Reversed spitting device for silage harvester

A technology of silage and harvester, which is applied in the field of silage harvester reverse discharge device, which can solve the problems of long downtime, inconvenient operation, clogging of cutting table and feeding parts, and cutting device, and achieves high efficiency , the effect of convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

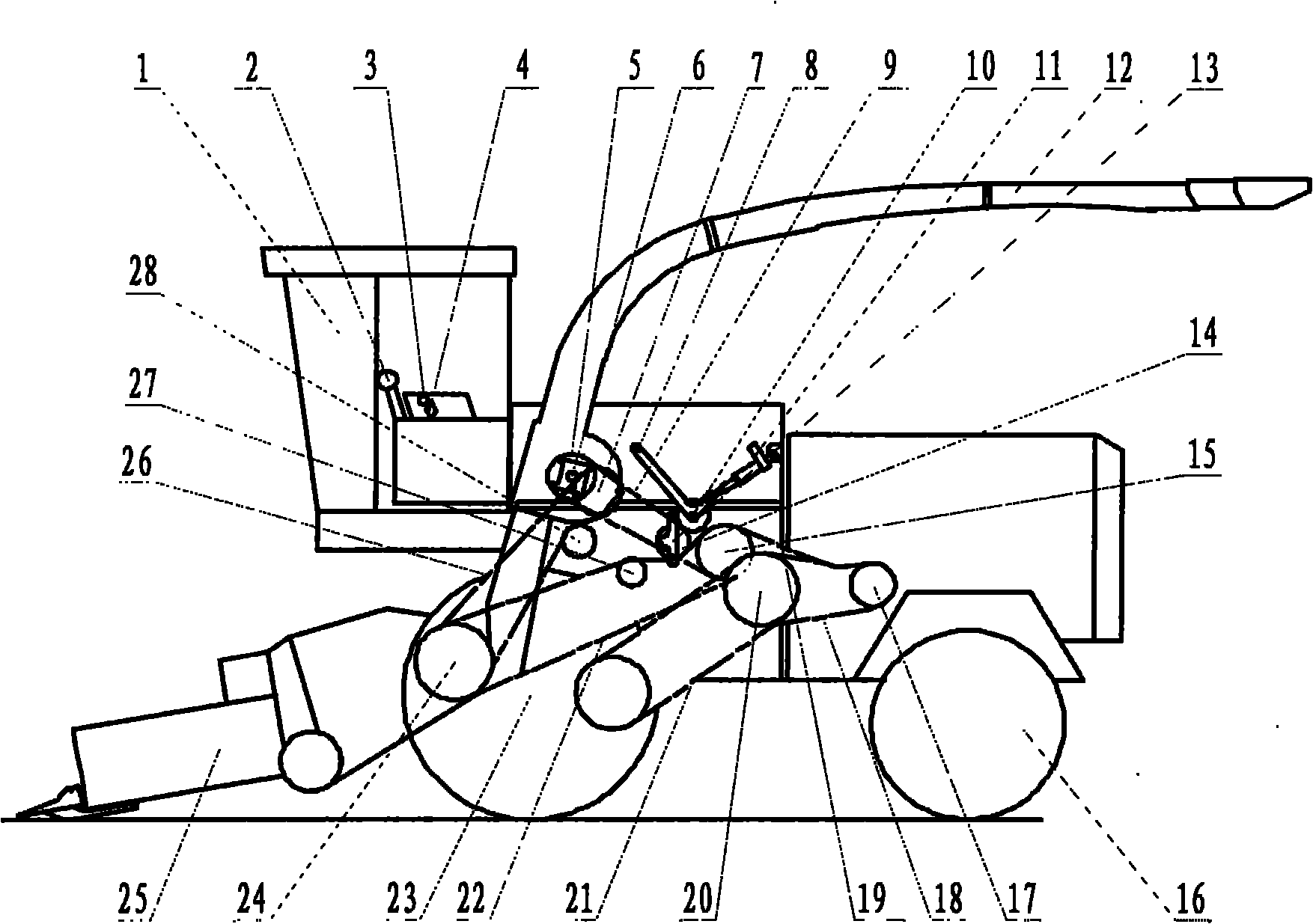

[0013] The preferred embodiment of the silage harvester reversing spouting device of the present invention is:

