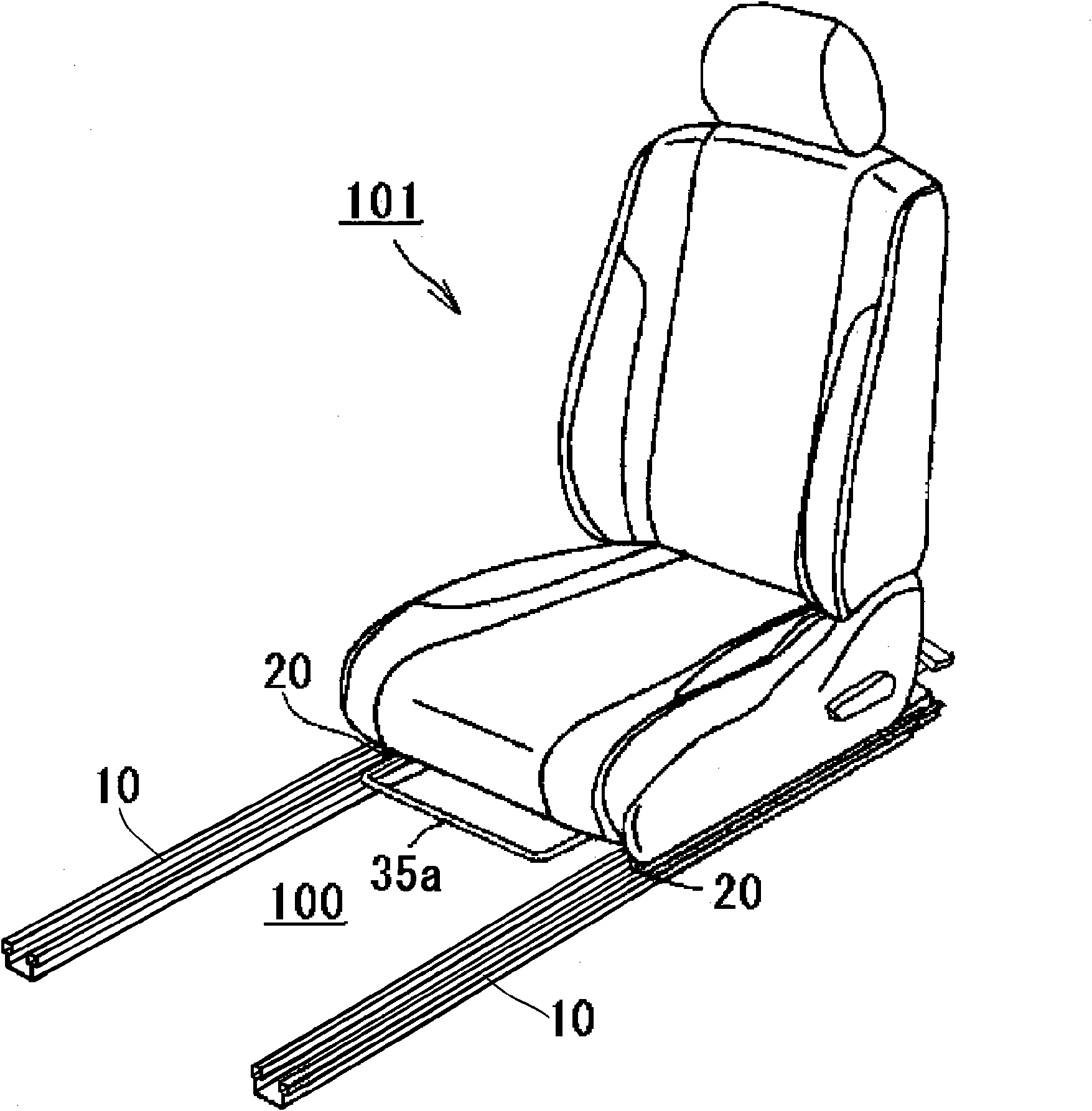

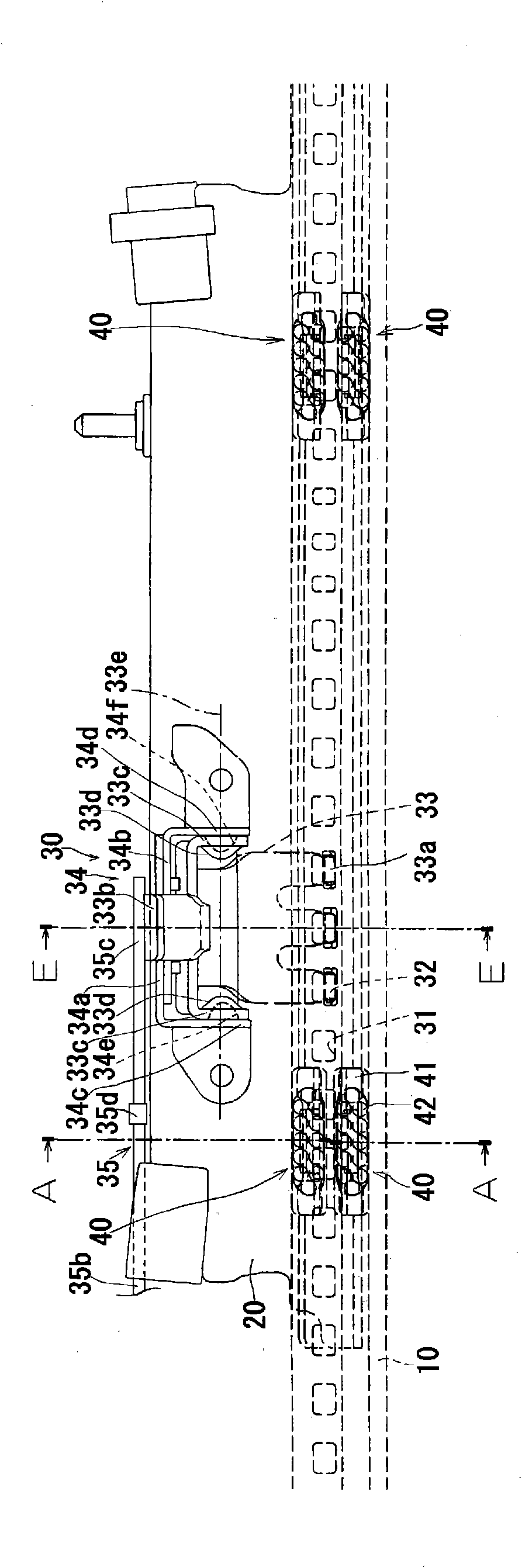

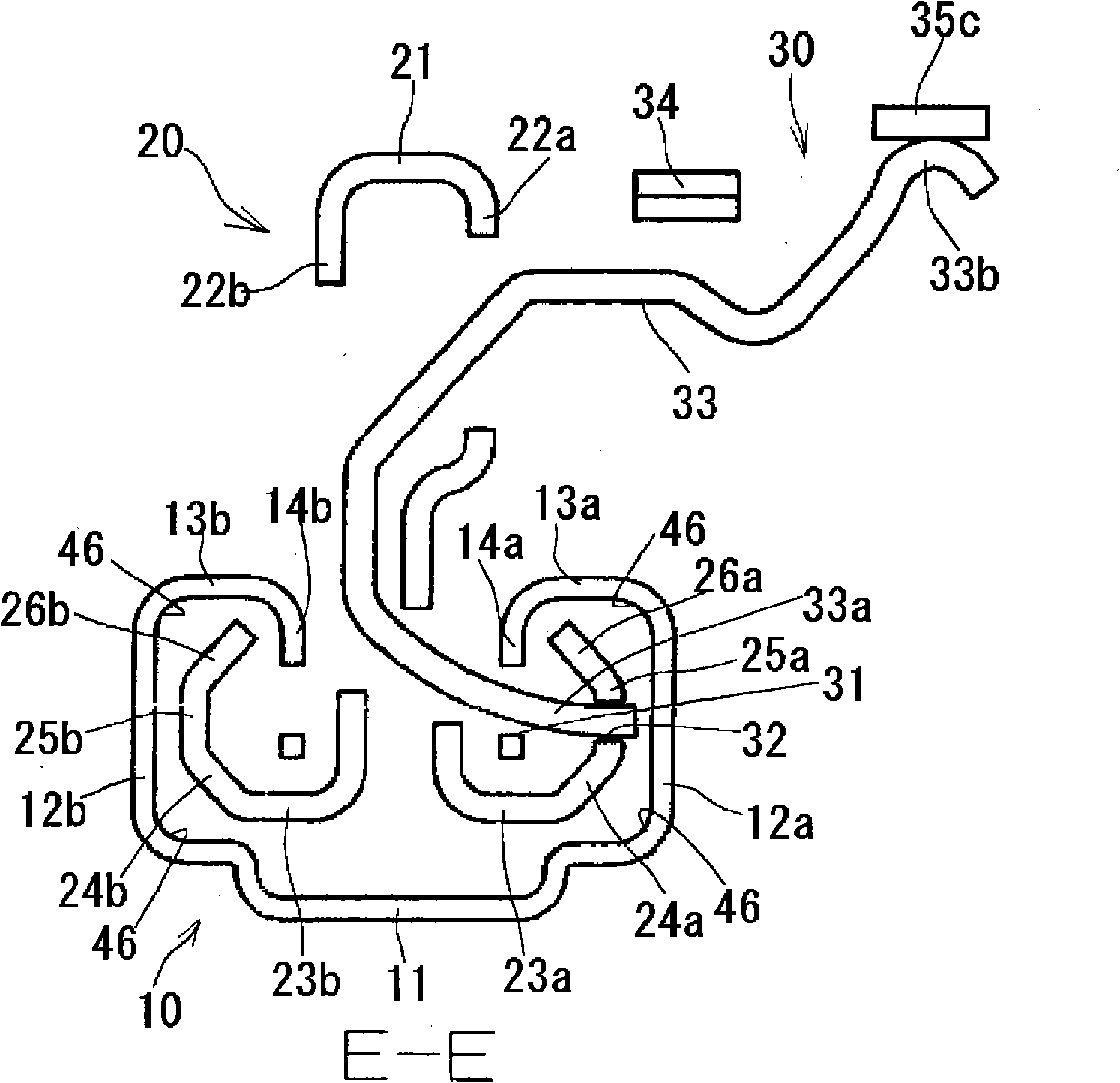

[0049] Next, a first embodiment of the sliding device for a vehicle according to the present invention will be described below with reference to the drawings. Such as figure 1 , figure 2 and Figure 7 As shown, the sliding device for a vehicle according to the first embodiment includes: a pair of lower rails (first rails) 10 fixed in the front-rear direction of the floor 100 of the vehicle, fixed in the seat 101 of the vehicle so as to be able to be opposed to each other. A pair of upper rails (second rails) 20 movably supported on the lower rail 10 , and a rolling element circulation unit 40 installed in a mounting portion 43 for smoothly moving the upper rail 20 relative to the lower rail 10 without looseness. The mounting part 43 is configured so that the movement of the actuation surface 47 of the upper rail 20 facing the lower rail 10 and the non-actuation surface 47a formed by the surface opposite to the actuation surface 47 on the rail Both ends of the direction ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com