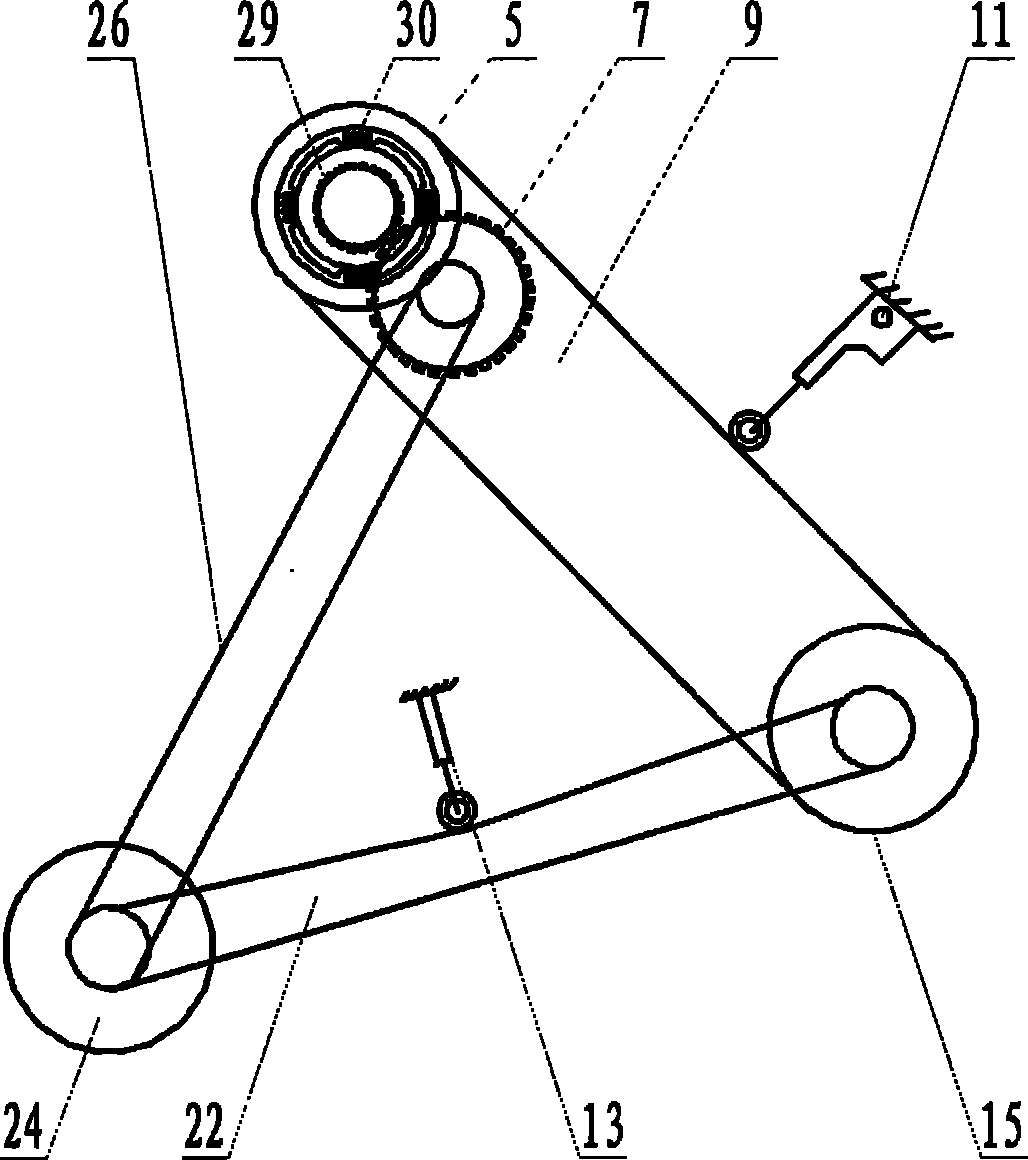

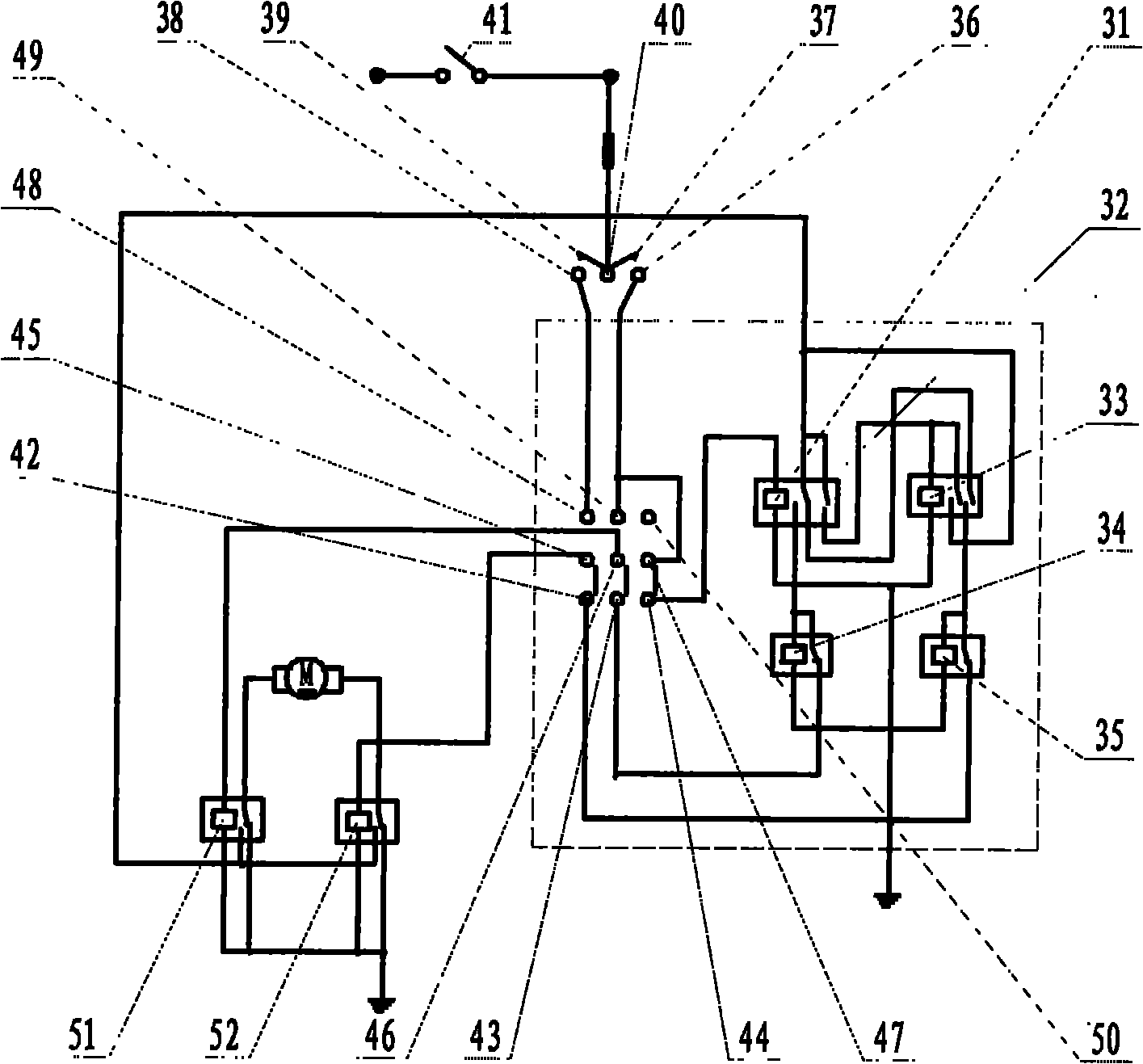

[0014] It includes a cutting platform, a feeding part, a chopping device, and a throwing part. The chopping device includes a driving wheel and a chopping part. A positive rotation drive belt is provided between the driving wheel and the chopping device. A reverse drive belt is also provided between the wheel and the chopping device. The forward drive belt and the reverse drive belt are respectively provided with tension pulleys, and the action drive elements of the tension pulleys are connected with an electric control mechanism.

[0015] The driving element for driving the belt tensioner in normal rotation includes a hydraulic oil cylinder.

[0016] The driving element for driving the belt tensioner in reverse direction includes an electric push rod.

[0017] The reverse drive belt includes a reverse primary drive belt and a reverse secondary drive belt, the rear...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com